Patents

Literature

34results about How to "Rhythmic" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

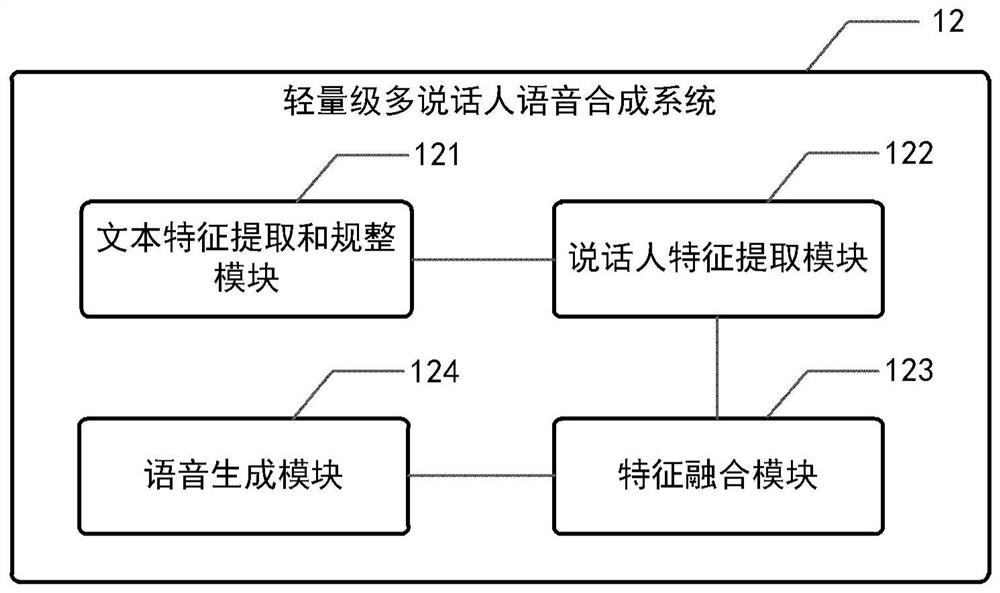

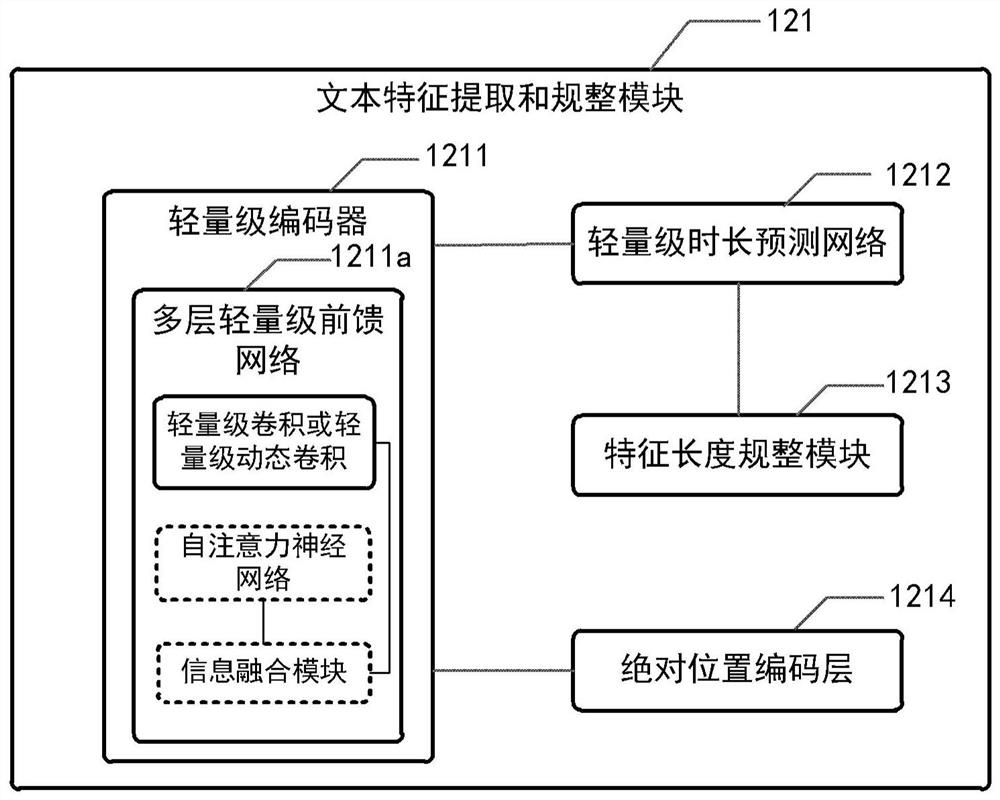

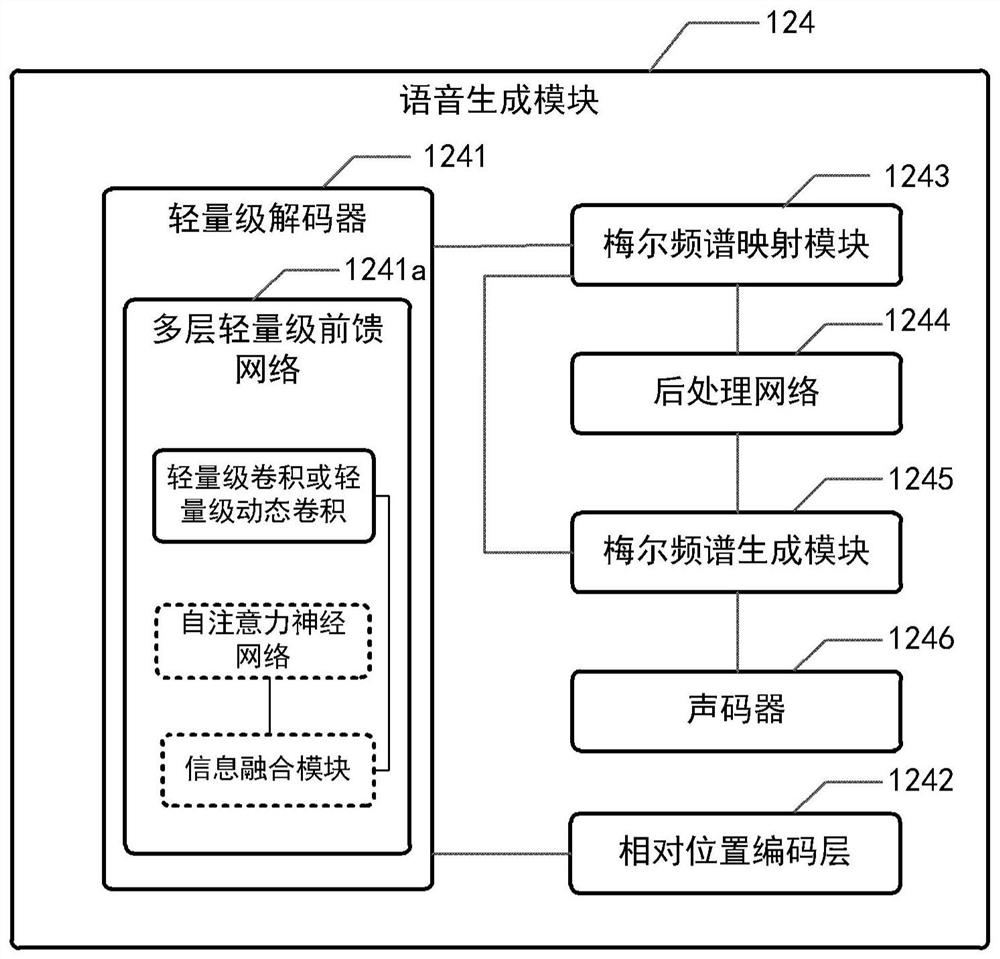

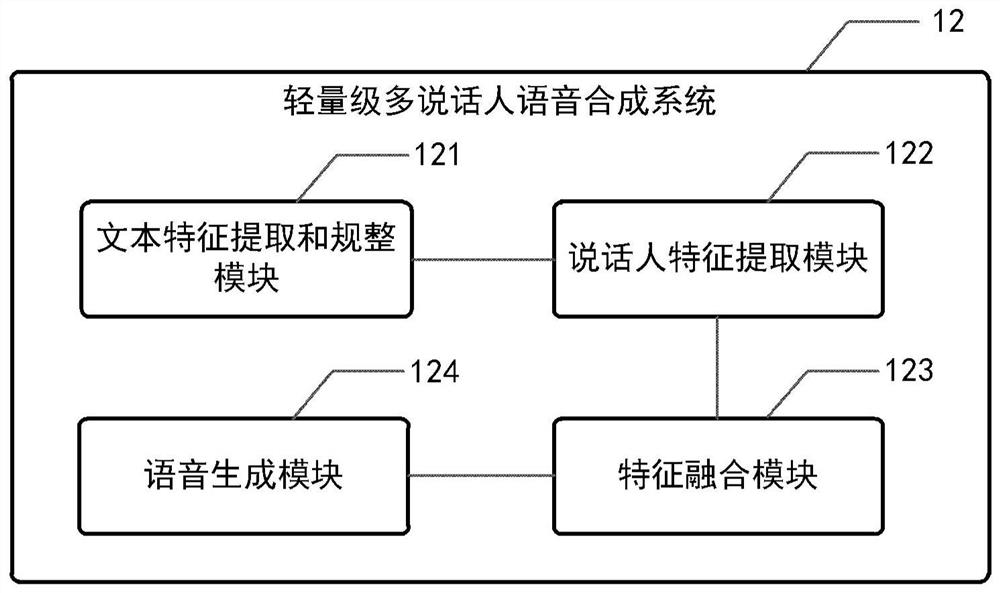

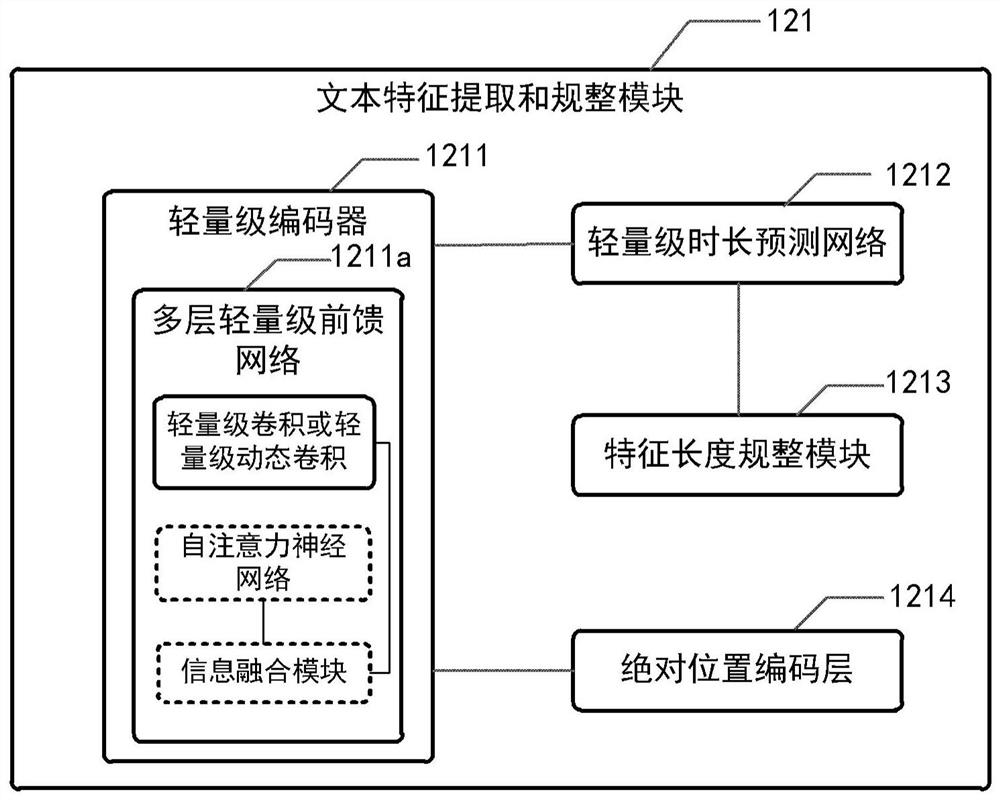

Lightweight multi-speaker voice synthesis system and electronic equipment

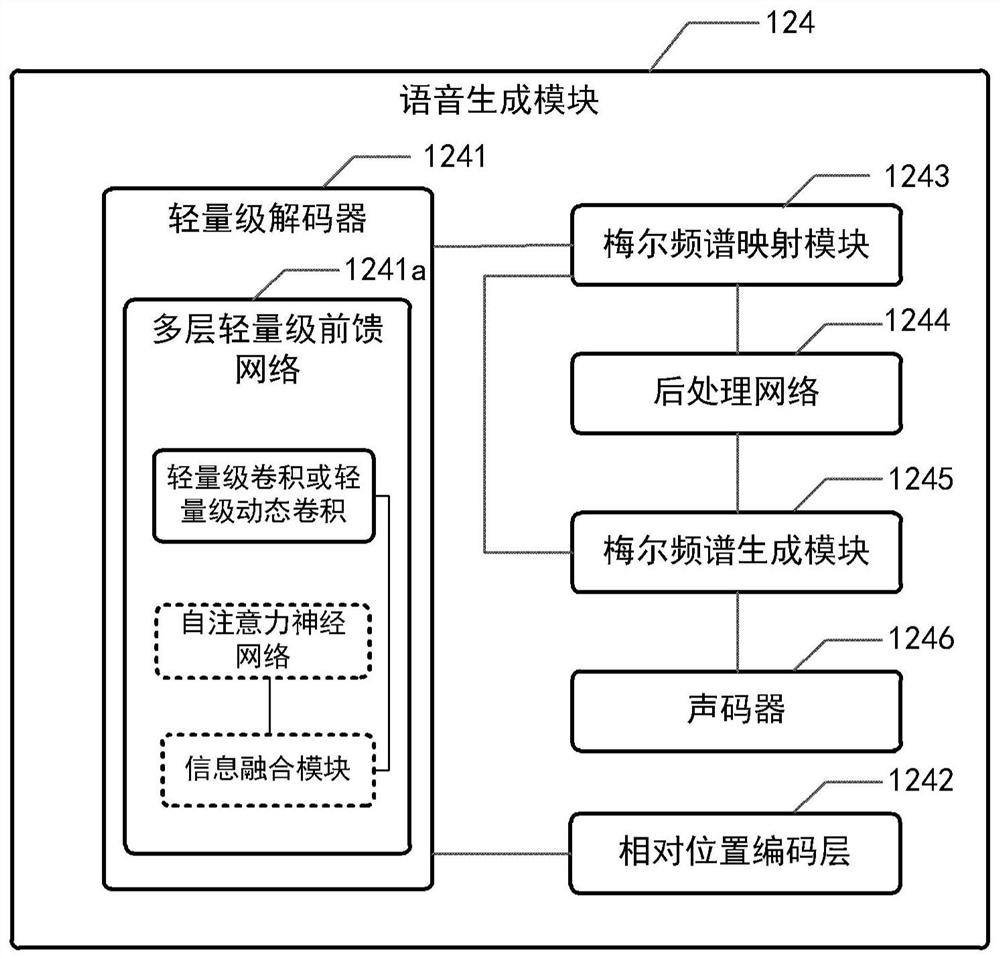

The invention discloses a lightweight multi-speaker voice synthesis system and electronic equipment. The system comprises a text feature extraction and normalization module, a speaker feature extraction module, a feature fusion module and a voice generation module. The text feature extraction and normalization module is used for carrying out encoding and feature extraction on to-be-processed textinformation by adopting a lightweight encoder, carrying out duration prediction on each word or phoneme corresponding to text deep features output by the lightweight encoder by adopting a lightweightduration prediction network, and carrying out length normalization processing to obtain regular text features with length equal to that of a target Mel spectrum. The speaker feature extraction moduleis used for generating features capable of representing a target speaker. The feature fusion module is used for fusing the features of the target speaker with the regular text features. The voice generation module is used for carrying out deep feature extraction, dimension mapping and residual error integration on the fused features and generating voice. The system supports multi-speaker voice synthesis and is high in synthesis speed.

Owner:XIAMEN UNIV

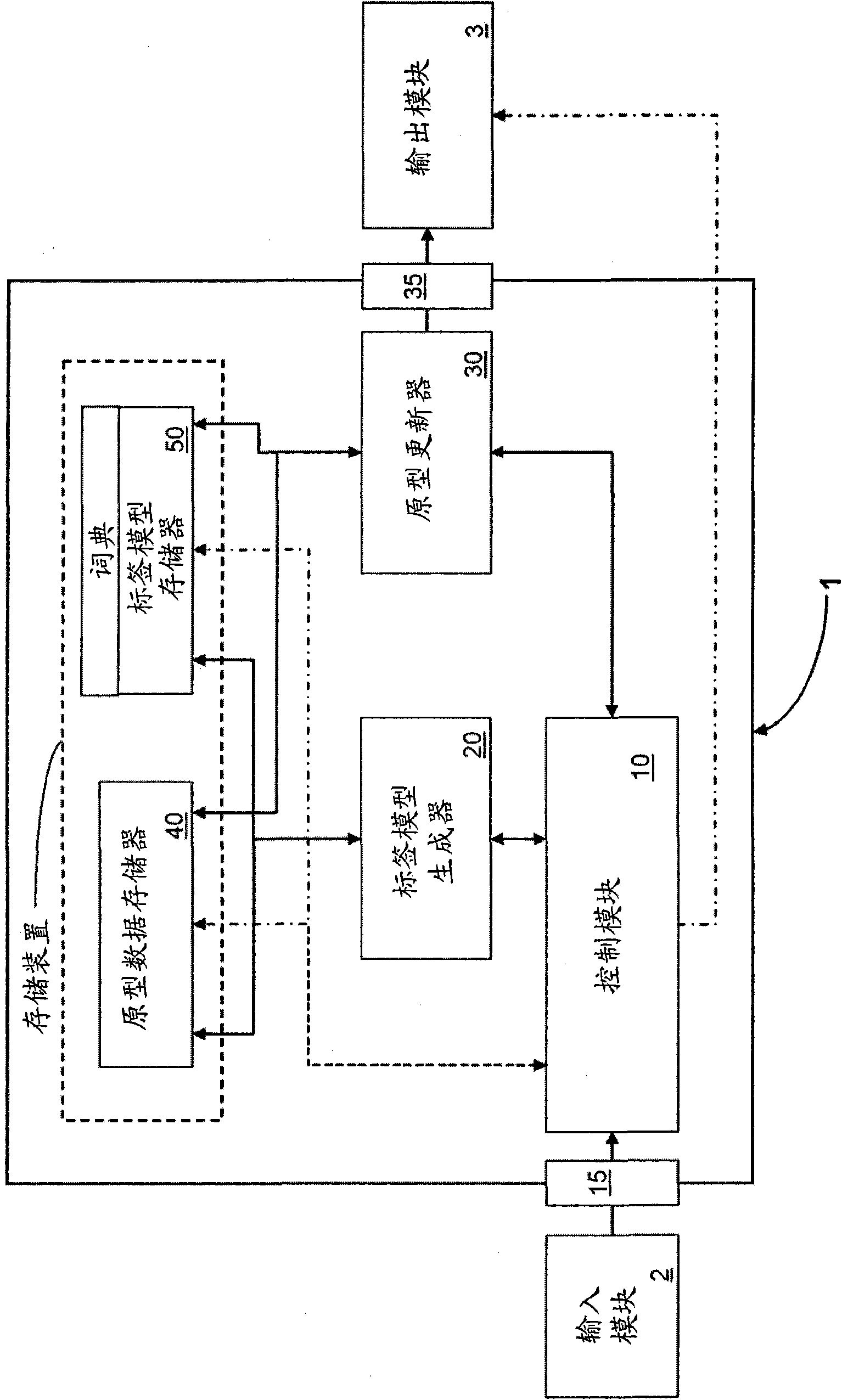

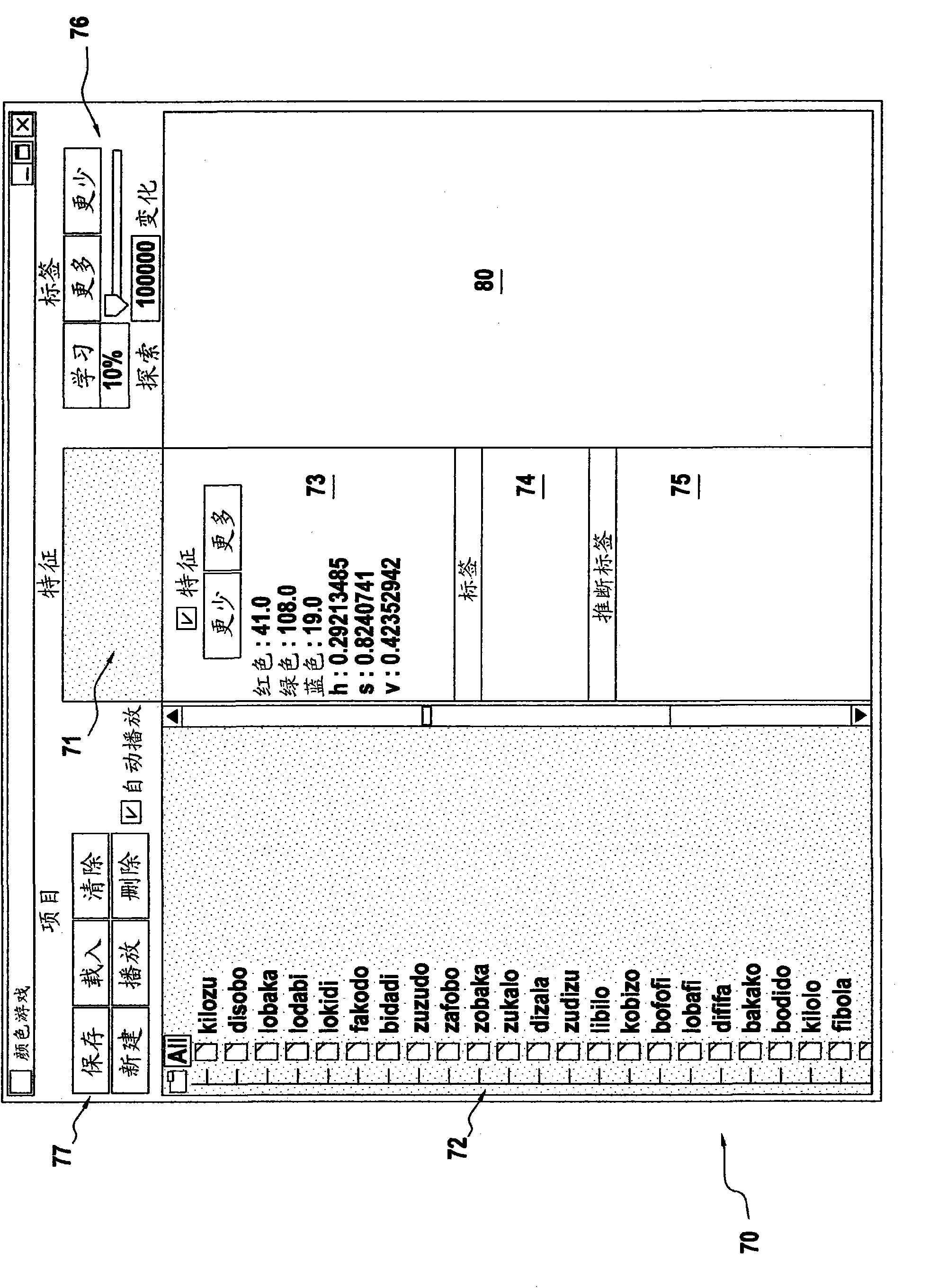

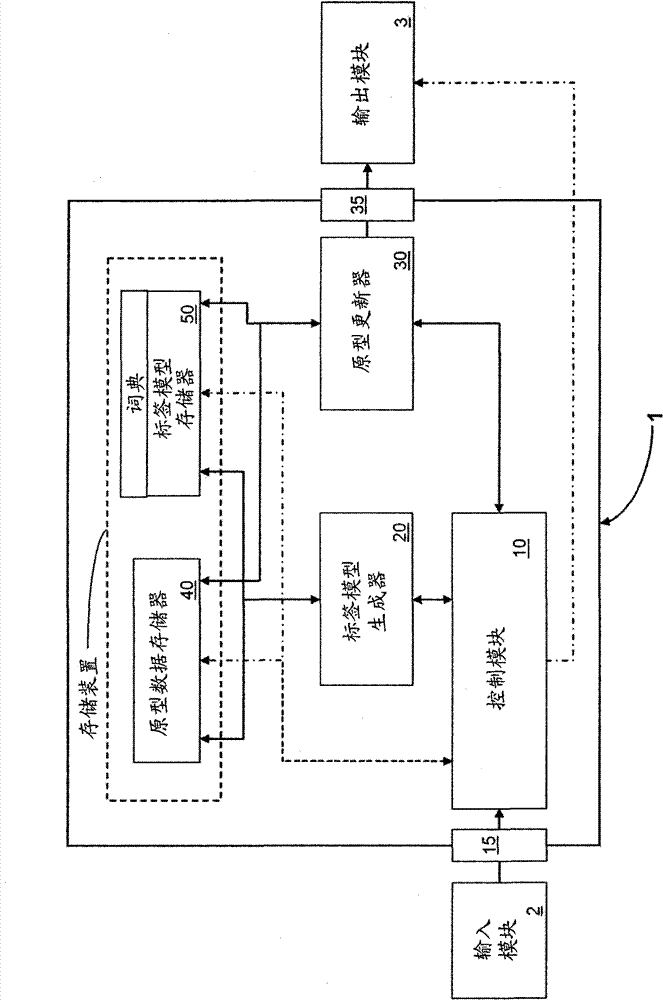

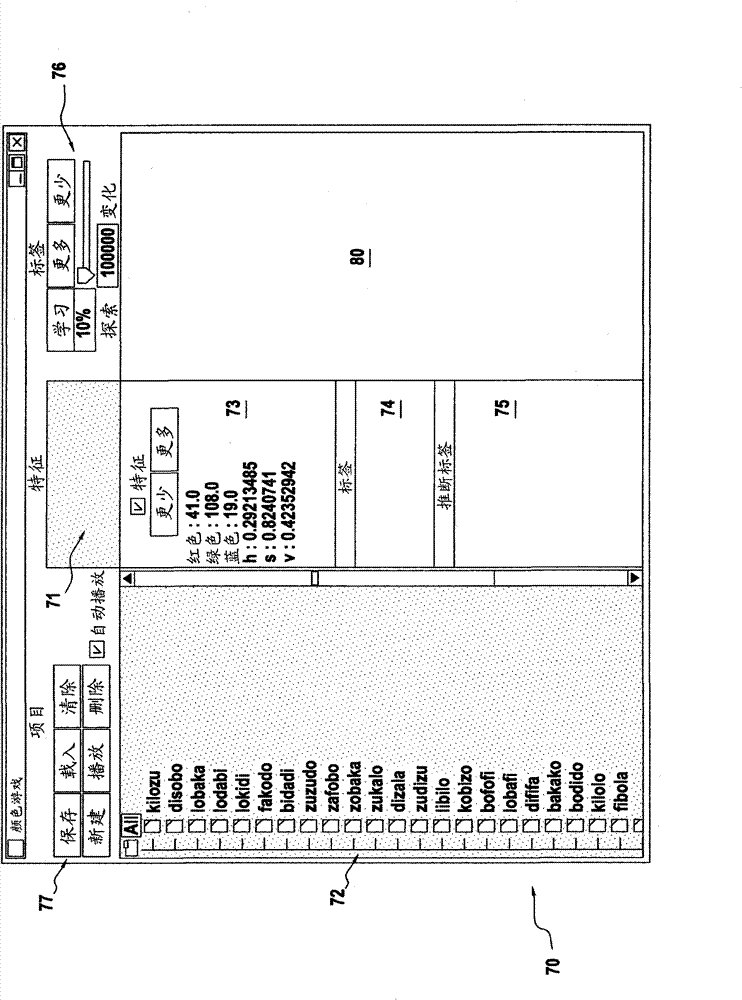

Method and apparatus for updating prototypes

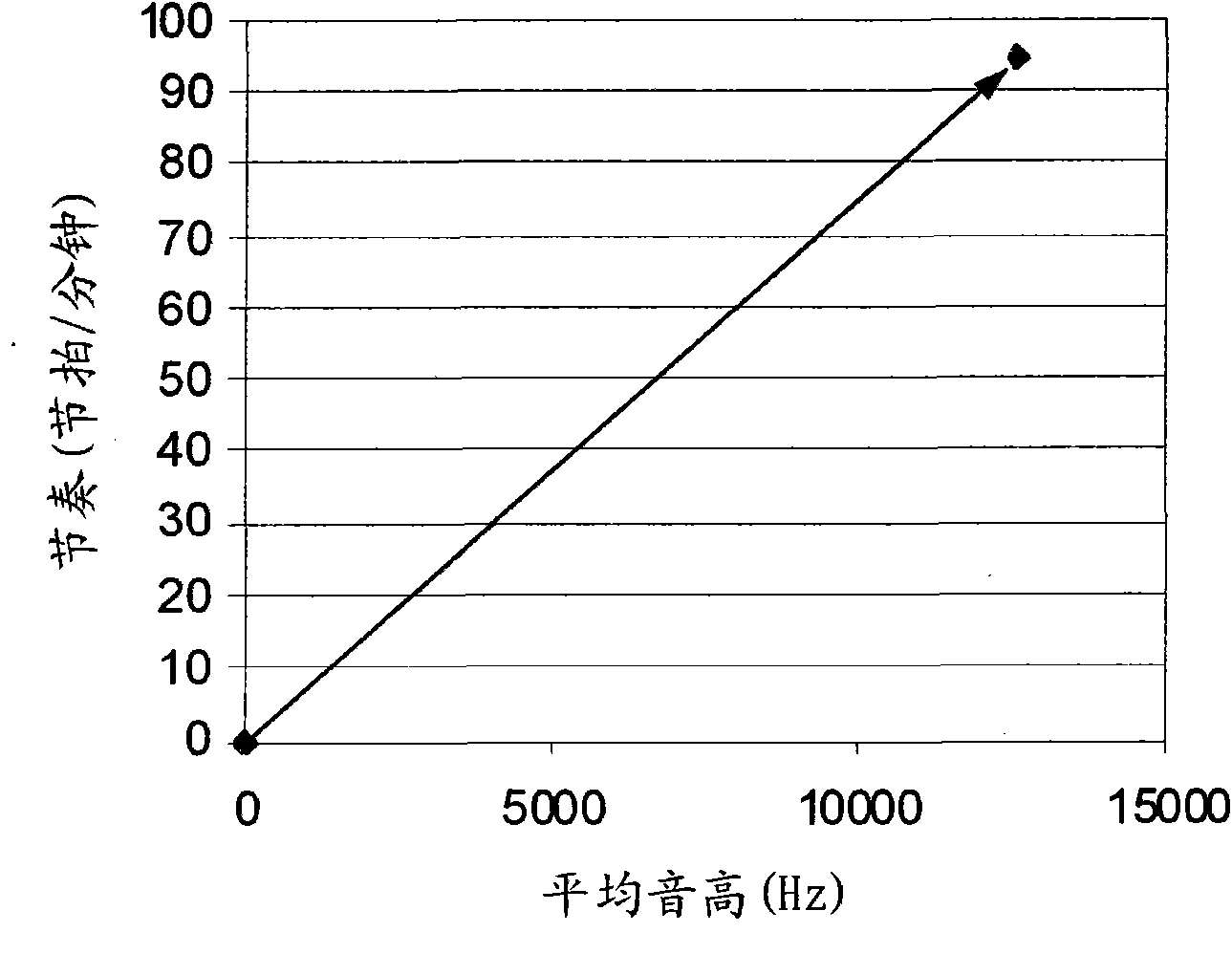

InactiveCN101828183ARhythmicWeak sense of shockMetadata multimedia retrievalSpecial data processing applicationsTheoretical computer scienceDigital object

An apparatus and method for machine-updating of prototypes - for example, during design of digital objects, or content-management - has input means (15) for inputting descriptive classifiers (tags) that a user assigns to prototypes and a tag model generator (20) that uses machine learning techniques to produce a model of the association between the assigned tags and the values of quantifiable, non-subjective attributes of the tagged prototypes. In order to obtain a desired updating of a current prototype, the user issues a command which defines the desired variation of the current prototype by referring to one or more conditions that should be met by specified tags of the updated prototype. The prototype-updating apparatus / method has a prototype updater (30) that identifies a suitable updated prototype whose tags meet the condition(s) specified in the user's command and which, globally, is fairly similar to the pre-update prototype. The user can, thus, express instructions for prototype-updating using his own terminology.

Owner:索尼欧洲有限公司

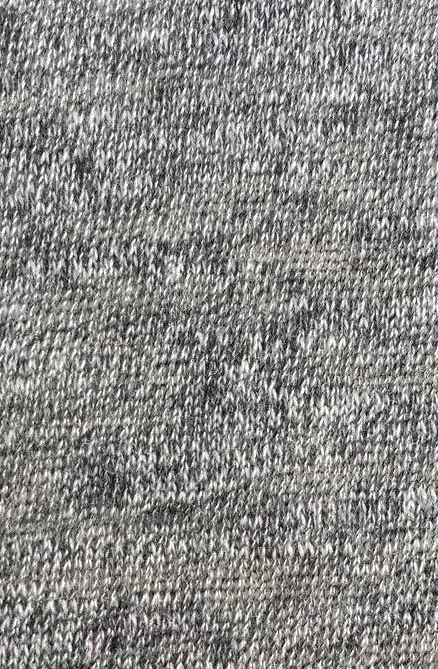

Preparing method of slub AB yarn

The invention provides a method for preparing snowflake slub AB yarn, which is characterized in that: the method includes preparing A roving, preparing B roving, and spun yarn; The twist coefficient of A roving is 105-107; the twist coefficient of B roving is 42-47. The snowflake slub AB yarn prepared by the present invention has the structural characteristics of slub appearance with uneven thickness distribution, the evenness CV% reaches 22.7%, the detail reaches 558 / km, and the thick knot reaches 1182 / km. The number of neps reaches 516 per kilometer; the preparation method of the present invention produces 1 ton of fabric, which can save 50 tons of water, reduce industrial sewage by 50 tons, save labor by 50%, and reduce the cost of dyeing and chemical materials by 50% or more. , By changing the cotton blending, carding noil and spinning process, the cost of cotton production is greatly saved, the carding noil rate is changed from 5% to 1%, and 40 kg of raw materials can be saved for tons of cotton used for yarn.

Owner:寿光市嘉信生态科技有限公司

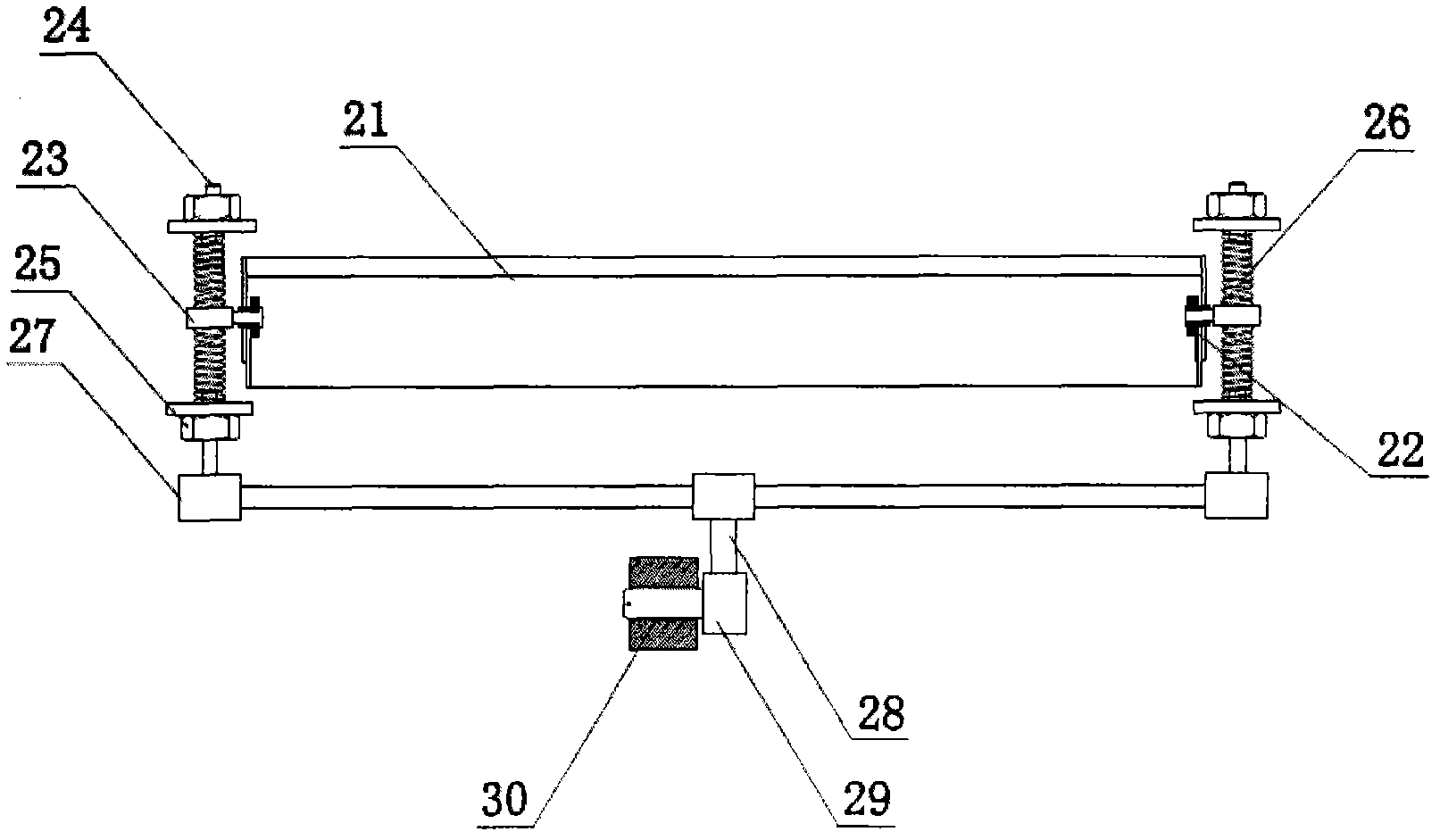

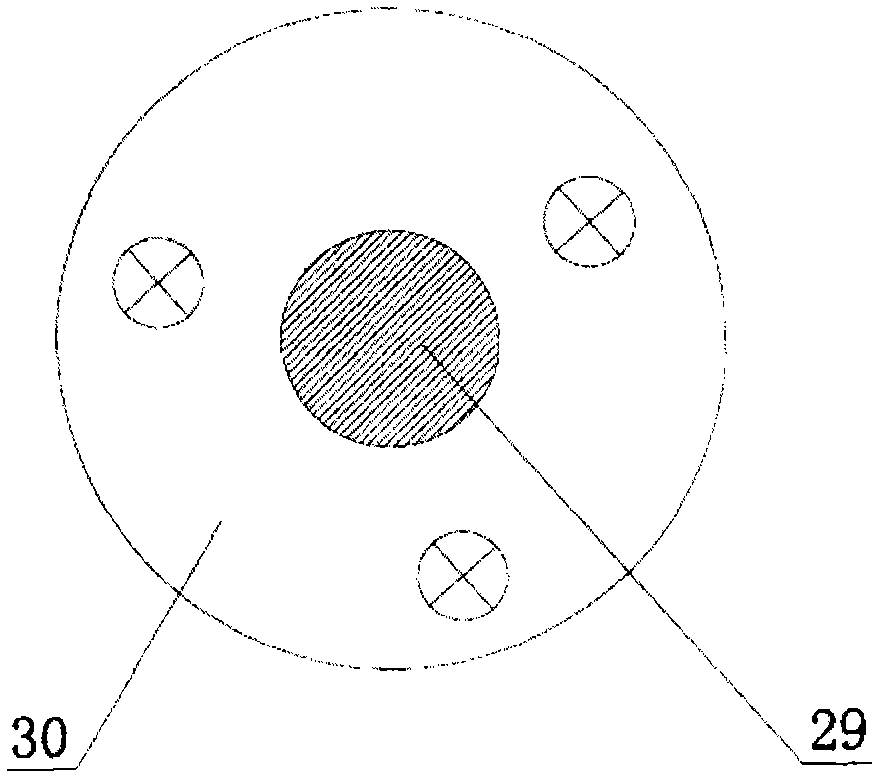

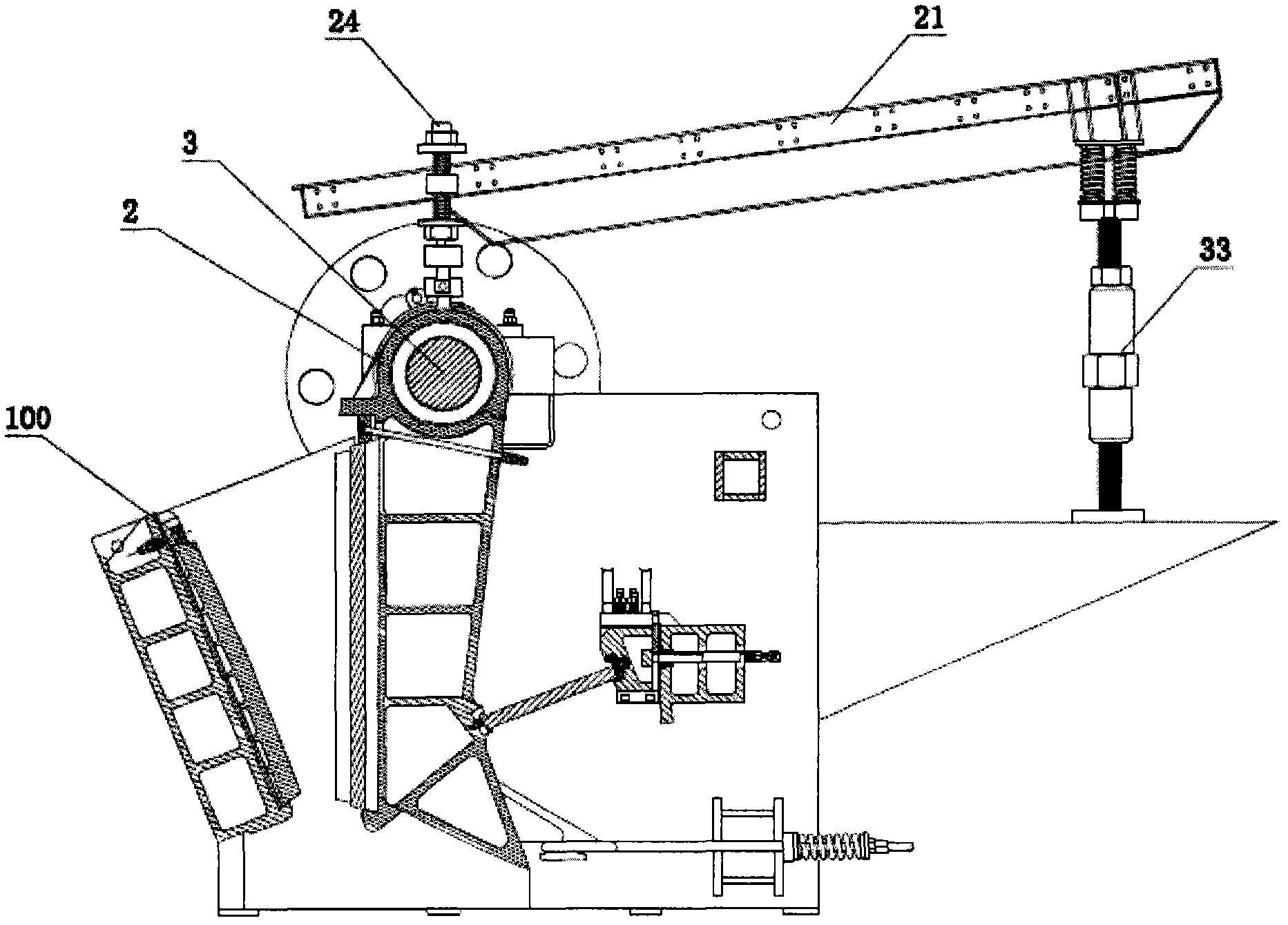

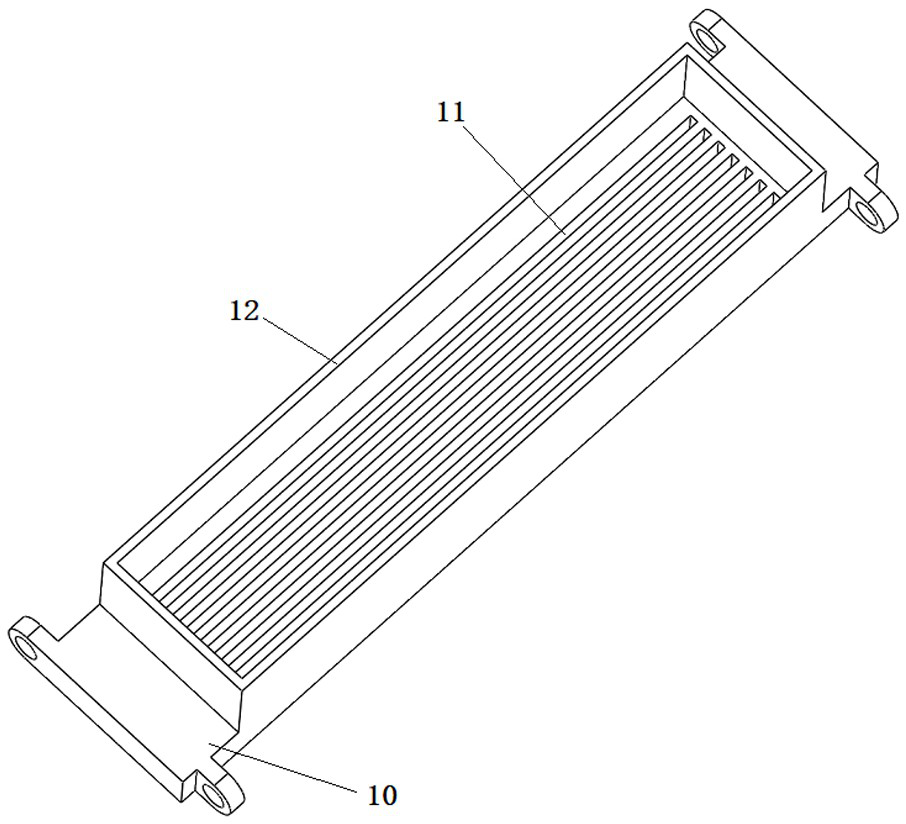

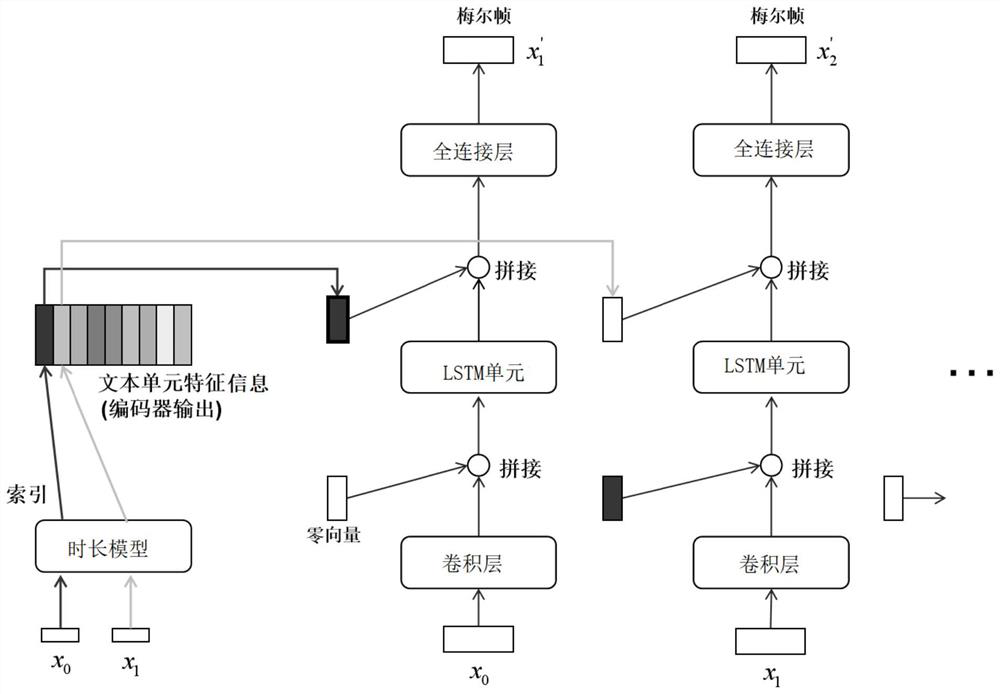

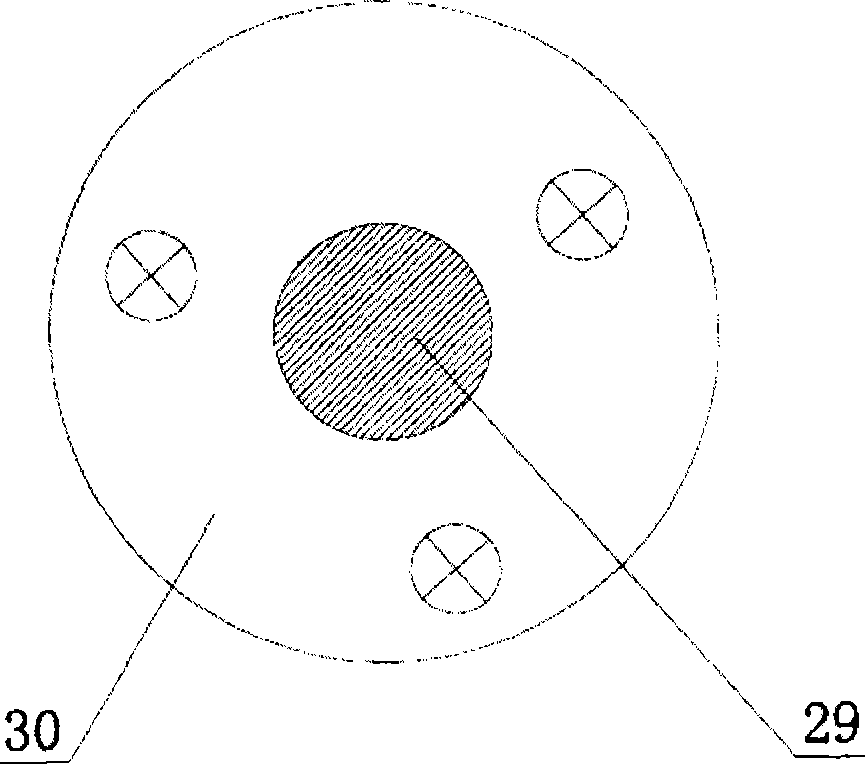

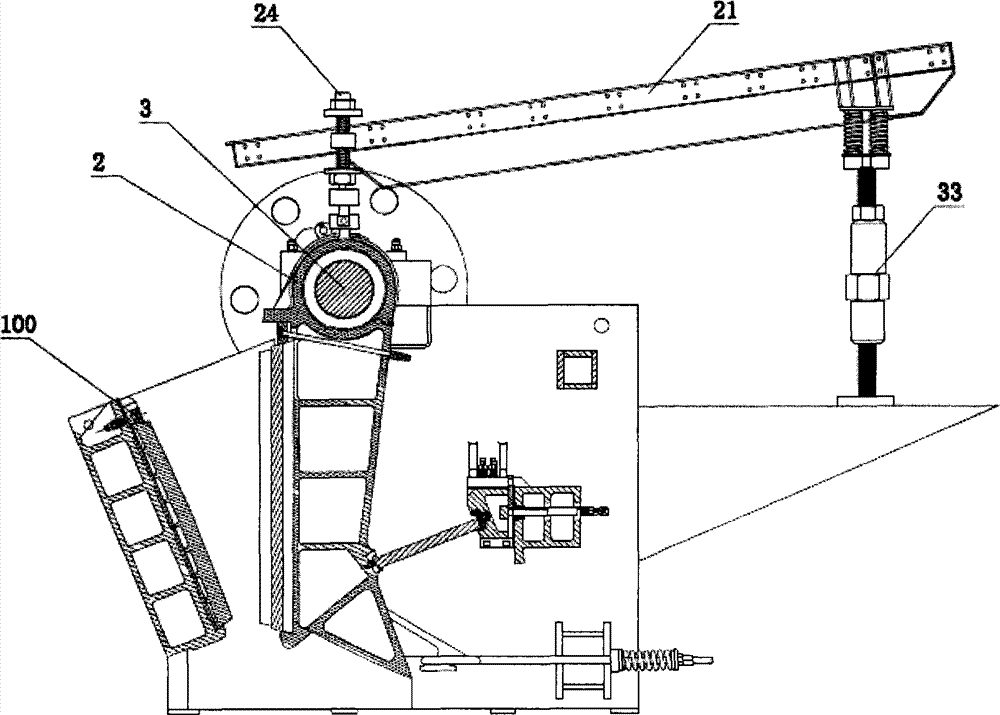

Externally-assisted vibrating feeder

The invention discloses an externally-assisted vibrating feeder which comprises a feeding compartment body, the underside of one end of the feeding compartment body is erected on an installed crusher driving shaft mechanism through a docked connecting rod device, and the other end of the feeding compartment body is erected on an installed crusher rack through an adjustable supporting device. According to the invention, through skillfully using the linked fixed installation of the feeder and a crusher, synchronously operating and using realistic conditions, removing a vibration exciter and adding a docked connecting rod device, a feeding operation is completed by using an exciting force generated by the rotary motion of the crusher driving shaft mechanism. In such a way, the feeder becomes extremely concise and light, the equipment manufacturing and running costs are greatly reduced, and the application and maintenance of the feeder are more convenient. Due to the versatility of the docked connecting rod device, the docked connecting rod device can be widely matched with different types of crushers (such as impact crushers and hammer crushers) for using purpose.

Owner:YIWU BLACK AND WHITE MINING MACHINERY

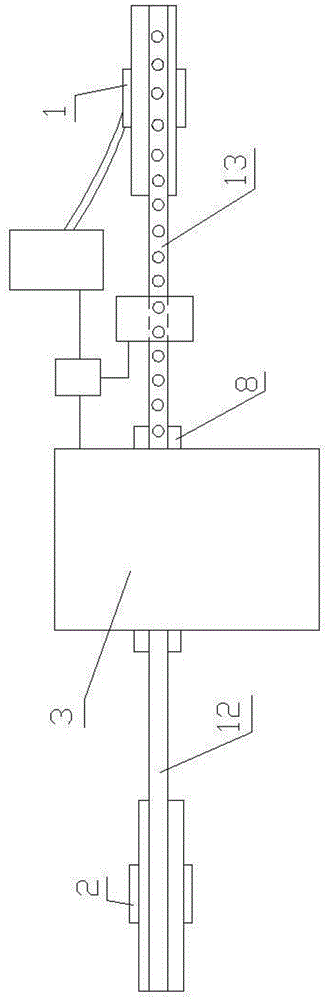

Feeding and receiving device of punch press

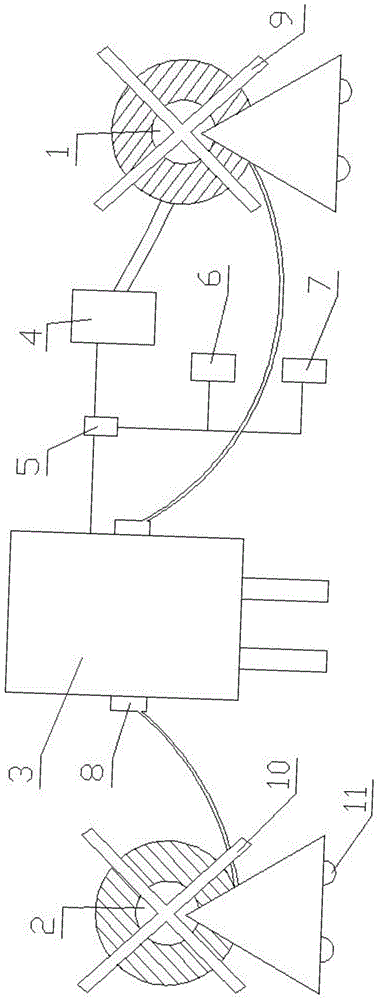

InactiveCN104056987AEfficient recyclingEffective automatic feedingMetal-working feeding devicesStripping-off devicesElectricityPunch press

The invention relates to a punch press, discloses a feeding and receiving device of a punch press and belongs to the technical field of punch presses. The feeding and receiving device comprises a first coiling disc, a motor and a controller, wherein the motor is in transmission connection with the first coiling disc and is electrically connected with the controller; the controller is electrically connected with the punch press. The feeding and receiving device can effectively and full automatically feed material and recycle waste material, is high in safety and beat property, excellent in continuity and low in cost, greatly improves the production efficiency, and reduces the manual labor intensity.

Owner:ANHUI HONGQIAO METAL MFG

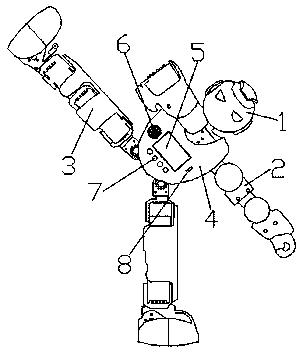

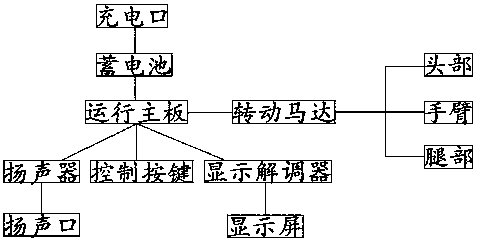

Performance robot

The invention discloses a performance robot. The performance robot comprises a head, arms, legs and a trunk. The head, the arms and the legs are all connected with the trunk through rotary disks. Thearms and the legs are both connected through multiple rotary screws. A display screen, a loudspeaker port, control keys and a charge port are arranged on the outer portion of the trunk. The trunk is internally provided with a running mainboard, a display demodulator, a storage battery and a loudspeaker. The running mainboard is connected with the control keys, the display demodulator, the storagebattery and the loudspeaker through integration lines. The problems of complexity of repeated replacement of batteries and pollution of waste batteries to the environment are solved through the charging method. Different sound effects and videos can be changed through the control keys. Meanwhile, the performance robot can effectively achieve synchronization of the sound effects and operation of amotor through an information matching module and a motor control module on the running mainboard, so that the robot has better rhythm sensation during operation. Accordingly, the cognition degree of children to the music and rhythm is stimulated, and interest of the children is further increased.

Owner:FOSHAN XUEZI ENTERPRISE SERVICE CO LTD

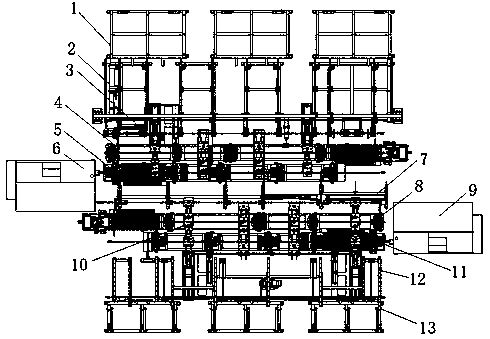

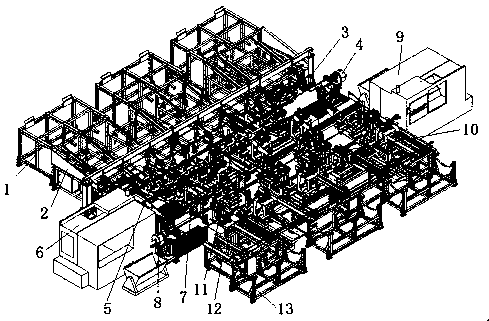

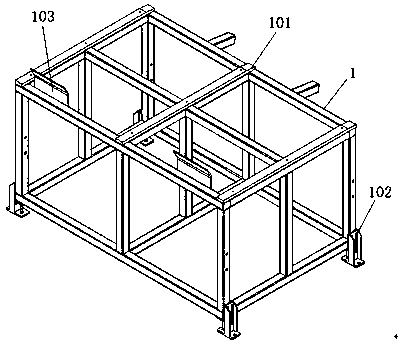

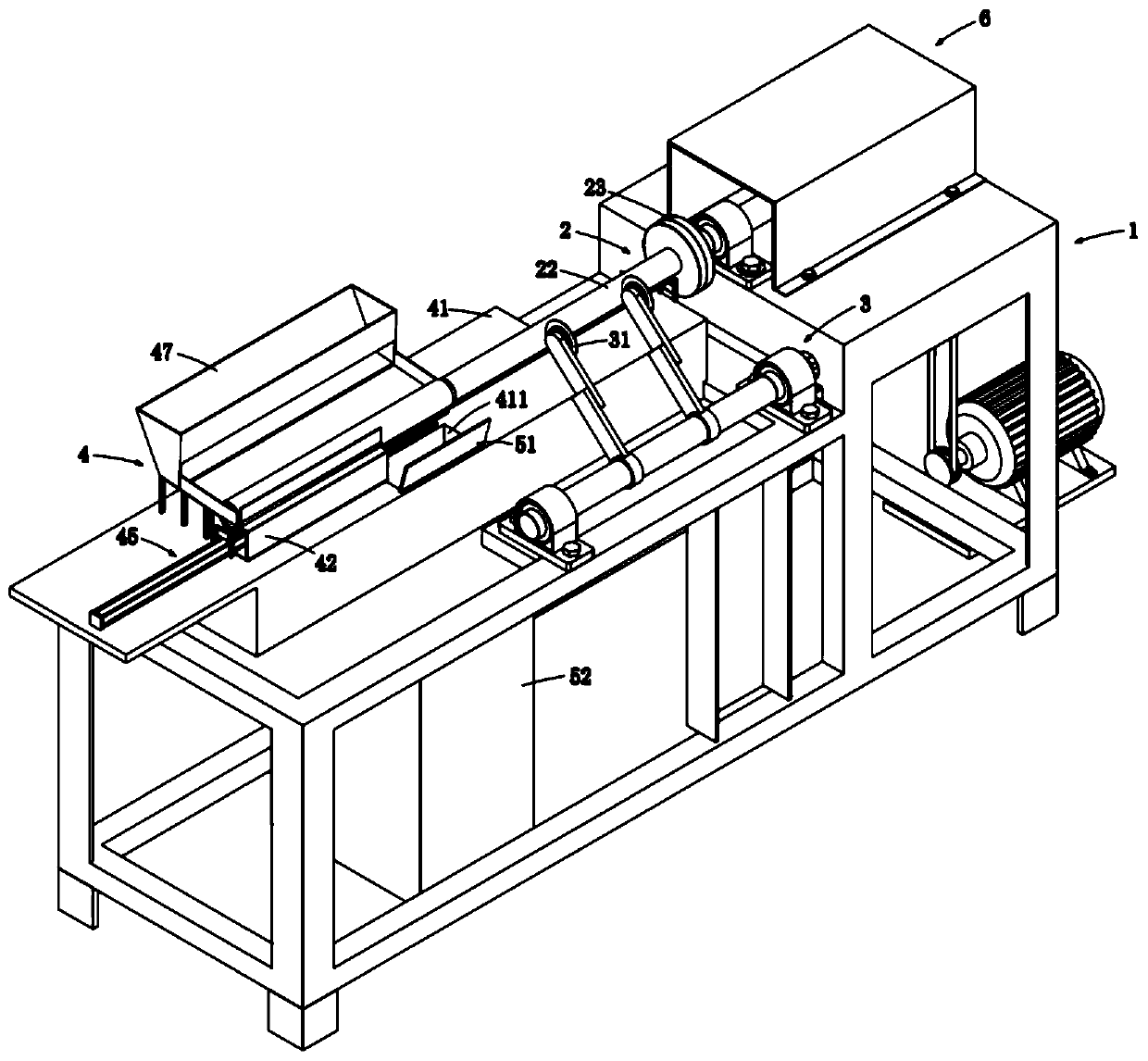

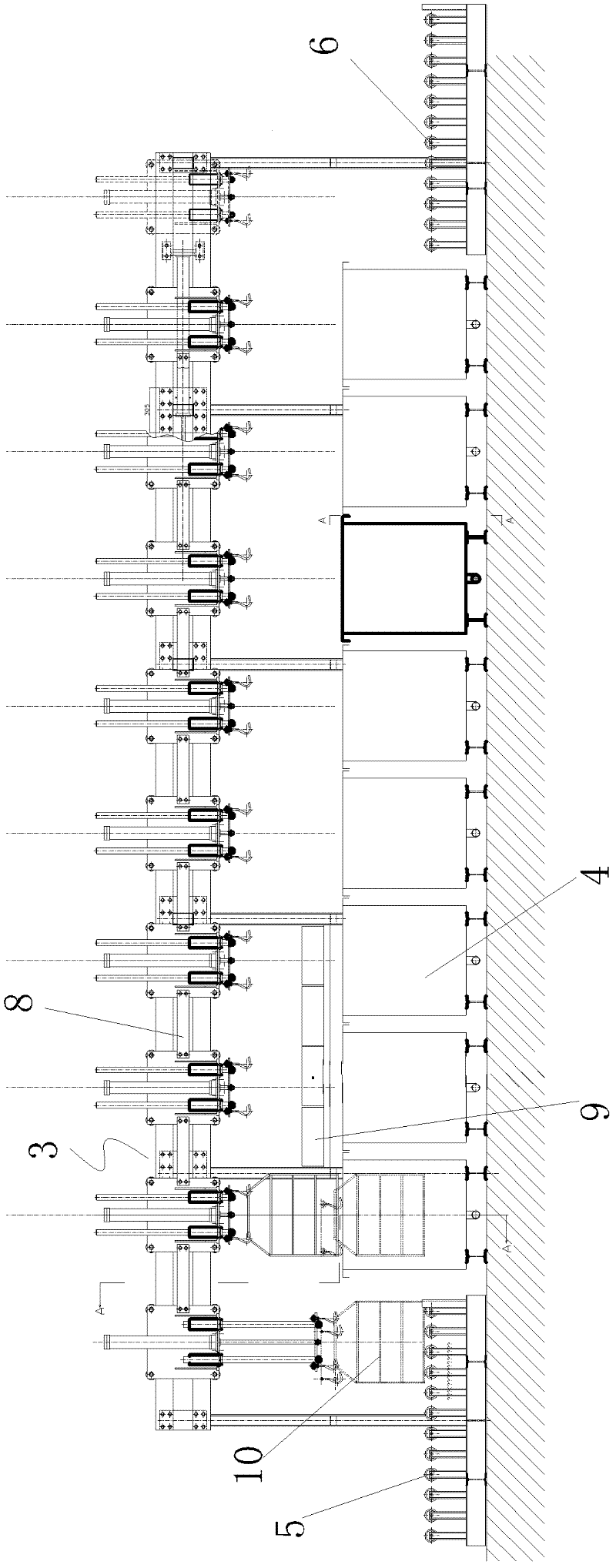

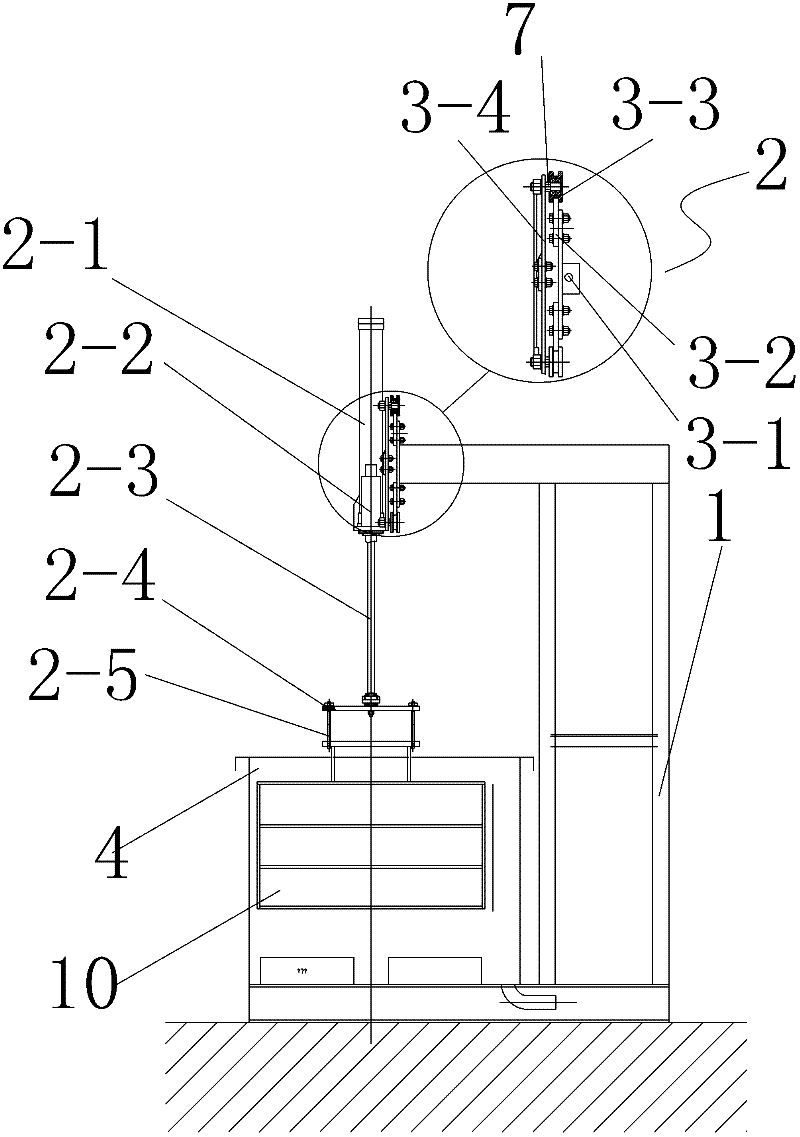

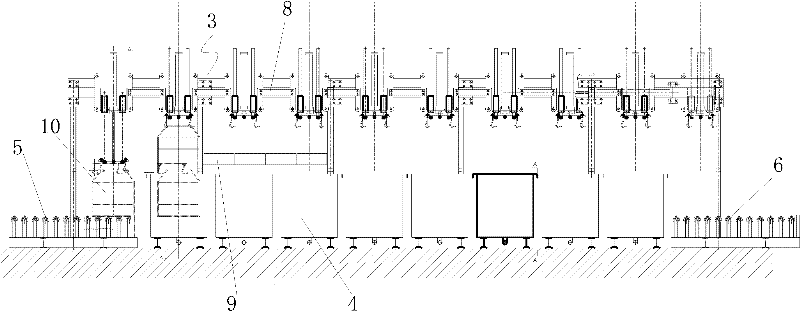

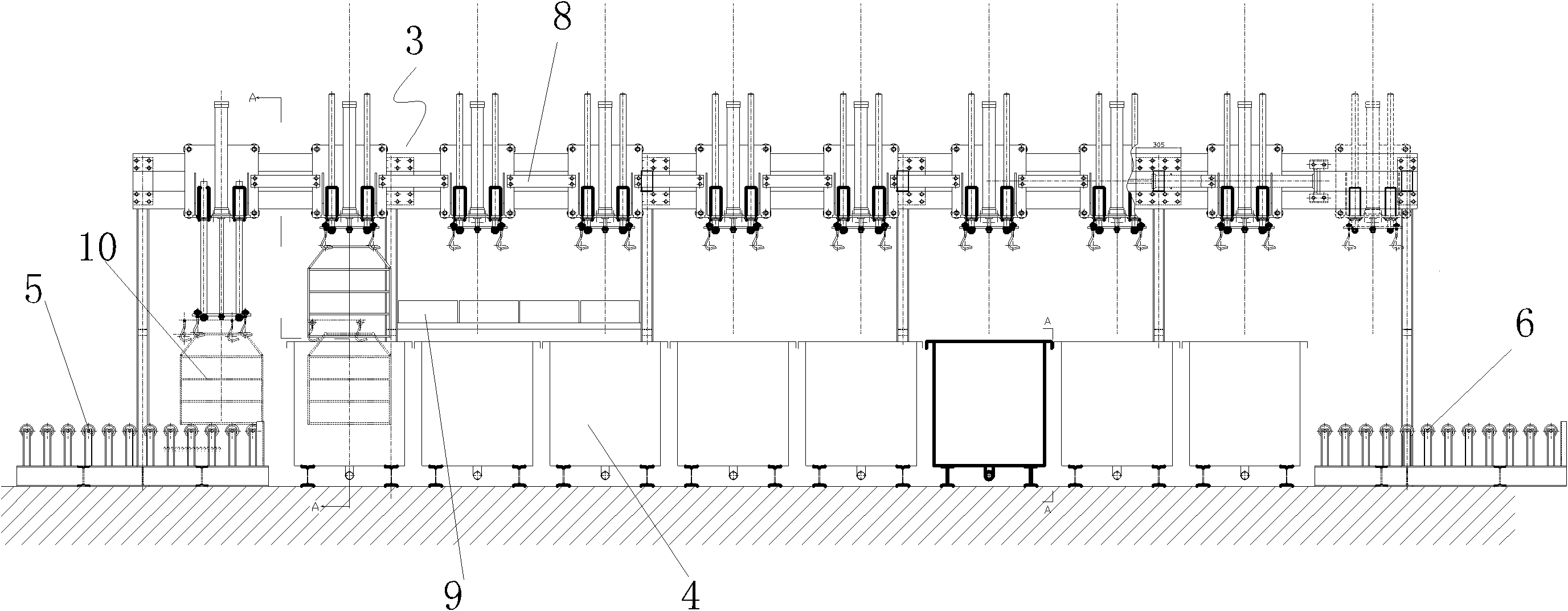

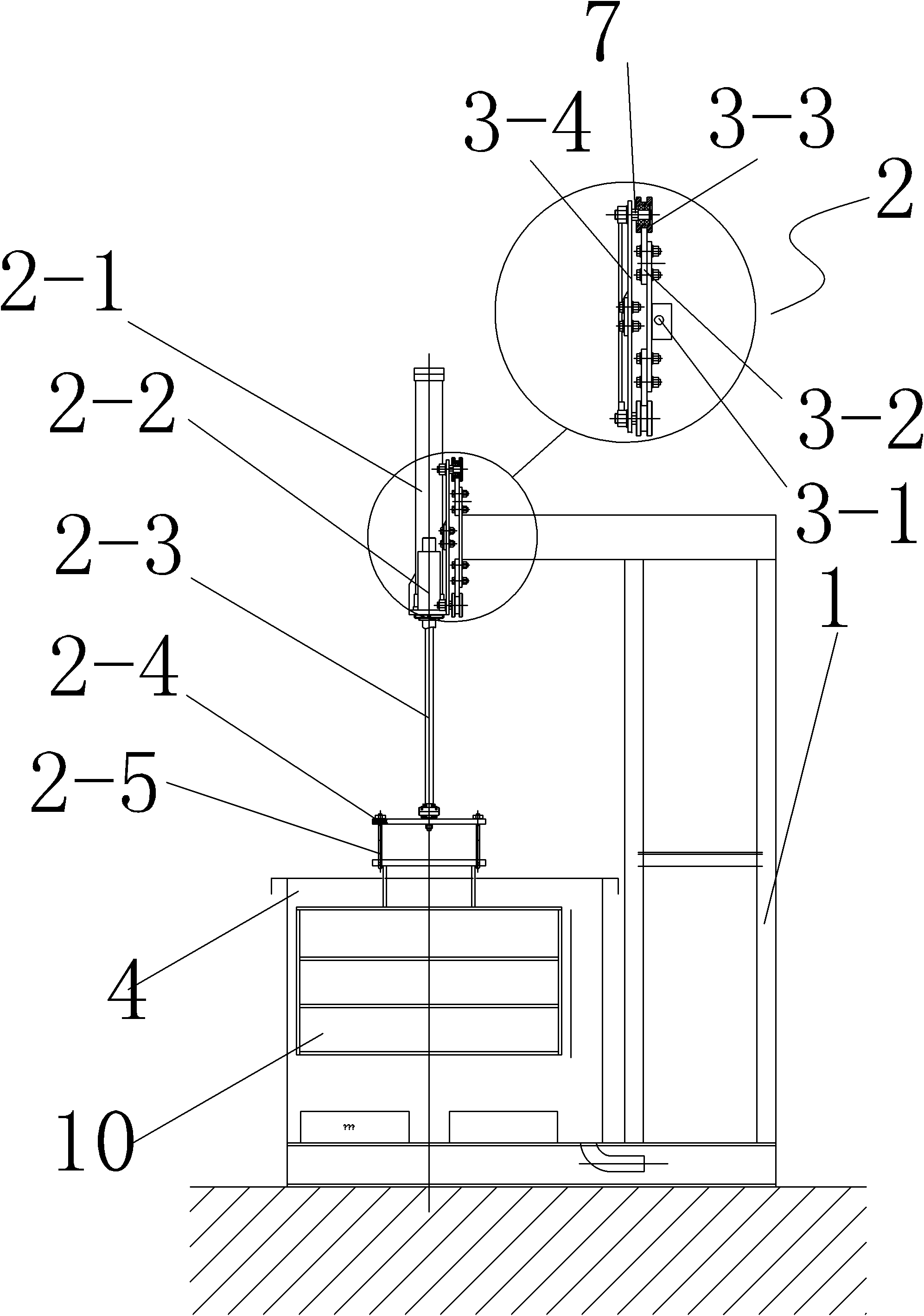

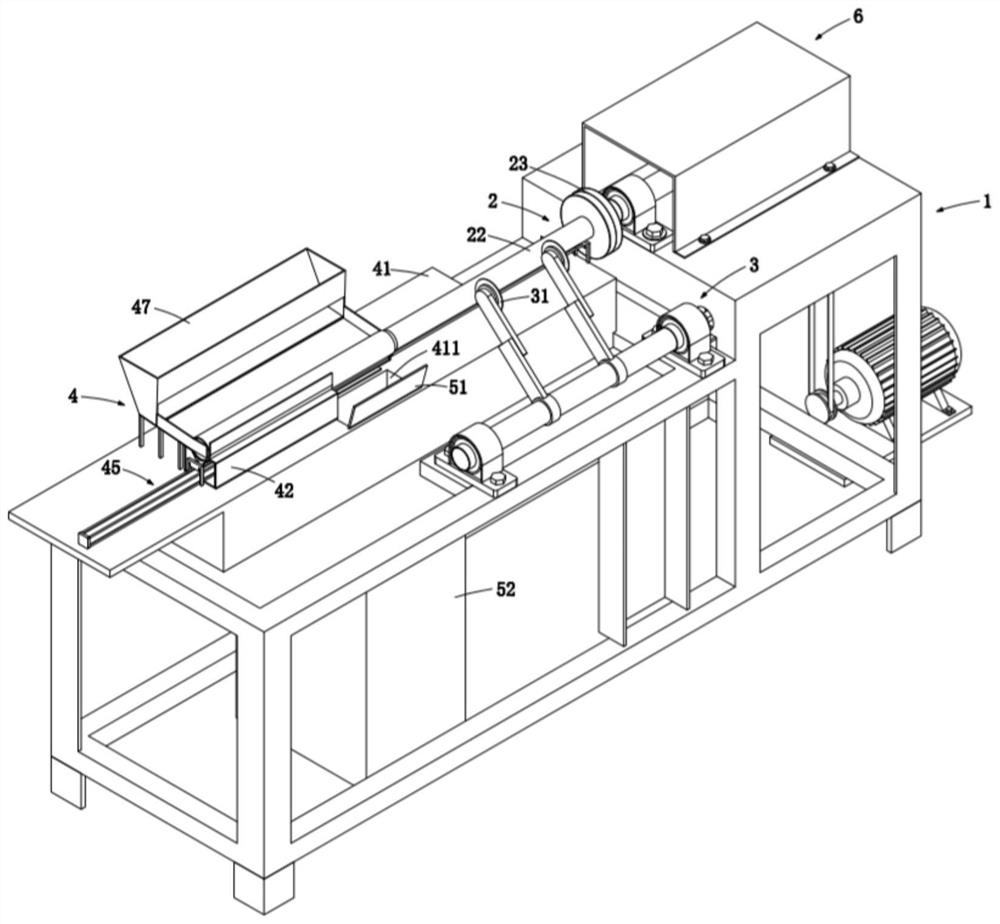

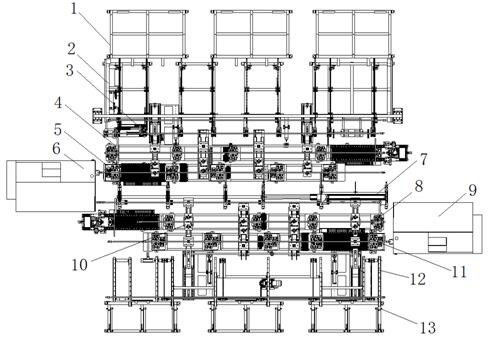

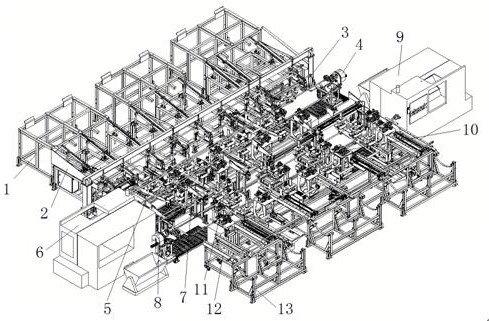

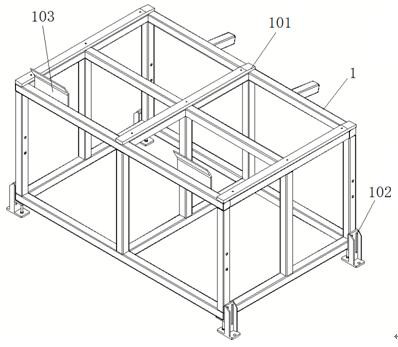

Oil sucker rod intelligent manufacturing production line

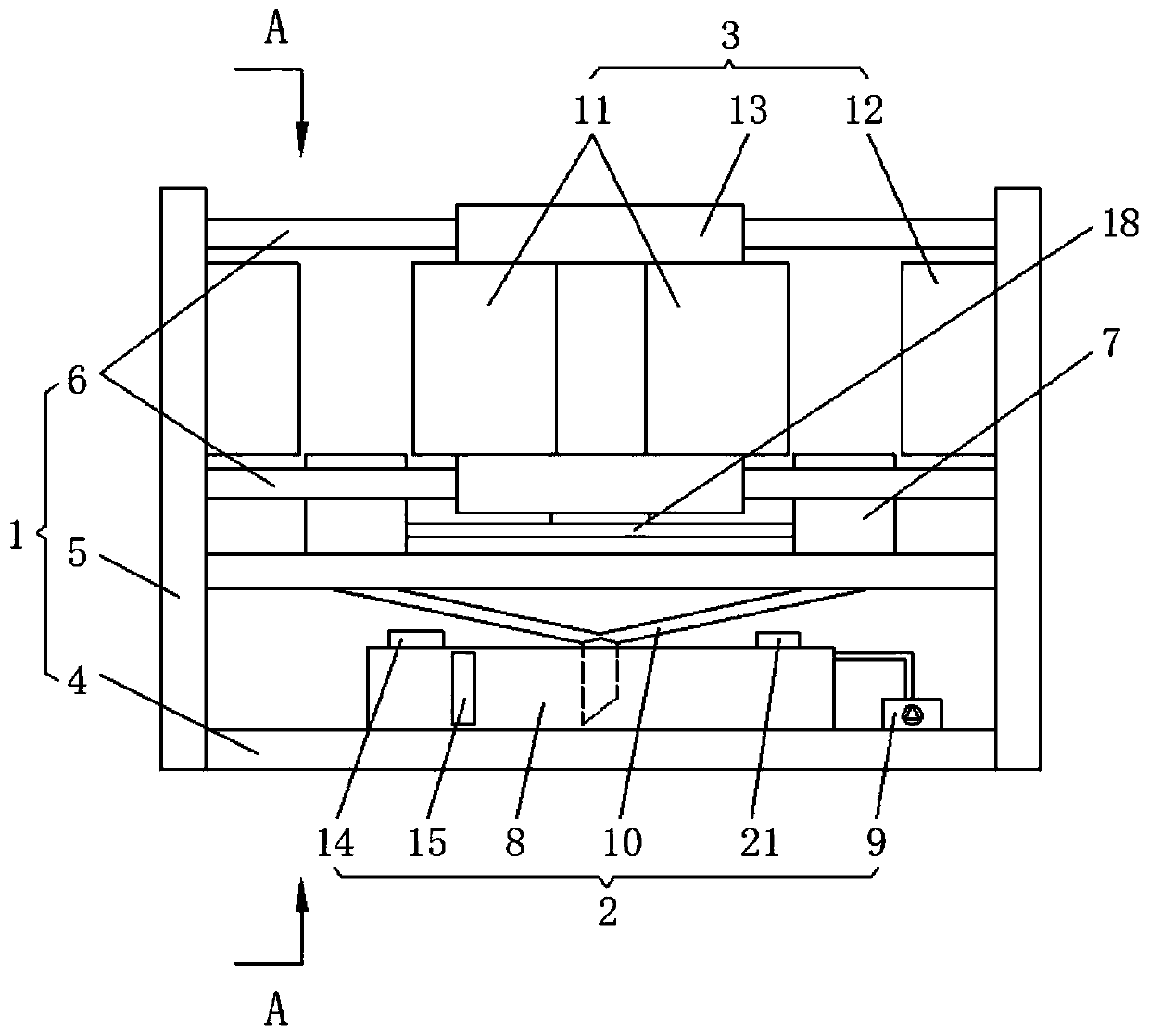

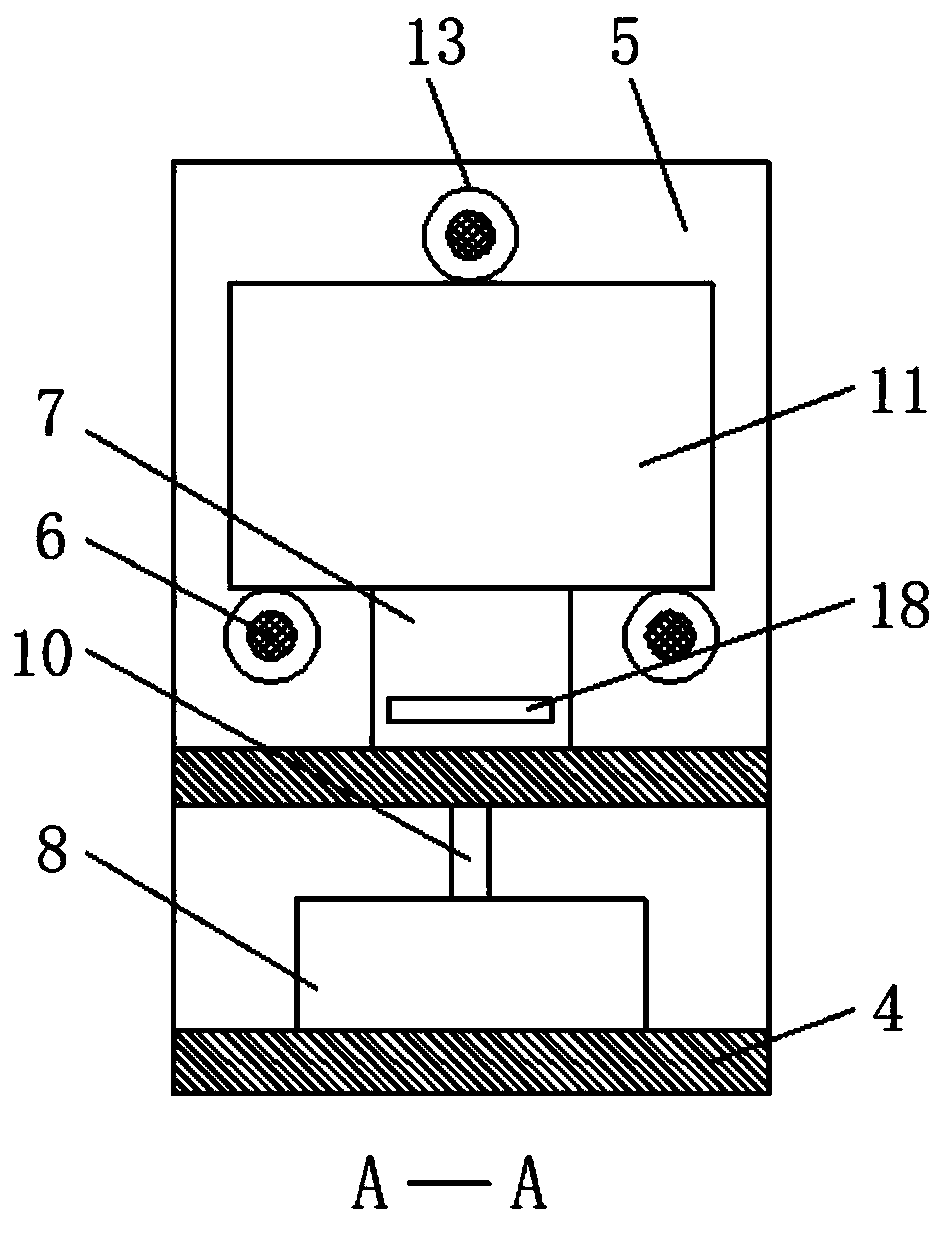

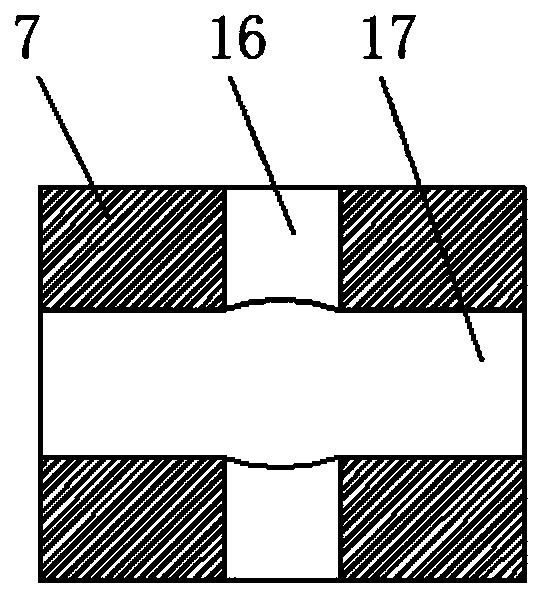

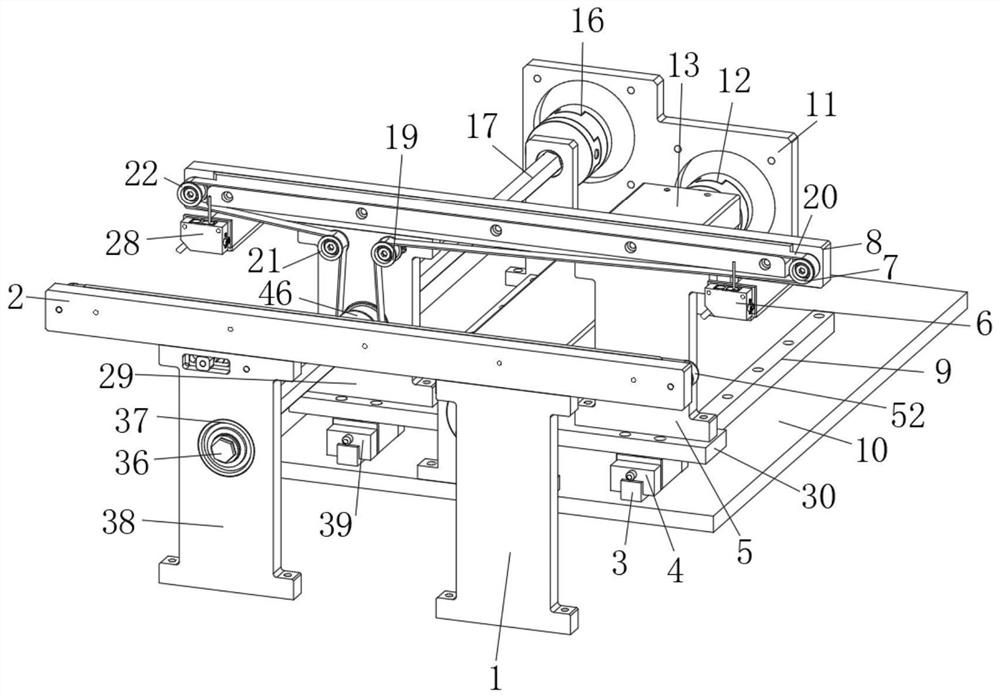

ActiveCN111390087AThe transfer process is stableRealize intelligent automatic productionForging/hammering/pressing machinesForging press detailsMachineMachining process

An oil sucker rod intelligent manufacturing production line comprises a feeding bin, a first stepping push device, a first angular positioning device, a first transferring device, an axial operation device, a second angular positioning device, a second stepping push device, a second transferring device and a discharging bin arranged in sequence in the workpiece operating direction; the outer sideof the first transferring device and the outer side of the second transferring device are both provided with machine tools; the first stepping push device pushes workpieces on the feeding bin, the first angular positioning device and the first transferring device forwards in sequence; and the second stepping push device pushes the workpieces on the axial operation device, the second angular positioning device, the second transferring device and the discharging bin forwards. According to the production line, the problems that conveying, clamping and positioning are difficult in the machining process of long and thin oil sucker rods are solved, intelligent automatic production of external threads of two ends of an oil sucker rod is achieved, the workpiece transferring stability is ensured, the paces are intense, the production efficiency is high, and the production cost is reduced.

Owner:山东弘名智能科技有限公司

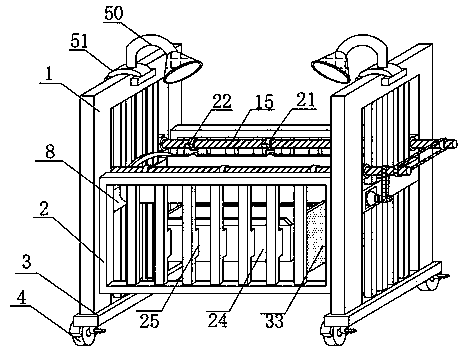

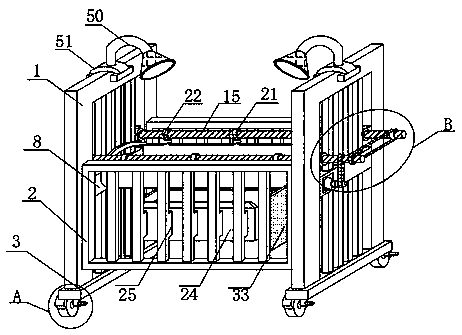

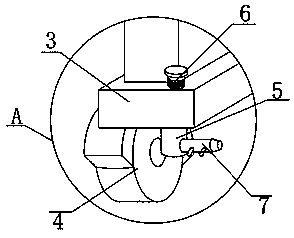

Slightly-swing-type double-layer crib for earthquake escape

The invention discloses aslightly-swing-type double-layer cribfor earthquake escape. Theslightly-swing-type double-layer crib comprisestwo sets of first frames, two sets of second frames, a swing bed and a crank rocker support, wherein the first frames and the second frames are distributedon the four sides of a crib body in asymmetrical mode, the lower ends of the first framesareconnected with supporting plates in a riveted mode, and two sets of No.1 universal casters are installed at the lower end corners of each of the supporting plates; and positioningcolumns are movably installed at the lower ends of the supporting platesand located beside theNo.1 universal casters, and adjusting bolts acting on thepositioning columns are movably installed in the supporting plates. According to the slightly-swing-type double-layer crib for earthquake escape,the crib adopts double-layer design, the common swing bedis arranged on an upper layer, and a steel box for earthquake escapeis arranged on a lower layer is;and the distribution design is reasonable, the size is moderate,the overall structure is high in fastening degree, firm and durable,anultraviolet sterilizing lamp is arranged, the bactericidal effect is achieved, the function ofthe crib is enriched, the crib is suitable for different working conditions, and better use prospects arebrought.

Owner:利辛县爱侣家俱加工有限公司

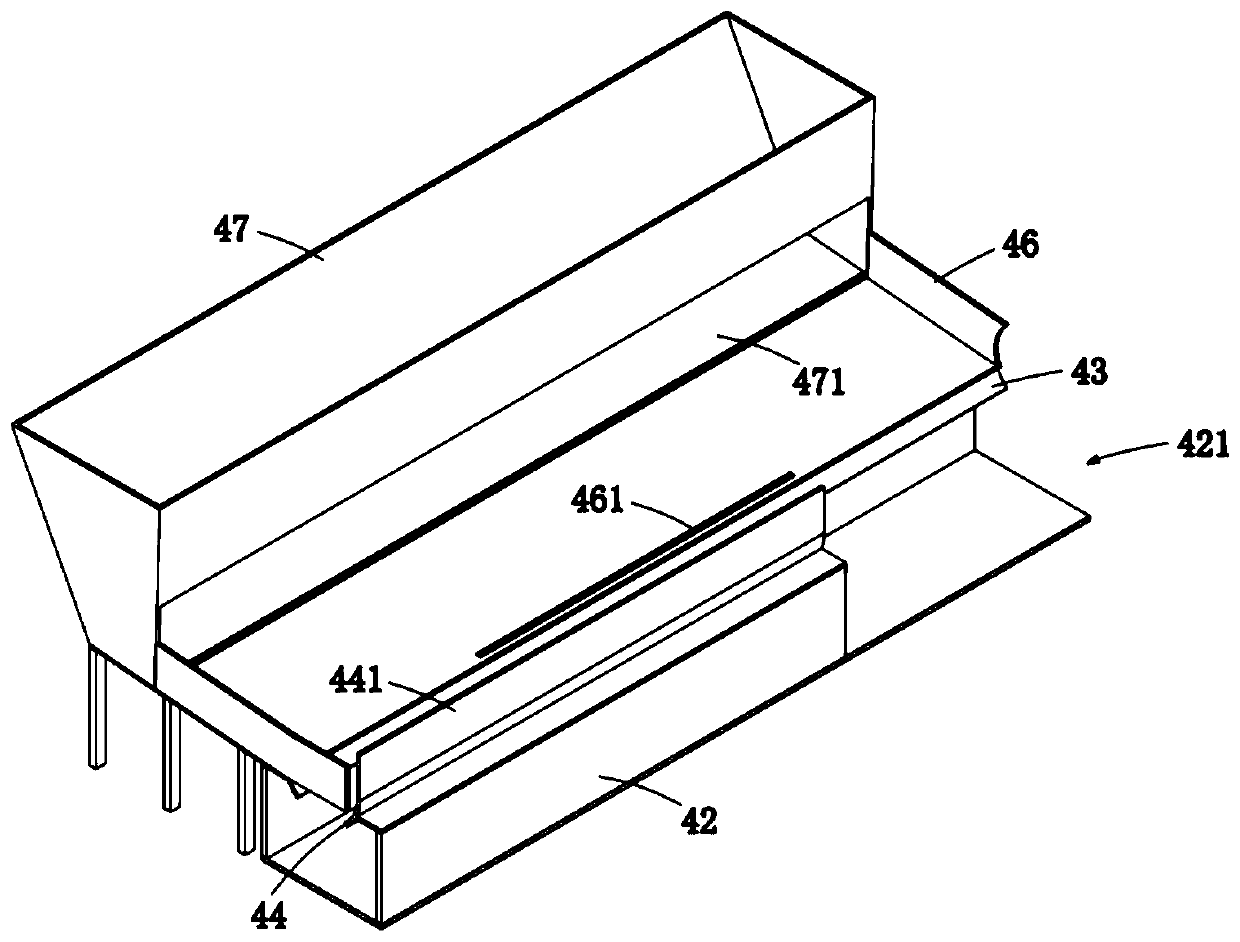

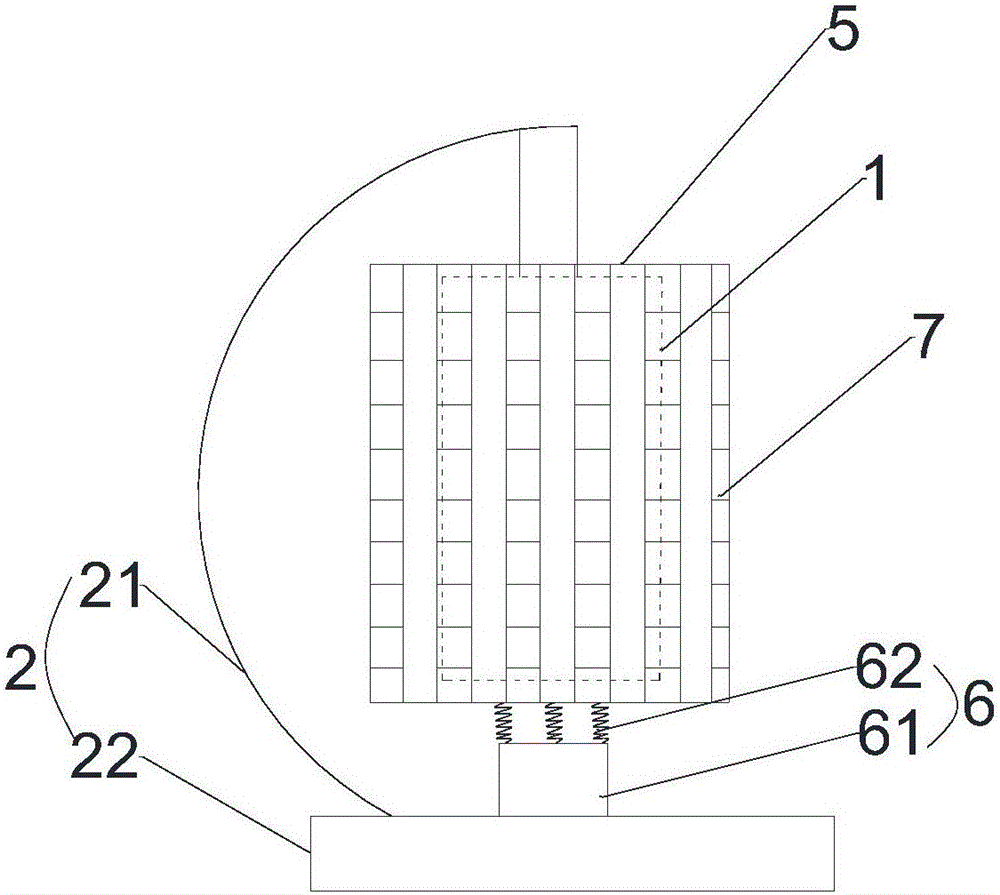

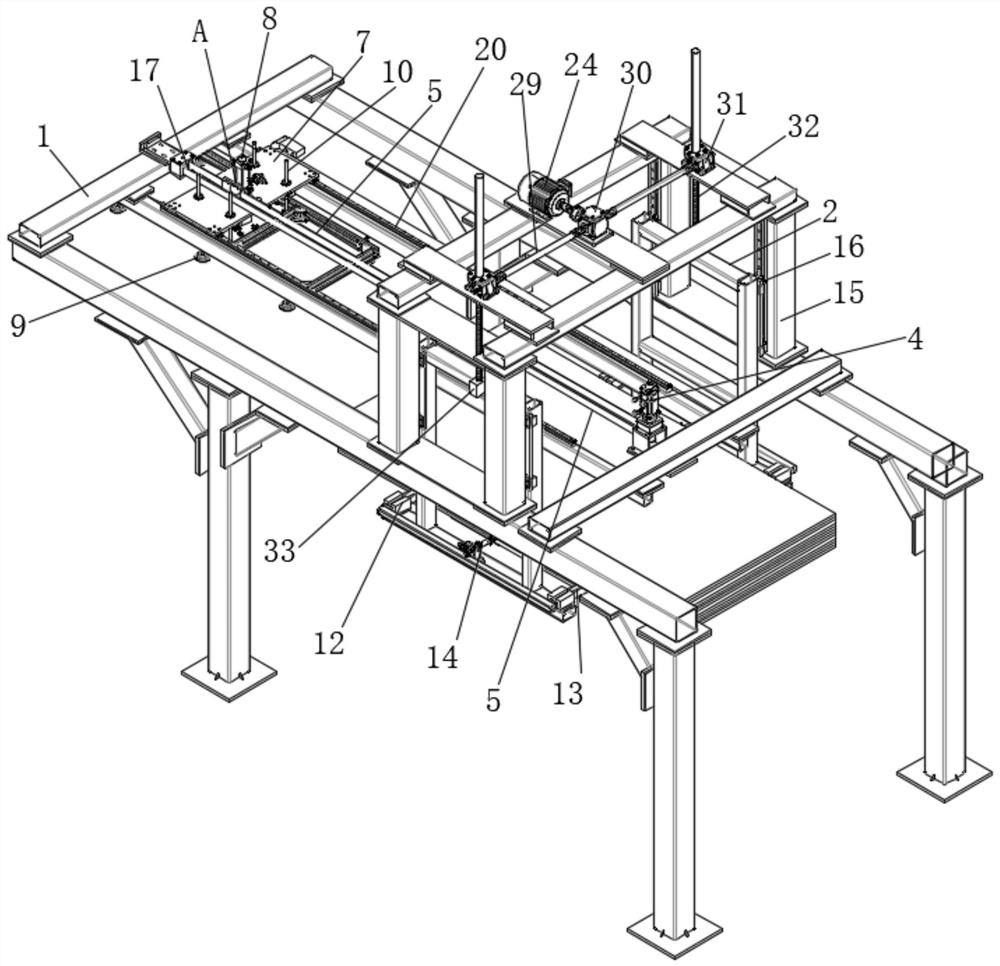

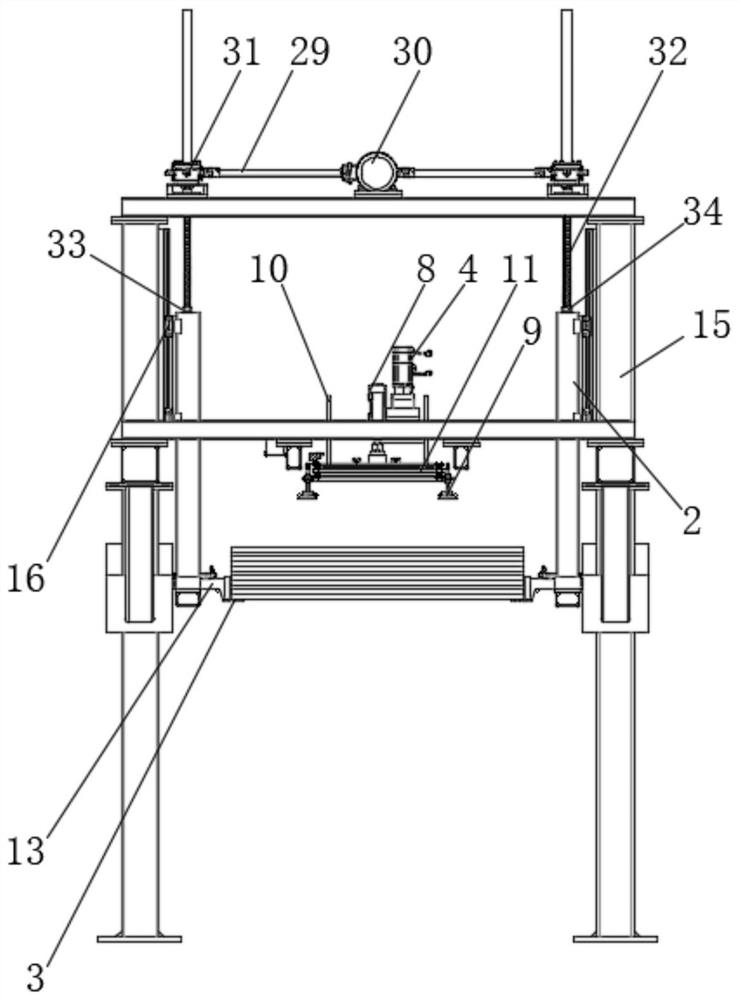

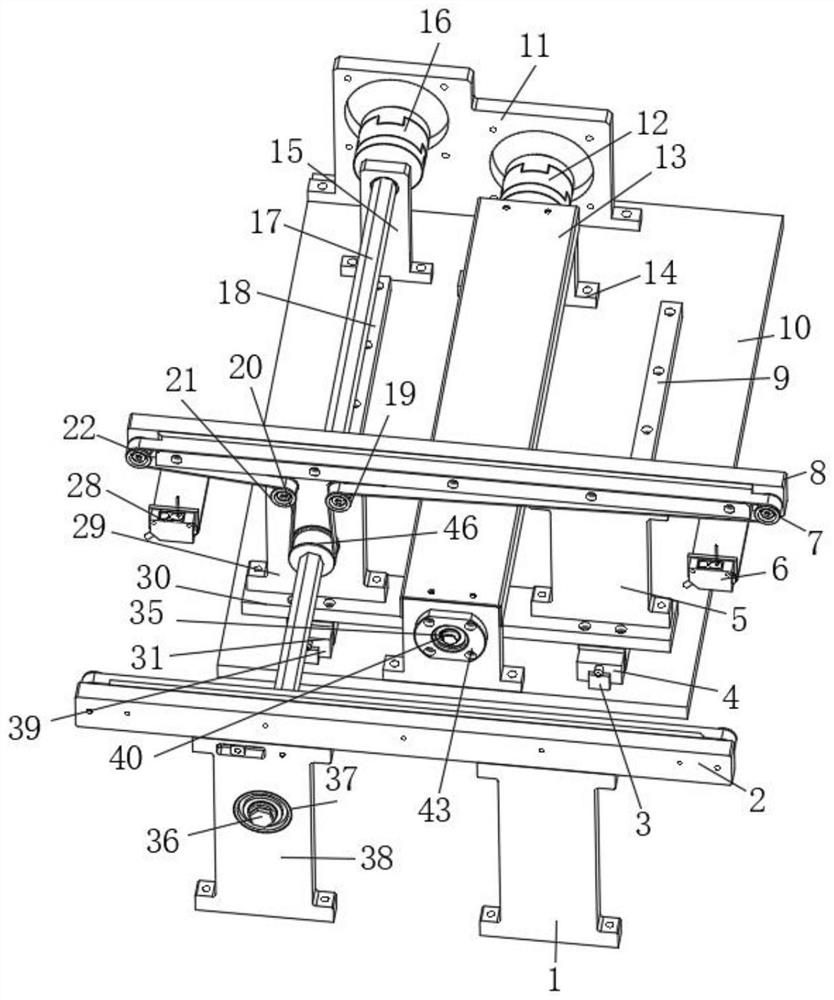

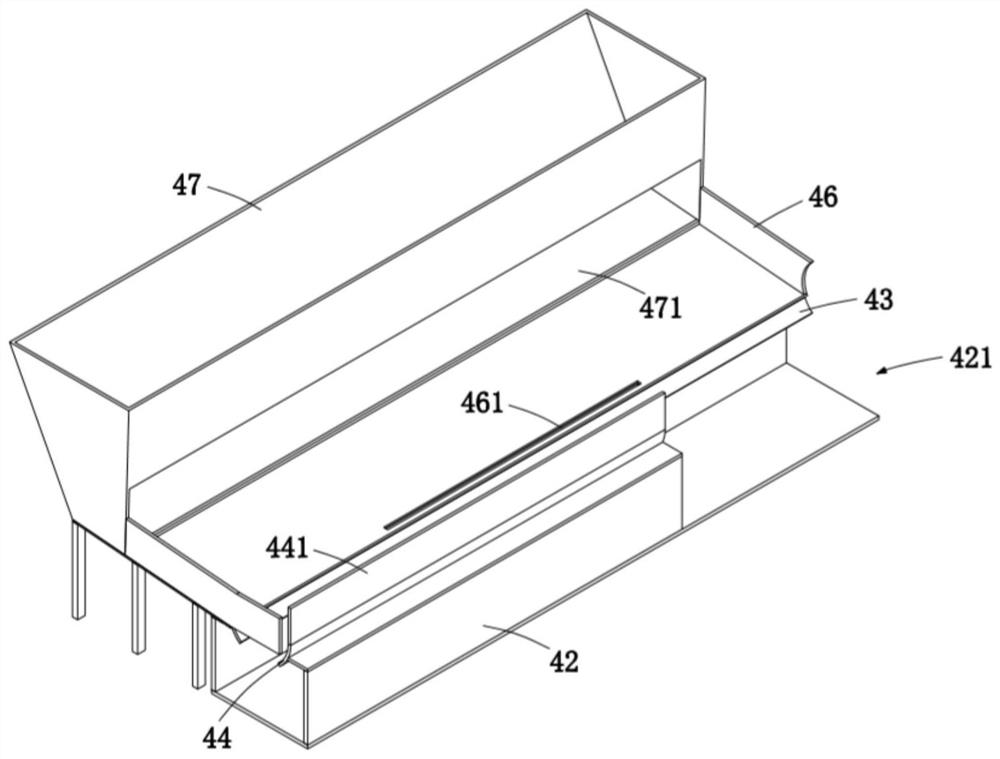

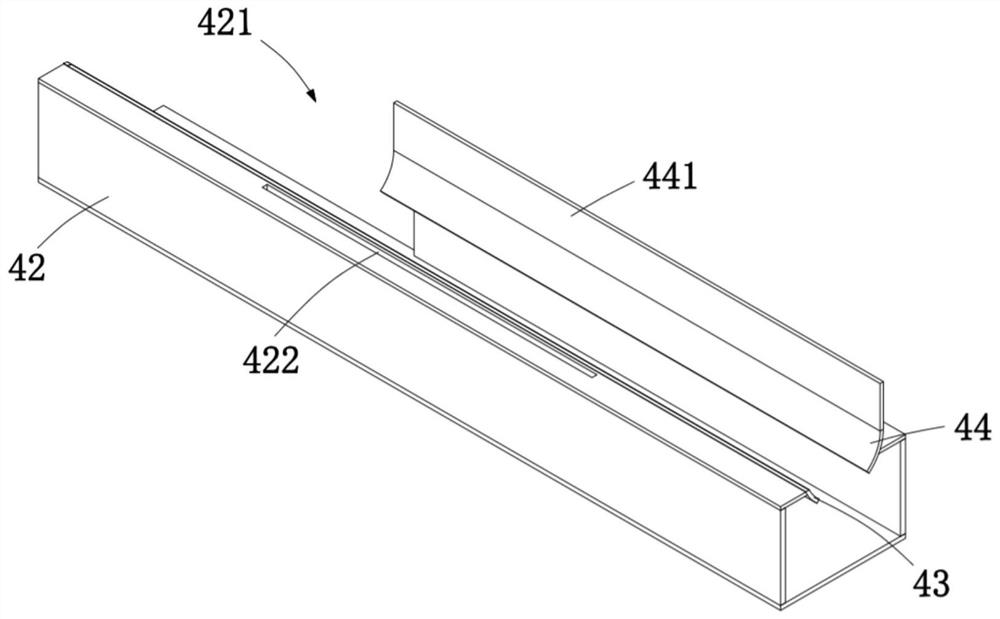

Paper tube finish cutting equipment with continuous loading and unloading functions

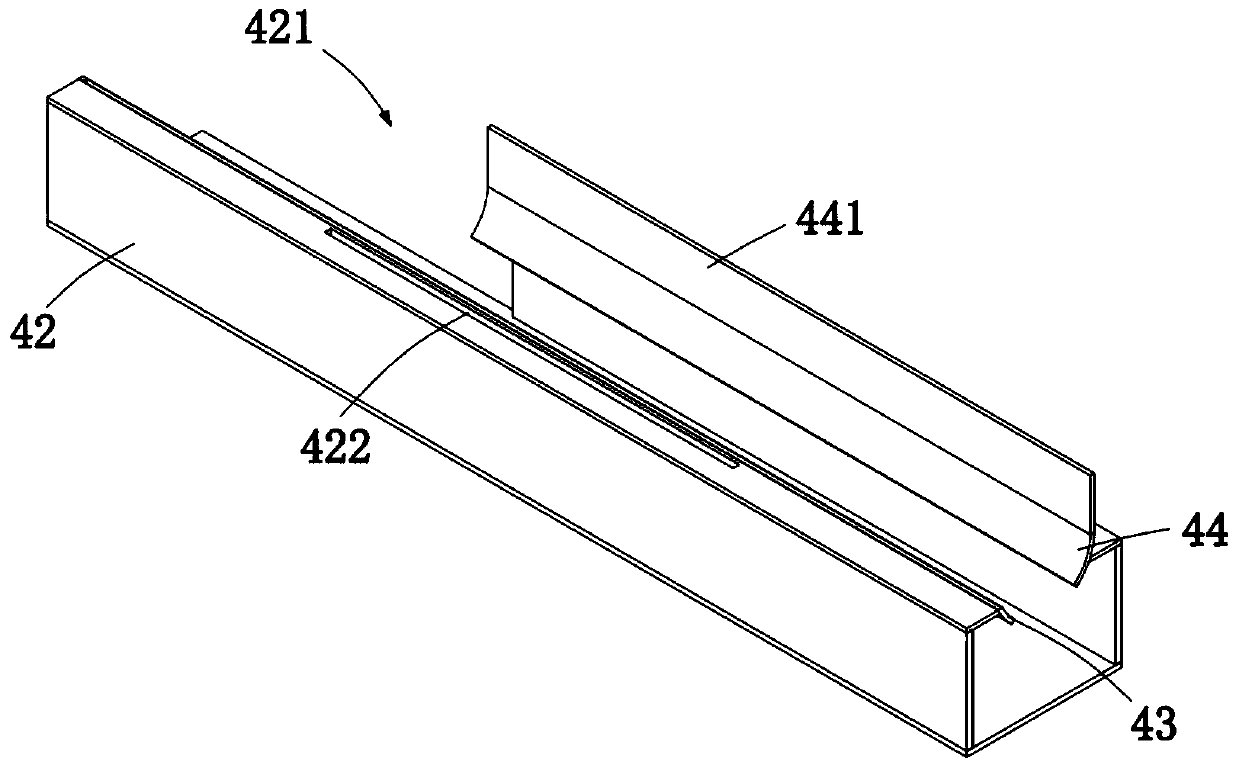

ActiveCN110682337AAffecting workRhythmicMetal working apparatusStructural engineeringMechanical engineering

The invention relates to paper tube finish cutting equipment with continuous loading and unloading functions. The equipment comprises a frame, a rotating module, a cutting module, an automatic loadingpart and a discharge module; the rotating module comprises a supporting module, a rotating roller and a limiting block; the cutting module comprises multiple cutters and a driving module; the automatic loading part comprises a support table, a bracket arranged on the support table, a first support plate, a second support plate, a horizontal driving module, a loading frame, and a loading box arranged at the end part of the loading frame; paper tubes in a loading box are input into the first support plate and the second support plate; then, the paper tubes in the first support plate and the second support plate sleeve the rotating roller through a horizontal driving module; then, the rotating roller drives the paper tubes to rotate, and is matched with the cutting module to cut the paper tubes; and after cutting of the paper tubes, the horizontal driving module is matched with the discharge module for centralized collection of the cut paper tubes.

Owner:嘉兴飞翔新材料股份有限公司

Continuous production type precoated sand core shooting machine

InactiveCN110280726AImprove efficiencyImprove securityMoulding machinesContinuous productionEngineering

The invention discloses a continuous production type precoated sand core shooting machine. The continuous production type precoated sand core shooting machine comprises a machine frame, a sand shooting assembly and a mold assembly, wherein the machine frame comprises a fixing base, side supporting plates and guide columns, the side supporting plates are symmetrically and fixedly connected to the left side and the right side of the fixing base, the guide columns are fixedly connected between the side supporting plates, material carrying plates and the sand shooting assembly are fixedly connected to the surface of the fixing base, the material carrying plates are symmetrically distributed above the sand shooting assembly, the sand shooting assembly comprises a sand storage box, a sand shooting air pump and a material conveying pipe, the side wall of the sand storage box is fixedly connected with the sand shooting air pump, the material conveying pipe is vertically and fixedly connected in the sand storage box, the mold assembly is located above the sand shooting assembly, and the mold assembly comprises movable mold plates, fixed mold plates and an air cylinder. According to the continuous production type precoated sand core shooting machine, the two sets of molds cooperate with the air cylinder for movement, so that the molds on the two sides perform production alternately, therefore, on one hand, continuous production can be performed without stopping conveniently, on the other hand, the rhythm of production is conformed, workers can take materials in production gaps conveniently, and the safety during material taking is improved.

Owner:新沂市天巍覆膜砂实业有限公司

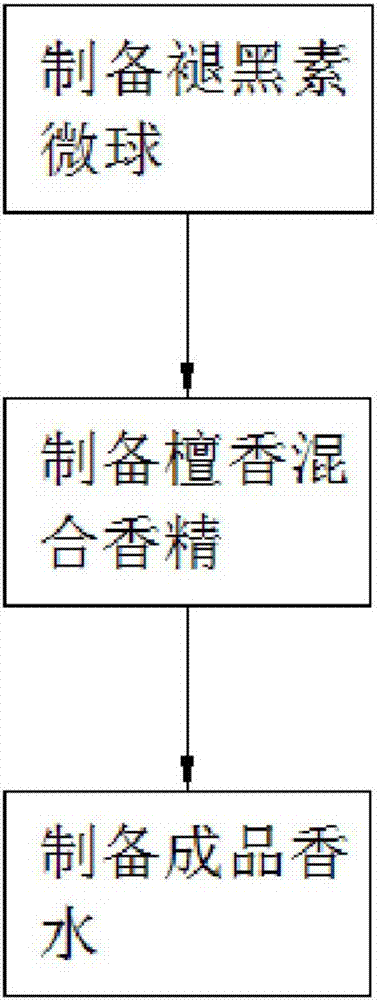

Melatonin slow-release nasal healthcare perfume with sleep promoting efficacy and preparation method

InactiveCN107184409AImprove sleepingAnti agingOrganic active ingredientsCosmetic preparationsNasal cavityPhysiology

The invention discloses melatonin slow-release nasal healthcare perfume with a sleep promoting efficacy and a preparation method. The healthcare perfume is prepared from the following raw materials in proportion by weight: 0.1 to 3 percent of melatonin, 1 to 5 percent of a traditional Chinese medicine additive with a nasal healthcare efficacy, 0.1 to 0.5 percent of santal mixed essence, 0.1 to 0.3 percent of a preservative, a proper amount of medicinal auxiliary materials, and slow-release auxiliary materials for the surplus. The healthcare perfume has efficacy of sleep promotion through the melatonin, has natural nasal healthcare efficacy through the additive, is diffused into the air in a perfume mode, is inhaled through respiratory tract nasal cavity, can bypass a blood brain barrier and enter the central nervous system, ensures that the maximum release amount is achieved after the perfume is used for 2 to 4 hours through release slow treatment, ensures that the concentration of the melatonin presents a high physical demand variation, and improves the sleep environment through different odor types of essences, thereby achieving the effect of sleep promotion and nasal health protection, and has the advantages that the perfume is convenient to carry, safe and non-toxic and nonirritating.

Owner:西宝生物科技(上海)股份有限公司

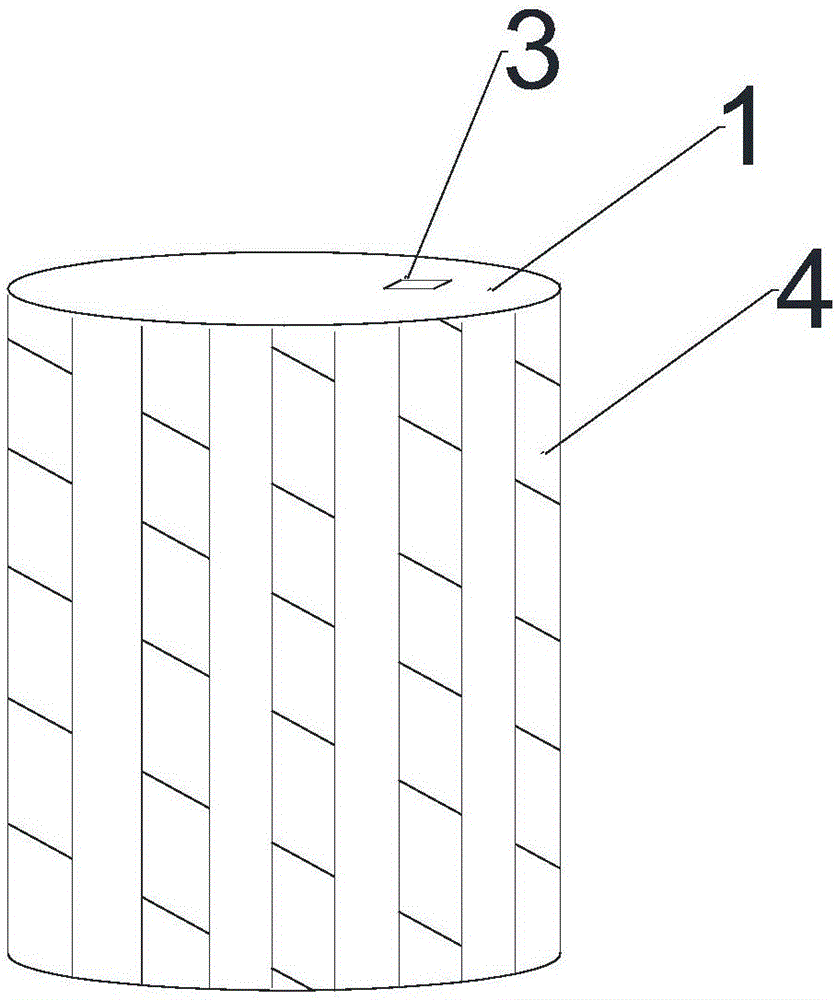

Dynamic stage lighting loudspeaker box

The invention discloses a dynamic stage lighting loudspeaker box. The dynamic stage lighting loudspeaker box comprises a cylindrical box body, a loudspeaker, a box body bracket, an interface, multiple light bands and a single chip microcomputer, wherein the mouth of the loudspeaker faces the bottom surface of the box body; the box body bracket comprises a base and a C-shaped support, one end of the C-shaped support is fixed on the base, and the other end of the C-shaped support is fixedly connected with the top end of the box body through a vertically arranged suspender, so that the box body is enabled to be located in a cambered surface of the C-shaped support and does not interfere with the C-shaped support; the interface is formed in the top surface of the box body and used for receiving frequency and amplitude of current signals for voice frequency and sound intensity conversion of external music; the multiple light bands are vertically embedded in the side wall of the box body at intervals in a circumferential direction of the side wall of the box body; the single chip microcomputer is arranged in the box body, an input end of the single chip microcomputer is electrically connected with the interface, an output end is electrically connected with multiple lamps, and the single chip microcomputer controls change of color and light brightness of the multiple lamps according to the change of frequency and amplitude of the current signals. The loudspeaker box is higher in ornamental value, extremely high in visual sense and rhythmicity and higher in interestingness.

Owner:北海威德电子科技有限公司

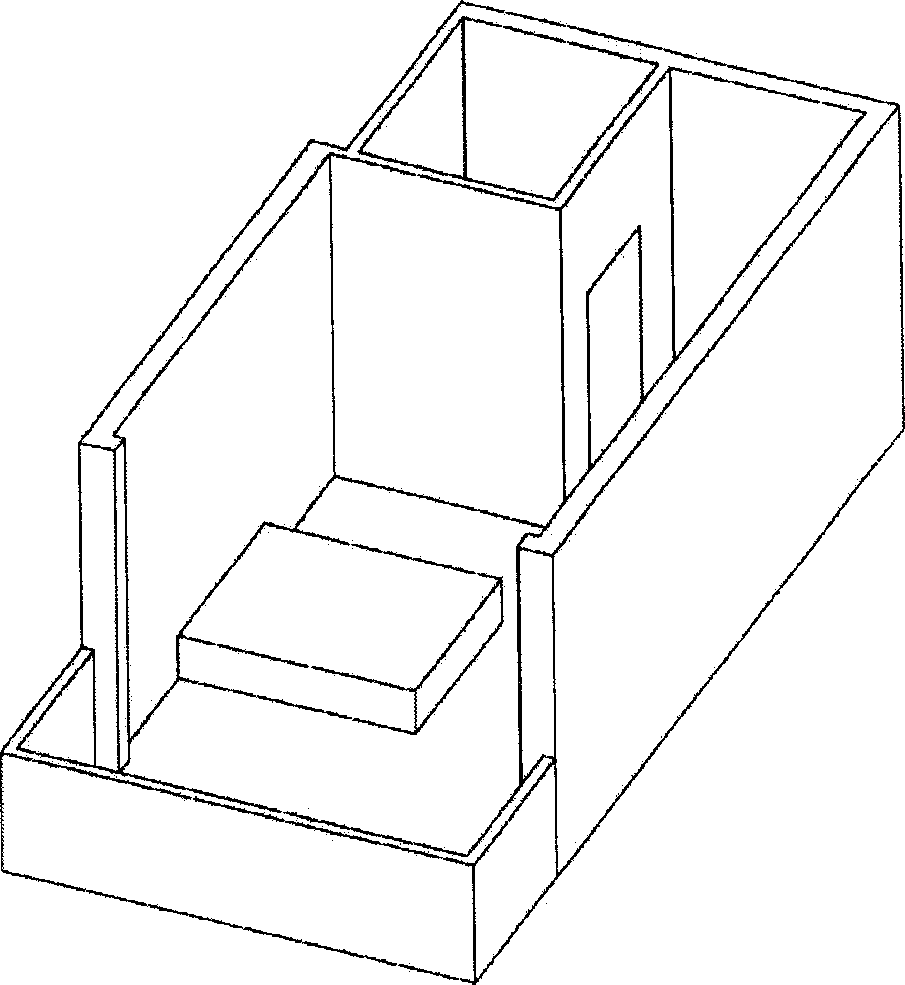

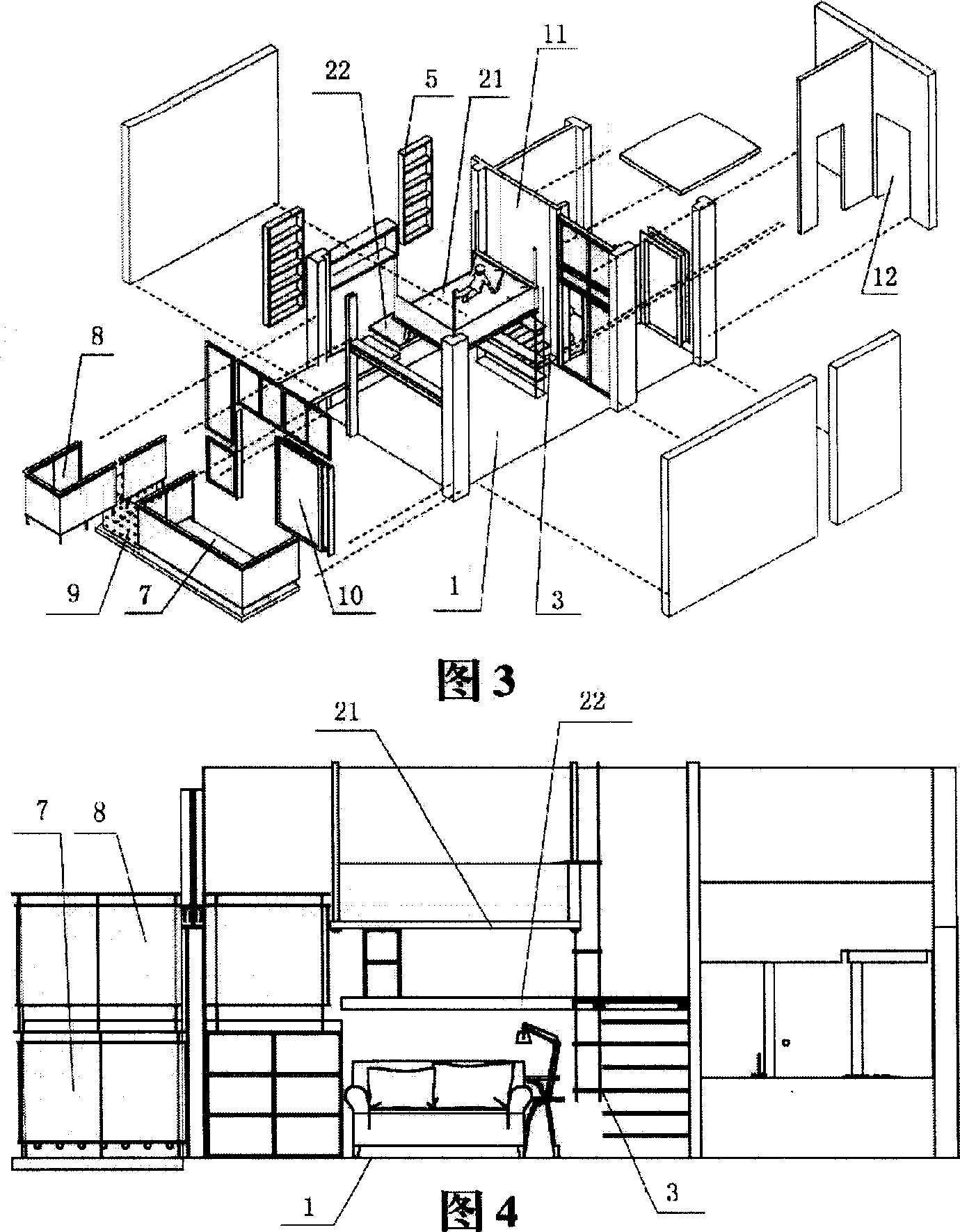

Spatial hotel type rooming houses

InactiveCN1873165AConvenient lifeWith villa outdoor landscape privatizationDwelling buildingEngineeringApartment house

An apartment house of three-dimensional hotel type is prepared as applying 3.6-4.0m as height of apartment house and applying 25-40sq.m as square area of apartment house; dividing said house to be three sections from entrance door to balcony as internal section being used to arrange kitchen at wall side and to arrange toilet at another side, middle section being used to arrange video device at wall side and to arrange local double layer with stair structure on 2.0m height at another side apace for placing beds and external section being used to arrange balcony for forming three- dimensional space.

Owner:巴硕建筑设计咨询(上海)有限公司

Chinese-character input method for computer

InactiveCN1391159ACoding is regularRhythmicInput/output processes for data processingSpeech recognitionConsonant

A Chinese-character input method for computer features that the strokes of Chinese characters are assinged to the numeral keys 1-9, and after the strokes of a Chinese character are input, its initial consonant is input. Its advantages are high regularity, less contents to be memorized, and convenient operation.

Owner:任成涵

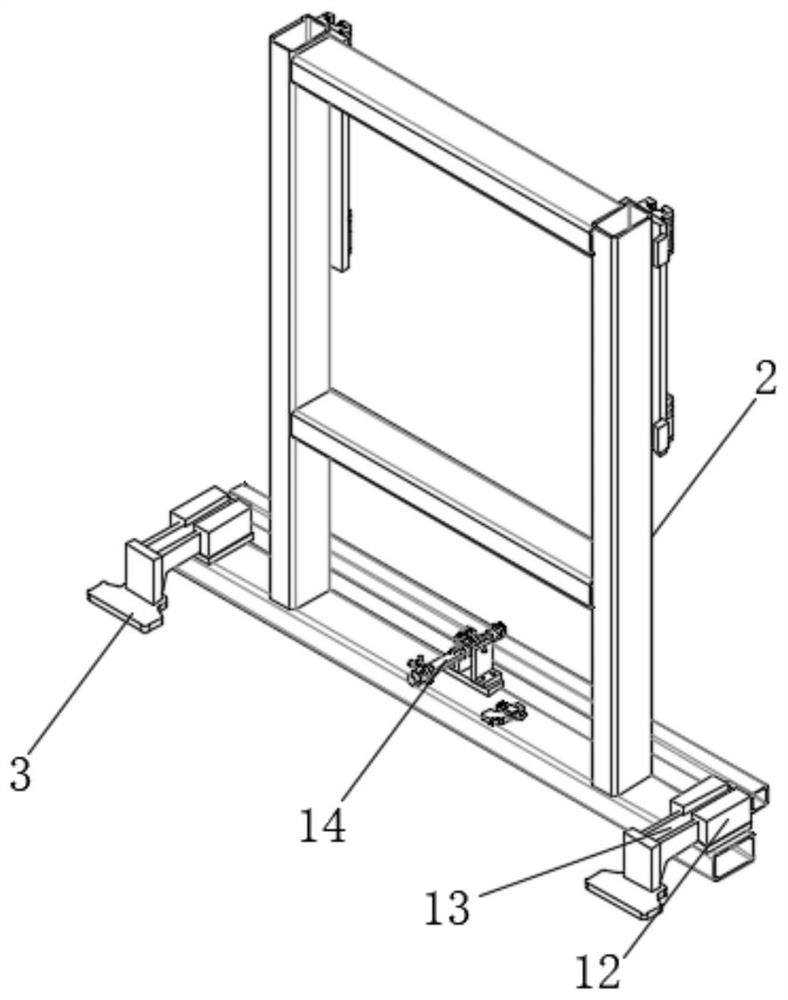

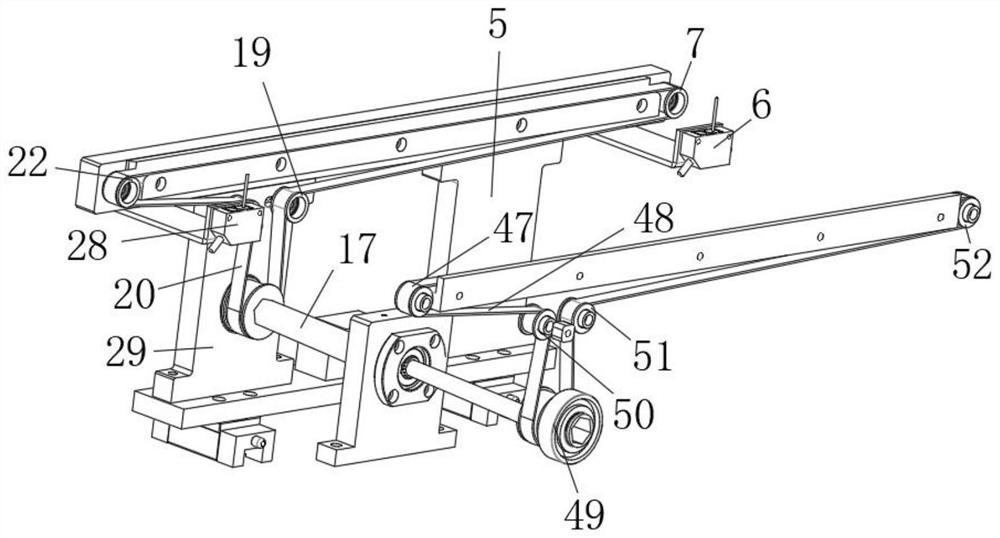

Board feeding device

PendingCN112124959AAdjustable working heightMeet operational requirementsStacking articlesConveyor partsMechanical engineeringWood plank

A board feeding device is used for solving the technical problem of low board conveying and feeding efficiency in the prior art mentioned in the background art, and comprises a support, a clamping assembly, a conveying assembly and an adsorption assembly. The clamping assembly comprises two opposite connecting frames and two opposite support plates; the two connecting frames are slidably connectedwith the support and can slide in the vertical direction; the two support plates are slidably connected with the two connecting frames in a one-to-one correspondence manner and can slide in the transverse direction for placing and clamping a board; the conveying assembly is arranged on the support and connected with the adsorption assembly for directionally conveying the adsorption assembly; andthe adsorption assembly is arranged on the support for adsorbing the board placed on the support plates. The board feeding device is rapid and easy to operate and mainly used for feeding the board.

Owner:JIAXING QUNLUN MACHINERY

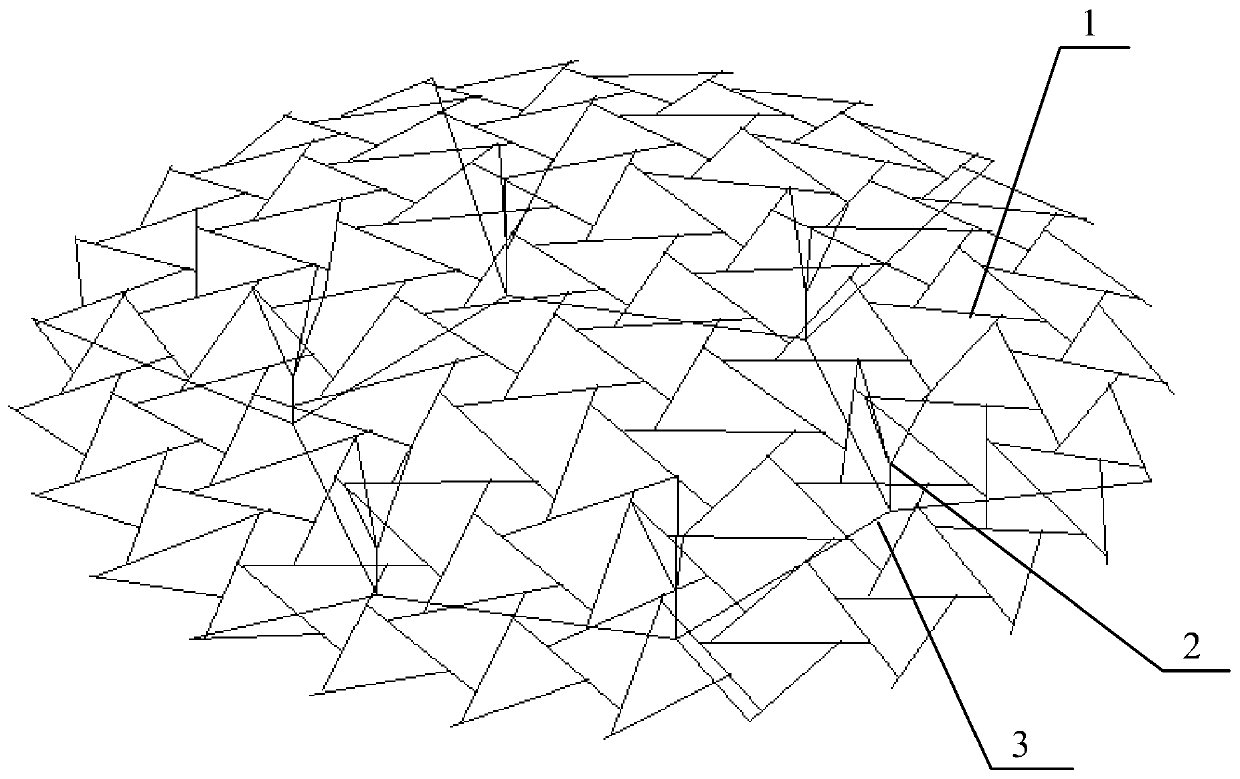

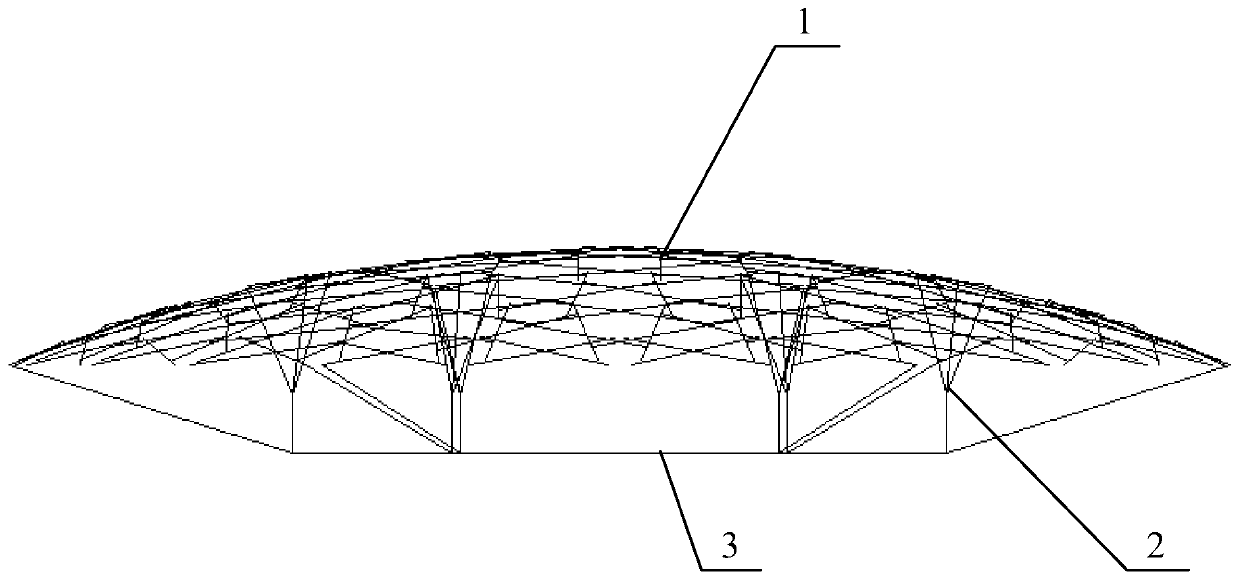

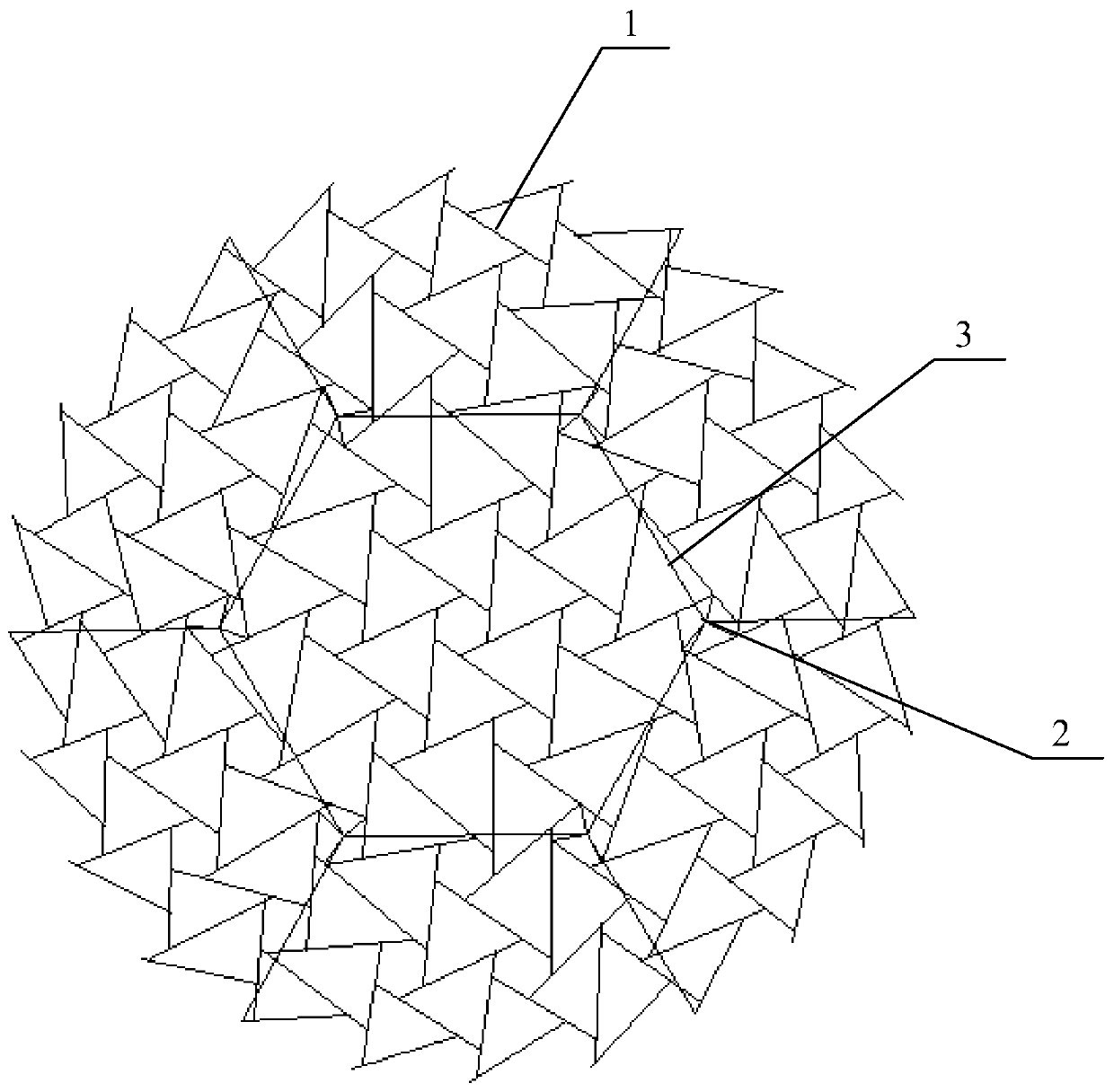

A mutual-supporting tension string reticulated shell structure

ActiveCN108018946BImprove mechanical propertiesMeet the design requirementsBuilding roofsArched structuresSpatial structureEngineering

The invention provides a mutually-bearing type string reticulated shell structure and relates to a space structure system. The mutually-bearing type string reticulated shell structure aims to solve the problems that an existing string reticulated shell structure is simplex in grid mode, poor in supporting rod stability and low in material utilization rate. The mutually-bearing type string reticulated shell structure comprises an upper string mutual bearing grid assembly, a plurality of tree-shaped supporting rod assemblies and a plurality of lower string cables. The multiple tree-shaped supporting rod assemblies are evenly arranged at the lower end of the upper string mutual bearing type grid assembly in the circumferential direction, the lower ends of every two adjacent tree-shaped supporting rod assemblies are connected through the corresponding lower string cable, and the lower end of each tree-shaped supporting rod assembly is connected with the nearest end of the edge of the upperstring mutual bearing grid assembly through the corresponding lower string cable. The mutually-bearing type string reticulated shell structure is used for constructing the space structure system.

Owner:黑龙江省工研院资产经营管理有限公司

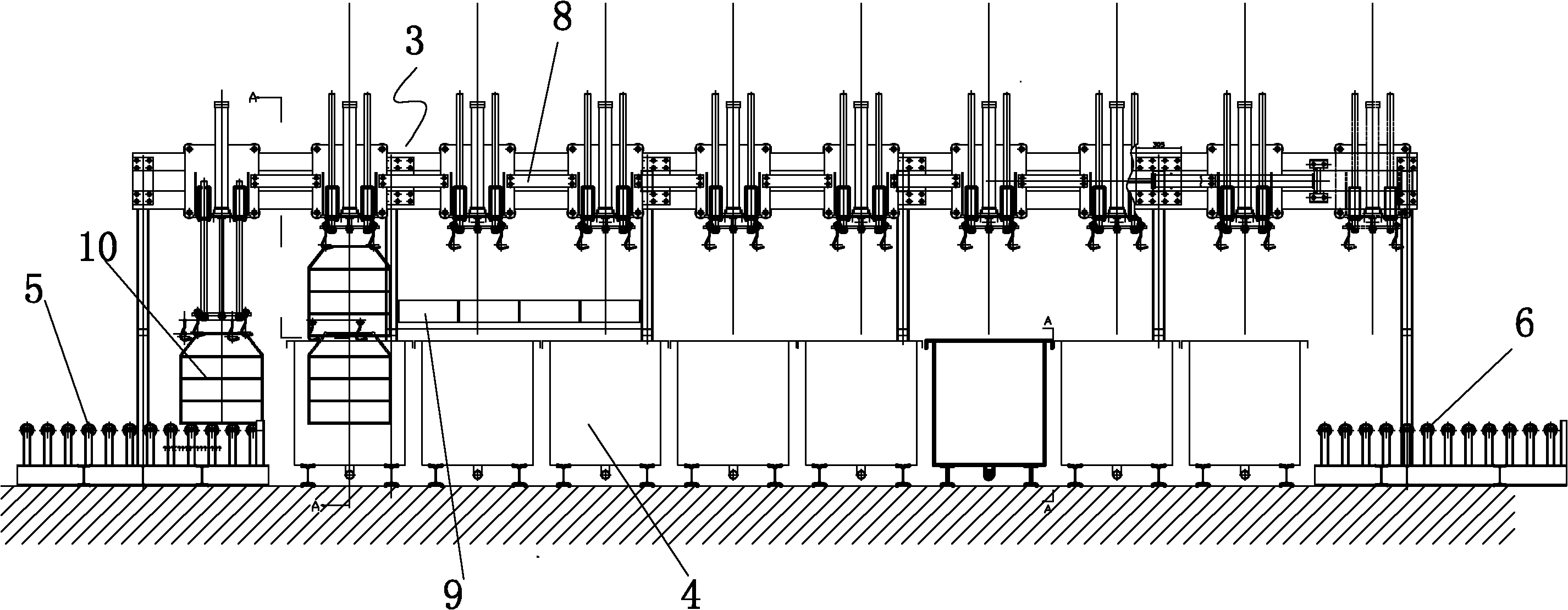

Automatic washing device of cantilever structure

ActiveCN101984141BThe overall structure is simple and reliableLow costCantilevered beamHydraulic cylinder

The invention relates to an automatic washing device of a cantilever structure, which is characterized by mainly comprising a frame-type rack, a plurality of pneumatic lifting mechanisms, a hydraulic translation mechanism, a washing tank, a basket conveying roller way and a basket returning roller way, wherein, the hydraulic translation mechanism consists of a hydraulic cylinder, a cantilever beam guide rail, roller groups and a connecting plate; the cantilever beam guide rail is fixedly connected with the upper part of the frame-type rack to form the cantilever structure, and the cantilever beam guide rail is connected with the upper roller group and the lower roller group in a rolling manner; the upper roller group and the lower roller group are fixedly connected with the connecting plate through a support respectively; the connecting plate is fixedly connected with the pneumatic lifting mechanisms; and the piston of the hydraulic cylinder is fixedly connected with the connecting plate. The automatic washing device has the beneficial effects that the pneumatic-hydraulic cantilever beam structure is adopted, thus achieving simple and reliable structure and low cost; an adjustable time relay is adopted for controlling washing time, thus ensuring stable quality and good consistency; and a programmable controller is adopted for controlling the whole washing device, thus achieving less labor consumption, high yield, strong rhythm and stable production.

Owner:天津锐新昌科技股份有限公司

Adjustable assembly line table bed and using method

The invention discloses an adjustable assembly line table bed. The bed comprises a first supporting leg plate, a first sliding rail, a first clamping block, a second supporting leg plate, a first button module, a first buffer pillow, a first upper transmission auxiliary shaft, a bearing bottom plate, a transmission shaft shell, a first supporting plate and a second supporting plate. The first sliding rail is arranged at the upper end of the first supporting leg plate, a hand clamping plate is arranged at the lower end of the first sliding rail, the first clamping block is arranged at one end of the hand clamping plate, the second leg supporting plate is arranged at one end of the first clamping block, the first button module is arranged at the upper end of the second leg supporting plate, the first upper transmission auxiliary shaft is arranged at the upper end of the first button module, the second sliding rail is arranged at one end of the first upper transmission auxiliary shaft, the first buffer pillow is arranged at the lower end of the second sliding rail, the bearing bottom plate is arranged at the lower end of the first buffer pillow, and a module supporting frame is arranged at one end of the bearing bottom plate. The table bed has the advantages of facilitating cleaning of a transmission belt, reducing workload of workers, being high in stability and improving working efficiency.

Owner:任峰

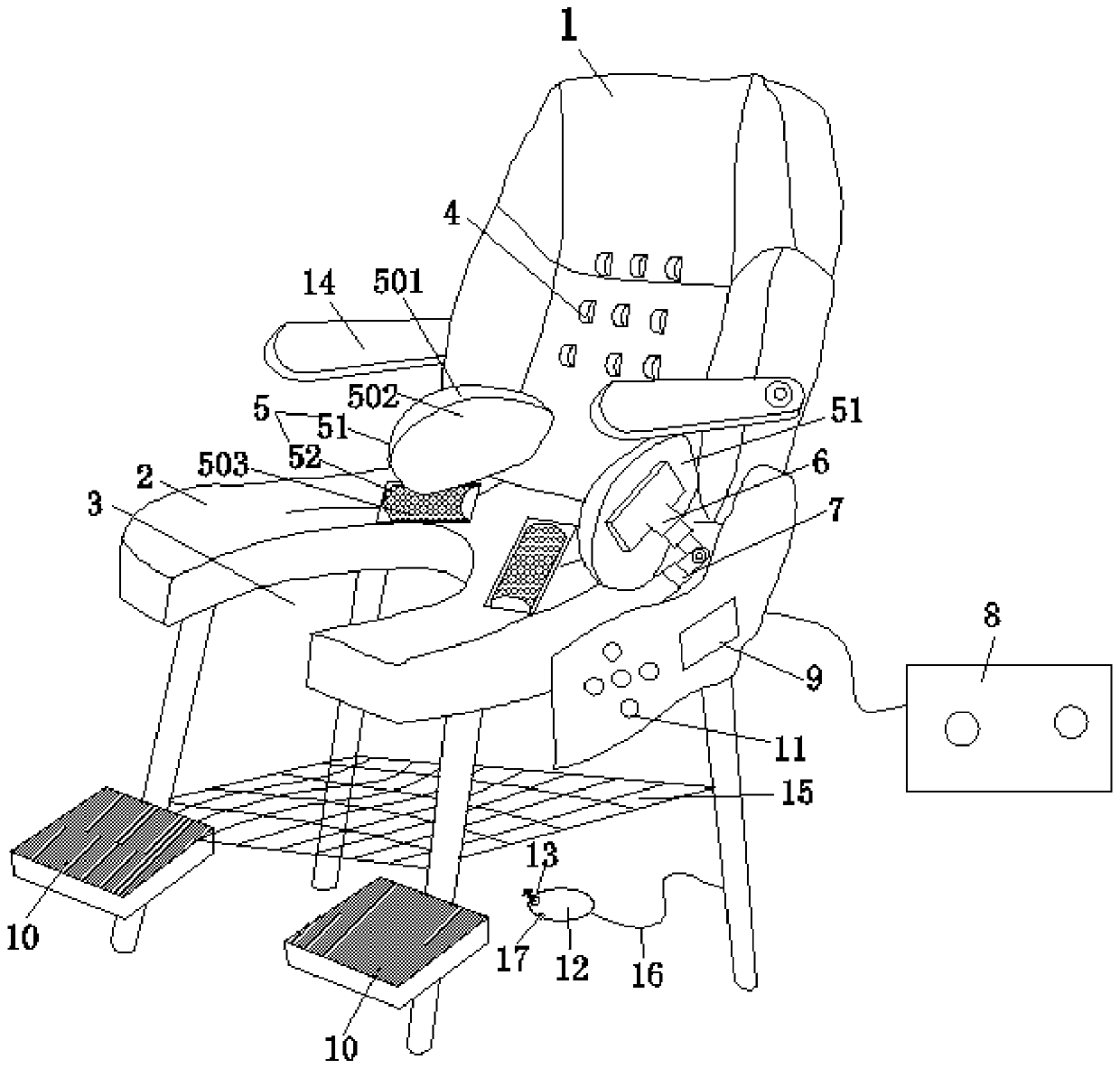

Pain-relieving delivery chair

PendingCN109893395AFull massageEase labor painsOperating chairsDental chairsObstetricsMedical equipment

The invention relates to the technical field of painless delivery medical equipment, in particular to a pain-relieving delivery chair. The delivery chair comprises a chair body, wherein the chair bodycomprises a chair back and a seat, the middle of the seat is hollowed out to form a midwifery channel, and the seat is provided with a pelvic massager; the pelvic massager comprises an iliac crest massager and an ischial tuberosity massager, the iliac crest massager is located on the left side and the right side of the seat, and the iliac crest massager can simultaneously press the bilateral iliac crests of a lying-in woman to opposite sides so as to slightly narrow the upper part of the pelvis, loosen sacroiliac joints and widen the midpelvis and the transverse outlet; the ischial tuberositymassager is located on the board surface of the seat and can push the ischial tuberosity of the lying-in woman to release the pelvic floor space, relieve ligament pressure and facilitate rotation ofthe fetal head. The seat is provided with a controller connected with the pelvis massager. The delivery chair can relieve delivery pain and accelerate the delivery process, and has the characteristicsof being safe and high in applicability and saving labor.

Owner:GUANGZHOU MEDICAL UNIV

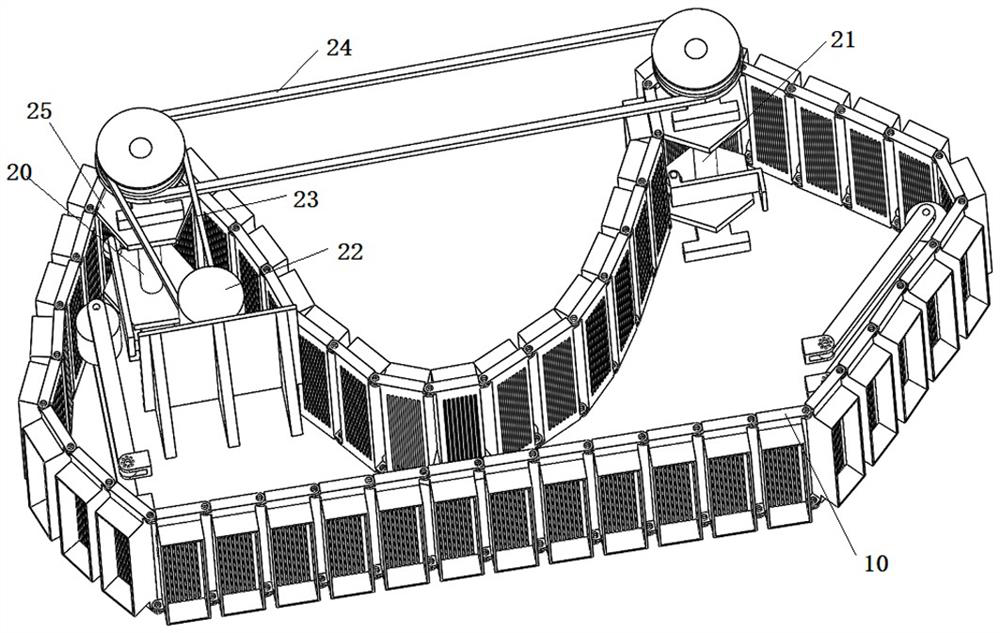

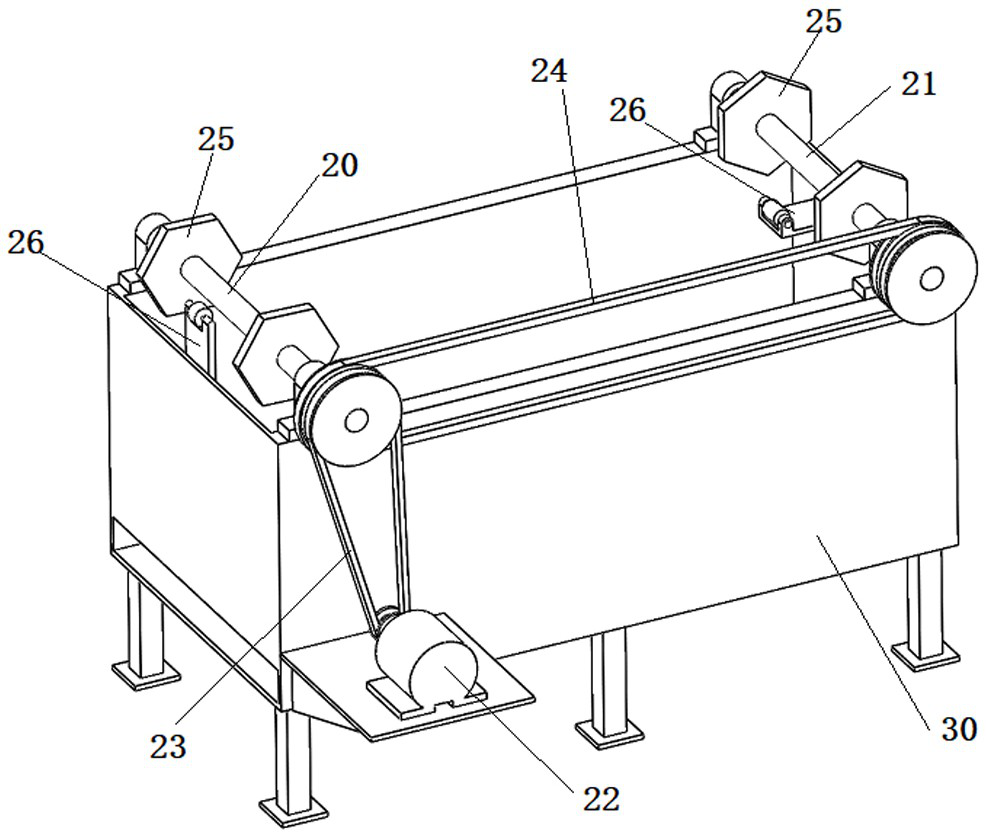

Conveying device of boiling pool for livestock and poultry meat processing line

InactiveCN112124965ACook evenlyMeet the needs of useConveyorsCharge manipulationPoultry meatLivestock

The invention discloses a conveying device of a boiling pool for a livestock and poultry meat processing line, and relates to the field of livestock and poultry meat automatic production equipment. The conveying device comprises a conveying belt and a transmission mechanism; the conveying belt comprises a plurality of chain plates, and the chain plates are sequentially hinged; the transmission mechanism comprises a driving shaft, a driven shaft, a power device, a driving belt transmission device and a driven belt transmission device; the driving shaft and the driven shaft are arranged in parallel; the power device is in transmission connection with the driving shaft through the driving belt transmission device; the driving shaft is in transmission connection with the driven shaft through the driven belt transmission device; the rotating speed of the driving shaft and the driven shaft is the same; transmission plates are fixedly arranged at the two ends of the driving shaft and the twoends of the driven shaft correspondingly and are in a regular polygon shape; the conveying belt is erected on the transmission plates; and every two adjacent chain plates can be matched with the two adjacent sides of the transmission plates respectively. The conveying device of the invention can achieve uniform cooking of meat, guarantees the cooking effect, achieves automatic assembly line work,and can be directly connected to an automatic production line for use.

Owner:珙县鑫诚食品有限责任公司

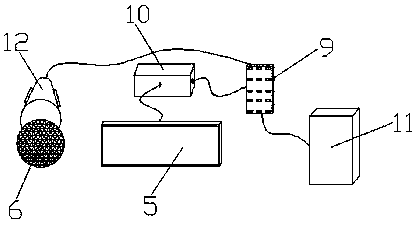

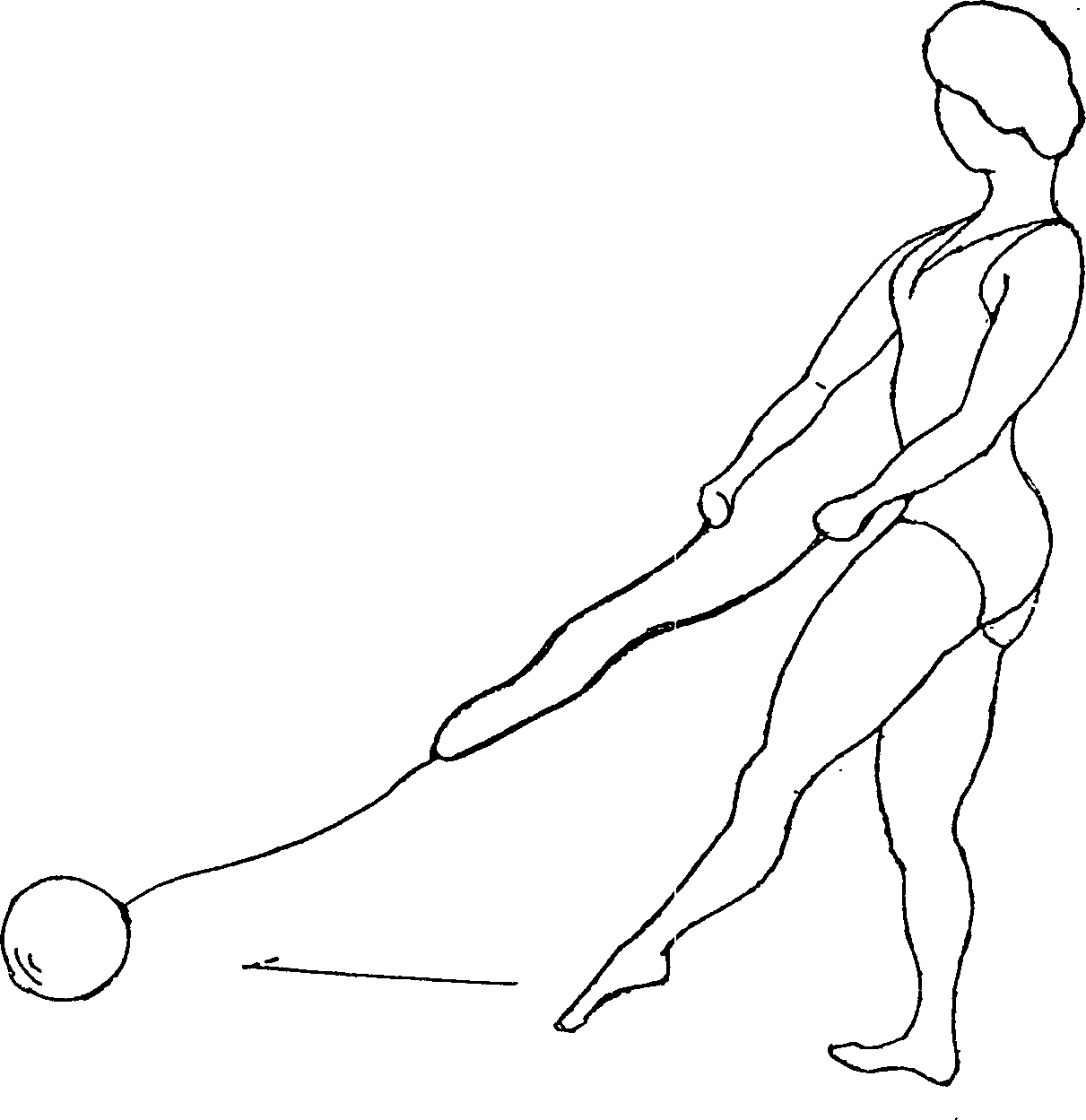

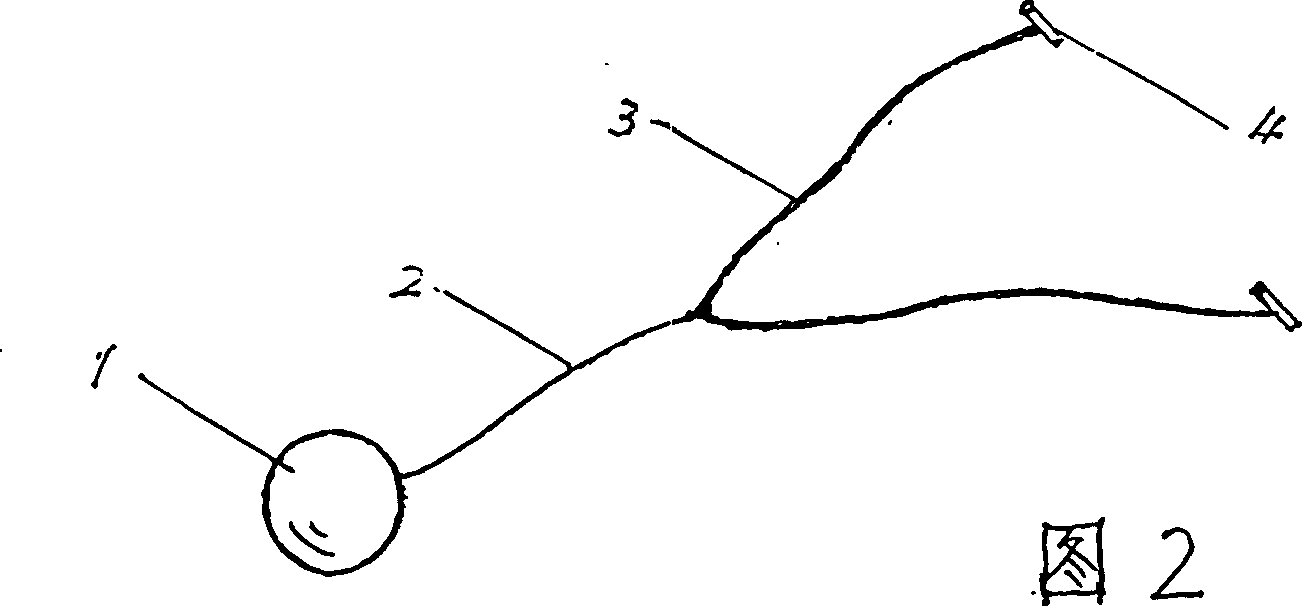

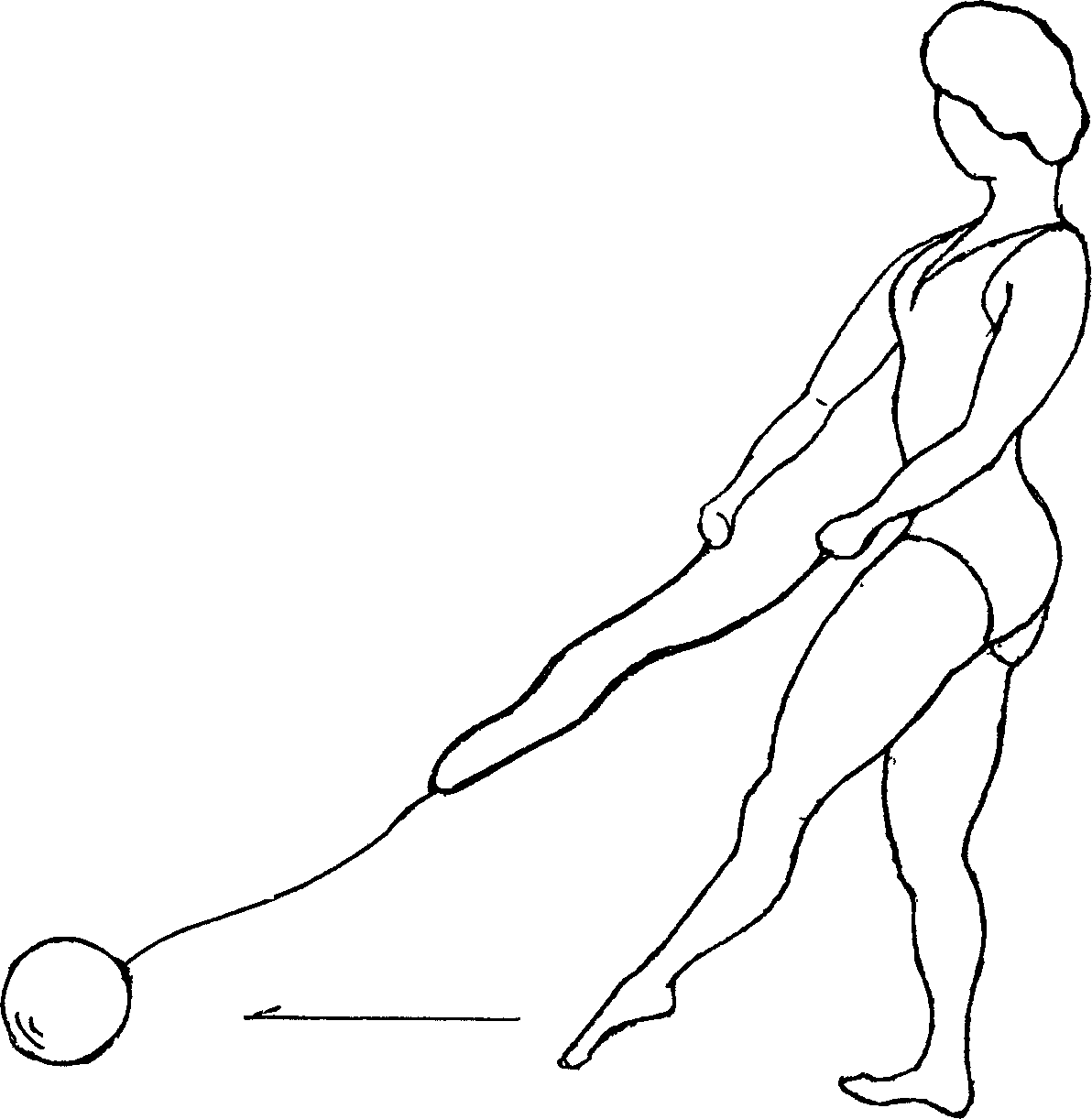

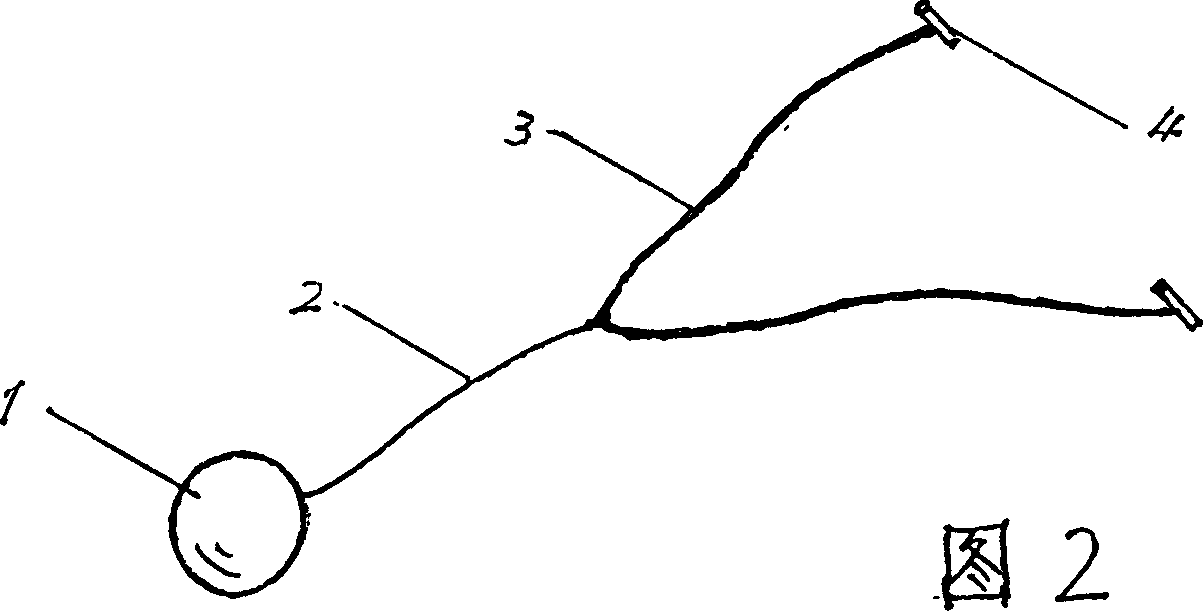

Free-kick ball

The invention is a personal kicked ball for health, using a ball only proper for kicking to link with one end of one rope less than one meter, the other end of the rope linked with the middle point of the other rope (or elastic) whose length is equal to the width when extending two arms horizontally and whose two ends have handles. When kicking, two hands hold the handles and two arms extend forward to slide the ball forward. The ball slides, not far away, and is pulled by the rope, here if you extend two arms, the ball surely returns to the foot and then is kicked successively. It has three breakthroughs compared with the football: 1, making ball kicking enter family; 2, making the average middle-old aged all able to enjoy kicking ball, even the handicapped; 3, combining ball kicking with music. At present, it has 8 kicking methods. The young can make more difficult action by it.

Owner:高锡庚

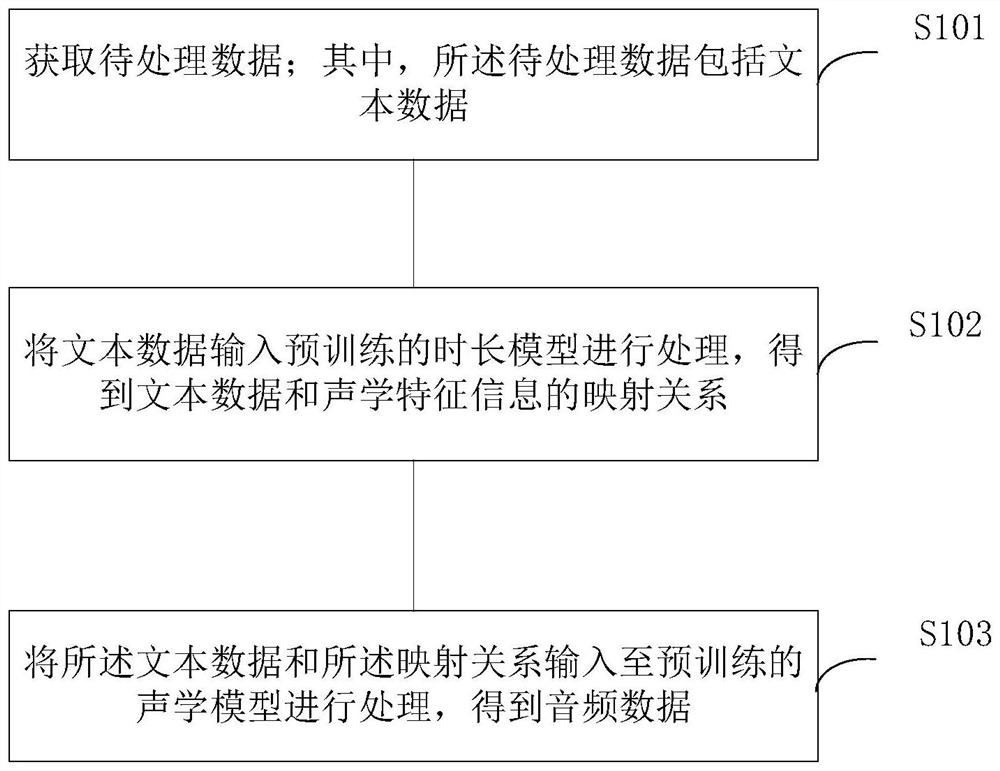

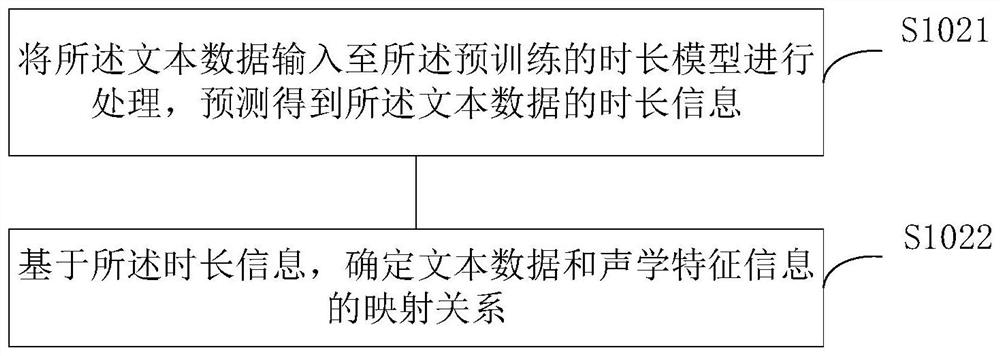

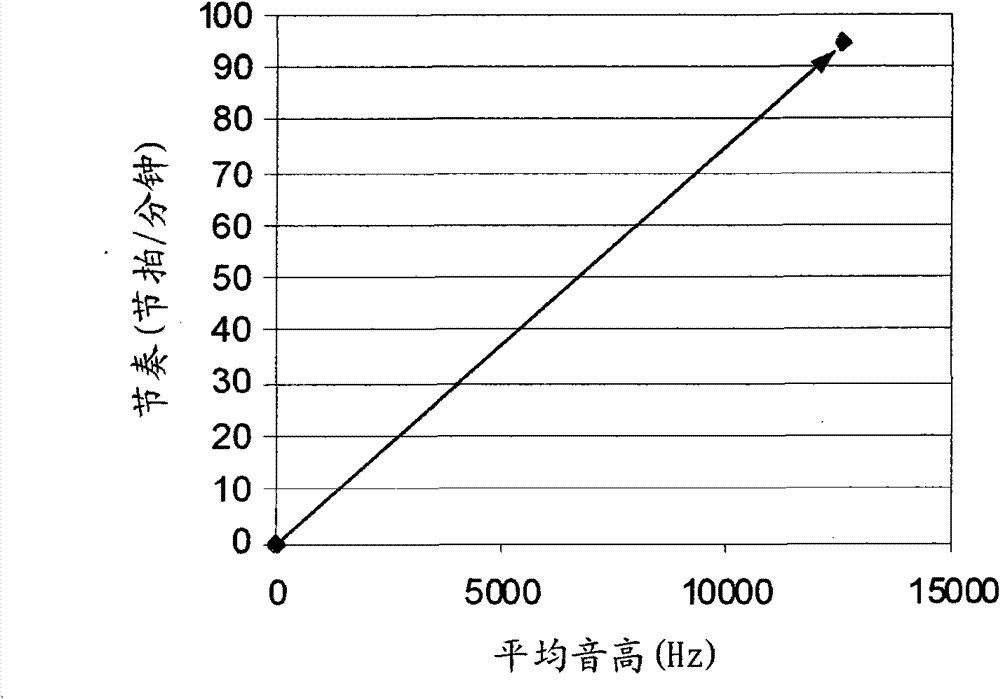

Audio synthesis method and device based on duration information and terminal equipment

The invention is suitable for the technical field of audio synthesis, and provides an audio synthesis method and device based on duration information and terminal equipment, and the method comprises the steps: obtaining text data, inputting the text data into a pre-trained duration model for processing, and obtaining a mapping relation between the text data and acoustic feature information, and inputting the text data and the mapping relationship into a pre-trained acoustic model for processing to obtain audio data. And performing feature extraction on the text data through the duration model, determining the duration information of the text data, and determining the mapping relationship between the text data and the corresponding acoustic feature information based on the duration information, thereby obtaining the audio data corresponding to the text data based on the acoustic model. Strong supervision signals are provided for alignment processing of the text data and the voice data, the alignment problem in voice synthesis is obviously reduced, and the audio data which are completely close to the rhythm of human voice and better in rhythm are output.

Owner:UBTECH ROBOTICS CORP LTD

Externally-assisted vibrating feeder

The invention discloses an externally-assisted vibrating feeder which comprises a feeding compartment body, the underside of one end of the feeding compartment body is erected on an installed crusher driving shaft mechanism through a docked connecting rod device, and the other end of the feeding compartment body is erected on an installed crusher rack through an adjustable supporting device. According to the invention, through skillfully using the linked fixed installation of the feeder and a crusher, synchronously operating and using realistic conditions, removing a vibration exciter and adding a docked connecting rod device, a feeding operation is completed by using an exciting force generated by the rotary motion of the crusher driving shaft mechanism. In such a way, the feeder becomes extremely concise and light, the equipment manufacturing and running costs are greatly reduced, and the application and maintenance of the feeder are more convenient. Due to the versatility of the docked connecting rod device, the docked connecting rod device can be widely matched with different types of crushers (such as impact crushers and hammer crushers) for using purpose.

Owner:YIWU BLACK AND WHITE MINING MACHINERY

Lightweight multi-speaker speech synthesis system and electronic equipment

A lightweight multi-speaker speech synthesis system and electronic equipment, the system comprises: a text feature extraction and regularization module, a speaker feature extraction module, a feature fusion module and a speech generation module. The text feature extraction and regularization module is used to use a lightweight encoder to encode and extract the text information to be processed, and use a lightweight duration prediction network to perform each word corresponding to the text deep features output by the lightweight encoder. Or phoneme for duration prediction, and for length warping to obtain regular text features with the same length as the target mel spectrum. The speaker feature extraction module is used to generate features that can characterize the target speaker. The feature fusion module is used to fuse the features of the target speaker with regular text features. The speech generation module is used to perform deep feature extraction, dimension mapping, residual integration and speech generation on the fused features. The system supports multi-speaker speech synthesis and the synthesis speed is fast.

Owner:XIAMEN UNIV

Free-kick ball

The invention is a personal kicked ball for health, using a ball only proper for kicking to link with one end of one rope less than one meter, the other end of the rope linked with the middle point of the other rope (or elastic) whose length is equal to the width when extending two arms horizontally and whose two ends have handles. When kicking, two hands hold the handles and two arms extend forward to slide the ball forward. The ball slides, not far away, and is pulled by the rope, here if you extend two arms, the ball surely returns to the foot and then is kicked successively. It has three breakthroughs compared with the football: 1, making ball kicking enter family; 2, making the average middle-old aged all able to enjoy kicking ball, even the handicapped; 3, combining ball kicking with music. At present, it has 8 kicking methods. The young can make more difficult action by it.

Owner:高锡庚

Method and apparatus for updating prototypes

InactiveCN101828183BRhythmicWeak sense of shockMetadata multimedia retrievalSpecial data processing applicationsTheoretical computer scienceDigital object

An apparatus and method for machine-updating of prototypes - for example, during design of digital objects, or content-management - has input means (15) for inputting descriptive classifiers (tags) that a user assigns to prototypes and a tag model generator (20) that uses machine learning techniques to produce a model of the association between the assigned tags and the values of quantifiable, non-subjective attributes of the tagged prototypes. In order to obtain a desired updating of a current prototype, the user issues a command which defines the desired variation of the current prototype by referring to one or more conditions that should be met by specified tags of the updated prototype. The prototype-updating apparatus / method has a prototype updater (30) that identifies a suitable updated prototype whose tags meet the condition(s) specified in the user's command and which, globally, is fairly similar to the pre-update prototype. The user can, thus, express instructions for prototype-updating using his own terminology.

Owner:索尼欧洲有限公司

Automatic washing device of cantilever structure

ActiveCN101984141AThe overall structure is simple and reliableLow costHydraulic cylinderAtmospheric pressure

The invention relates to an automatic washing device of a cantilever structure, which is characterized by mainly comprising a frame-type rack, a plurality of pneumatic lifting mechanisms, a hydraulic translation mechanism, a washing tank, a basket conveying roller way and a basket returning roller way, wherein, the hydraulic translation mechanism consists of a hydraulic cylinder, a cantilever beam guide rail, roller groups and a connecting plate; the cantilever beam guide rail is fixedly connected with the upper part of the frame-type rack to form the cantilever structure, and the cantilever beam guide rail is connected with the upper roller group and the lower roller group in a rolling manner; the upper roller group and the lower roller group are fixedly connected with the connecting plate through a support respectively; the connecting plate is fixedly connected with the pneumatic lifting mechanisms; and the piston of the hydraulic cylinder is fixedly connected with the connecting plate. The automatic washing device has the beneficial effects that the pneumatic-hydraulic cantilever beam structure is adopted, thus achieving simple and reliable structure and low cost; an adjustable time relay is adopted for controlling washing time, thus ensuring stable quality and good consistency; and a programmable controller is adopted for controlling the whole washing device, thus achieving less labor consumption, high yield, strong rhythm and stable production.

Owner:天津锐新昌科技股份有限公司

A paper tube precision cutting equipment with continuous loading and unloading function

ActiveCN110682337BStable supportStable outputMetal working apparatusStructural engineeringMechanical engineering

Owner:嘉兴飞翔新材料股份有限公司

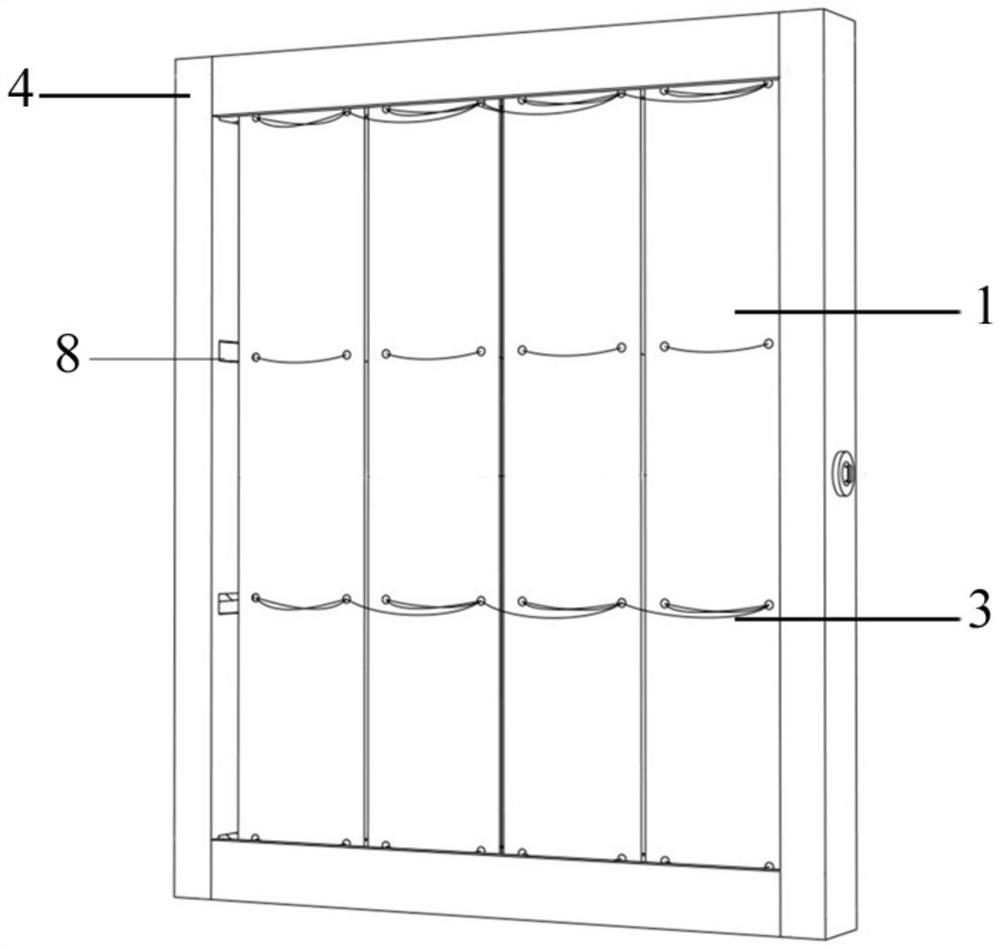

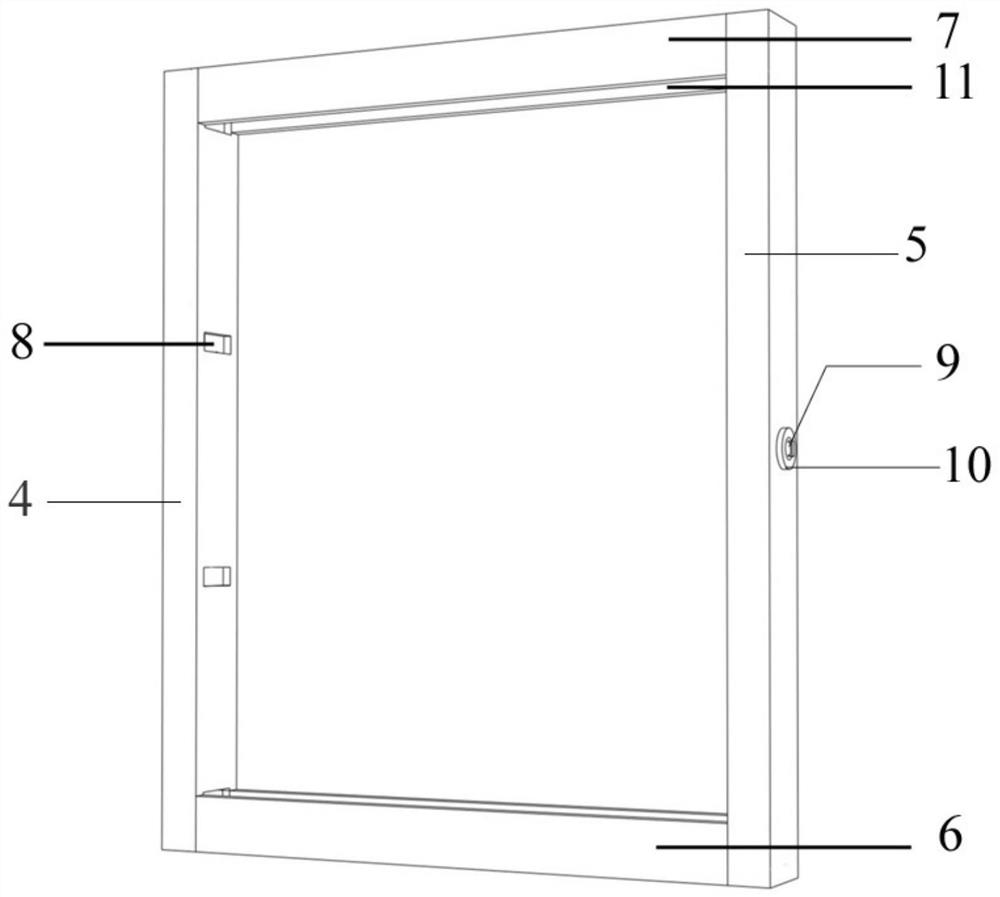

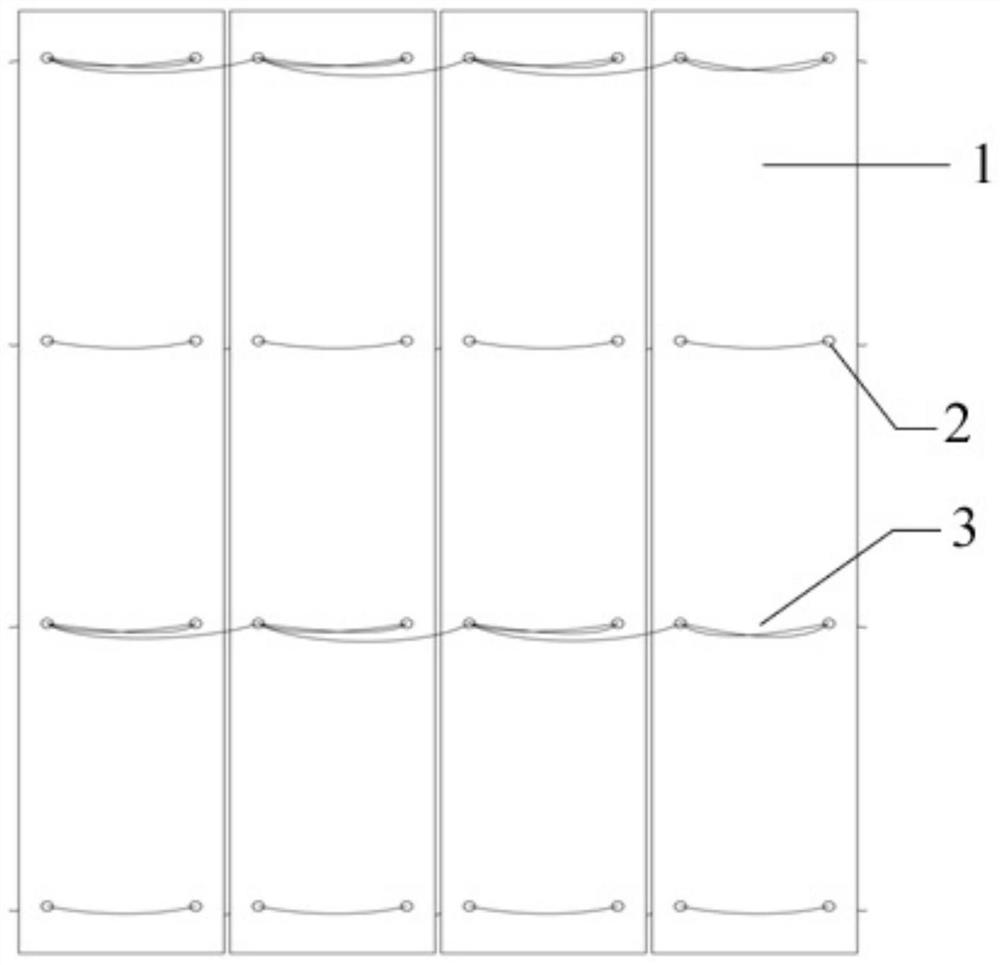

A movable partition structure made of bamboo skin

ActiveCN113374114BEven by forceEven force up and downWallsStructural engineeringMechanical engineering

Owner:ZHEJIANG SCI-TECH UNIV

Sucker Rod Intelligent Manufacturing Production Line

ActiveCN111390087BThe transfer process is stableRealize intelligent automatic productionForging/hammering/pressing machinesForging press detailsMachineMachine tool

An intelligent manufacturing production line for sucker rods, which includes a feeding bin, a first stepping device, a first angular positioning device, a first running device, an axial running device, and a second angular positioning device arranged in sequence according to the running direction of the workpiece. To the positioning device, the second stepping device, the second operating device and the lower bin; the outside of the first operating device and the second operating device are provided with processing machine tools; the first stepping device pushes the workpiece in the upper bin, the second An angular positioning device and the first running device are pushed forward sequentially, and the second stepping pushing device pushes the workpiece forward between the axial running device, the second angular positioning device, the second running device and the lower bin . This production line solves the problems of transportation, clamping and positioning difficulties in the process of slender sucker rod processing, and realizes the intelligent automatic production of external threads at both ends of the sucker rod, ensuring stable workpiece transfer, compact rhythm and high production efficiency , reducing production costs.

Owner:山东弘名智能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com