A design method of sheet-fed paper positioning feeding board

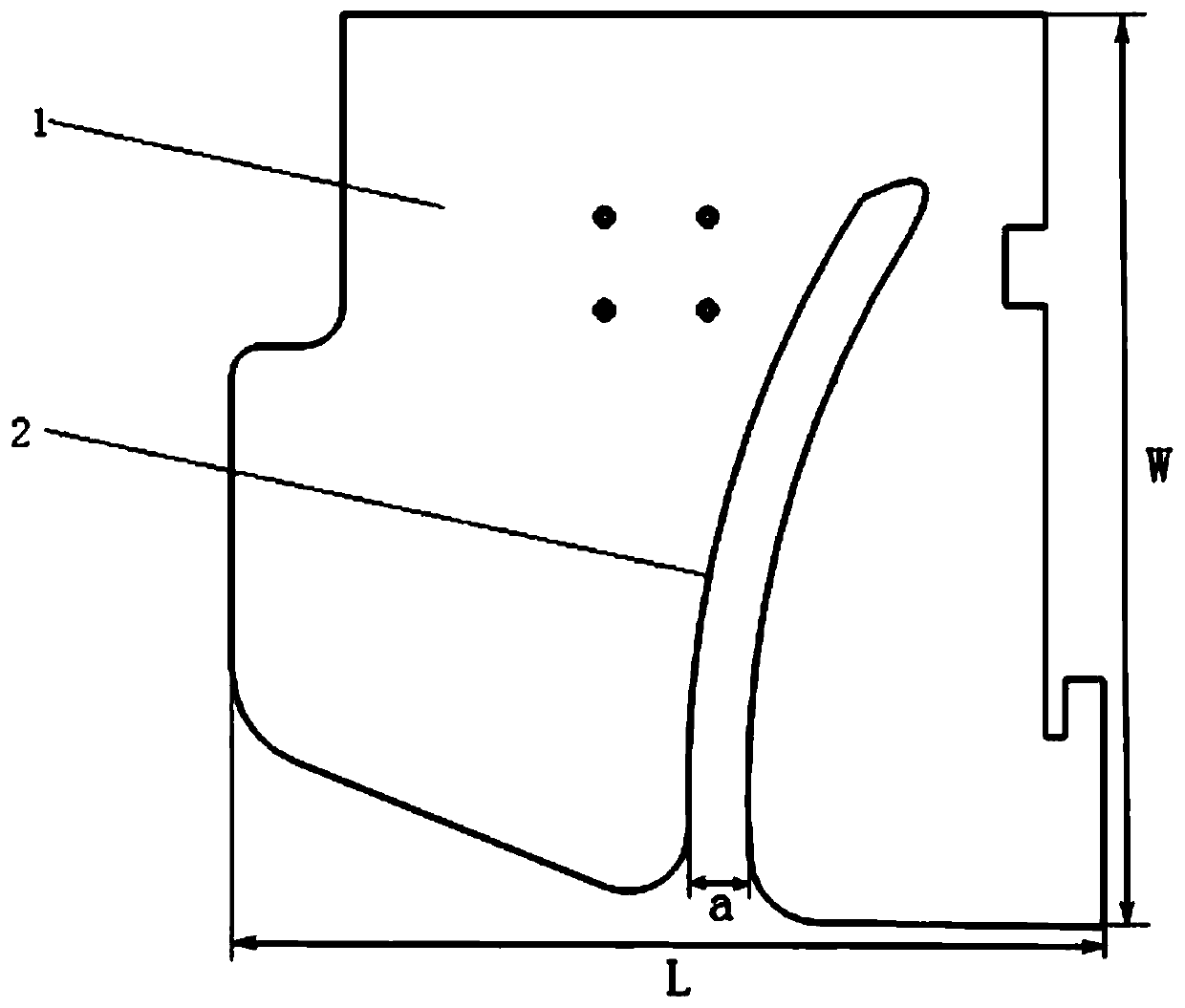

A design method and technology for feeding cardboard, which are applied in the directions of transportation and packaging, thin material handling, object supply, etc., can solve the problems of paper positioning deviation in the design of feeding cardboard, and achieve the effect of simple and reliable positioning method, easy adjustment and high positioning accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

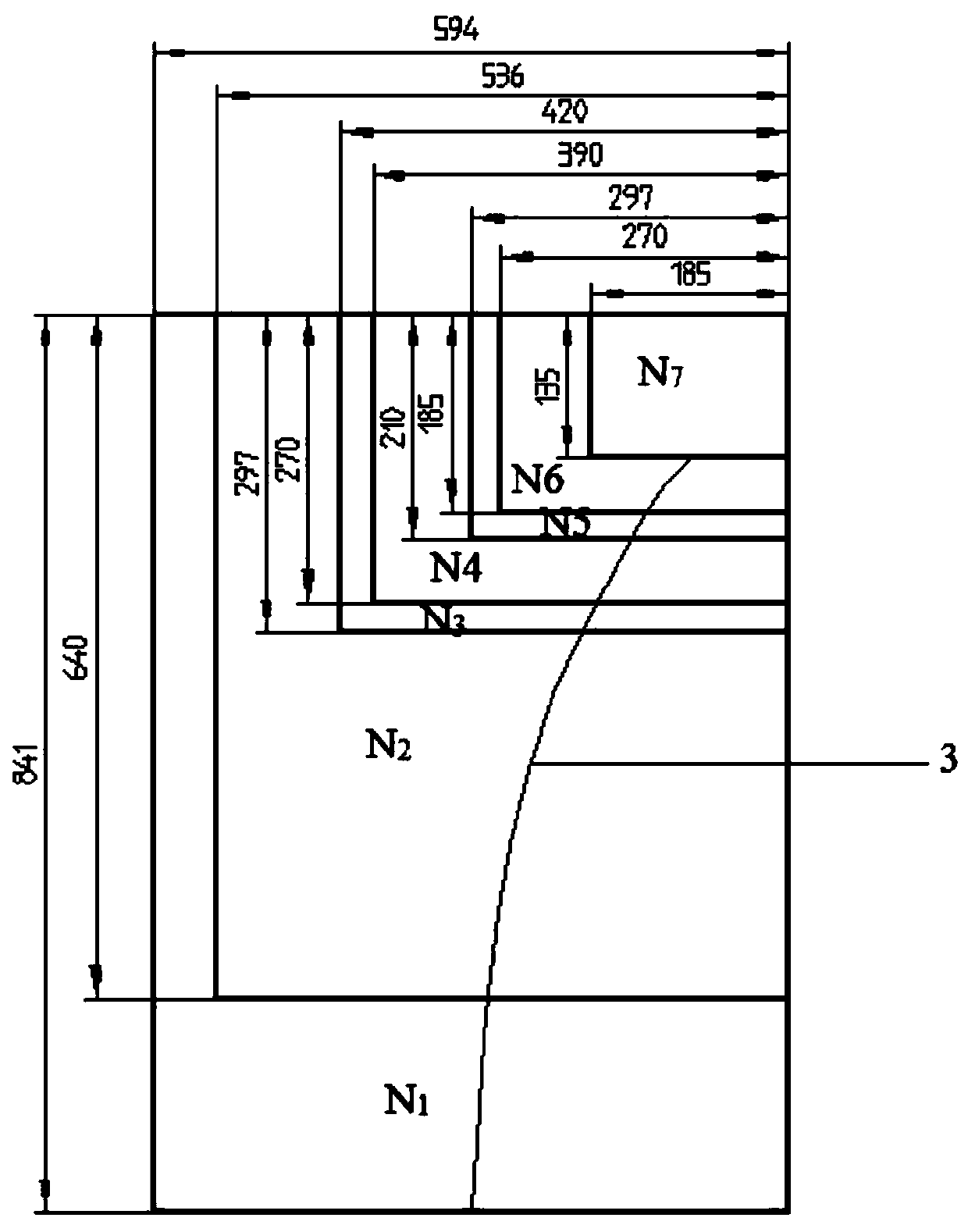

[0033] Step 1, such as figure 2 As shown, select commonly used different paper format specifications N 1 ~N 7 , the paper format includes the largest standard paper A1 format N 1 : 841mm*594mm, non-standard paper format N 2 : 640mm*536mm, standard paper A3 size N 3 : 420mm*297mm, A4 format N4: 297mm*210mm, positive degree 16 format N5: 270mm*185mm, positive degree 8 format N6: 390mm*270mm, positive degree 32 format N 7 : 185mm*135mm;

[0034] Step 2: Carry out the front gauge and left / right orientation of all specifications of paper in step 1. From step 1, it can be known that paper N 1 has an aspect ratio greater than Therefore choose paper N 1 right / left The location is the anchor point ( figure 2 Selected to the right The position is the anchor point); paper N 2 with an aspect ratio smaller than Therefore choose paper N 2 The middle position is the anchor point; the aspect ratio of paper N3 is equal to Therefore choose paper N 3 The middle position i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com