Patents

Literature

32results about How to "Even force up and down" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

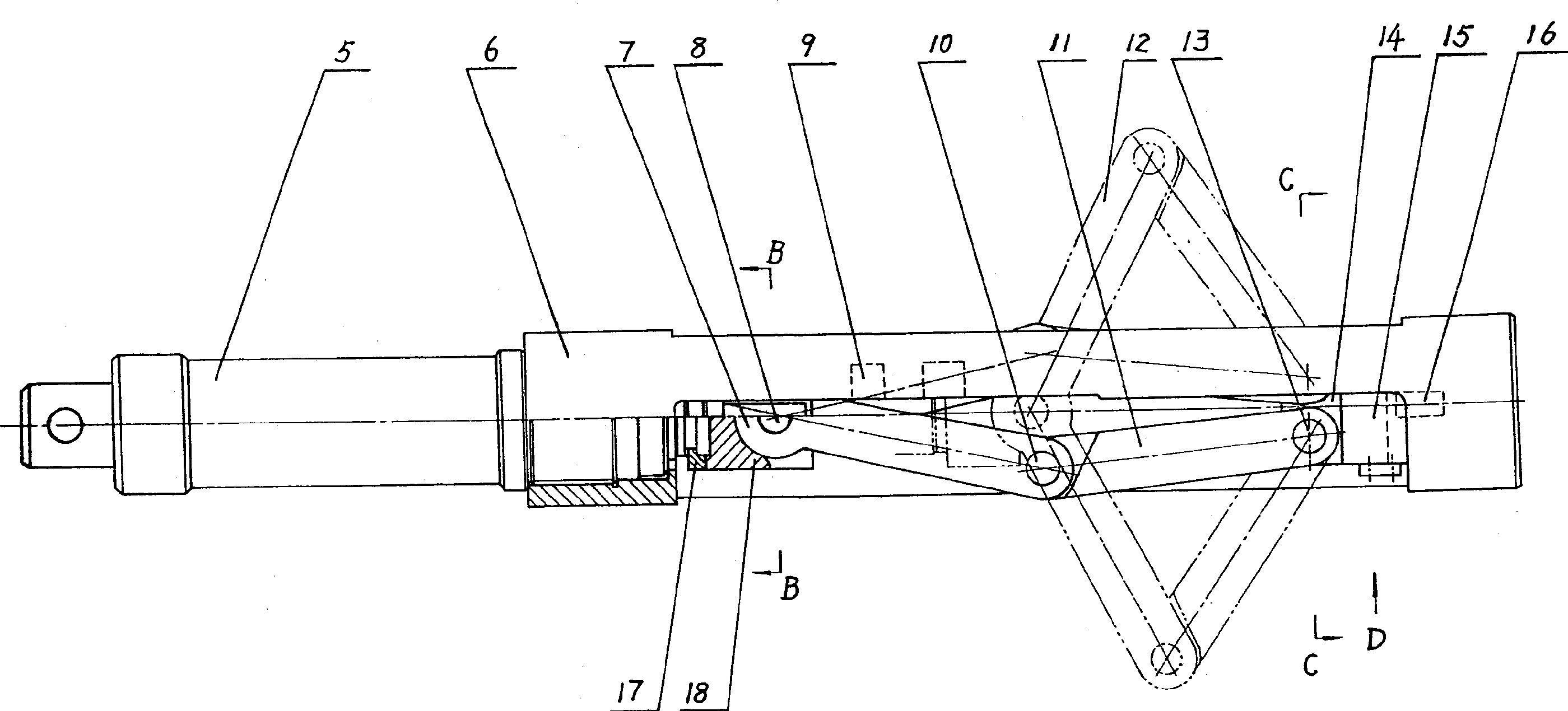

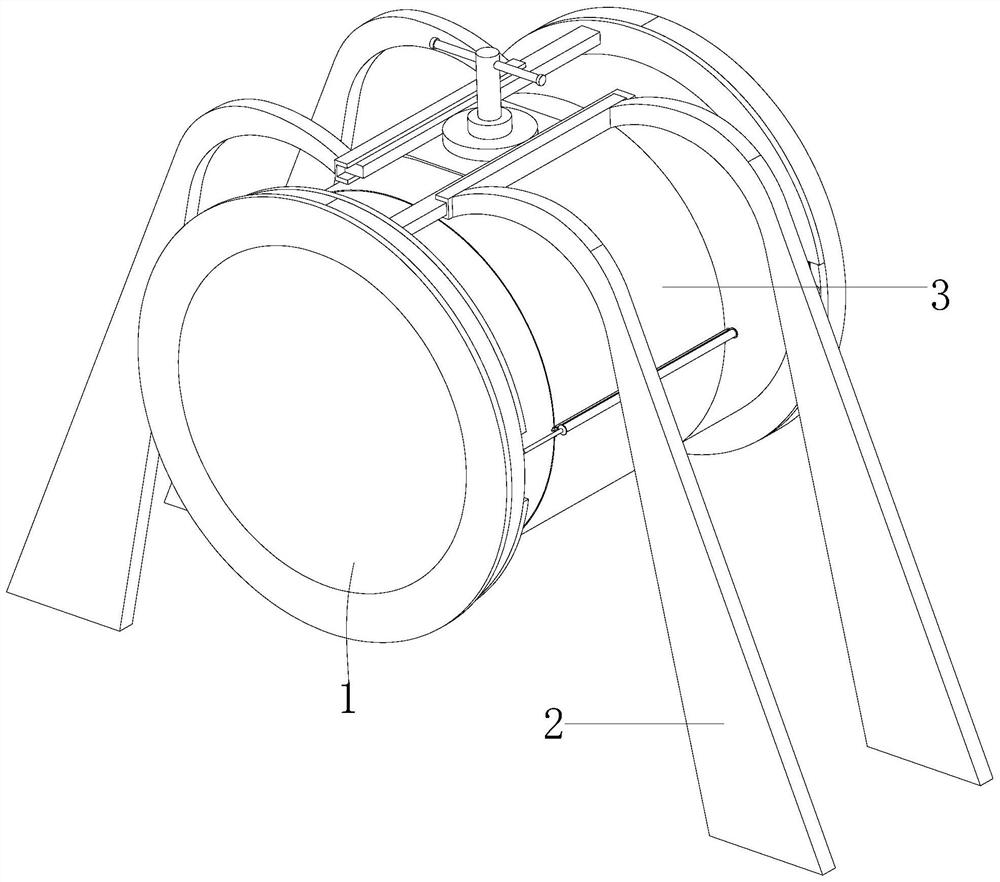

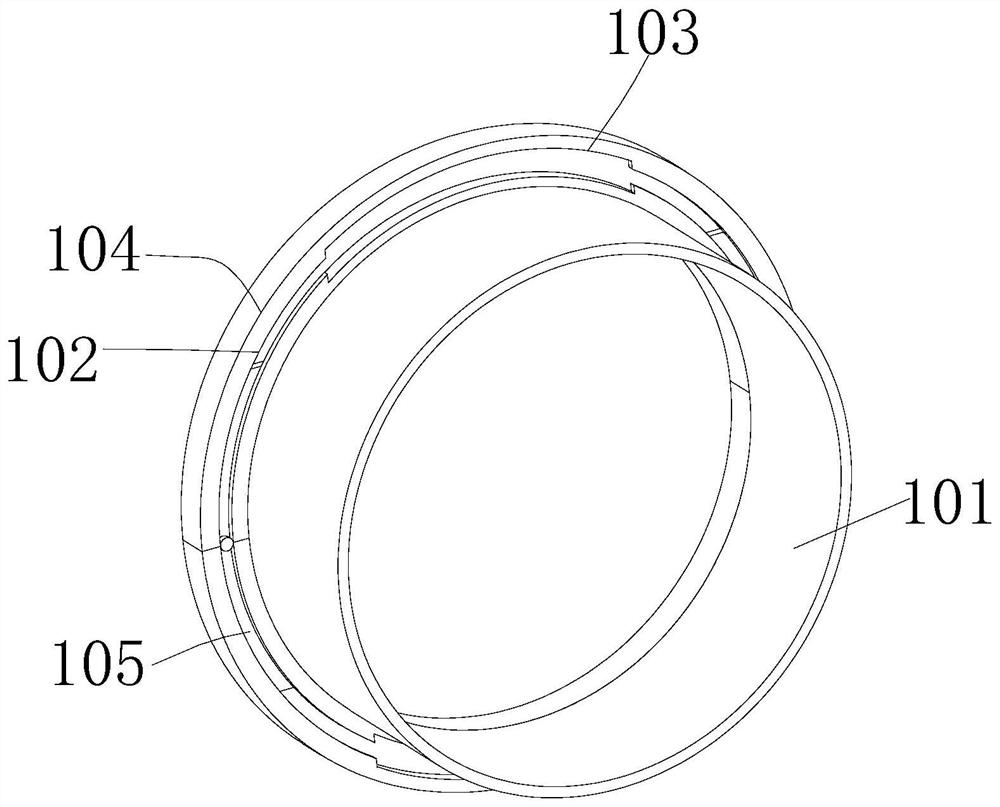

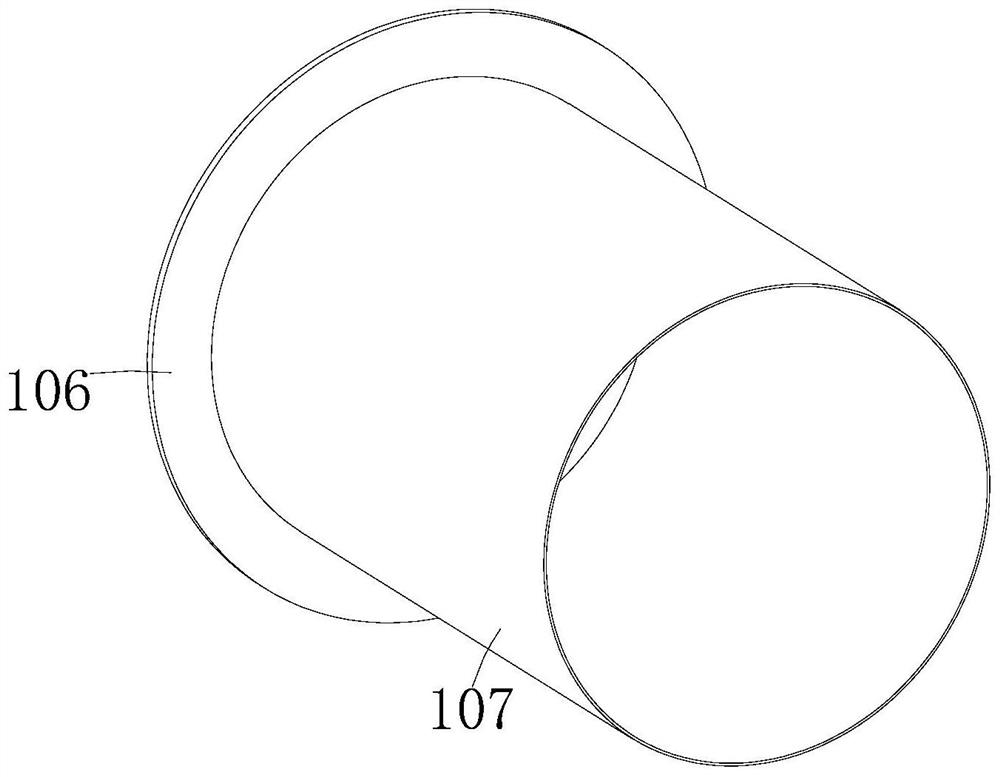

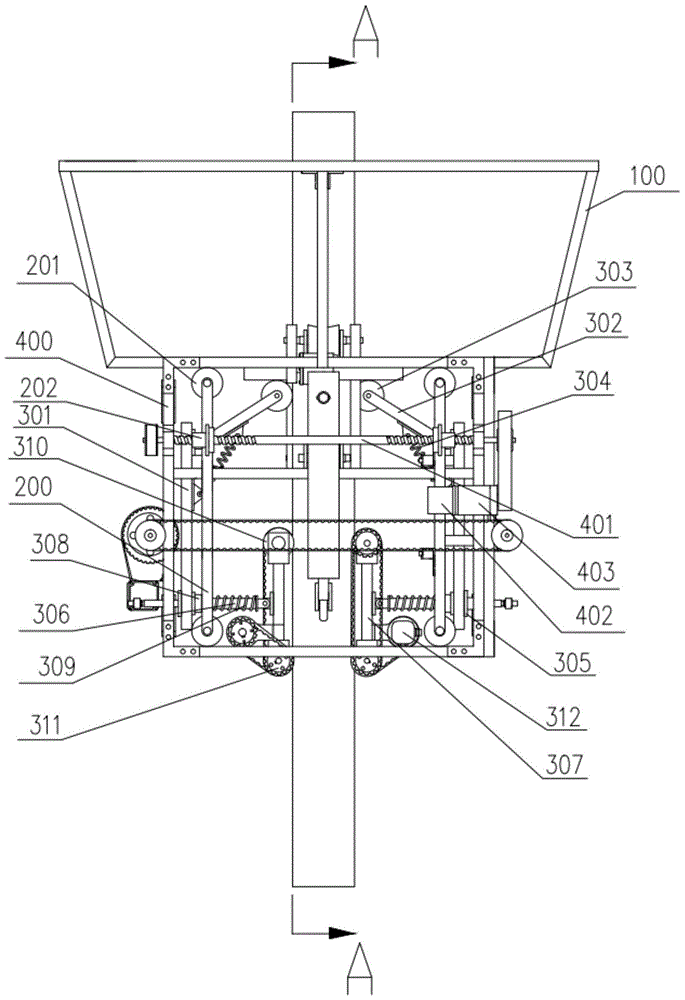

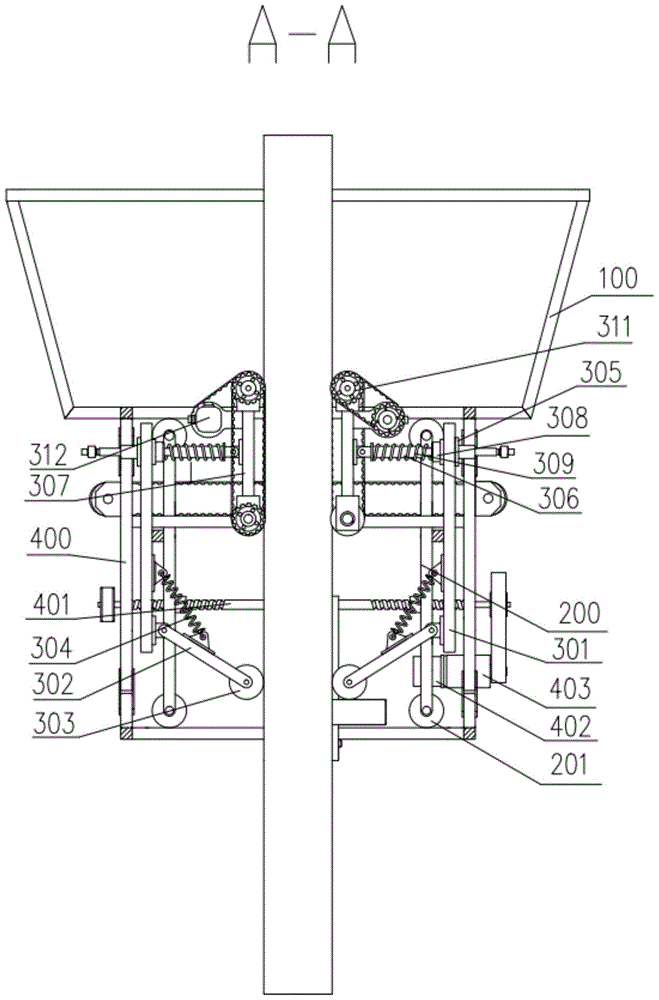

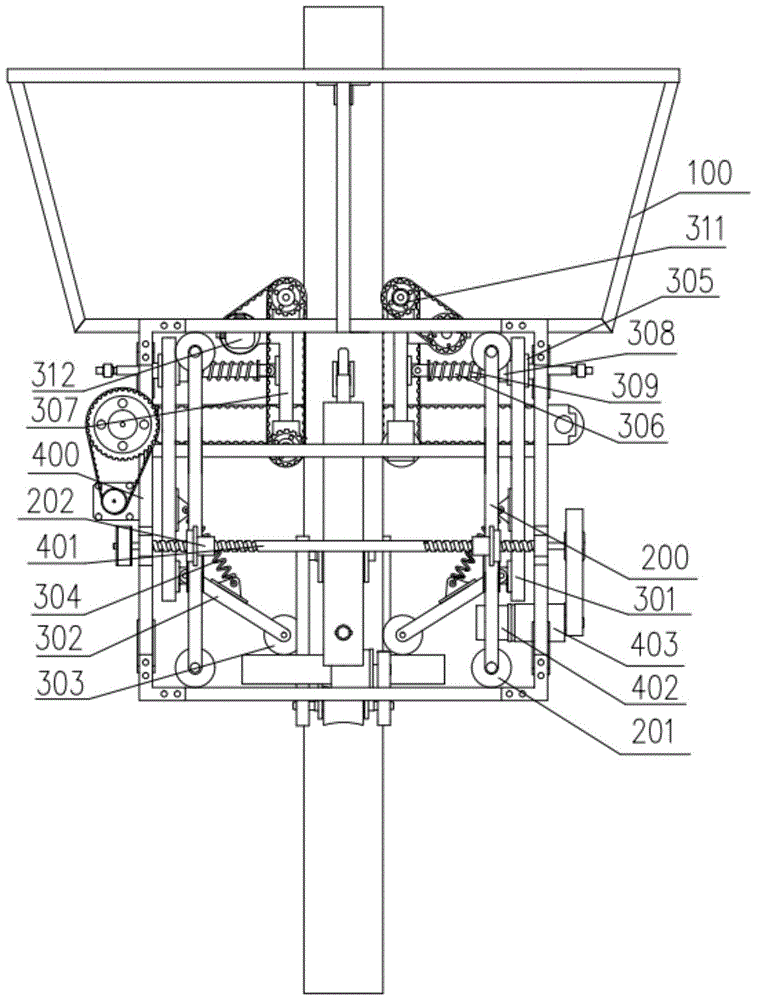

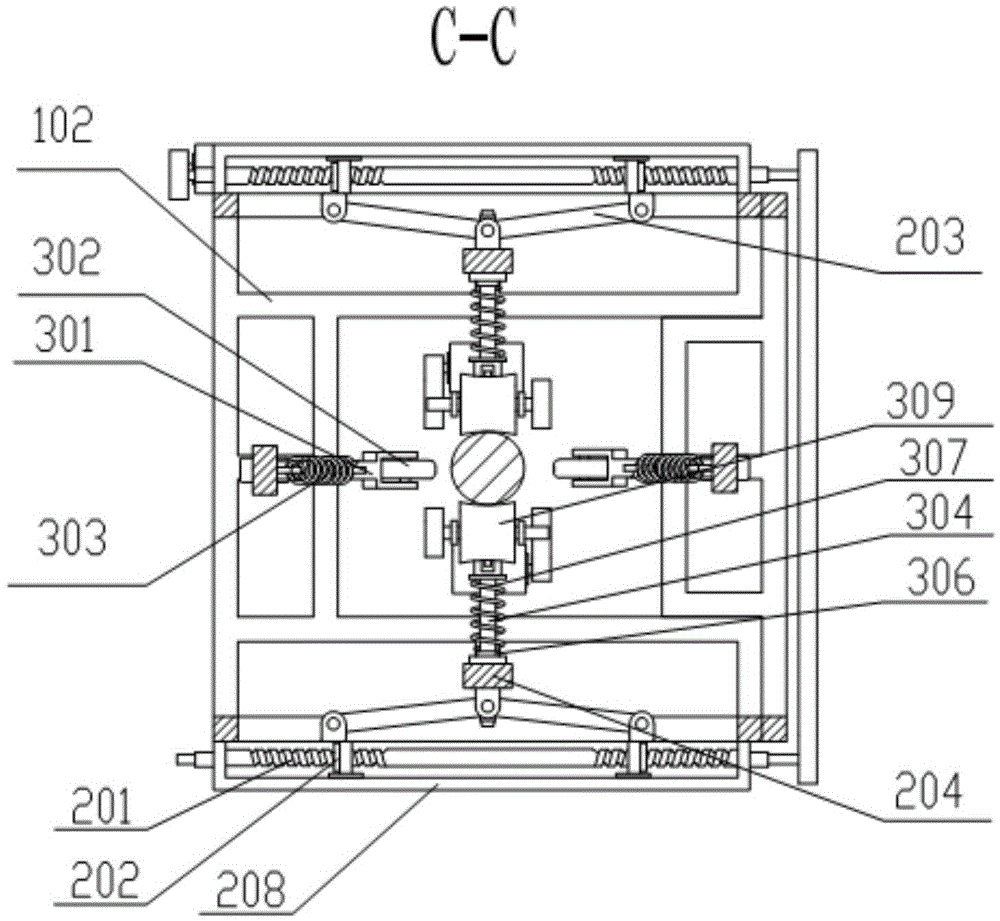

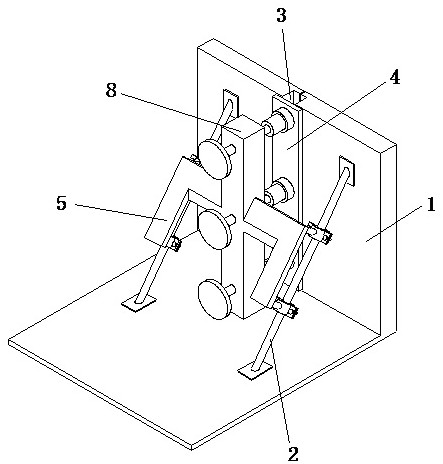

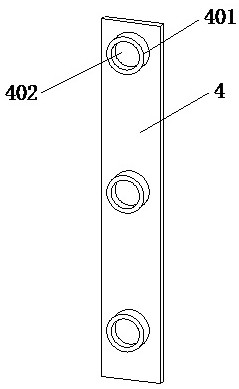

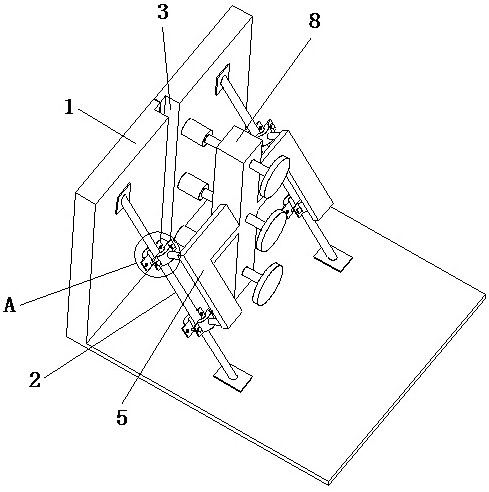

Cable climbing robot

A cable climbing robot comprises an outer frame and an inner climbing mechanism, wherein a ball screw with opposite turning directions at two ends is connected between upright tubes of each side face of the outer frame through bearings, and every two opposite ball screws are driven by a motor; each side face of the outer frame is provided with a slide block formed in a way that a cross rod connects two vertical rods, and slide block guide wheels at the upper and lower ends of the vertical rods are in contact with top rods and bottom rods of the outer frame; the outer sides of the two vertical rods both are fixedly provided with screw nuts; two pairs of clamping support plates are respectively fixed to two opposite pairs of cross rods, certain ends of the inner sides of the clamping support plates are hinged to guide rods with guide wheels, and extension springs are arranged between the guide rods and the clamping support plates, and the other ends of the clamping support plates are provided with guidance rods; the ends, extending inwards, of the guidance rods are hinged to balance beams, and pressure sensors and compression springs sleeve the guidance rods between the balance beams and the clamping support plates; the upper and lower ends of the balance beams are respectively provided with driven wheels and driving wheels connected with drive motors. The robot can be used for cables with great diameter differences, is good in clamping force and strong in cable climbing and obstacle crossing abilities.

Owner:SOUTHWEST JIAOTONG UNIV

Cable climbing robot

InactiveCN104674655ALarge clamping forceClamp firmlyBridge structural detailsEndless track vehiclesDrive wheelEngineering

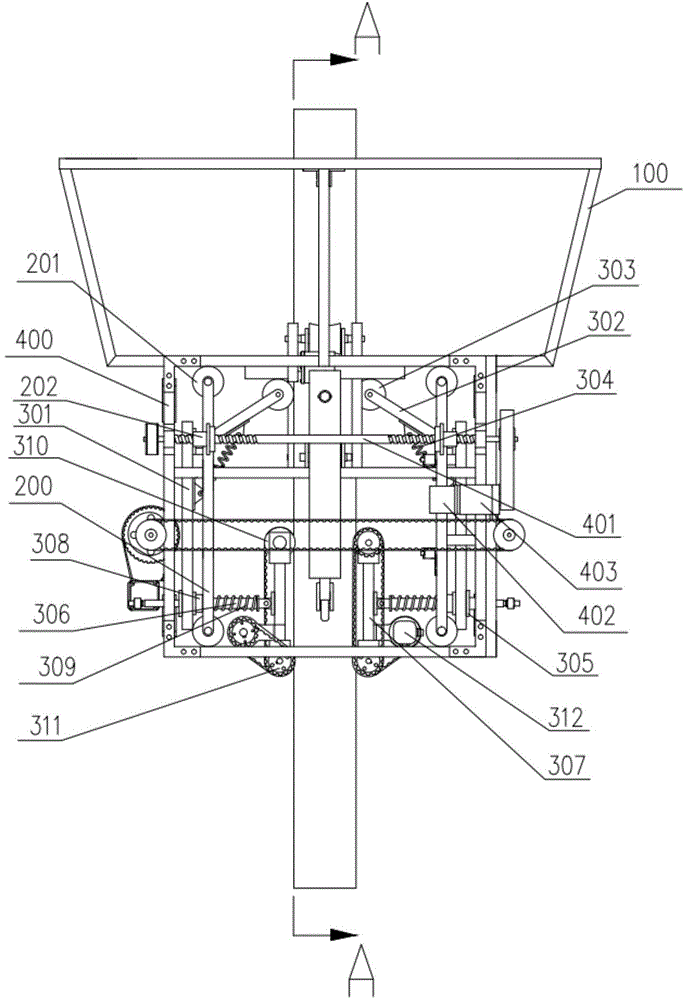

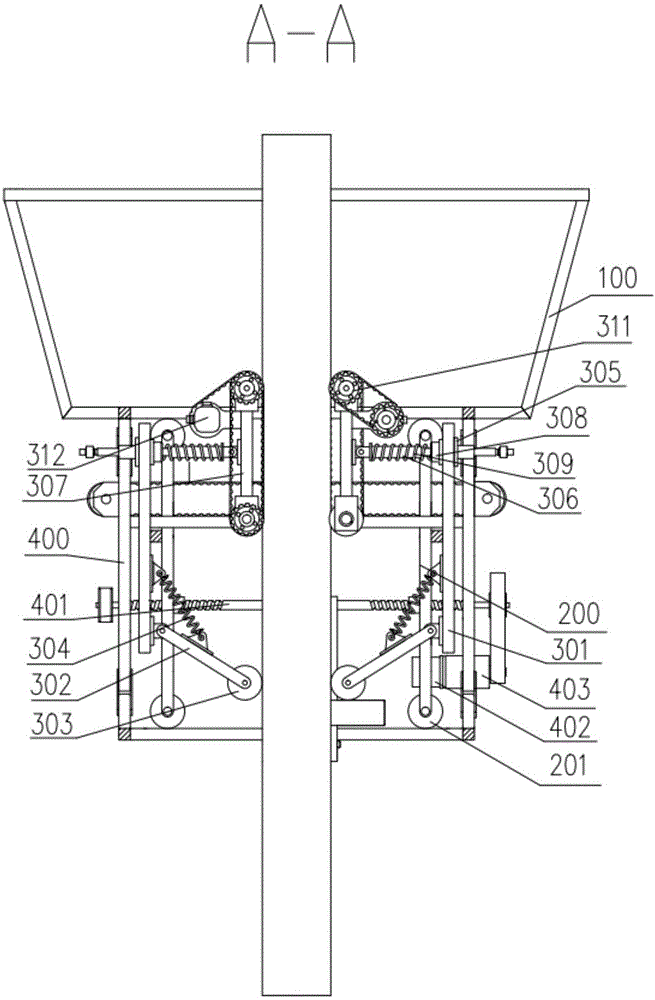

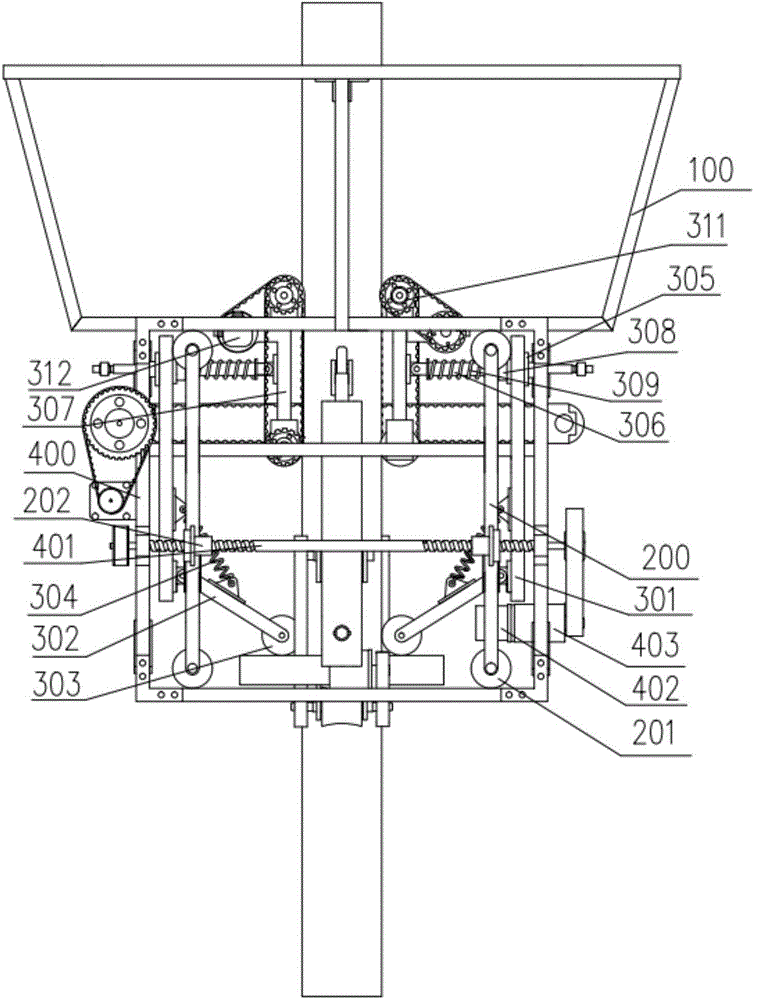

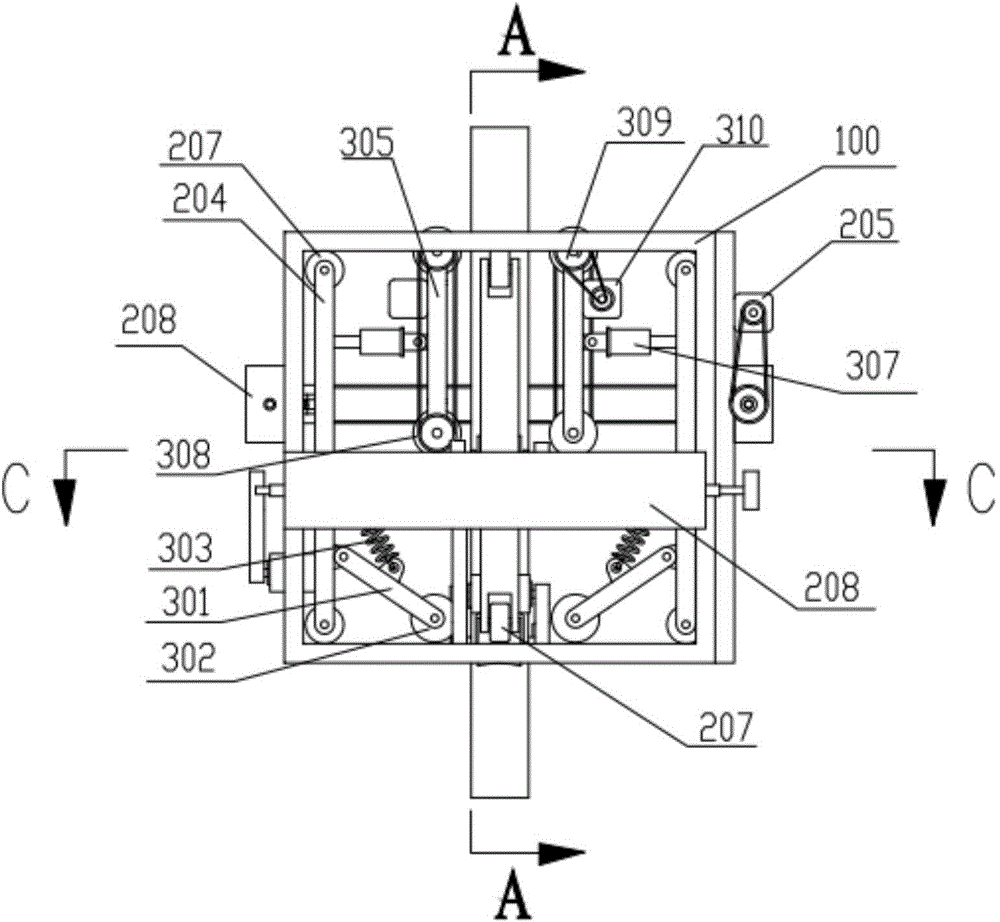

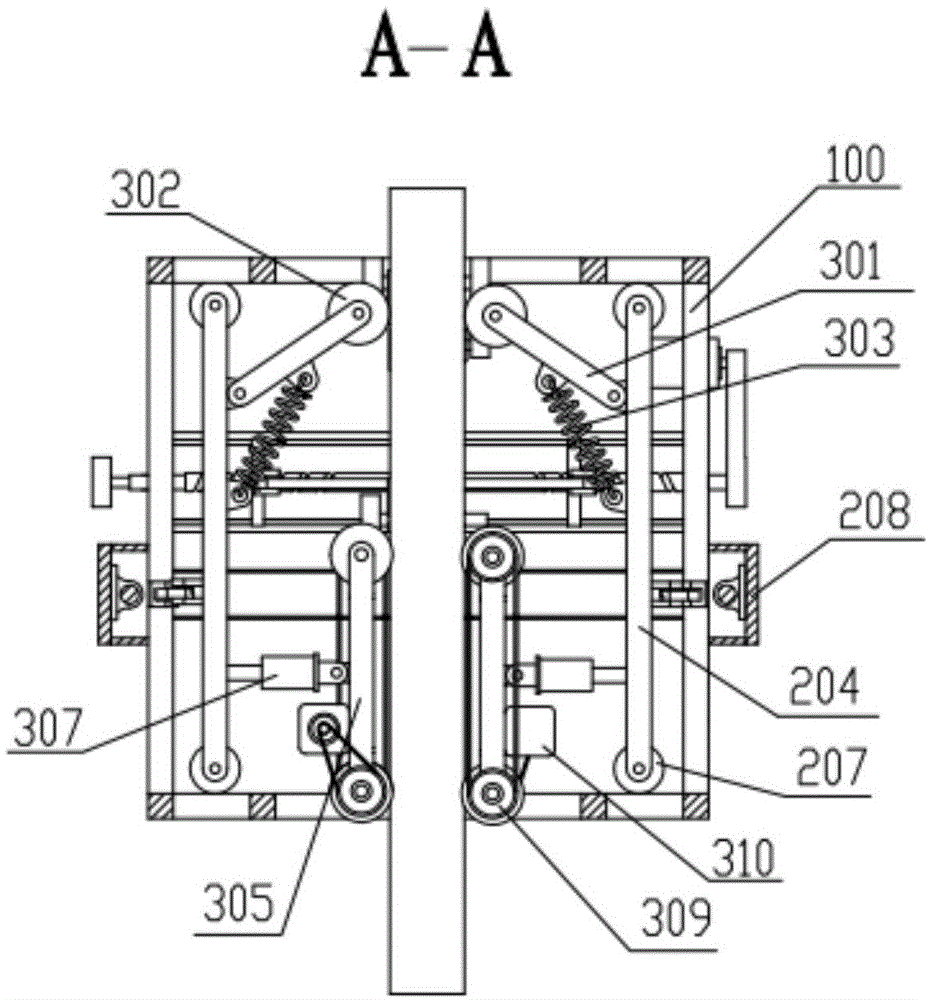

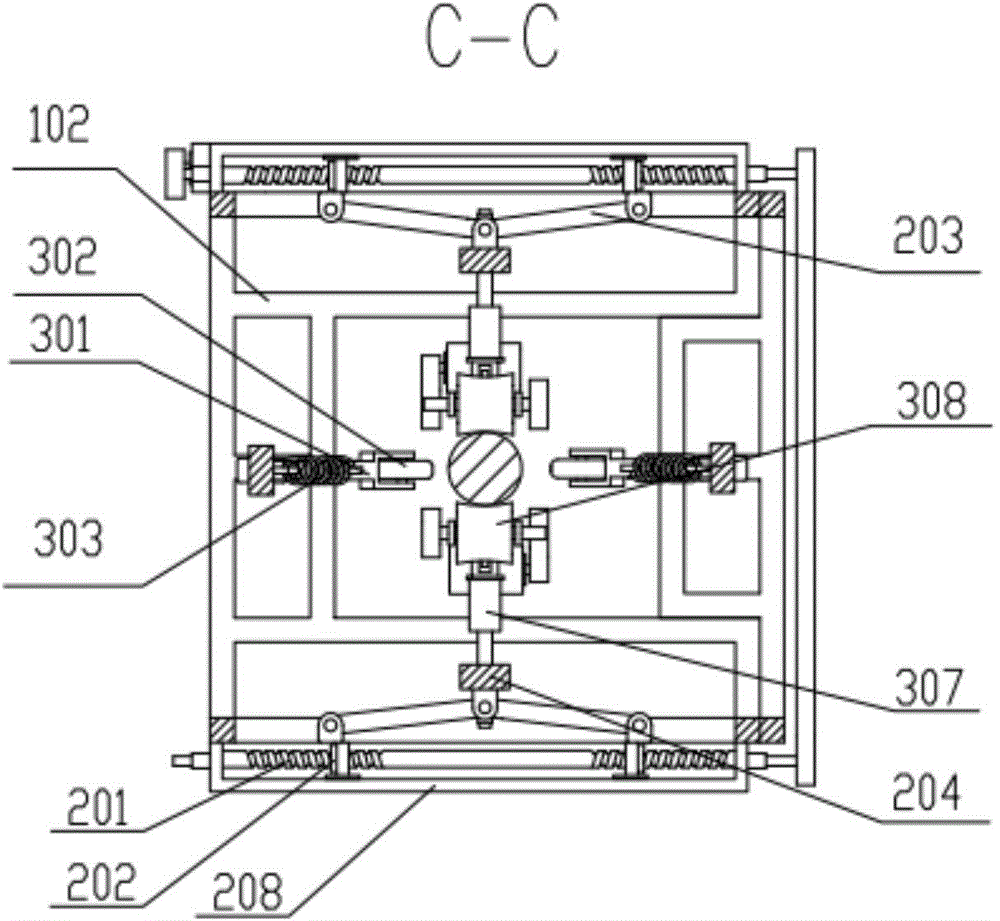

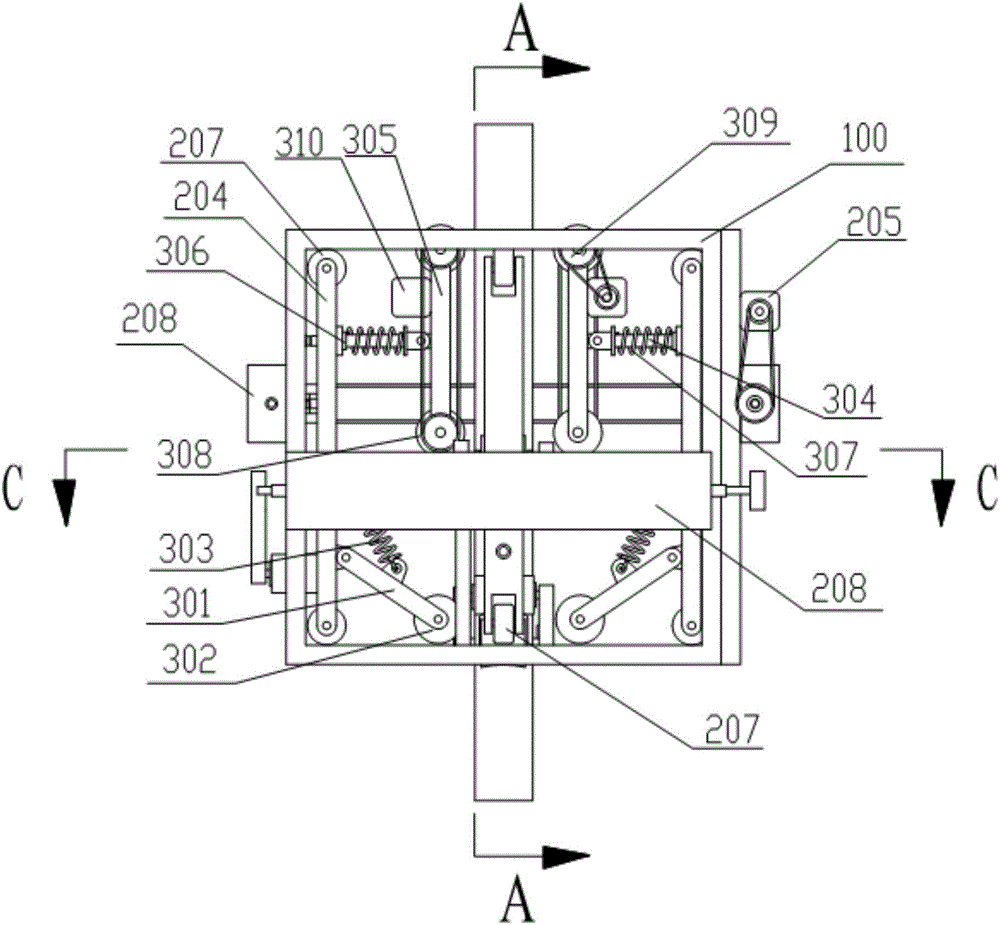

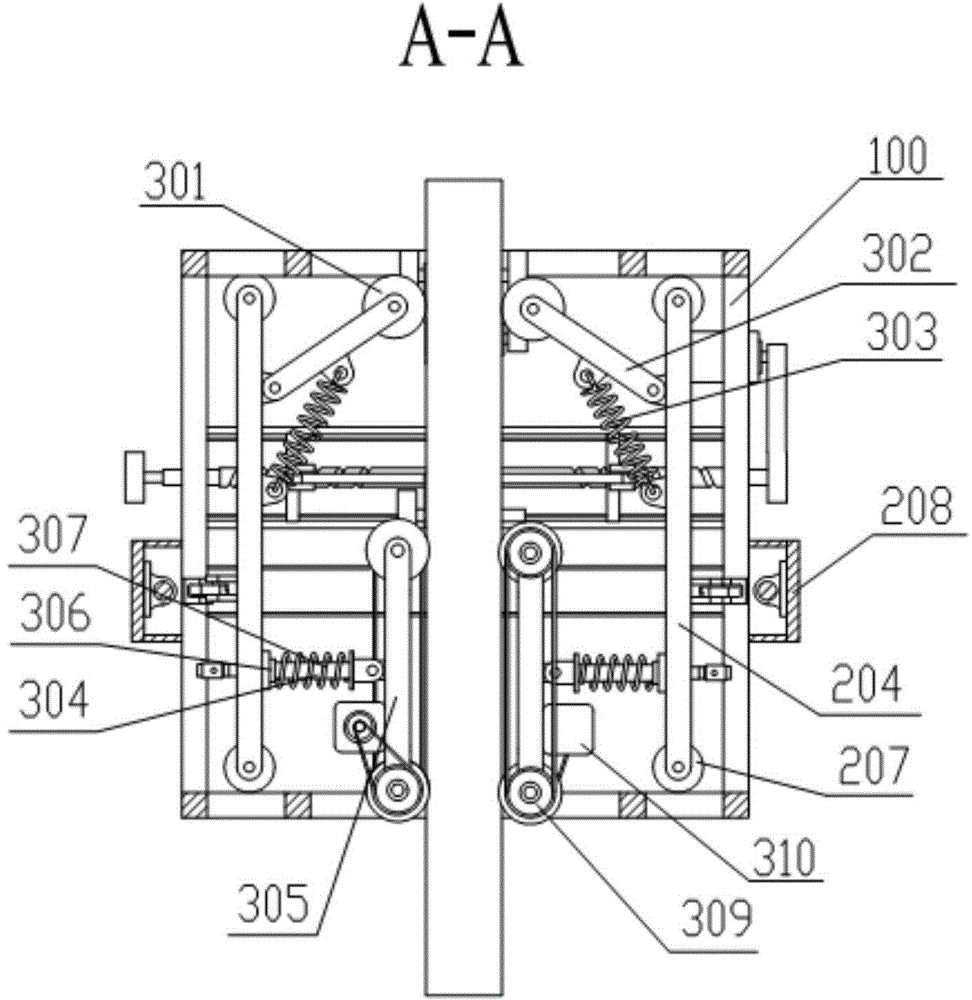

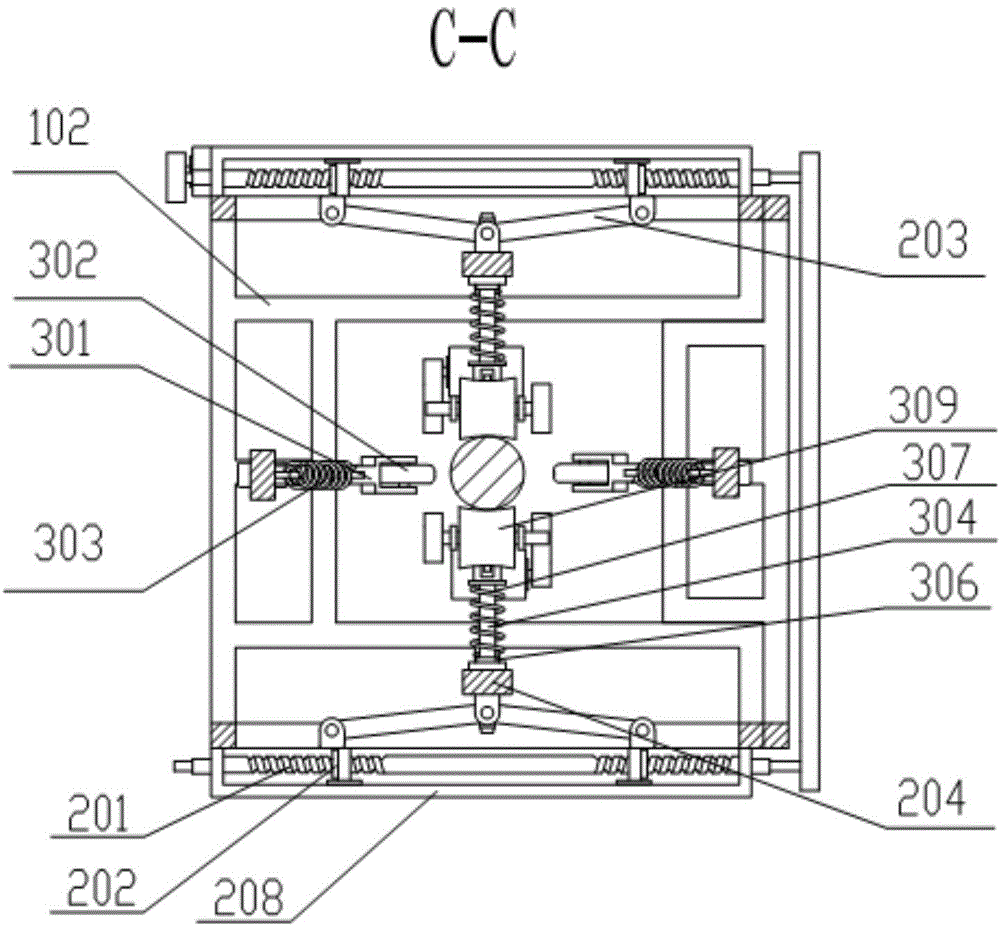

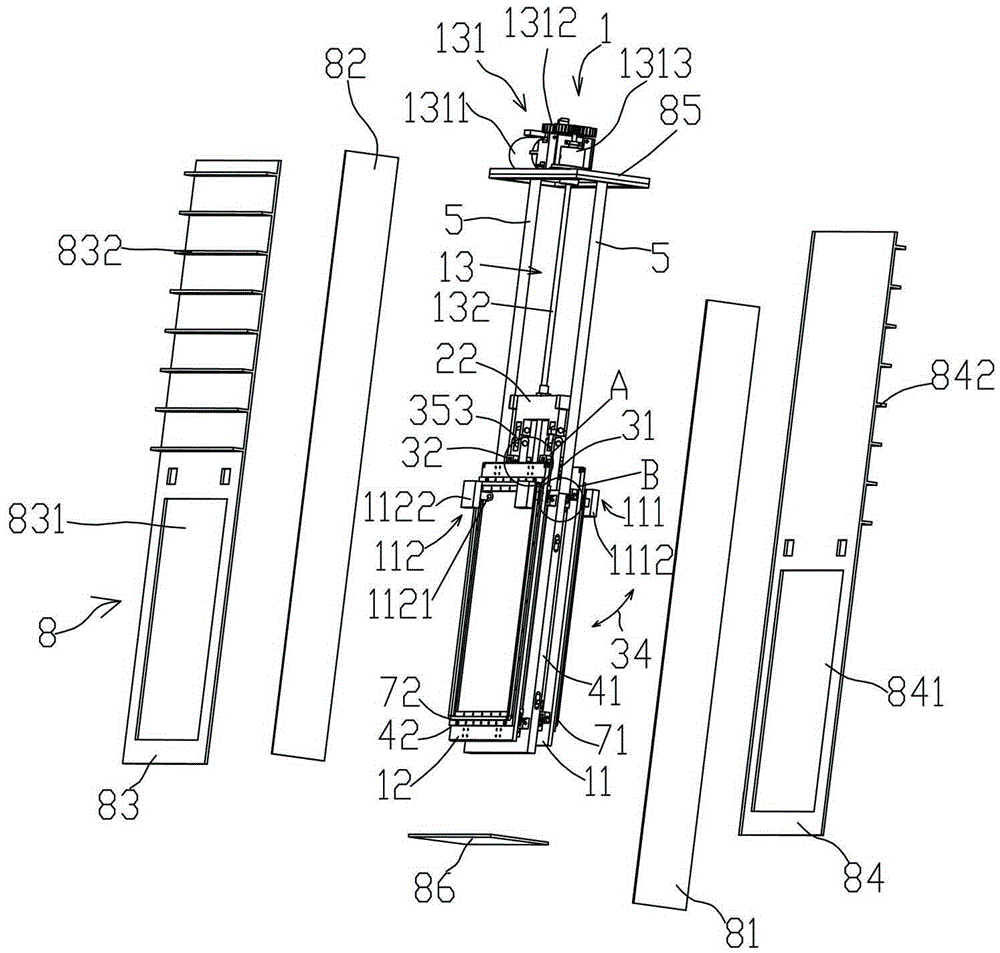

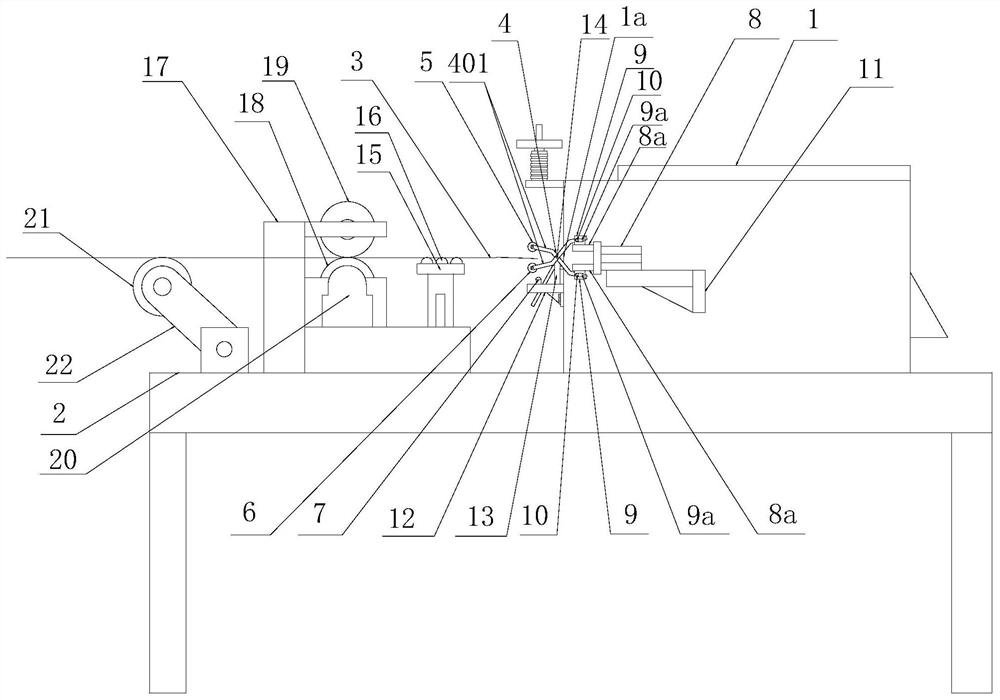

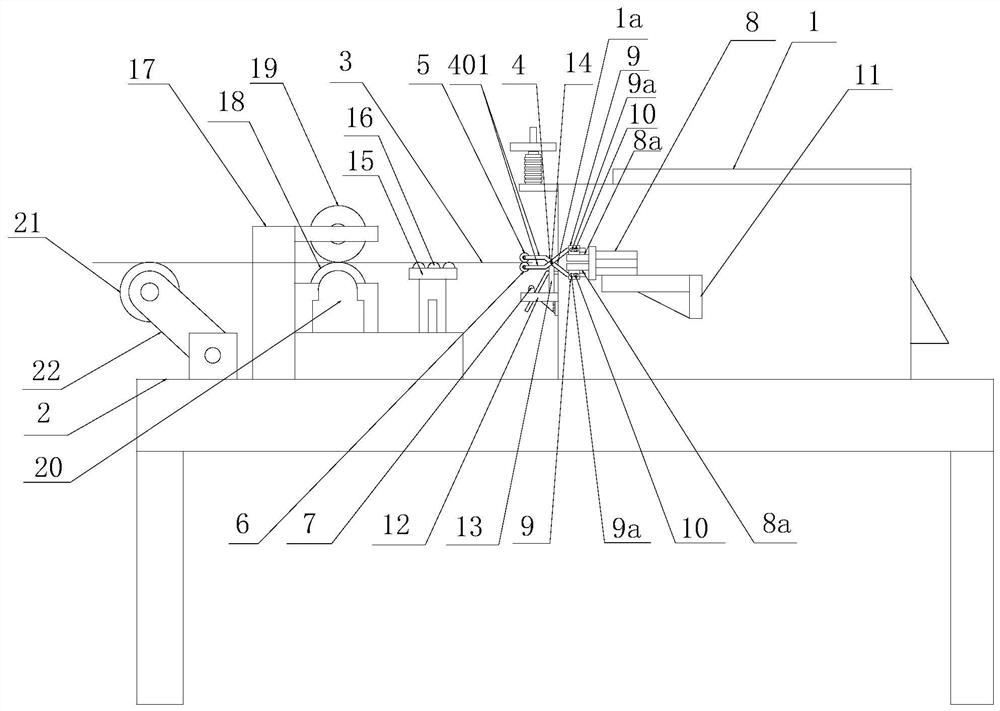

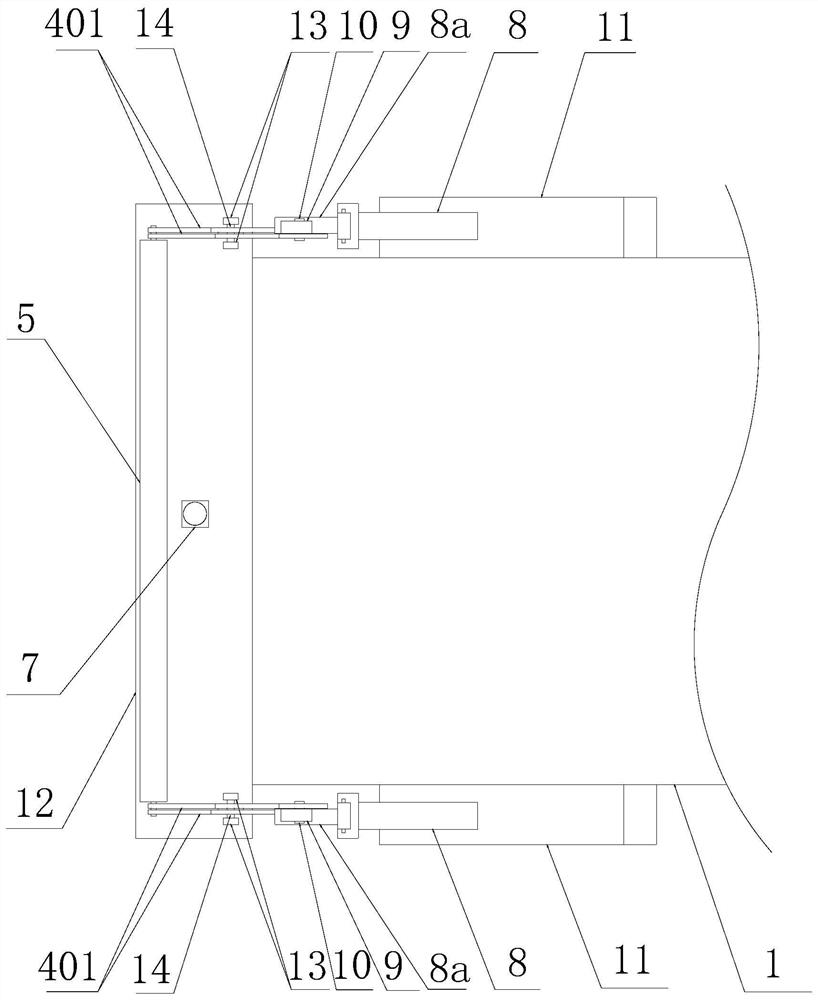

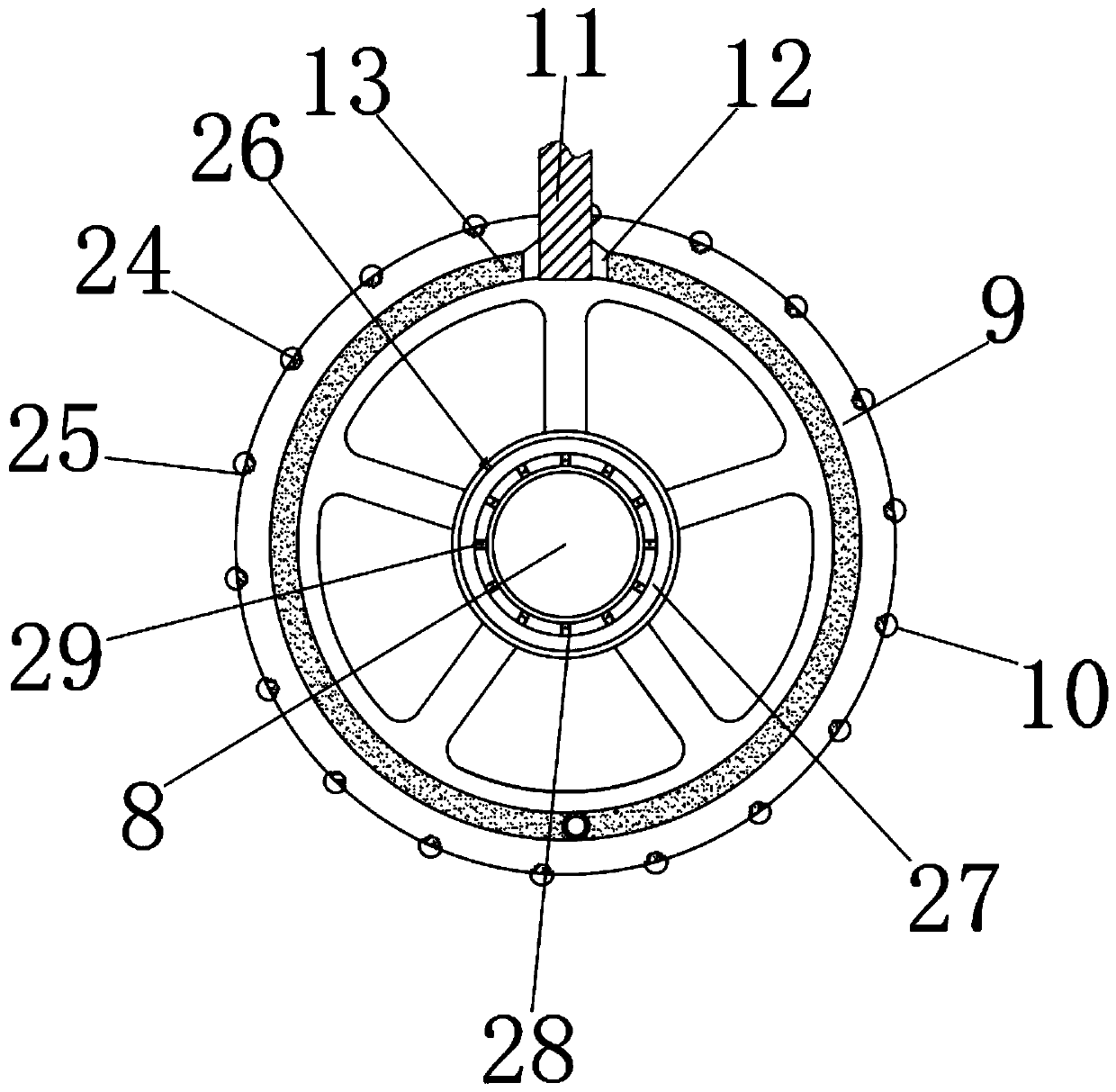

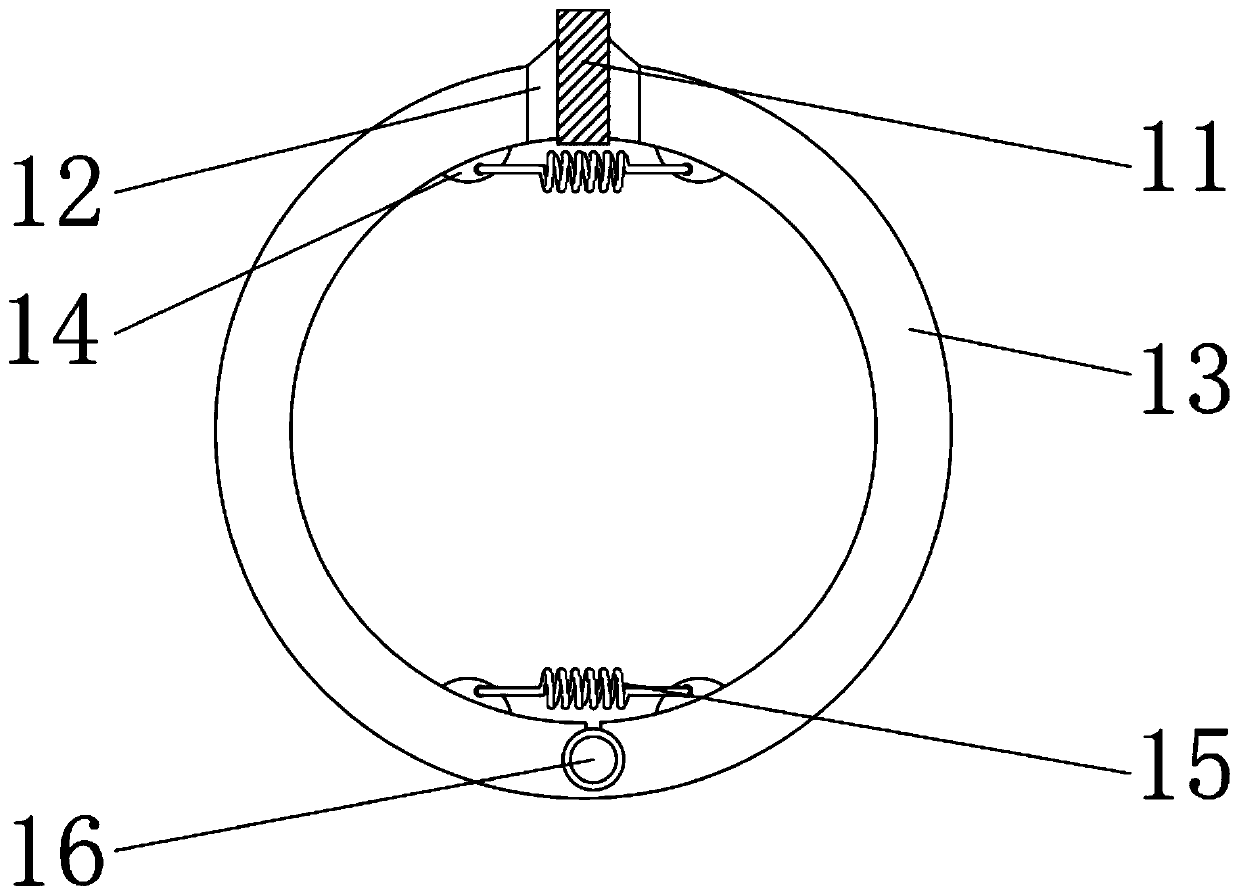

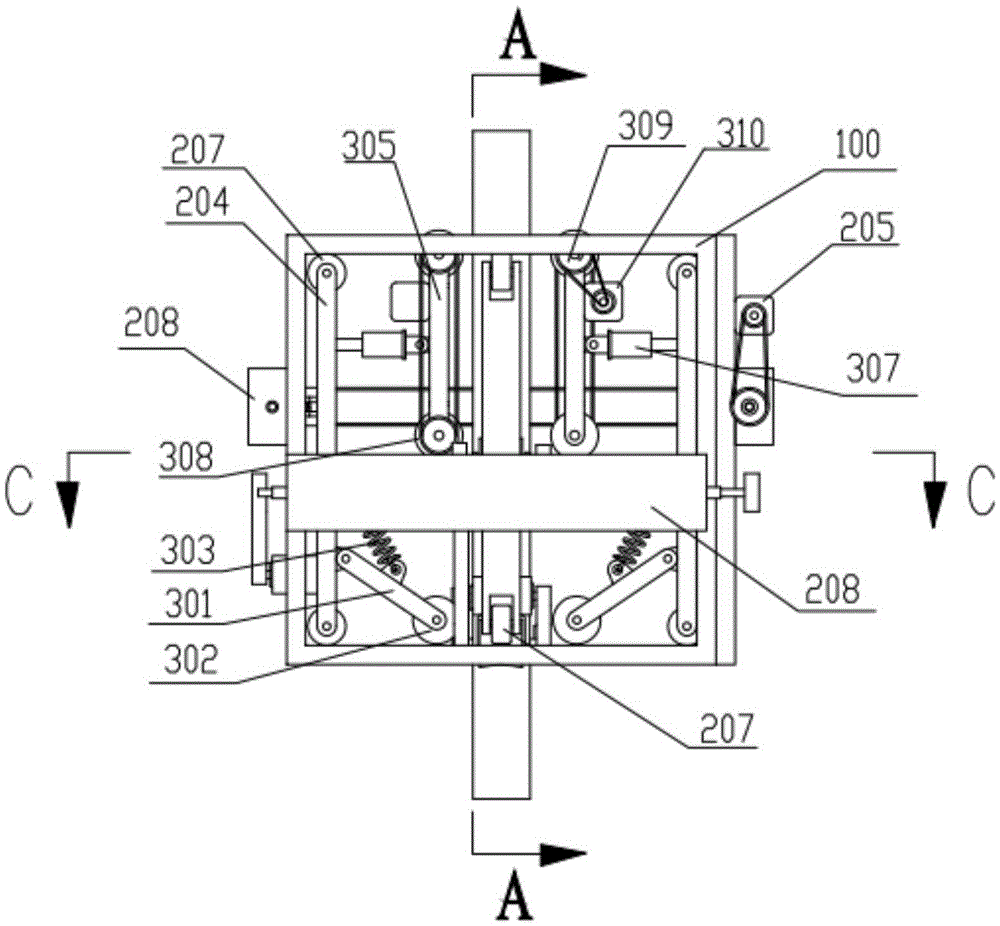

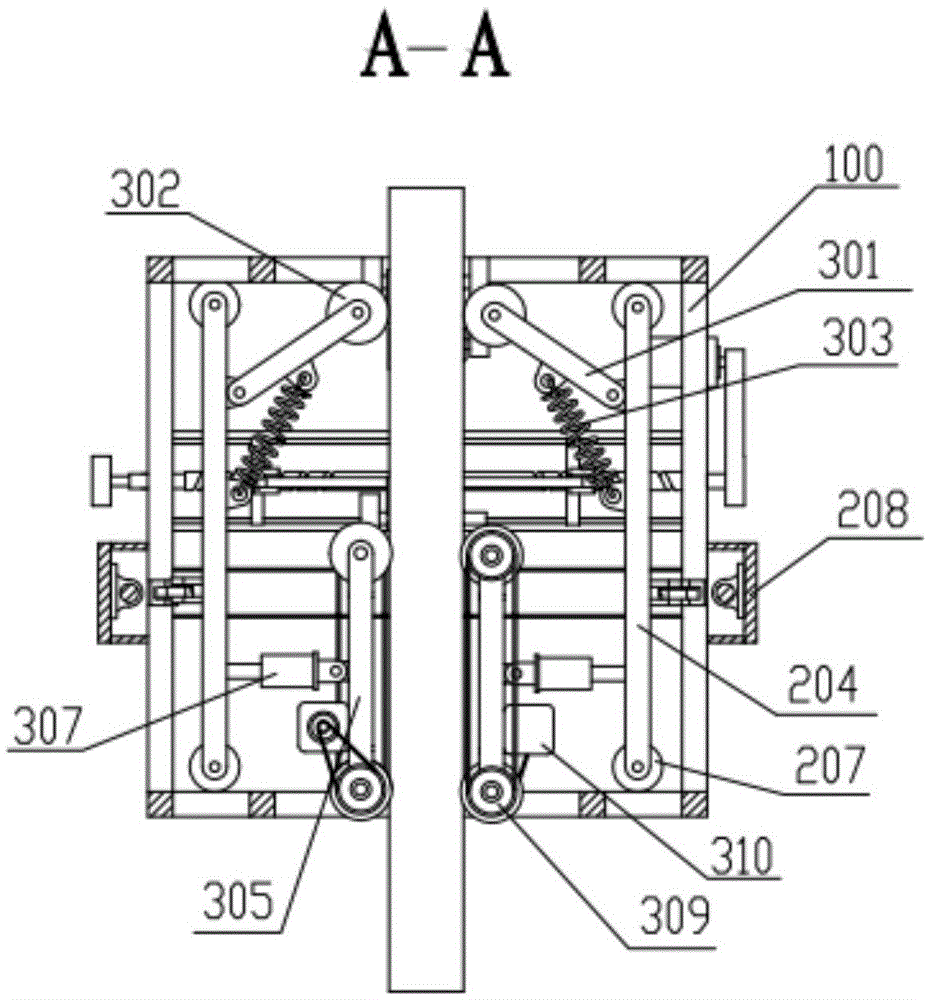

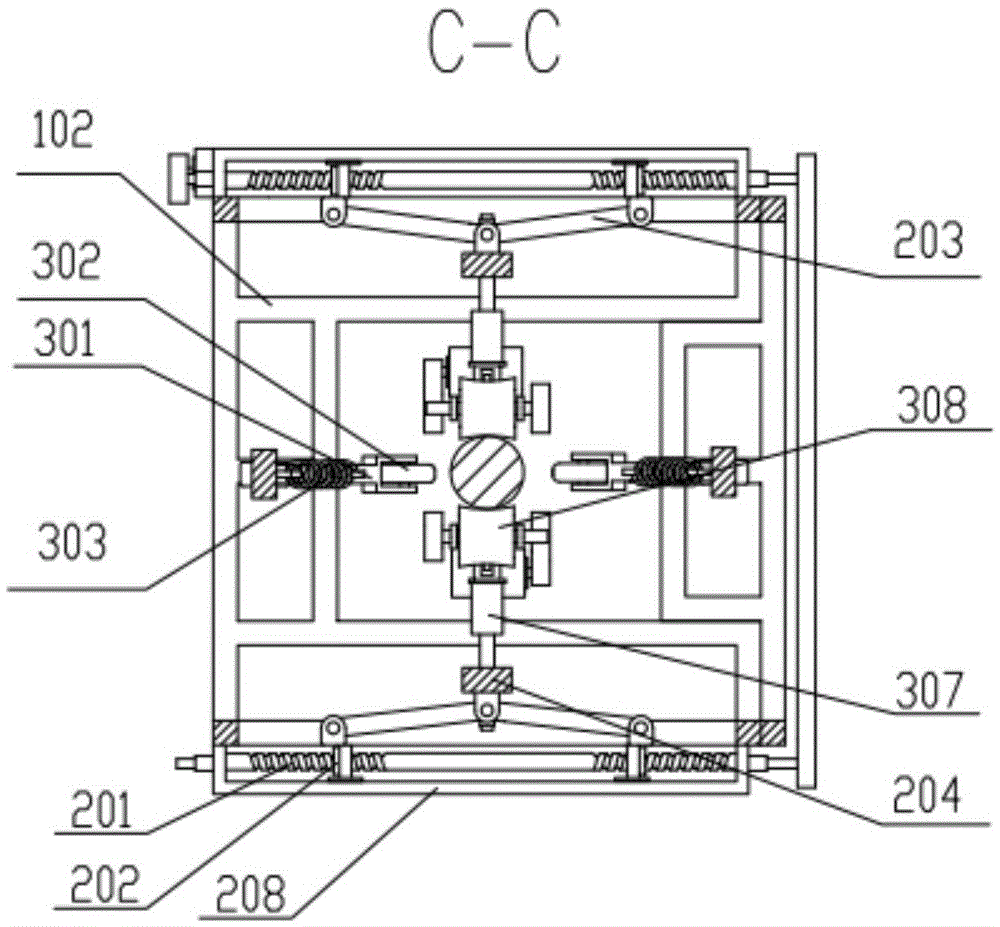

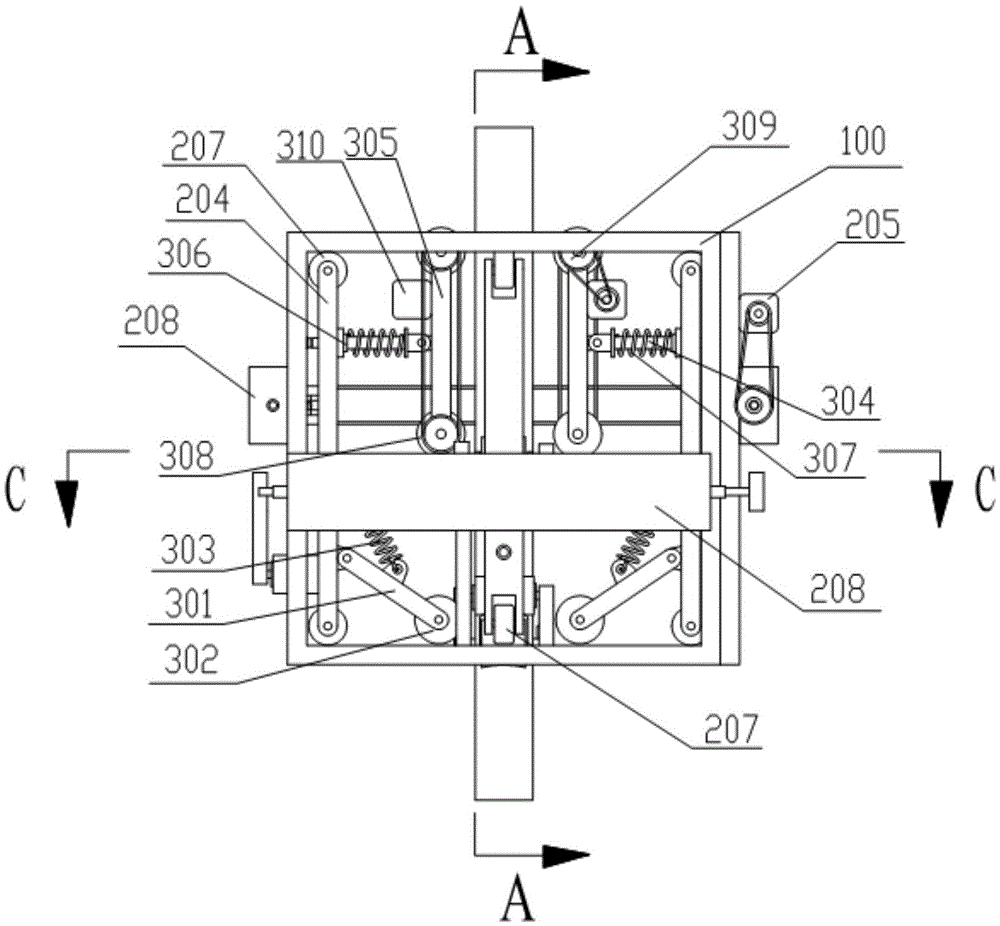

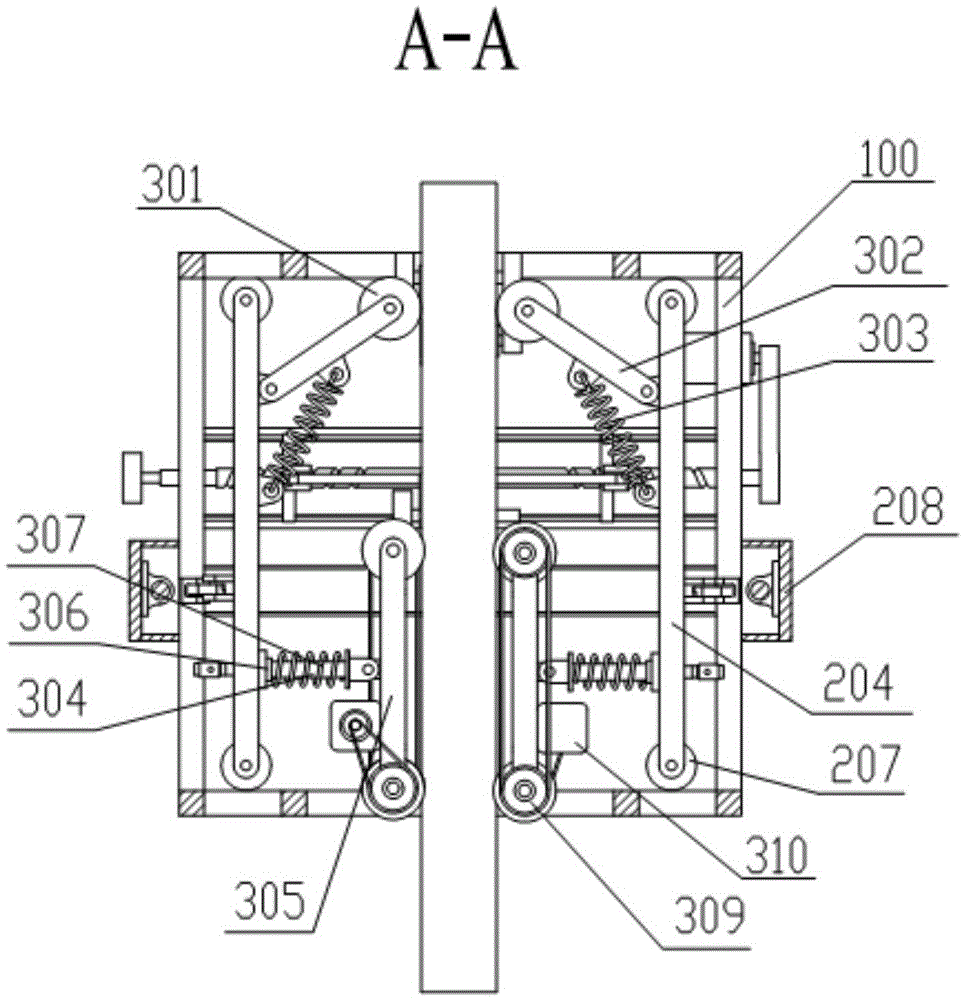

The invention relates to a cable climbing robot, which comprises an outer framework, clamping mechanisms and climbing mechanisms, wherein the clamping mechanisms and the climbing mechanisms are arranged on the outer framework; the outer framework is a cubic framework; each edge of the upper surface and the lower surface of the outer framework is respectively connected with an inner edge frame through a radial frame, and one clamping mechanism and one climbing mechanism are respectively arranged at each side surface of the outer framework; in each clamping mechanism, a ball screw is connected between vertical rods at the side surface of the outer framework; two edges of the ball screw have opposite screwing directions; two screw nuts of the ball screw are respectively hinged to connecting rods; the other end of each of the two connecting rods is hinged to the back part of a clamping support plate, and rolling wheels are arranged at the upper end and the lower end of the clamping support plate and are matched with the radial frame; in each climbing mechanism, a guide rod is hinged to one end of the inner side of the clamping support plate; a guide wheel is arranged on the guide rod; a nitrogen spring is arranged at the other end of the inner side of the clamping support plate and is hinged to a balance beam, and a driving wheel and a driven wheel are respectively arranged at the upper end and the lower end of the balance beam and are connected by a synchronous belt. The cable climbing robot has the advantages that the cable climbing robot can be used for cables with large diameter differences; the clamping force is good; the cable climbing capability and obstacle crossing capability are higher, and the seizure and slippage can be avoided.

Owner:SOUTHWEST JIAOTONG UNIV

Cable climbing robot

The invention relates to a cable climbing robot, which comprises an outer framework, clamping mechanisms and climbing mechanisms, wherein the clamping mechanisms and the climbing mechanisms are arranged on the outer framework; the outer framework is a cubic framework; each edge of the upper surface and the lower surface of the outer framework is respectively connected with an inner edge frame through a radial frame, and one clamping mechanism and one climbing mechanism are respectively arranged at each side surface of the outer framework; in each clamping mechanism, a ball screw is connected between vertical rods at the side surface of the outer framework, and two edges of the ball screw have opposite screwing directions; two screw nuts of the ball screw are respectively hinged to connecting rods; the other end of each of the two connecting rods is hinged to the back part of a clamping support plate, and rolling wheels are arranged at the upper end and the lower end of the clamping support plate and are matched with the radial frame; in each climbing mechanism, a guide rod is hinged to one end of the inner side of the clamping support plate; a guide wheel is arranged on the guide rod; a leading rod is arranged at the other end of the inner side of the clamping support plate, and is hinged to a balance beam; a pressure sensor and a compression spring sleeve the leading rod, and a driving wheel and a driven wheel are respectively arranged at the upper end and the lower end of the balance beam and are connected by a synchronous belt. The cable climbing robot has the advantages that the cable climbing robot can be used for cables with large diameter differences; the clamping force is good; the cable climbing capability and obstacle crossing capability are higher, and the seizure and slippage can be avoided.

Owner:SOUTHWEST JIAOTONG UNIV

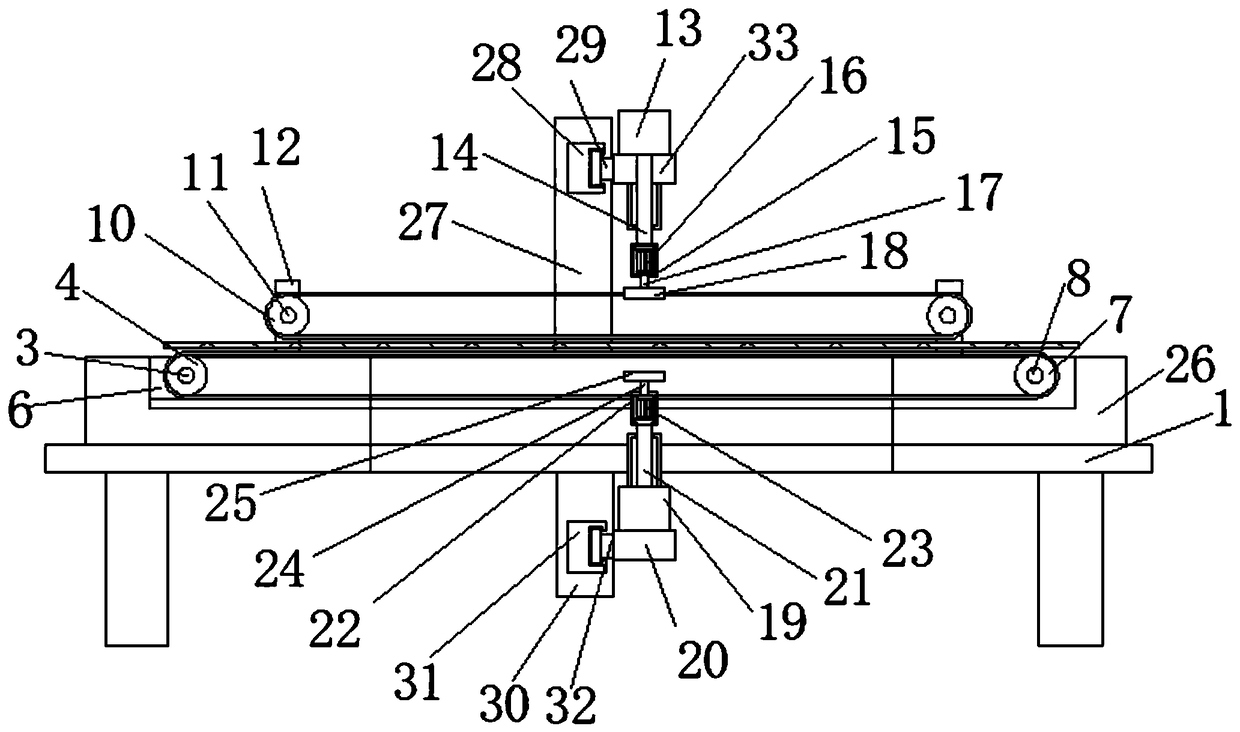

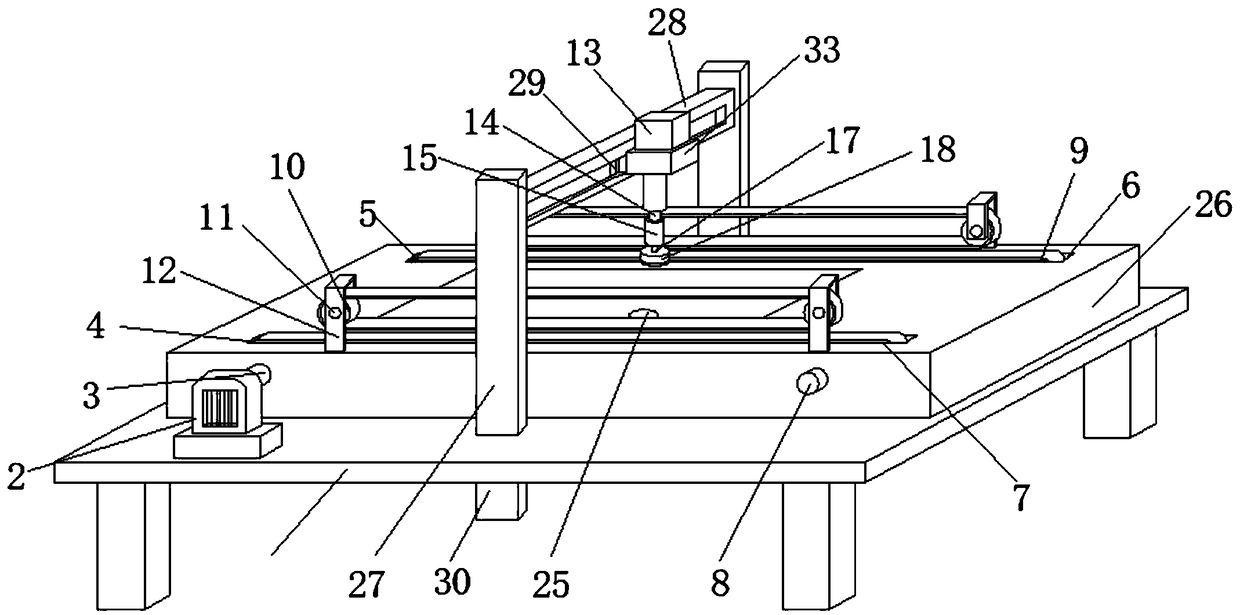

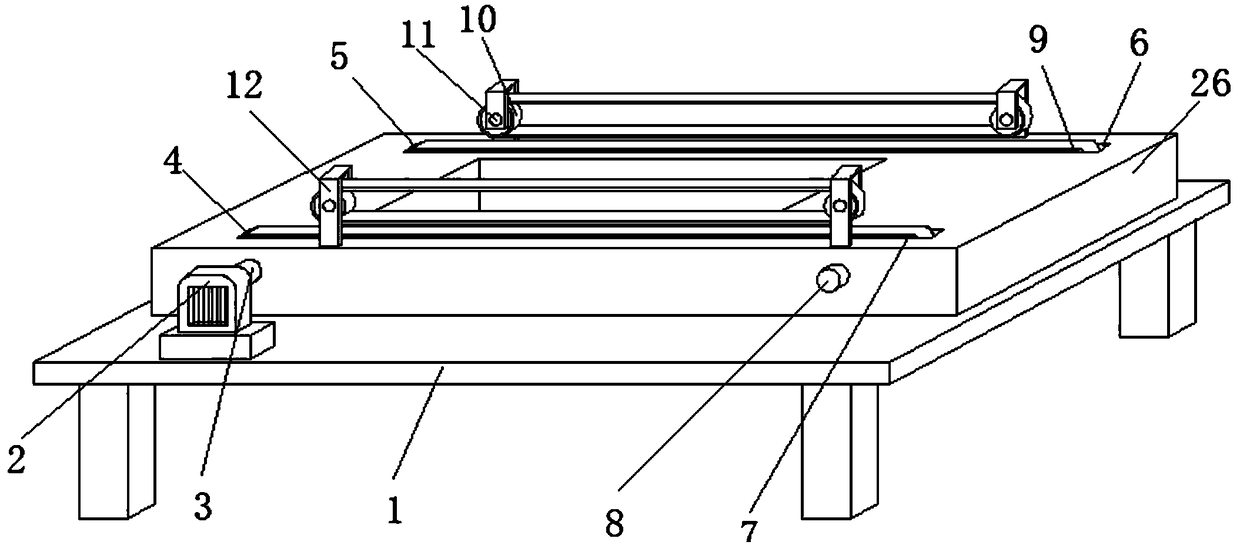

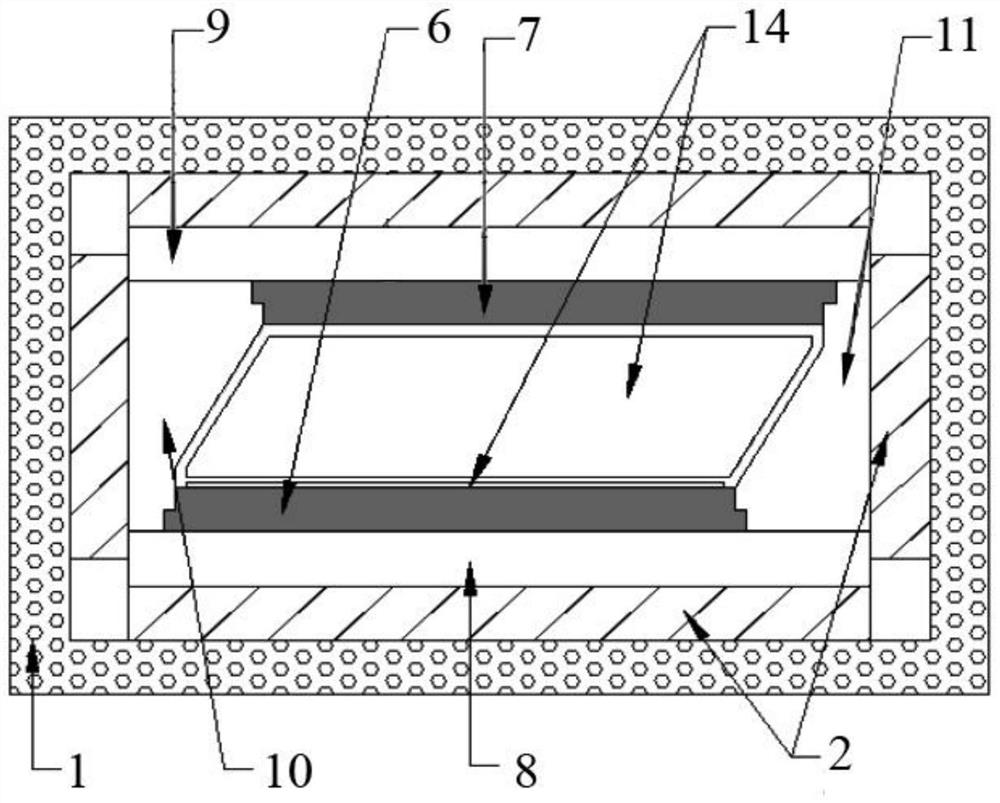

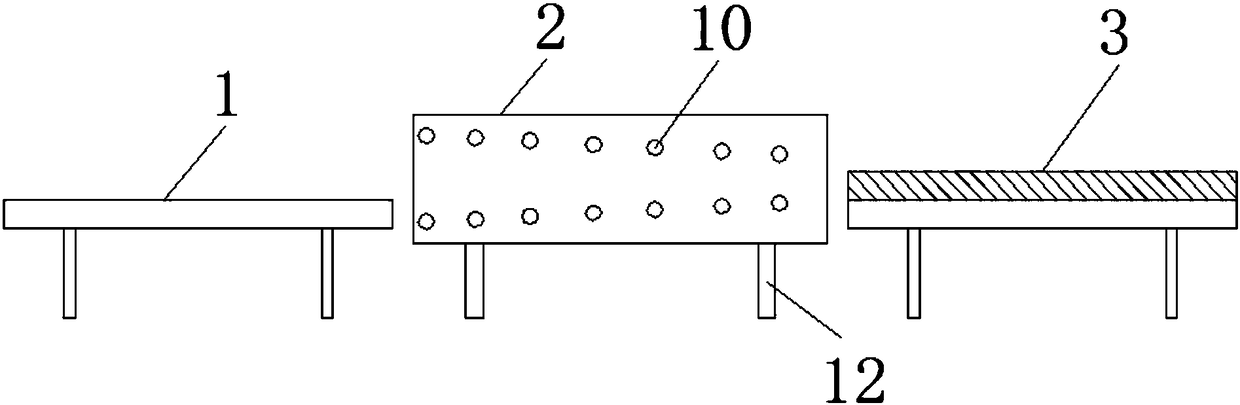

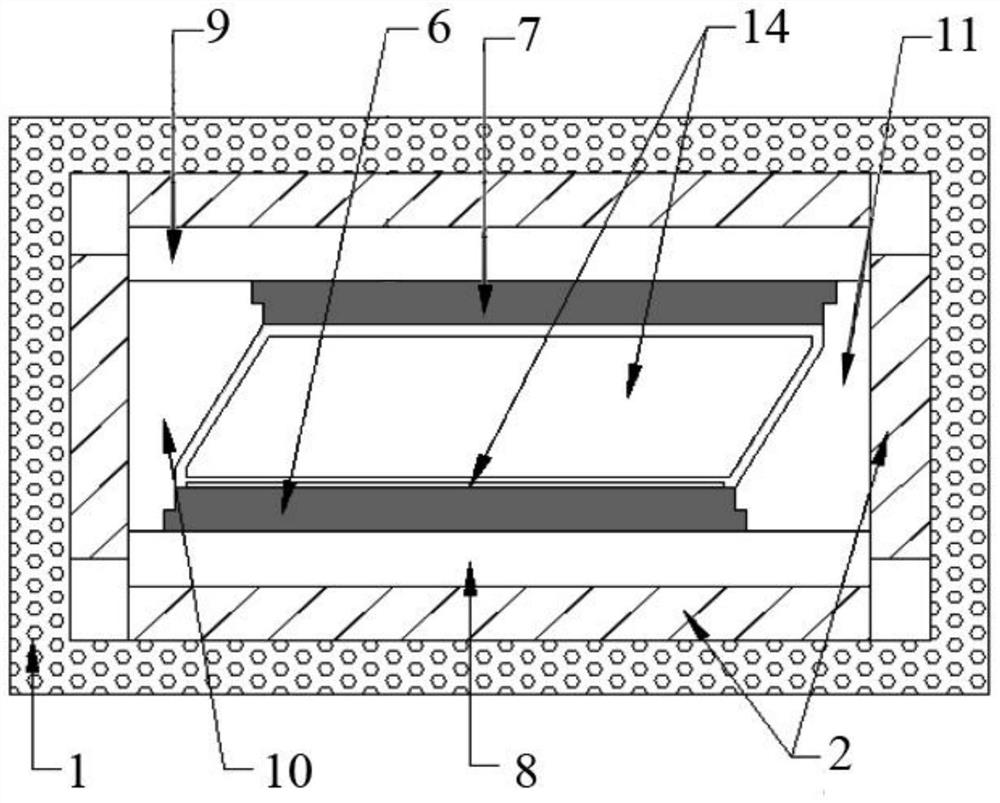

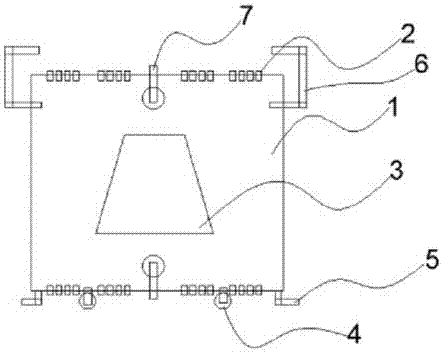

Plate double-surface synchronous polishing device

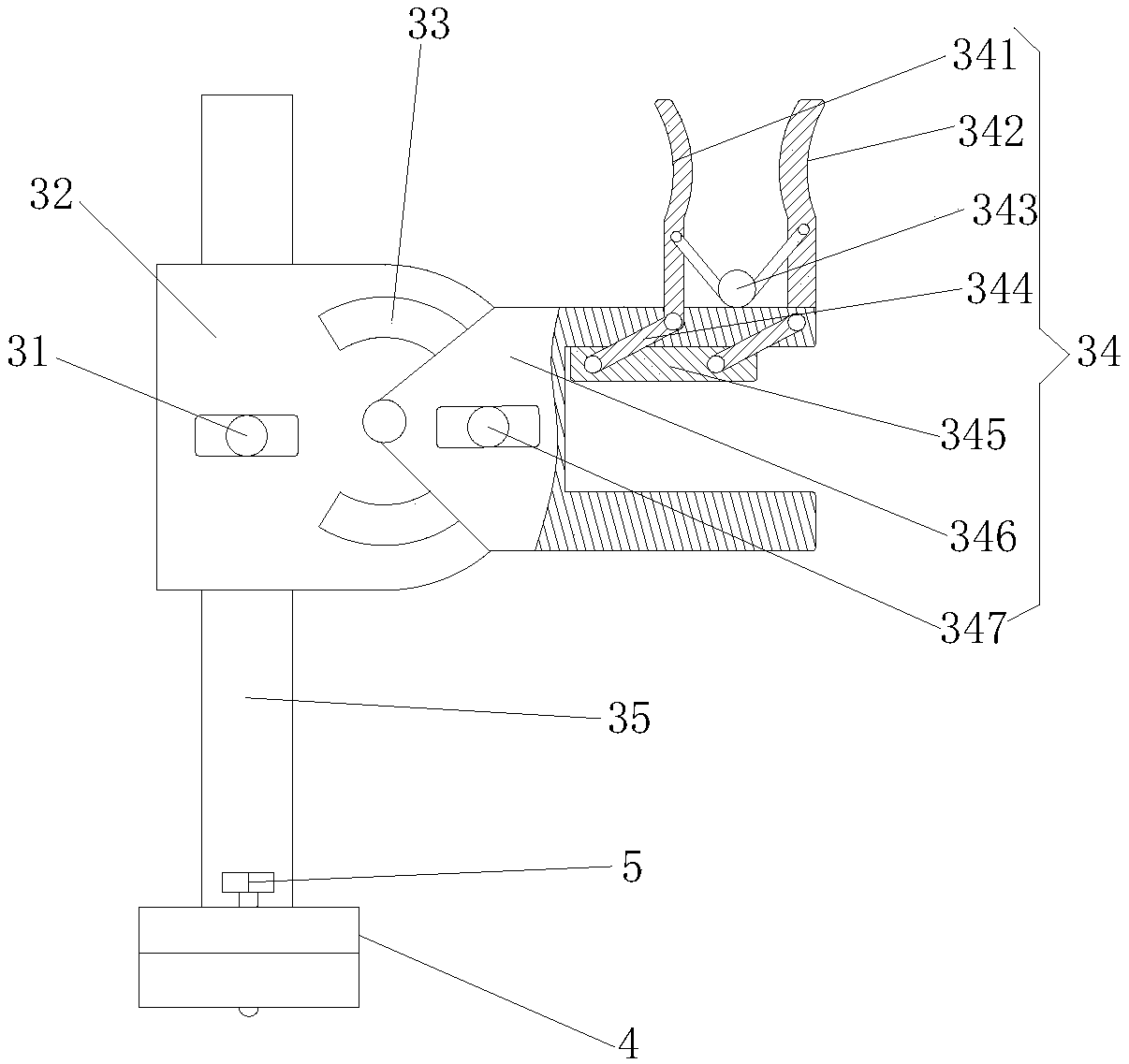

InactiveCN107225483AEven force up and downPolished evenlyBurnishing machinesGrinding machinesFixed frameAgricultural engineering

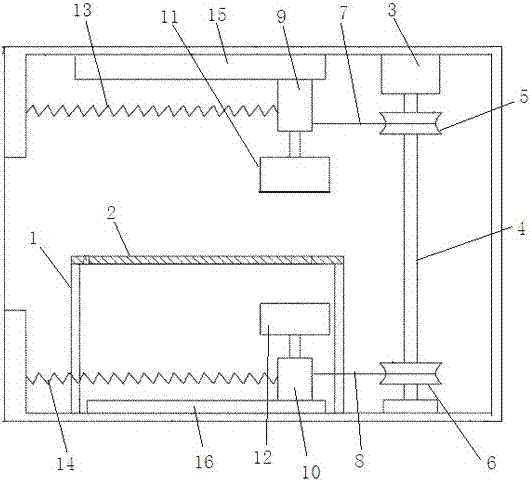

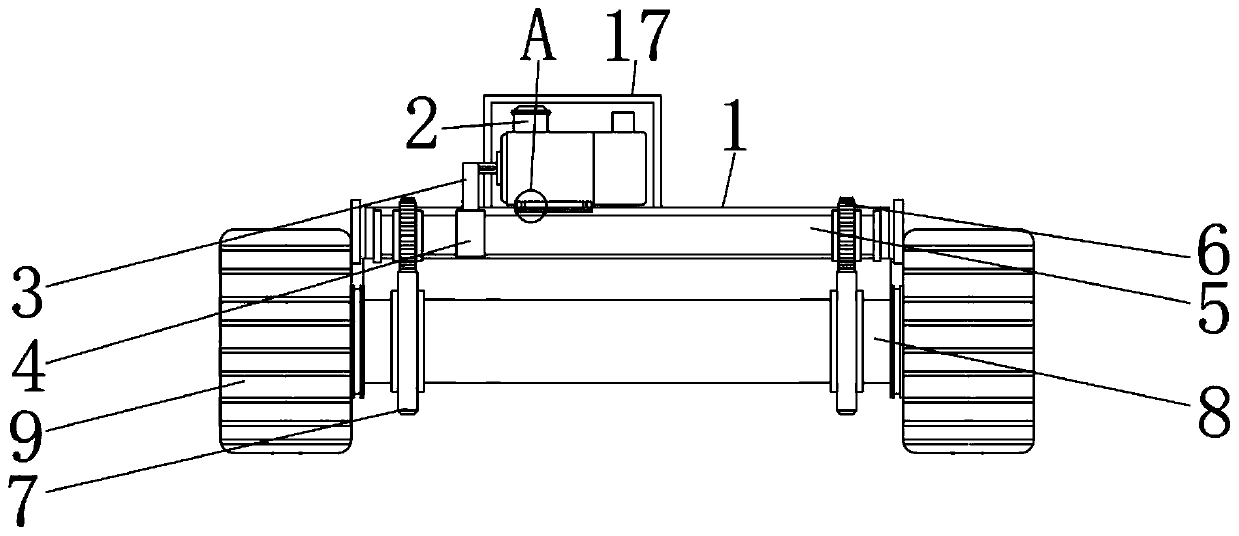

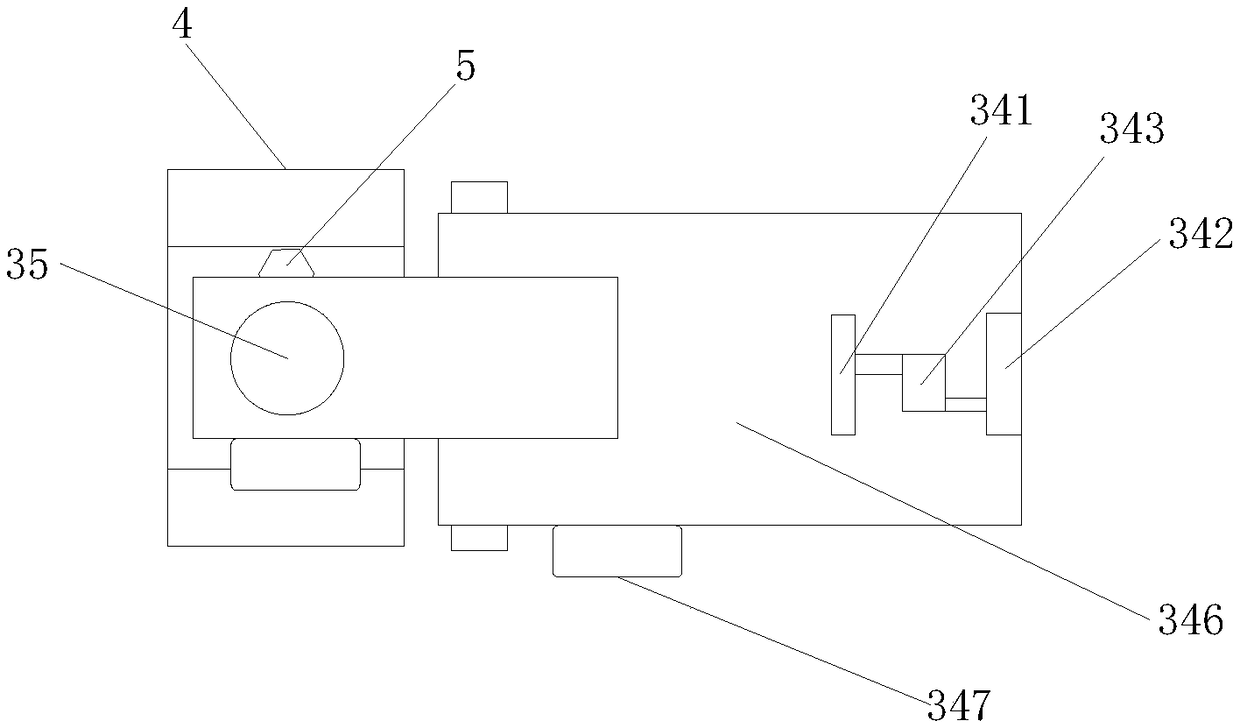

The invention discloses a plate double-surface synchronous polishing device. The plate double-surface synchronous polishing device comprises a plate fixing frame, polishing mechanisms and a synchronous driving mechanism. The number of the polishing mechanisms is two sets, and the two sets of polishing mechanisms are arranged above and below the plate fixing position of the plate fixing frame correspondingly. Each set of polishing mechanism comprises a fixedly-arranged installation base and a polishing machine slidably connected with the installation base. Each polishing machine comprises a polishing head. The polishing working surfaces of the polishing heads of the two polishing machines face the plate fixing position. The synchronous driving mechanism comprises a driving motor, a rotating shaft, transmission ropes and tension springs. An output shaft of the driving motor is fixedly connected with one end of the rotating shaft. The rotating shaft is axially perpendicular to the plate fixing plane and arranged on the side portion of the plate fixing frame. Wire wrapping wheels are fixedly arranged at the two ends of the rotating shaft correspondingly. One end of each transmission rope is connected with the corresponding wire wrapping wheel in a wrapped mode, and the other end of each transmission rope is fixedly connected with the corresponding polishing machine. One end of each tension spring is fixedly connected with the corresponding polishing machine. The length of each transmission rope connected to the corresponding wire wrapping wheel in the wrapped mode is increased, so that the corresponding tension spring is stretched. According to the plate double-surface synchronous polishing device, double-surface synchronous polishing of a plate can be achieved.

Owner:SUZHOU HENGDAL IND MATERIALS CO LTD

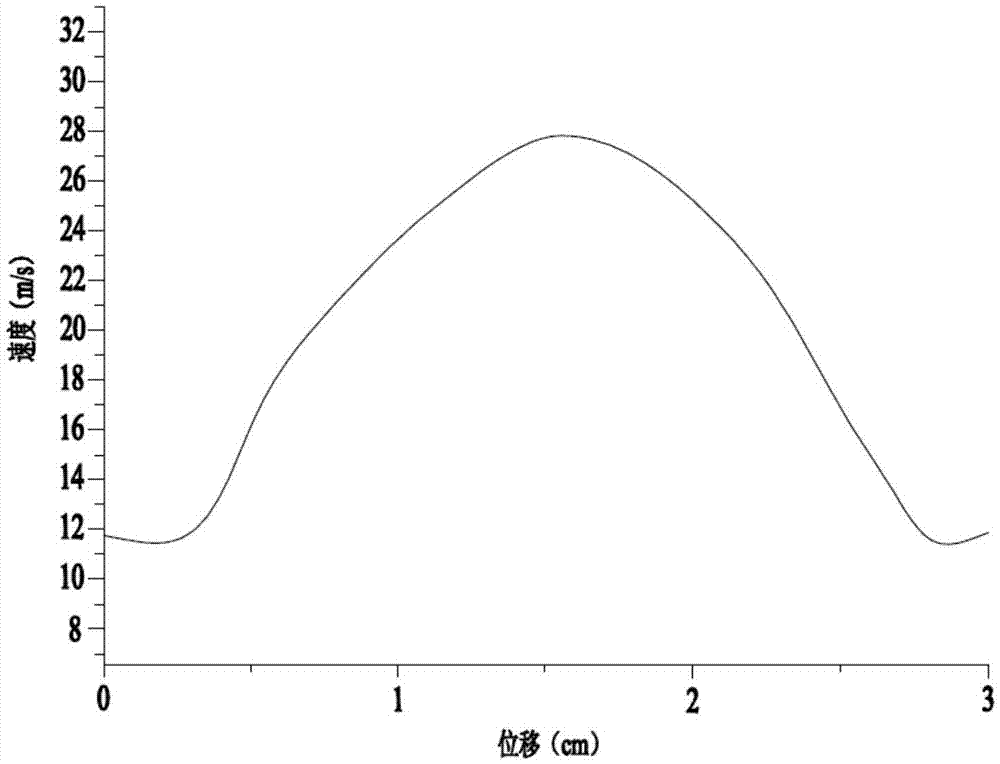

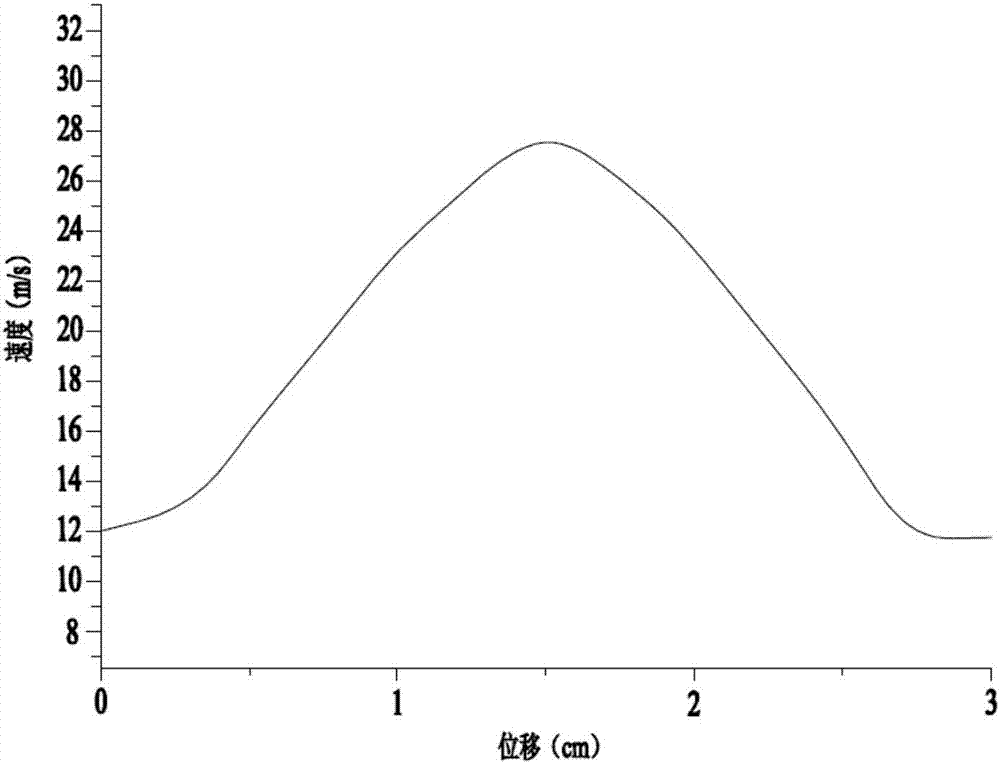

Auxiliary nozzle for air-jet loom

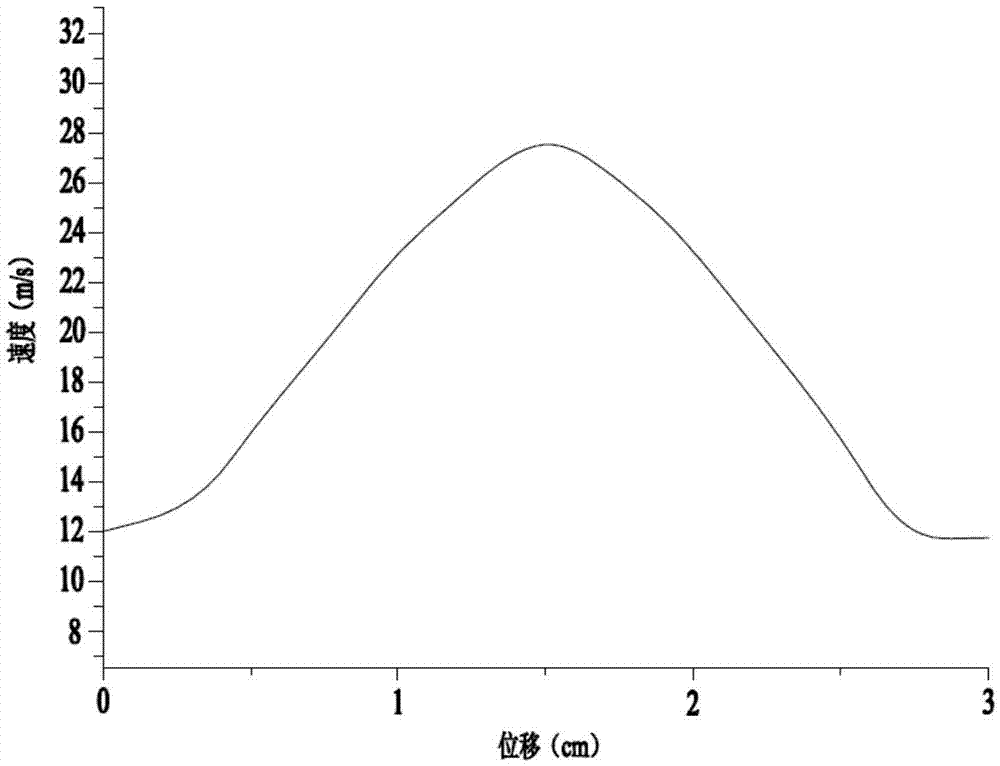

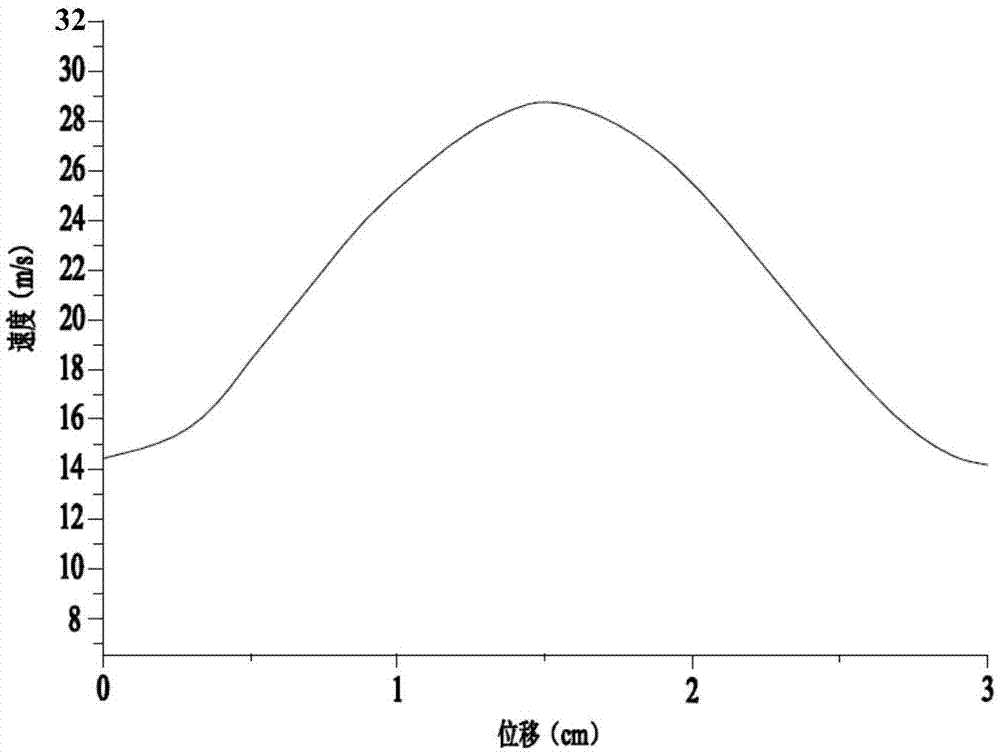

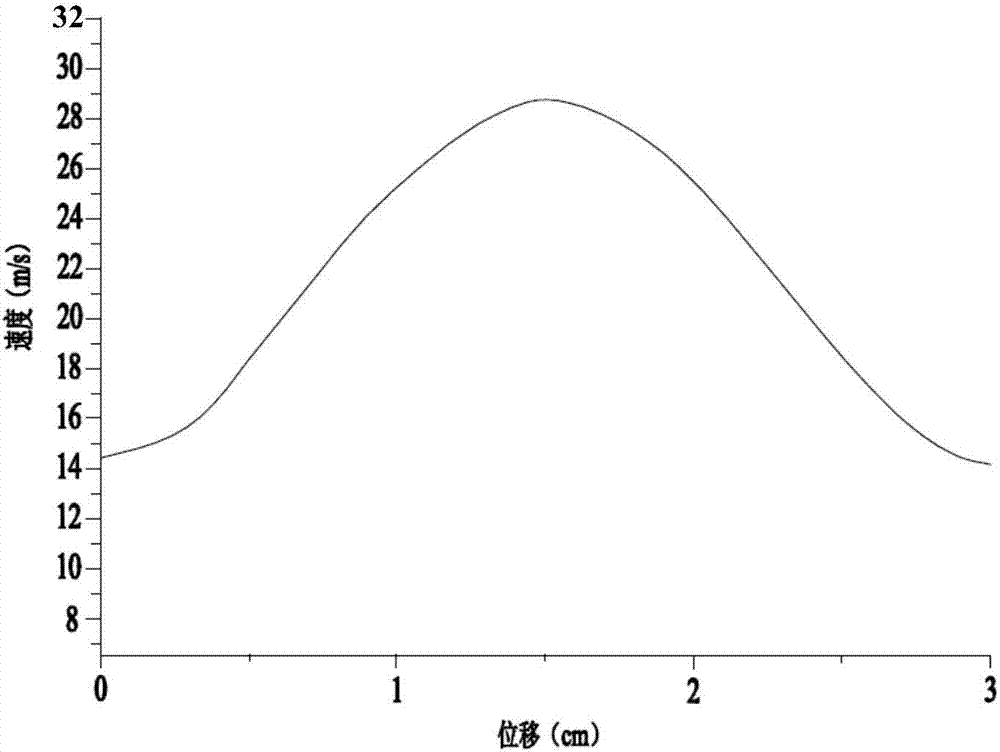

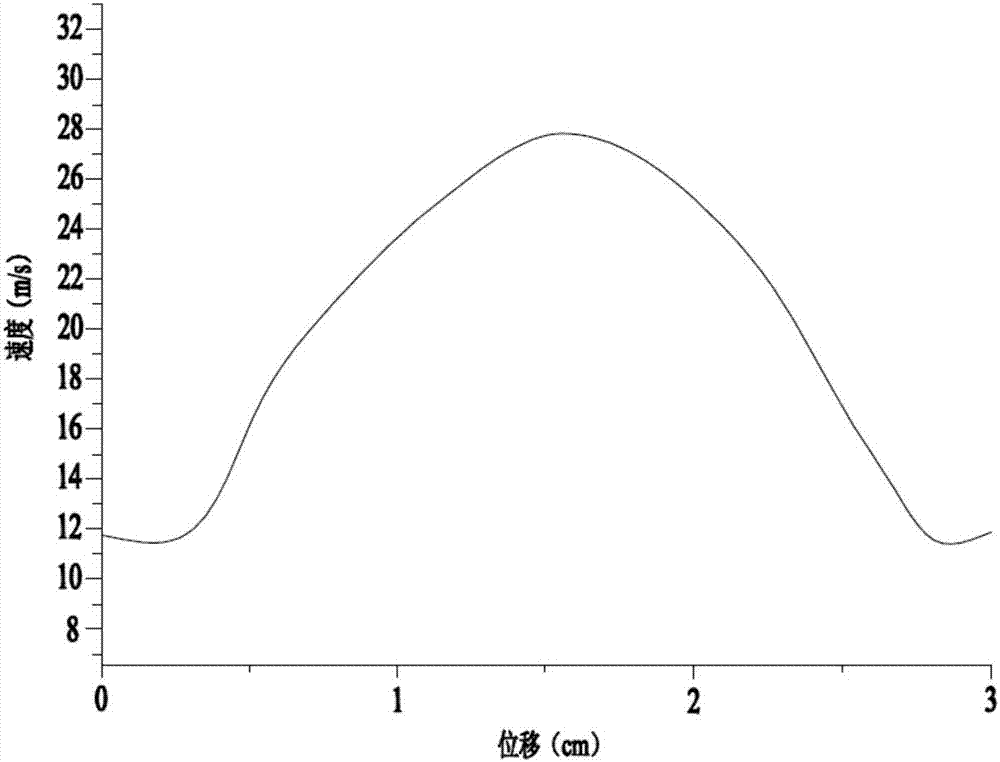

The invention discloses an auxiliary nozzle for an air-jet loom. The auxiliary nozzle for the air-jet loom comprises a nozzle body with an air flow chamber and a sprayer which is arranged on the nozzle body, wherein the sprayer comprises a first sprayer and a second sprayer which are arranged in parallel, a first air flow channel which is communicated with the air flow chamber is arranged in the first sprayer, a second air flow channel which is communicated with the air flow chamber is arranged in the second sprayer, rectangular blowholes are arranged on the first and the second sprayers, and the directions of the blowholes which are arranged on the first and the second sprayers are consistent. The auxiliary nozzle for the air-jet loom has strong injection capacity, specific performance in that the auxiliary nozzle for the air-jet loom is excellent in air flow stability on a flow channel section which is 250mm away from the blowholes, and can achieve 32m / s maximum speed of gas flow rate. Simultaneously, the first and the second sprayers respectively spray air from the upper and the lower sides of weft yarns, and enable the two sides of the weft yarns to evenly bear force, thereby being capable of perfectly maintaining kinematic velocity of the weft yarns, reducing fluctuation of the weft yarns, and guaranteeing stability of the weft yarns.

Owner:ZHEJIANG SCI-TECH UNIV

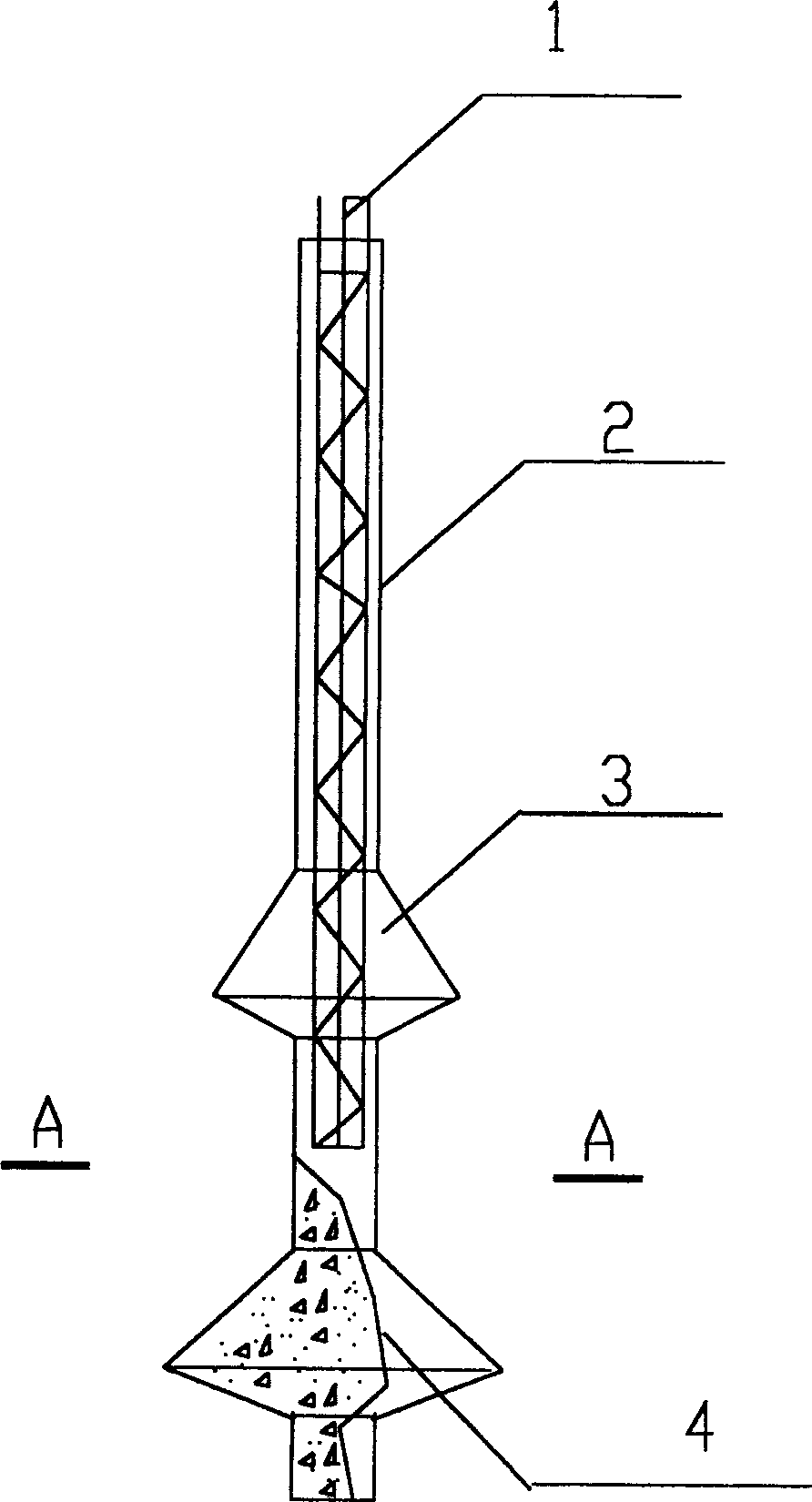

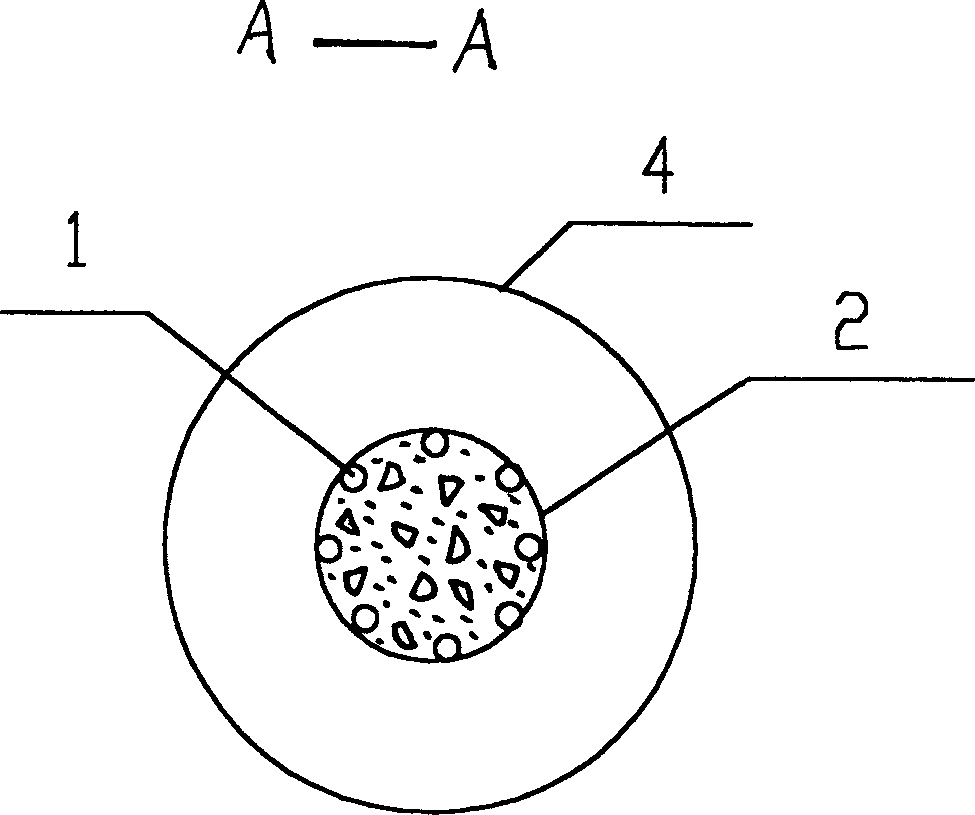

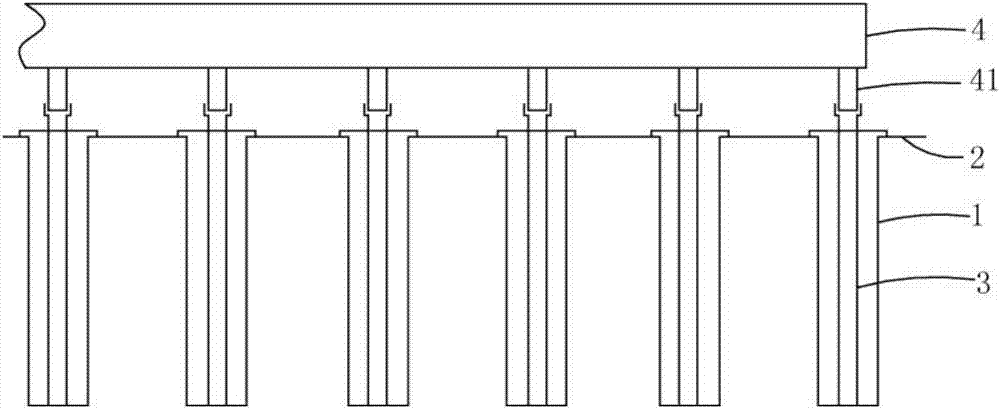

Variable bearing disk club-footed pile forming equipment

InactiveCN1170038CNot easy to cutEven force up and downBulkheads/pilesDrilling machines and methodsStructural engineering

Owner:赵书平

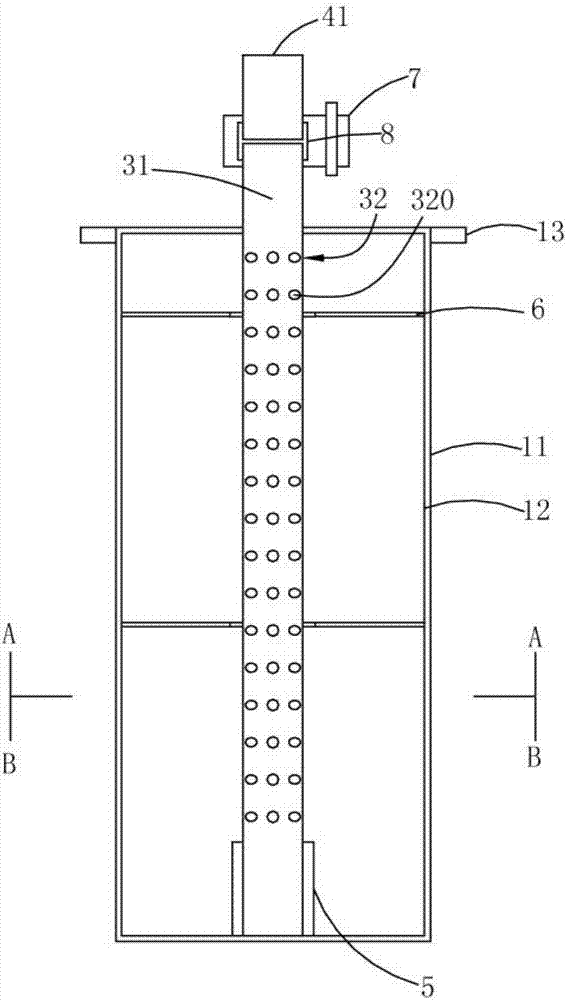

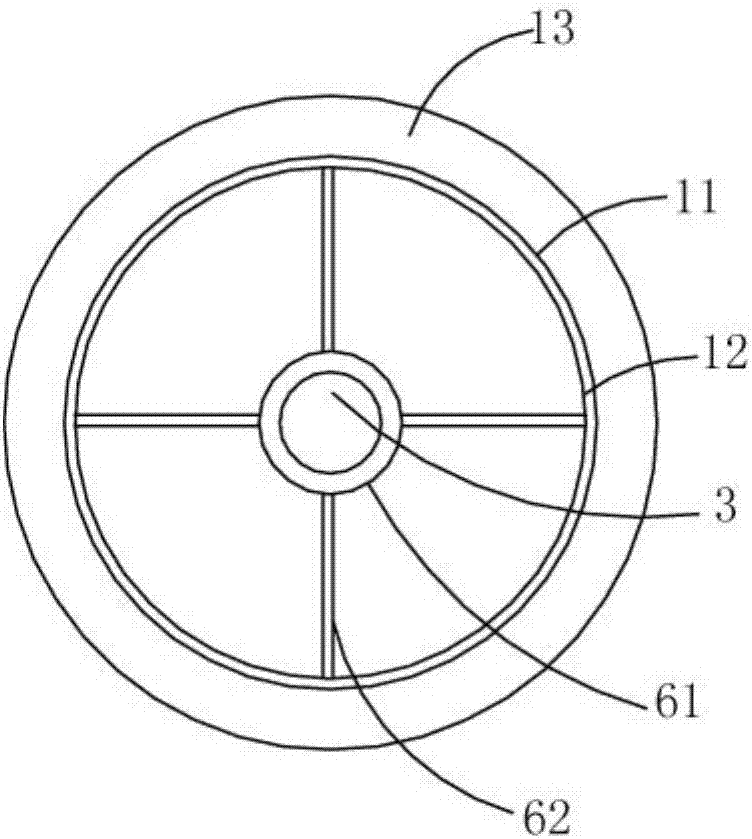

Blowback ash removal device and blowback ash removal system

InactiveCN107042036AImprove bindingNot easy to fall offDispersed particle filtrationTransportation and packagingWaste management

The invention discloses a backflow ash removal device. The blowback ash removal device is used for the backflow ash removal of a tubular filter, the tubular filter comprises an external filter membrane, an internal supporting frame for supporting the filter membrane and an air outlet channel formed in the supporting frame, the blowback ash removal device comprises a backflow tube located in the air outlet channel and matching with the length of the tubular filter, the backflow tube comprises a tube body, an air inlet located on the tube body and an air outlet structure for conducting the air inlet with the air outlet channel; and the air outlet structure comprises air outlet holes. The backflow ash removal device has the advantages of uniformity in the upper and lower force bearing of the filter membrane, good ash removal effect, difficulty in damage to the filter membrane, small noises generated in the use process, no damping, and no affection on the filtering efficiency.

Owner:CHENGDU INTERMENT TECH

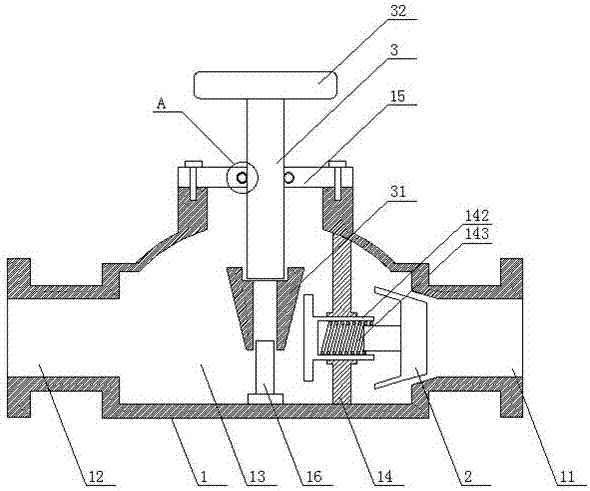

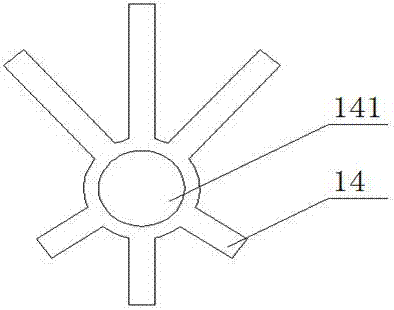

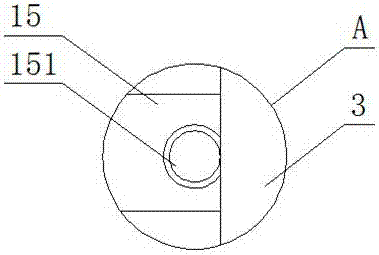

Friction-free conveying valve easy to open and close

ActiveCN105387224AEven by forceExtended service lifeOperating means/releasing devices for valvesSlide valvePhysicsEngineering

Owner:SHENZHEN XINYUREN TECH

Grinding and conveying device of PC board

InactiveCN109129070AGood delivery effectImprove work efficiencyGrinding carriagesGrinding feedersMotor driveEngineering

The invention discloses a grinding and conveying device of a PC board. The device comprises a bottom plate, a worktable is arranged on the top of the bottom plate, grooves are formed in the two ends of the top of the worktable, a first motor is arranged at one end of the top of the bottom plate, the output end of the first motor is provided with a first rotating shaft penetrating into one end of the worktable, the side, away from the first rotating shaft, of the worktable is provided with a second rotating shaft extending to one end inside the worktable, and a first driving wheel is arranged at the end, close to the first motor, of the first rotating shaft. A second motor drives a fourth rotating shaft to rotate, a first grinding plate is driven to grind the top of the PC board, a third motor drives a fifth rotating shaft to rotate, a second grinding board is driven to grind the bottom of the PC board, the upper and the lower of the PC board are uniform in stress, the breakage of the PC board in the grinding process can be avoided, and the use effect of the PC board grinding device is better.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

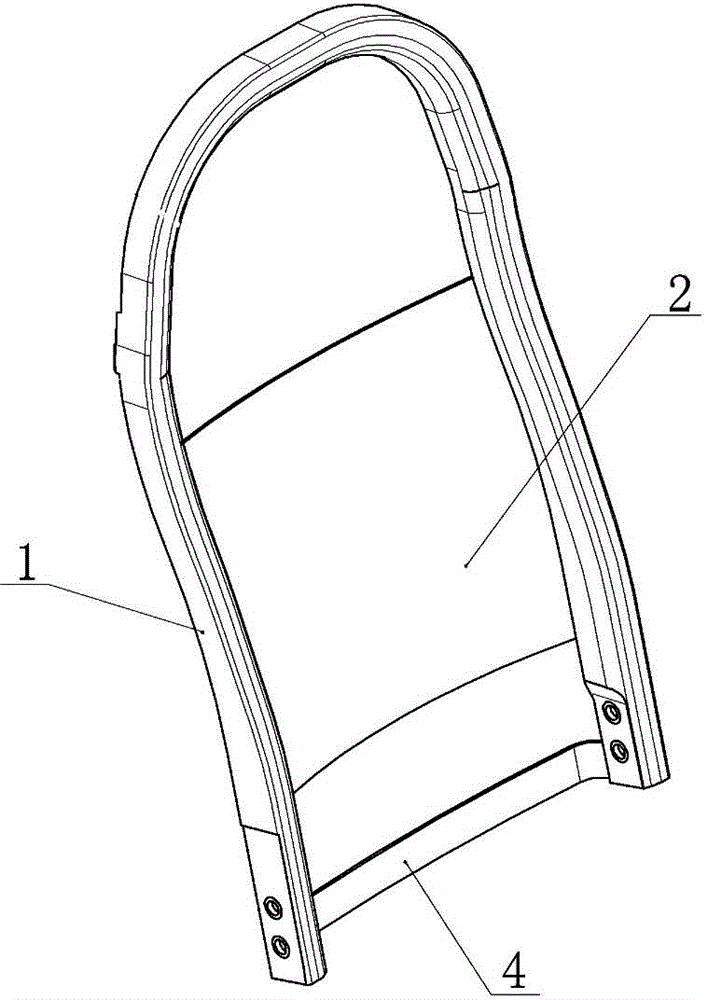

Manufacturing method of seat framework

The invention discloses a manufacturing method of a seat framework. The seat framework comprises an n-shaped frame which is integrally formed by a thermoplastic composite material, wherein reinforcing ribs are arranged on the inner side of the n-shaped frame; a backrest plate is connected to the inner sides, from the middles to the bottoms, of two side frames of the n-shaped frame, and is made of a woven fiber and PP (Polypropylene) pre-impregnated sheet or a horizontal continuous fiber yarn and PP pre-impregnated sheet. The structure of the seat backrest framework is improved and optimized, force bearing points can be uniformly dispersed, the force bearing time can be prolonged, and the maximum impact strength is greatly reduced. The overall force bearing situation is obviously improved. A finite element analysis result accords with an interurban coach safety standard. The thickness of the backrest plate is decreased, materials are saved, the cost is reduced, the seat framework is safe, reliable and long in service life, and the comfort of a human body is improved.

Owner:ZHENGZHOU LINGYU NEW MATERIALS

Automatic pressure relief valve

InactiveCN106969176AImplement auto-shrinkEasy to adjust the liquid inlet volumeSpindle sealingsOperating means/releasing devices for valvesEngineeringScrew thread

The invention discloses an automatic pressure relief valve comprising a valve body, a valve element and a valve rod. A liquid inlet is formed in one side of the valve body; a liquid outlet is formed in the other side of the valve body; a cavity is formed inside the valve body, and the two ends of the cavity are connected with the liquid inlet and the liquid outlet correspondingly; a supporting frame is installed on the side, at the end of the liquid inlet, inside the valve body; a circular through hole is formed in the lower end of the supporting frame, and a T-shaped circular cylinder is installed inside the circular through hole; a compression spring is installed inside the T-shaped circular cylinder; a valve cover is installed at the upper end of the valve body through a bolt; one end of the valve element is installed inside the liquid inlet, and the other end of the valve element is installed inside the T-shaped circular cylinder and connected with one end of the compression spring; a valve rod is installed at the center of the valve cover; a tapered sleeve is installed at the lower end of the valve rod through a thread; and a hand wheel is installed at the upper end of the valve rod. The automatic pressure relief valve has the characteristics of being simple and reasonable in structure and flexible in operation.

Owner:YANCHENG OURUN PETROCHEMICAL EQUIP MFG CO LTD

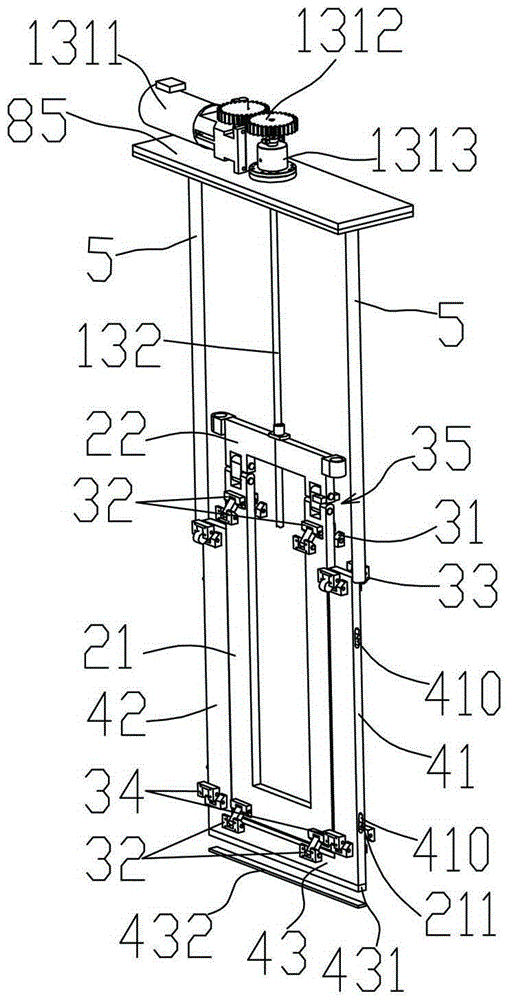

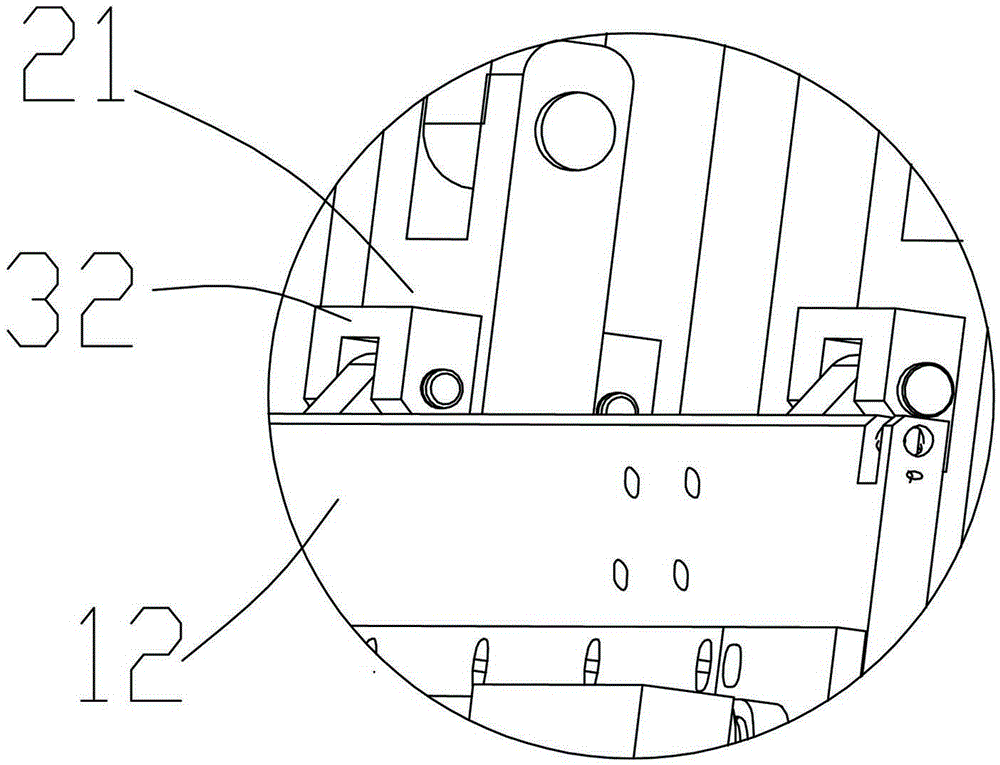

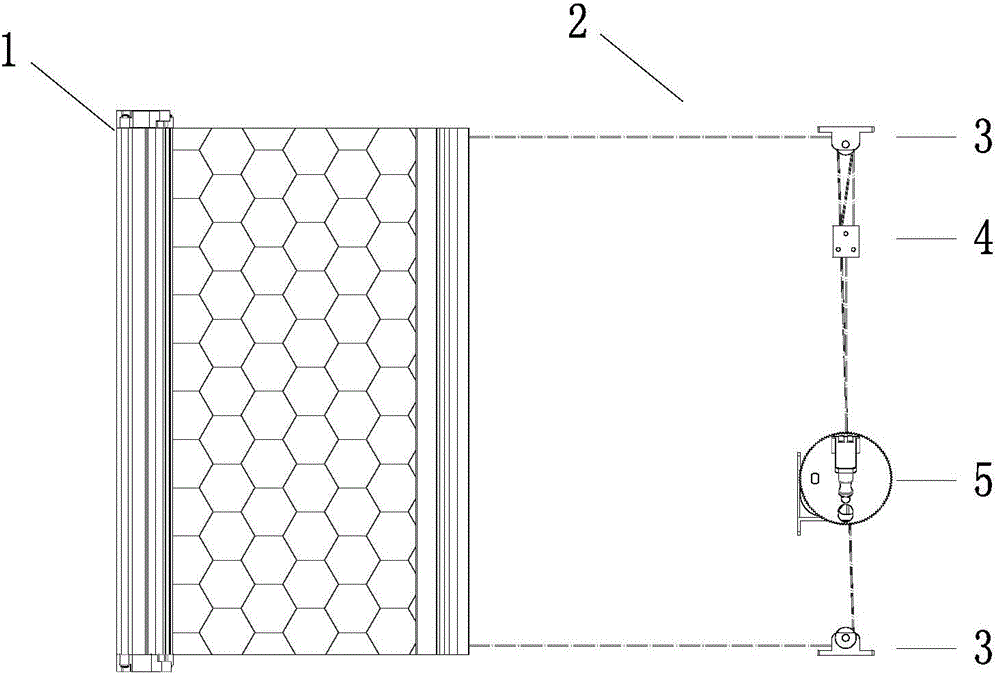

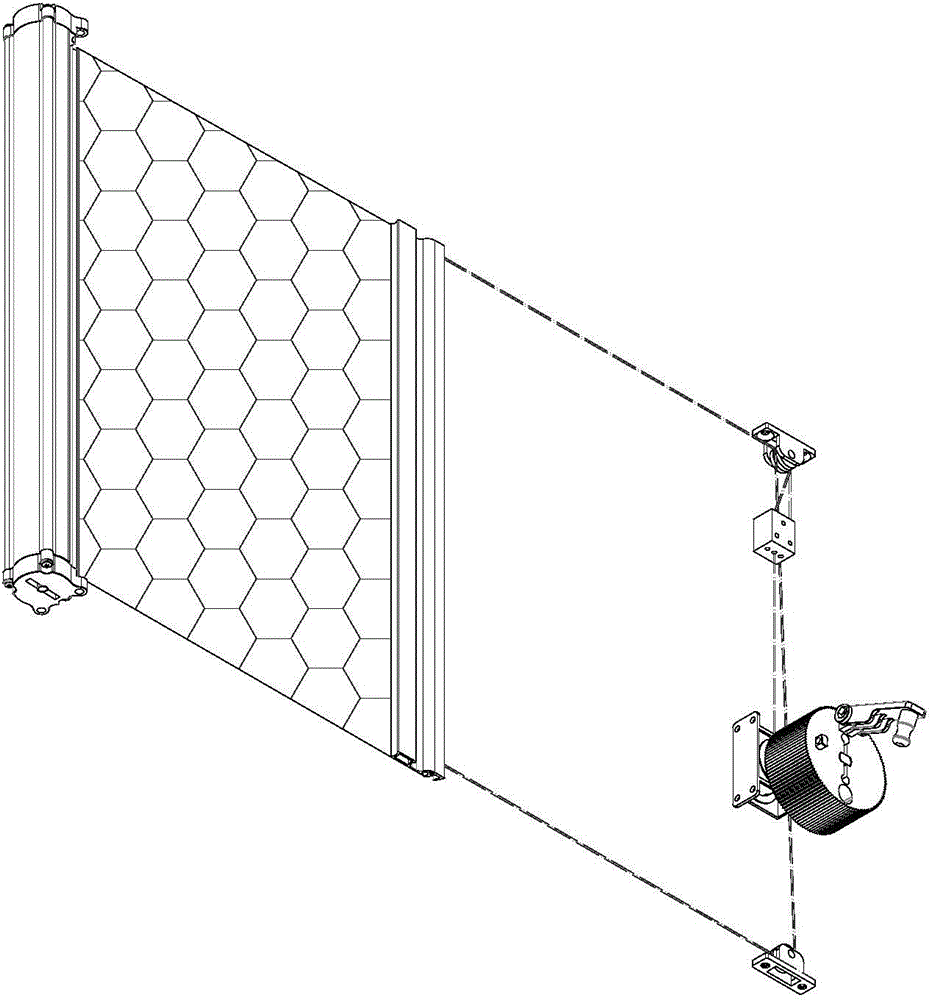

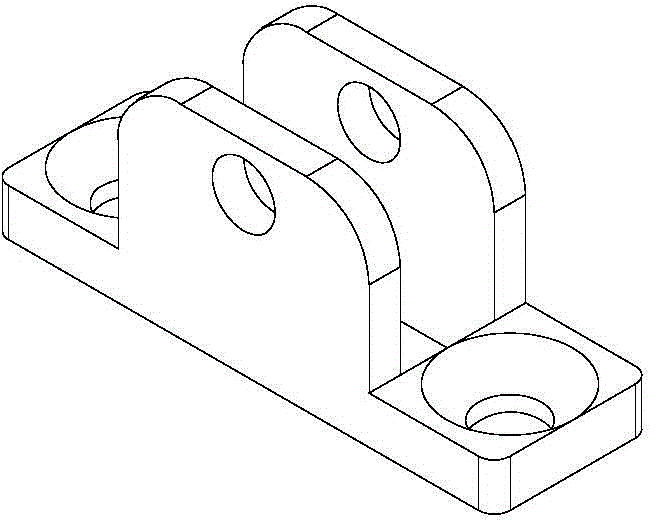

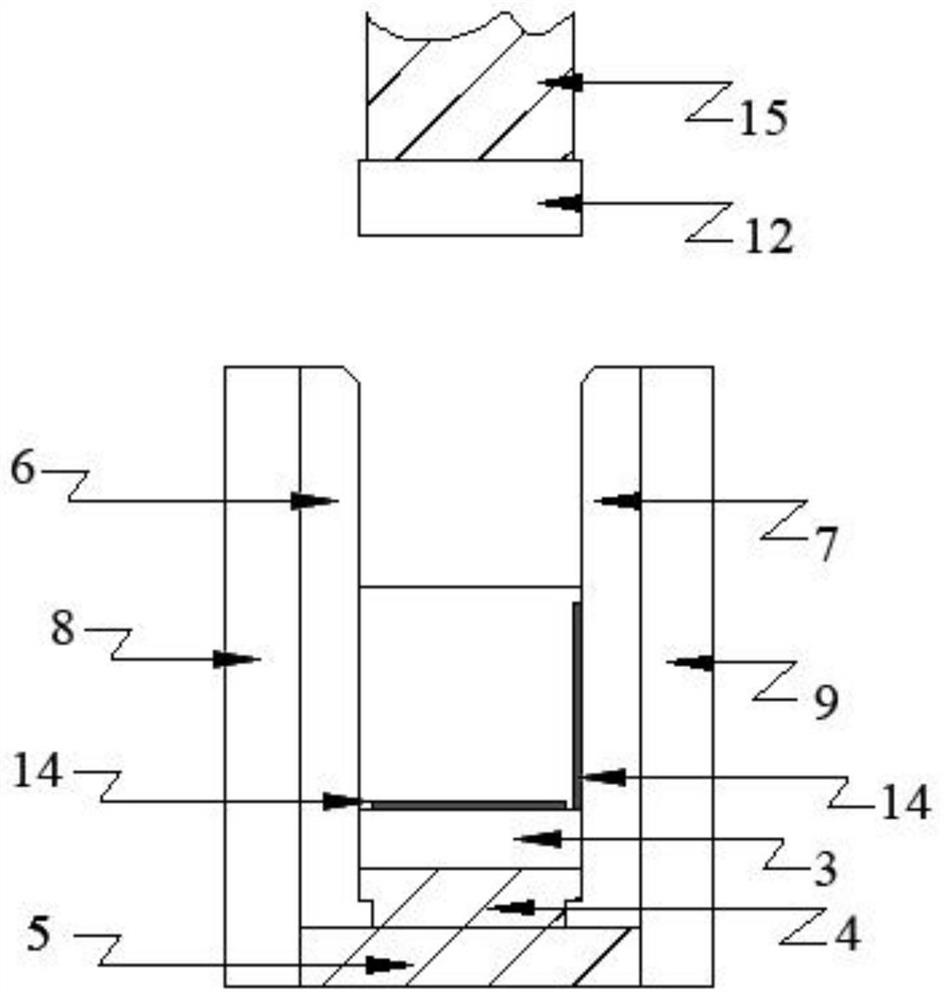

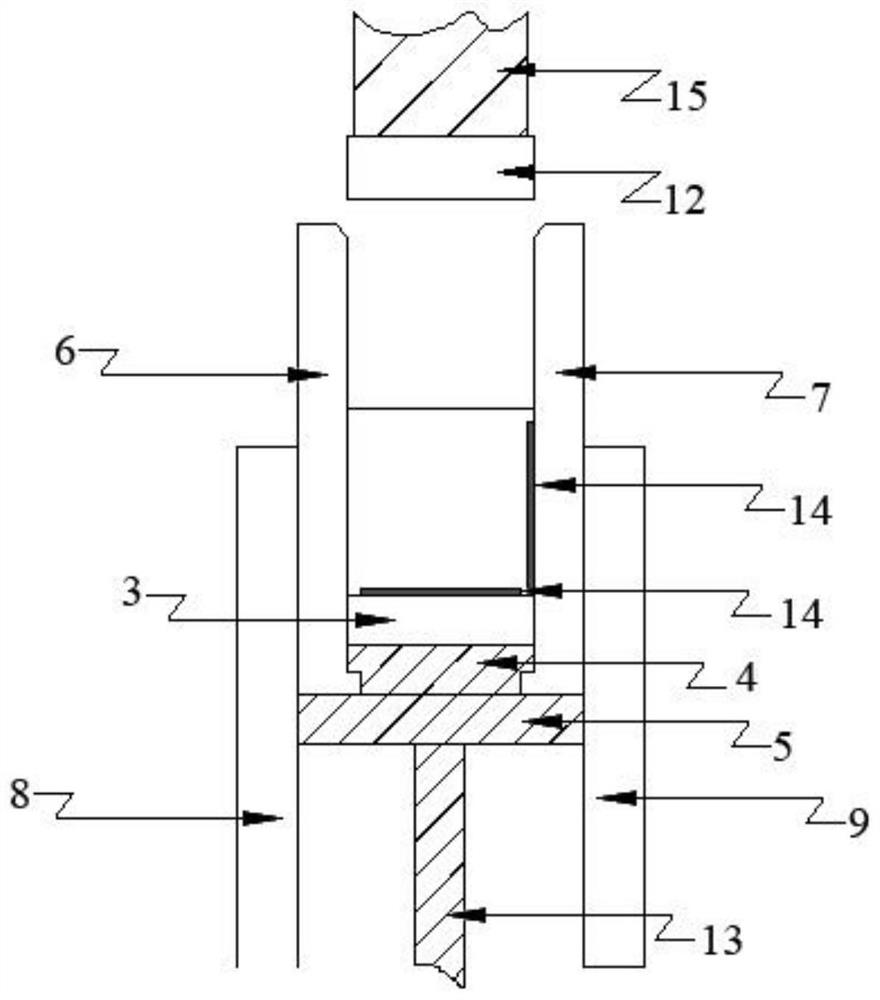

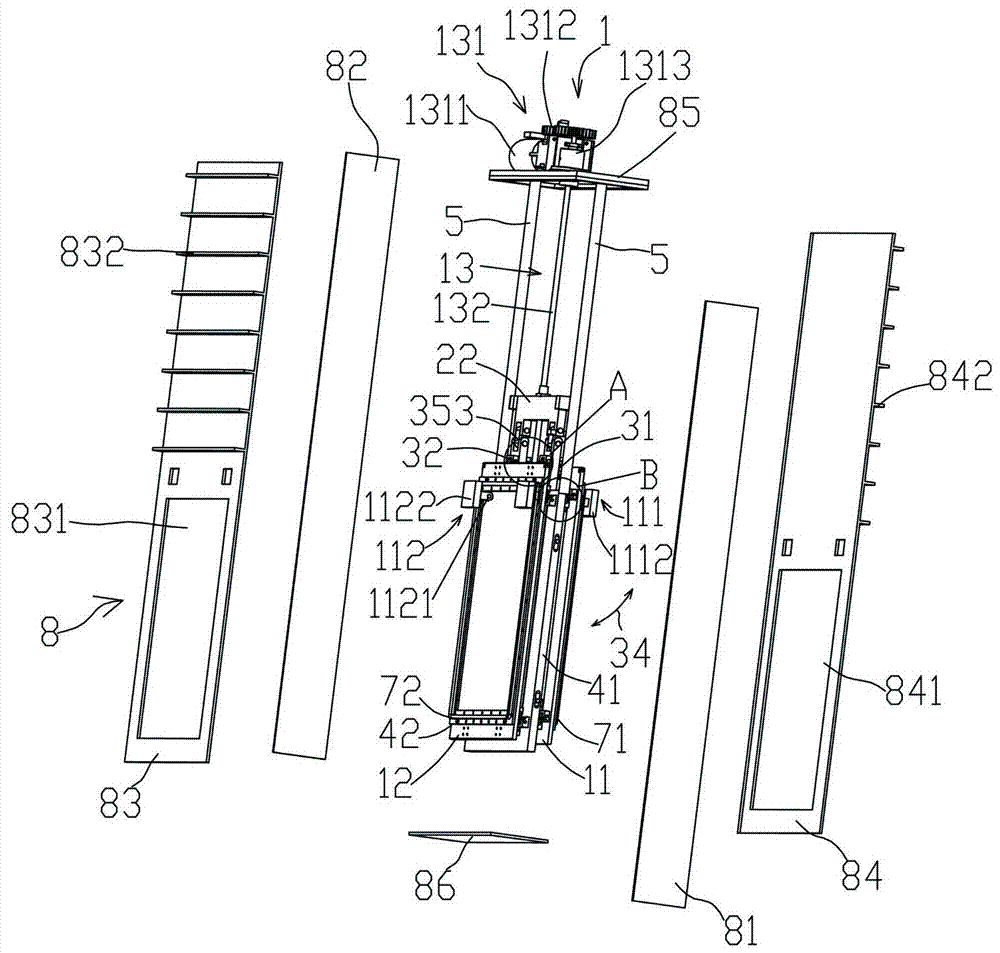

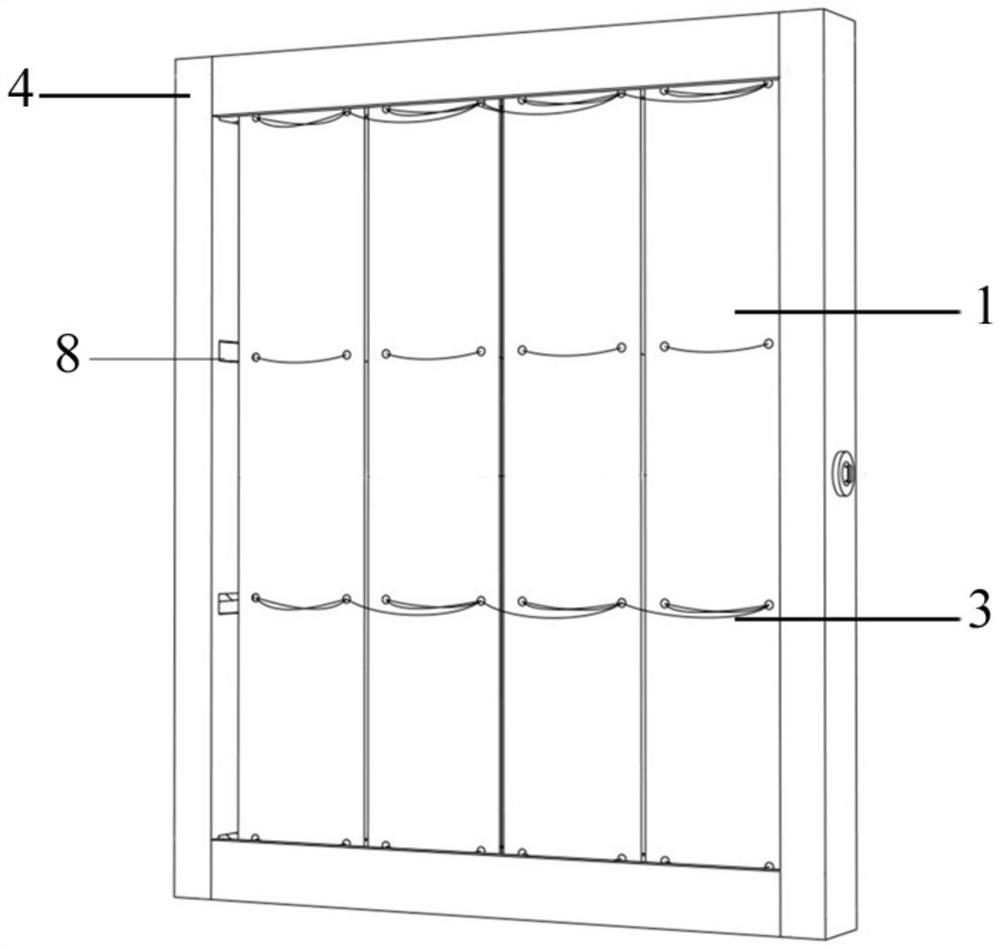

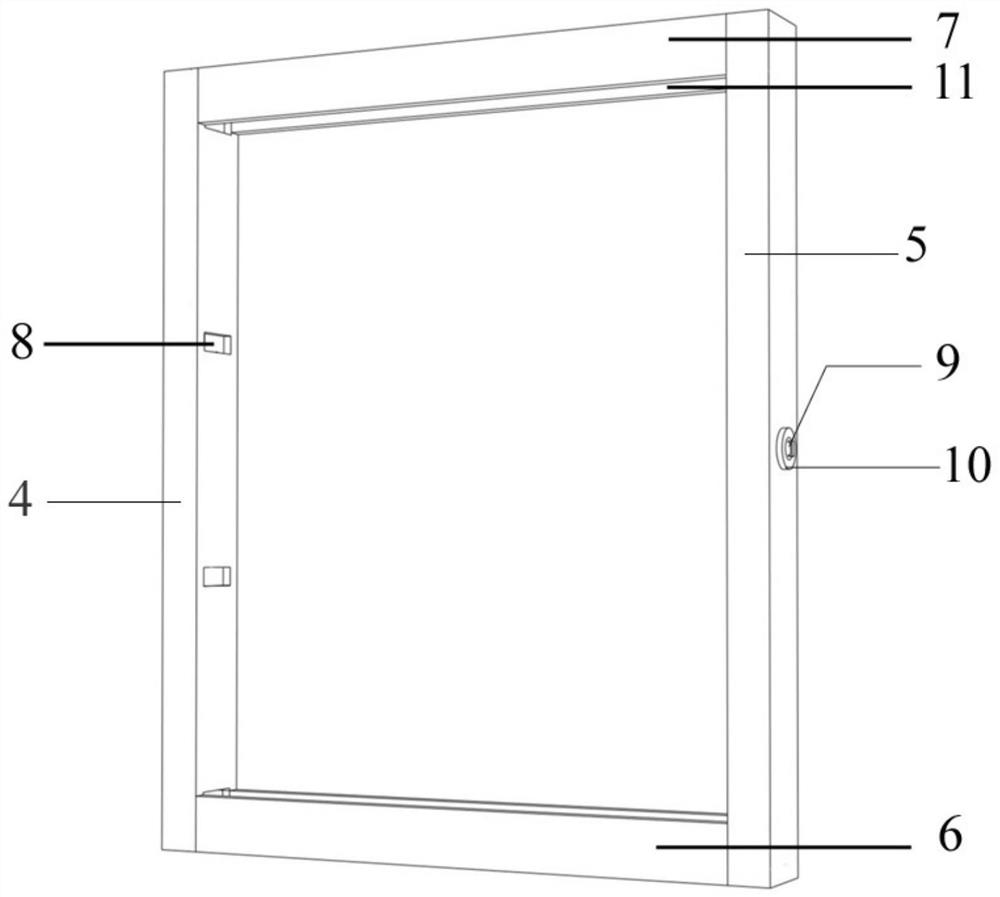

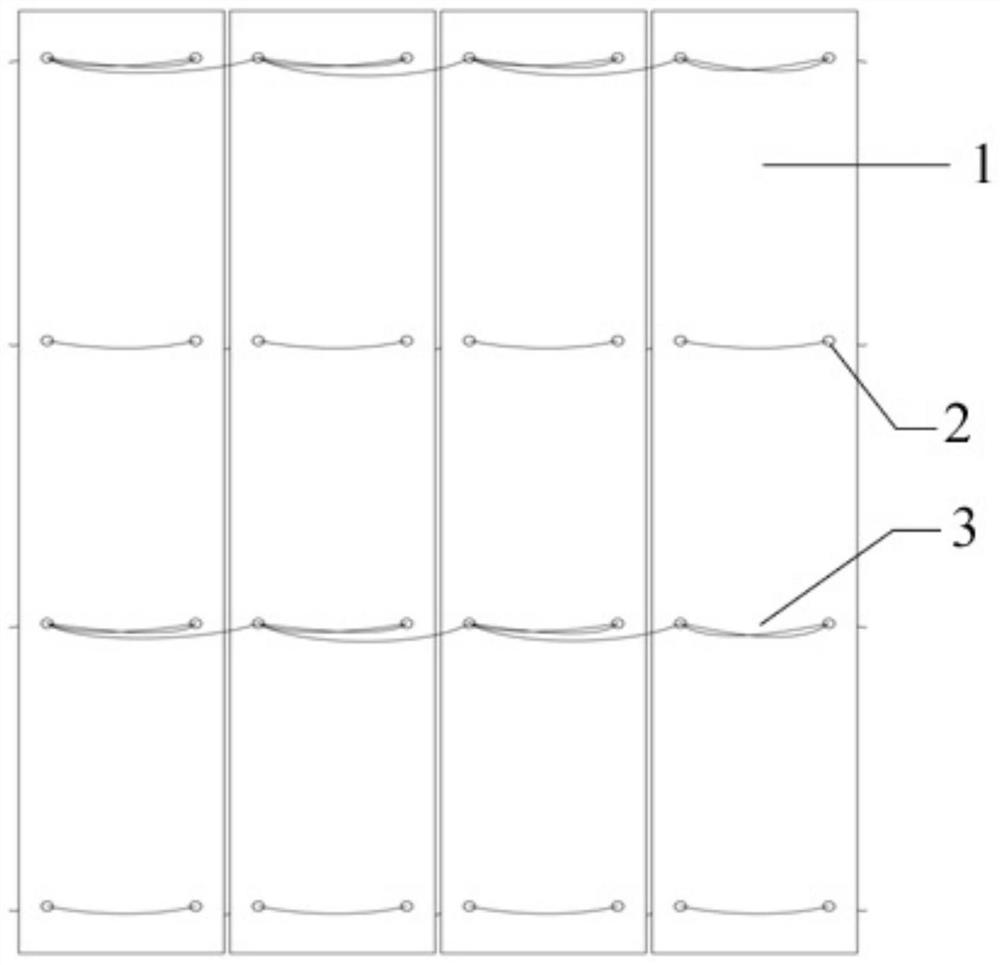

An opening and closing device for a roll-type invisible screen window

ActiveCN104047535BEven force up and downGuaranteed vertical movementInsect protectionStress pointEngineering

The invention relates to the technical field of winding roller type fly gauze windows, in particular to an opening and closing device for a winding drum type invisible gauze window. An invisible gauze lead-out device comprises a rotary handle, gears and a reel. A linkage device comprises pulleys, a wire connector and steel wire ropes. An invisible gauze assembly device comprises a gauze pull rod, and the gauze pull rod is connected with gauze. The rotary handle is connected with the gears. The gears are connected with the reel. The steel wire ropes are wound around the reel. The steel wire ropes extend out of the tail end and the head end of the invisible gauze lead-out device respectively and are connected with the two ends of the gauze pull rod through the pulleys, wherein the multiple steel wire ropes at one end are provided with the wire connector and are combined together through the wire connector so that vertical stress of the invisible pull rod can be uniform and vertical movement of the invisible pull rod can be guaranteed; at the moment, the invisible gauze is in a tightened state and can not deform under the wind action; consequently, the problems that the invisible gauze is inclined, gets stuck, trips and the like because of unbalanced stress points when the invisible gauze is led out due to different specifications of the invisible gauze, different elevations and operators with different heights in the industry are solved.

Owner:浙江富丽华铝业有限公司

A kind of preparation method of large size metal skin refractory brick and mobile mold thereof

ActiveCN113635433BEven force up and downEnsure the uniformity of pressingDischarging arrangementMould auxillary partsScarificationFire brick

A method for preparing large-sized metal skin refractory bricks and a mold thereof, belonging to the technical field of refractory materials. Plates, Die End Plates and Die Covers. The method of the invention improves the uniformity of the pressing force by designing the upper and lower forces of the refractory bricks, ensures that sufficient pressure does not crack, improves the covering firmness of the metal skin by designing the metal skin special-shaped hooks, and protects the metal skin through a special mold, and the movable side of the mold is The plate and the metal skin can move synchronously to avoid the deformation of the metal skin or the existence of friction and scratches, and at the same time protect the abrasive tool and prolong the service life of the abrasive tool, so as to improve the production qualification rate and production efficiency.

Owner:YINGKOU PUNAI MAGNESIUM MATERIALS CO LTD

A device for repairing and protecting leaking pipes for water conservancy projects

ActiveCN113108155BAvoid shockGuaranteed independent rotationPipe elementsLeaking waterStructural engineering

The invention provides a leakage pipeline repair and protection device for water conservancy projects, which relates to the field of water conservancy projects. The leaking pipeline repair protection device for water conservancy projects includes a wrapping mechanism, an adjustment mechanism is arranged above the outer surface of the wrapping mechanism, and a fixing mechanism is sleeved on the outer surface of the wrapping mechanism between the adjustment mechanism and the wrapping mechanism. This water conservancy project uses a leaking pipeline repair protection device. First, the cylinder liner sleeved outside the pipeline is separated from the rubber sleeve, the cylinder liner is taken out, the adjustment mechanism is sleeved on the outside of the sleeve mechanism, and the upper push plate and the lower push plate are moved toward each other. Push from the outside, so that the rubber sleeve can be stretched, so that the rubber sleeve is close to the outer surface of the pipe. At this time, the outer iron sheet is sleeved on the outer surface of the rubber sleeve, and the outer iron sheet is pulled, so that the outer iron sheet can be tightly attached to the rubber sleeve , fix the outer iron sheet, the repaired part can be isolated from the air through the tensioned rubber sleeve, and at the same time, the outer iron sheet can be used to protect the repaired part from impact.

Owner:湖南宝荣建设工程有限公司

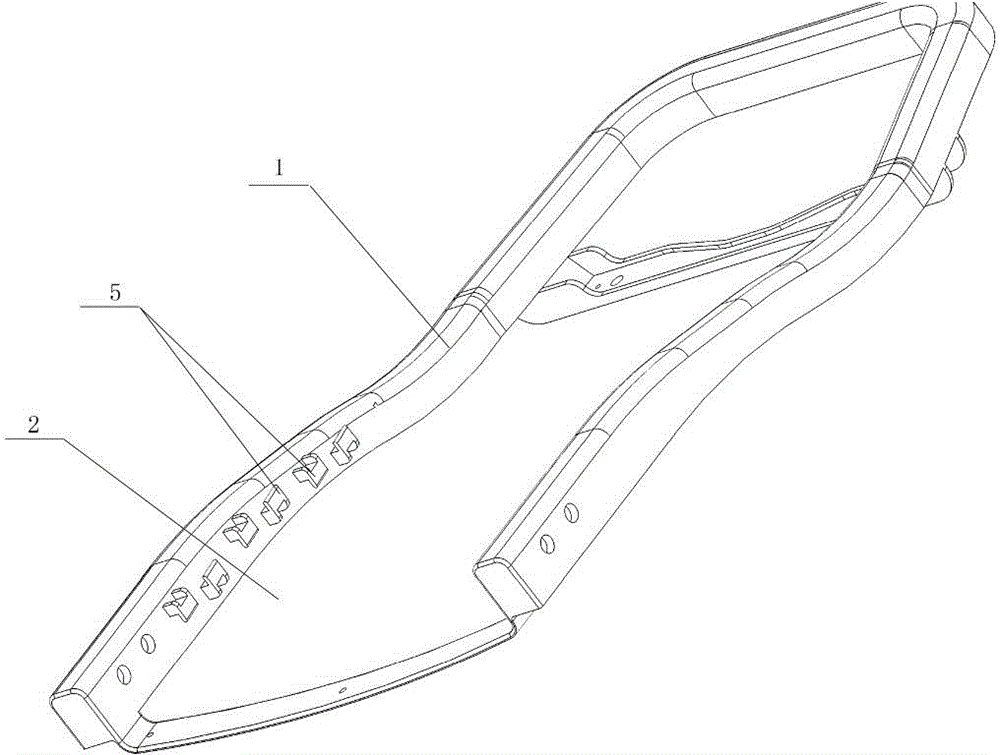

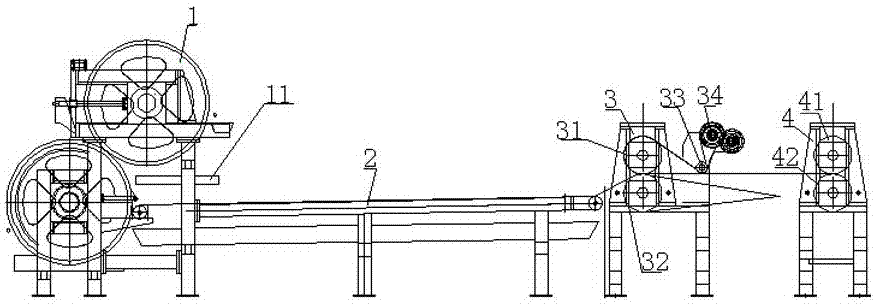

Automatic filament feeding device provided with roller type deviation rectifying mechanism and used for EPP granulator

The invention discloses an automatic filament feeding device provided with a roller type deviation rectifying mechanism and used for an EPP granulator. The automatic filament feeding device comprisesa machine table for mounting the EPP granulator. The automatic filament feeding device is characterized in that a conveying roller mechanism for conveying EPP long filaments to an inlet of the EPP granulator is arranged on the machine table, and the device further comprises the roller type deviation rectifying mechanism at the inlet of the EPP granulator, upper and lower deviation rectifying rollers mounted on an X-shaped cross bracket, a drive device for driving the X-shaped cross bracket to open and close, and a supporting frame for supporting the X-shaped cross bracket as well as a controller, wherein a photoelectric sensing device electrically connected to the controller is arranged on the supporting frame for emitting a signal to the controller for controlling the drive device to actwhile detecting that EPP long filaments pass through from a position between upper and lower deviation rectifying rollers, driving the X-shaped cross bracket to close for oppositely clamping the EPP long filaments through the upper and lower deviation rectifying rollers, and rectifying the long filaments to be aligned to the inlet of the EPP granulator. The device has a deviation rectifying function for the EPP long filaments, is better in filament feeding precision and stability, is simpler in structure and is lower in cost.

Owner:苏州祥侯新材料科技有限公司

Robot control device with stop function

InactiveCN111546308AAccurate transmissionRealize transmissionProgramme-controlled manipulatorGear wheelDrive shaft

The invention discloses a robot control device with a stop function. The robot control device with the stop function comprises an installation panel and a second transmission shaft. A motor is arranged at the left end of the upper side of the installation panel, a transmission belt is connected with the outer side of the left end of the motor, and a motor controller is installed on the outer sideof the lower end of the transmission belt. A first transmission shaft penetrates through the inner side of the motor controller, first gears are arranged at the two ends of the first transmission shaft, and second gears are connected with the lower sides of the first gears. The robot control device with the stop function comprises the first gears, the first gears and the second gears mesh with each other, easily conduct transmission and have the advantages of being accurate in transmission, high in efficiency, compact in structure, reliable in work, long in service life and the like, the transmission between the two parallel shafts including the first transmission shaft and the second transmission shaft can be achieved, the directions of the gravity and the acting force borne by the firstgears and the first transmission shaft in the rotating process are consistent, specifically, the axes of the first gears and the first transmission shaft coincide with each other, and the phenomenon that equipment skids, or the wear is serious cannot happen.

Owner:广东鹄志人才服务有限公司

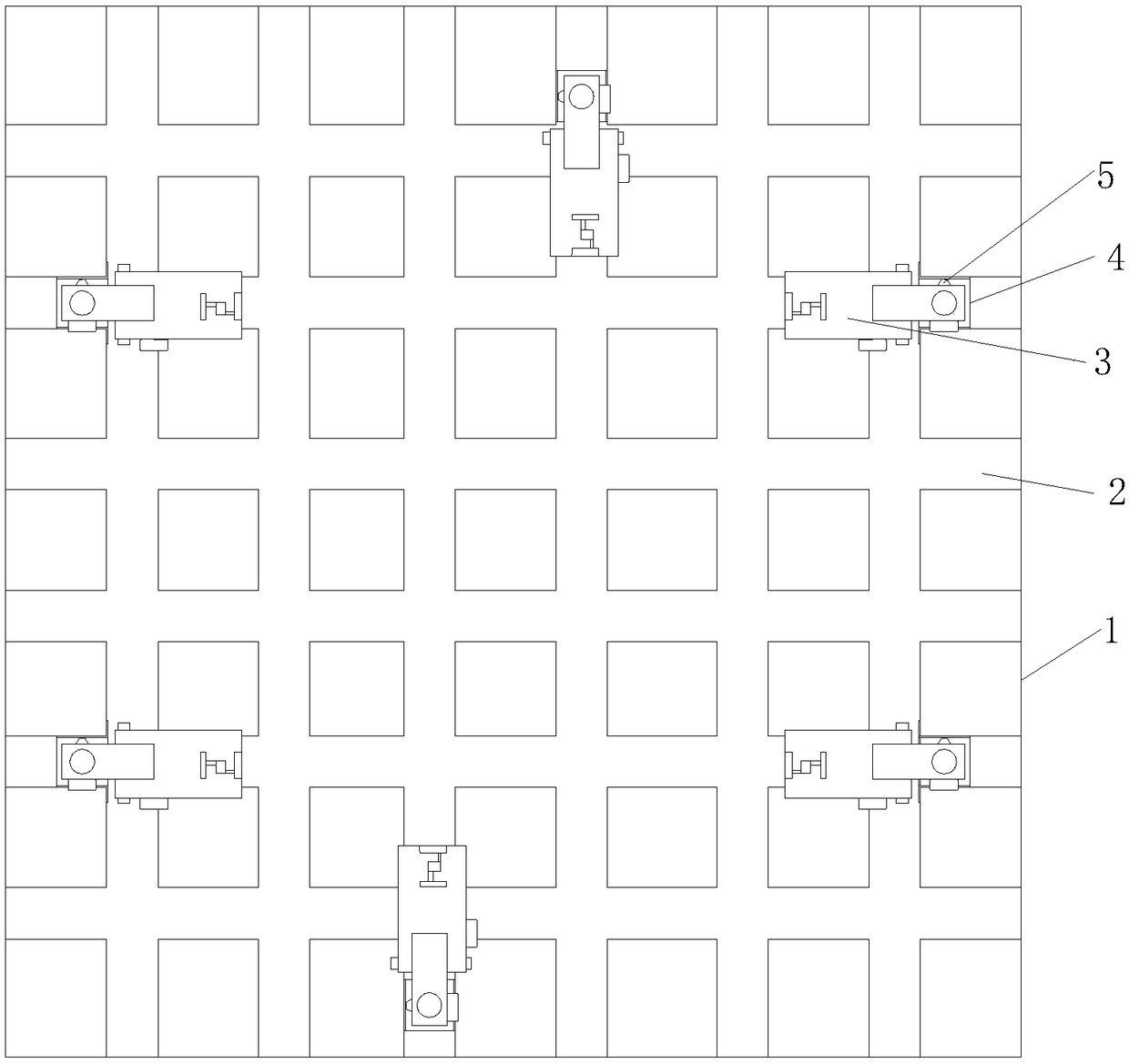

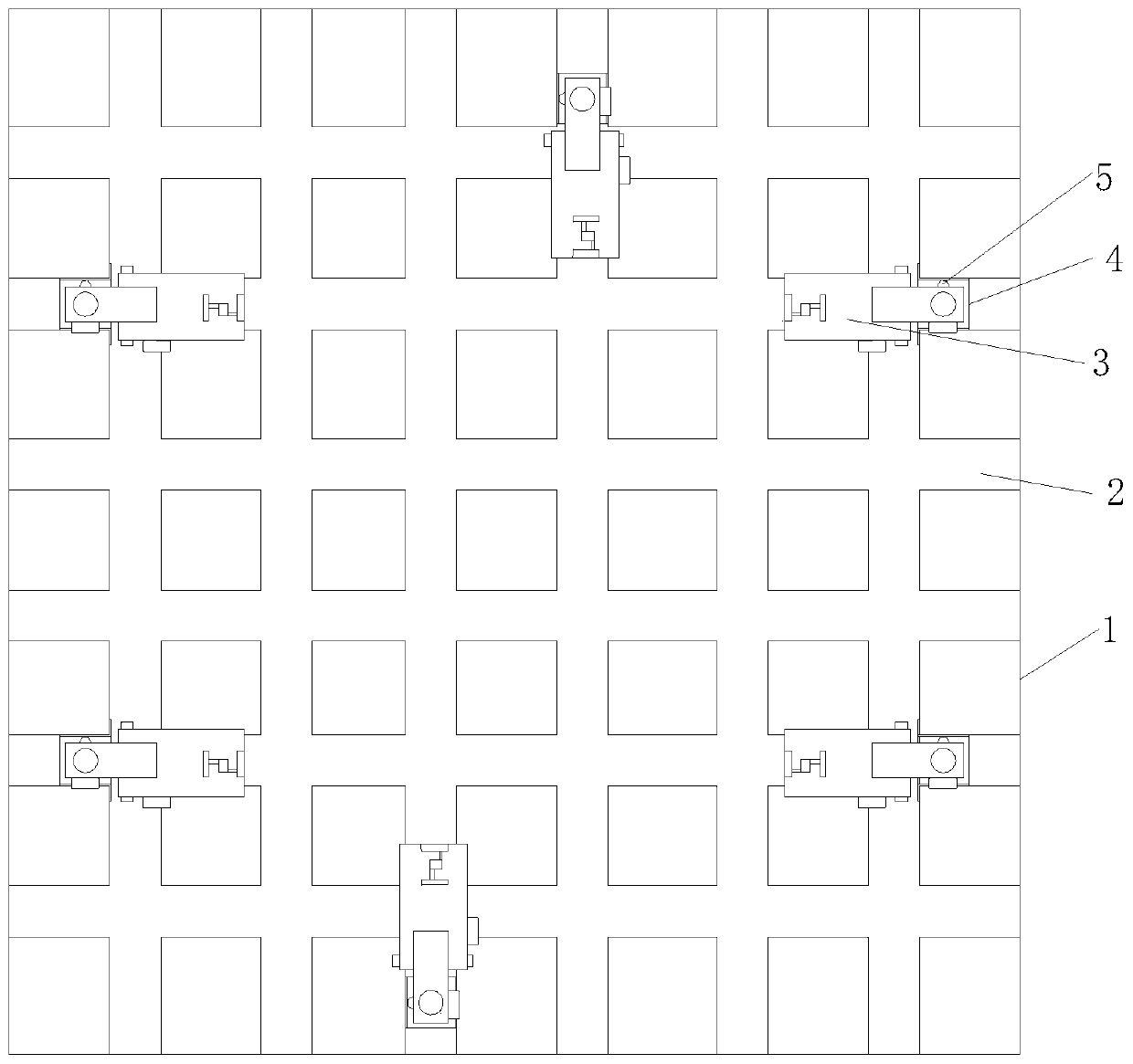

Door and window assembly fixing device

The invention discloses a door and window assembly fixing device. A fixed pedestal is included, chutes interlaced vertically and horizontally are formed in the fixed pedestal, the chutes are connectedwith slide blocks, the top of each slide block is provided with a fixing device, each fixing device comprises a connecting shaft, each connection shaft is rotationally connected with an adjusting plate, one side of the adjusting plate is rotationally connected with a locking mechanism via a rotating shaft, the locking mechanism comprises a U-shaped plate, the top of the U-shaped plate is providedwith an upper fixed plate, the upper fixed plate is in rotational connection with the U-shaped plate via two connecting rods in parallel, the top of the side, far from the connecting shaft, of the U-shaped plate is fixedly connected with a first handle, the top far from the first handle of the connecting rod is fixedly connected with a second handle, and a tensioning device is arranged between the first and second handles. Thus, the chutes interlaced vertically and horizontally are arranged, so that the fixing devices can be moved to random positions, and window / door frames in different shapes can be fixed.

Owner:六安市振宇模具有限公司

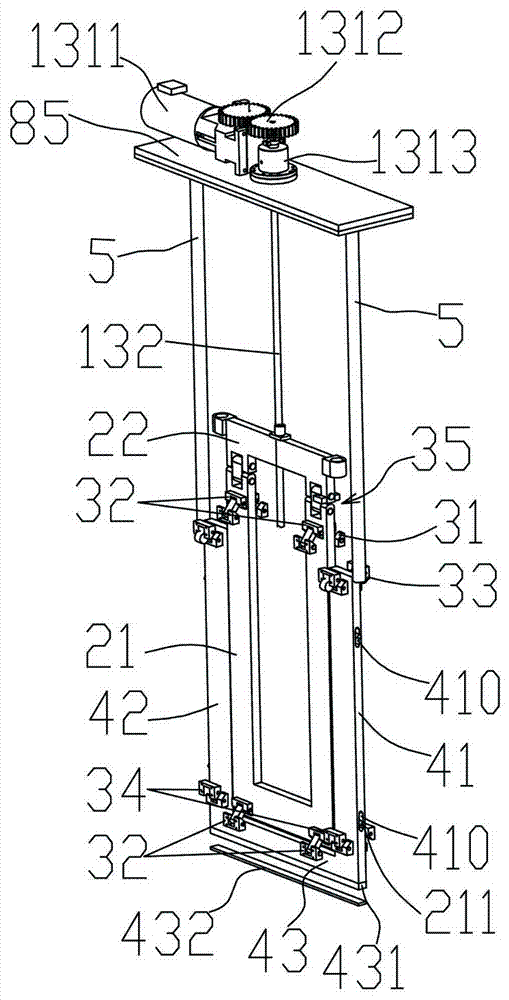

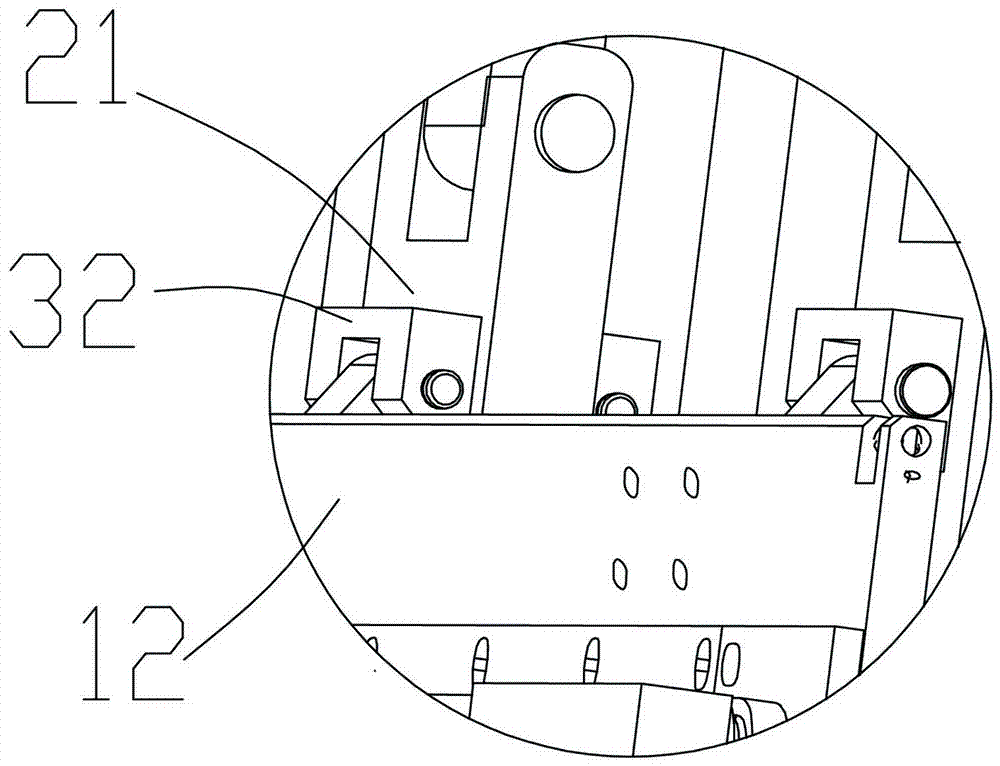

A cable climbing robot

InactiveCN104674655BLarge clamping forceClamp firmlyBridge structural detailsEndless track vehiclesDrive wheelBall screw

The invention relates to a cable climbing robot, which comprises an outer framework, clamping mechanisms and climbing mechanisms, wherein the clamping mechanisms and the climbing mechanisms are arranged on the outer framework; the outer framework is a cubic framework; each edge of the upper surface and the lower surface of the outer framework is respectively connected with an inner edge frame through a radial frame, and one clamping mechanism and one climbing mechanism are respectively arranged at each side surface of the outer framework; in each clamping mechanism, a ball screw is connected between vertical rods at the side surface of the outer framework; two edges of the ball screw have opposite screwing directions; two screw nuts of the ball screw are respectively hinged to connecting rods; the other end of each of the two connecting rods is hinged to the back part of a clamping support plate, and rolling wheels are arranged at the upper end and the lower end of the clamping support plate and are matched with the radial frame; in each climbing mechanism, a guide rod is hinged to one end of the inner side of the clamping support plate; a guide wheel is arranged on the guide rod; a nitrogen spring is arranged at the other end of the inner side of the clamping support plate and is hinged to a balance beam, and a driving wheel and a driven wheel are respectively arranged at the upper end and the lower end of the balance beam and are connected by a synchronous belt. The cable climbing robot has the advantages that the cable climbing robot can be used for cables with large diameter differences; the clamping force is good; the cable climbing capability and obstacle crossing capability are higher, and the seizure and slippage can be avoided.

Owner:SOUTHWEST JIAOTONG UNIV

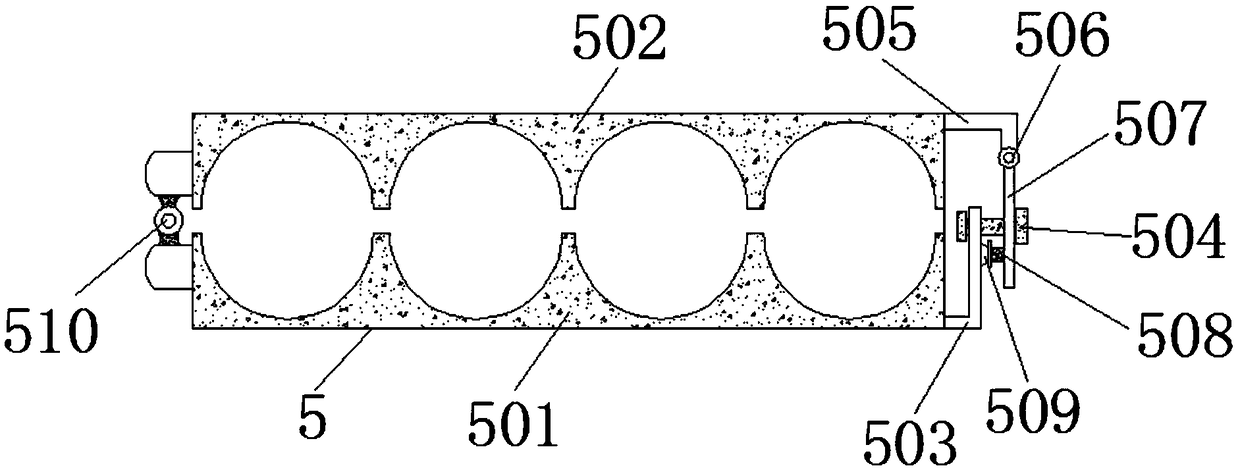

Bamboo pressing device for bamboo product processing

PendingCN108582340AEven by forceMaintain integrityCane mechanical workingProduct processingEngineering

The invention discloses a bamboo pressing device for bamboo product processing, and relates to the technical field of bamboo product processing. The bamboo pressing device comprises a feeding table, abamboo pressing machine and an output table. The feeding table and the output table are symmetrically distributed on the two sides of the bamboo pressing machine correspondingly. A first conveying belt is movably arranged on the upper end face of the feeding table, and a push baffle, a stabilization device and a limiting groove are sequentially fixedly formed in the upper surface of the first conveying belt. Press wheel rods are movably arranged on the side wall of the bamboo pressing machine, penetrate the two side walls of the bamboo pressing machine and are in cup joint with bamboo pressing sticks. The bamboo pressing device for bamboo product processing is provided with the two bamboo pressing sticks, after bamboo is conveyed into the bamboo pressing machine through the feeding table,the two bamboo pressing sticks are subjected to thrust of the bamboo to work at the same time, the uniform up-down stress of the bamboo is guaranteed, integrity of fiber in the bamboo is maintained,the bamboo pole cracking angle and hacking size are uniform, and later machining is convenient.

Owner:安吉刘氏竹木工艺厂

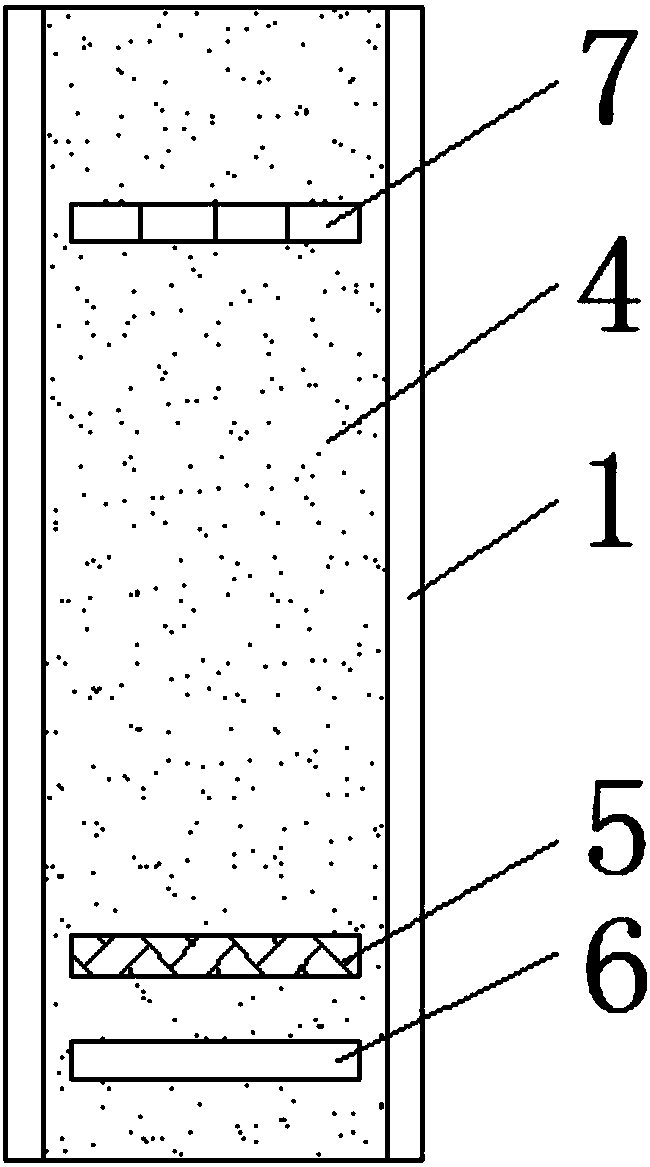

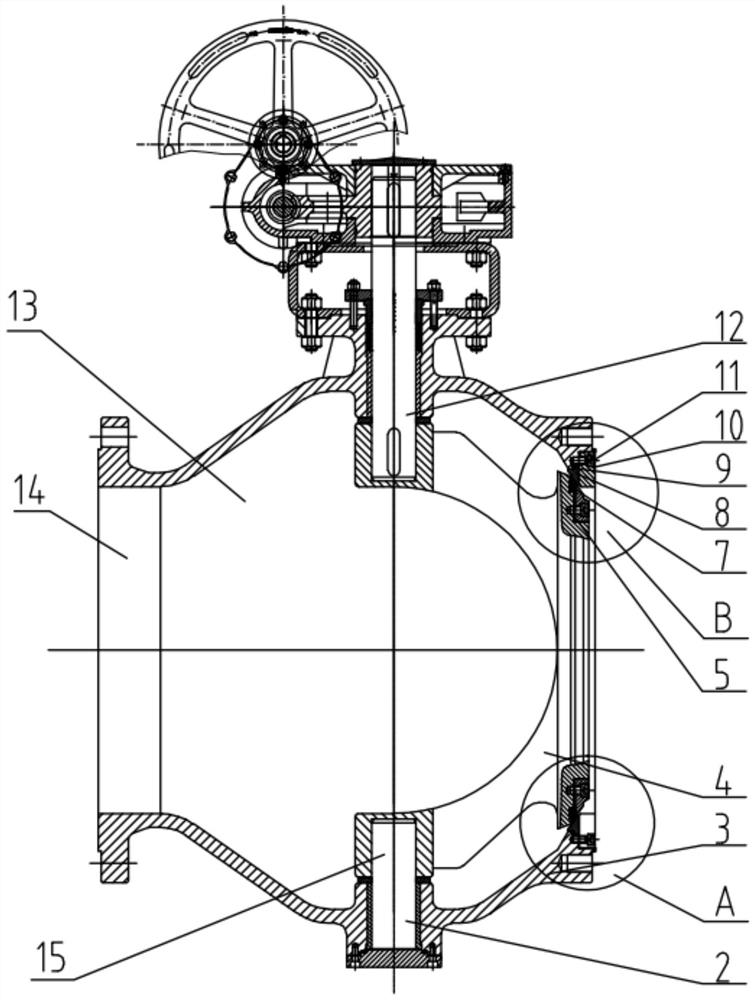

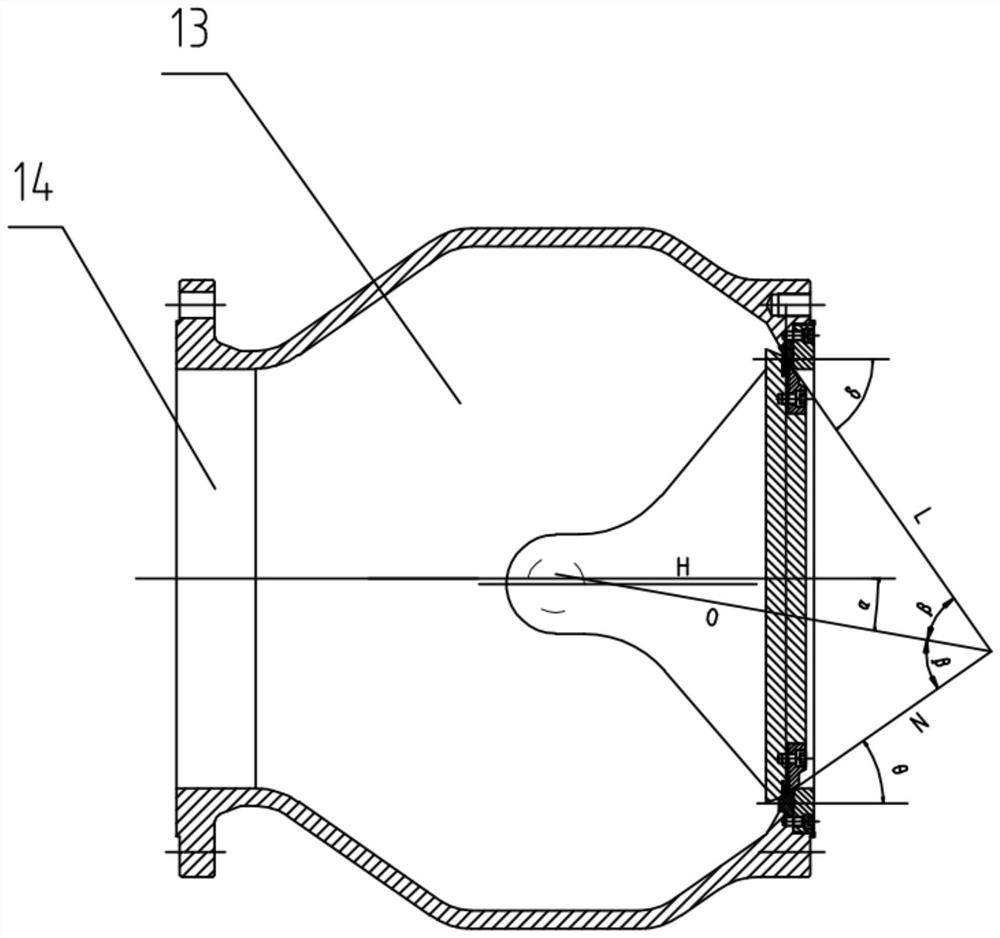

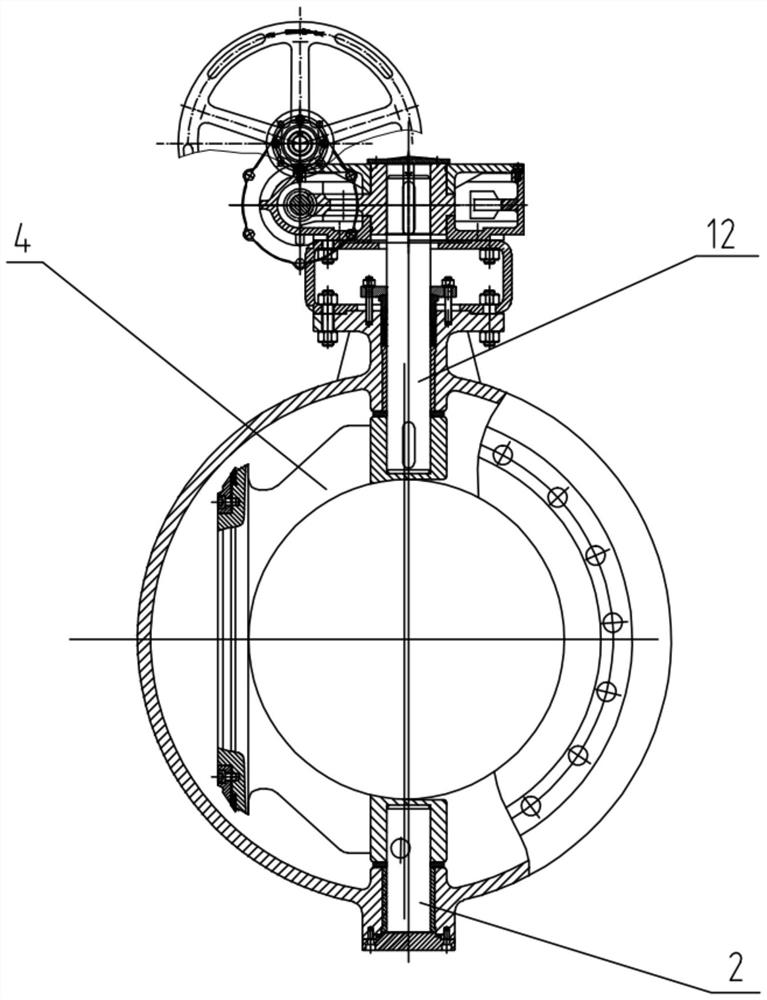

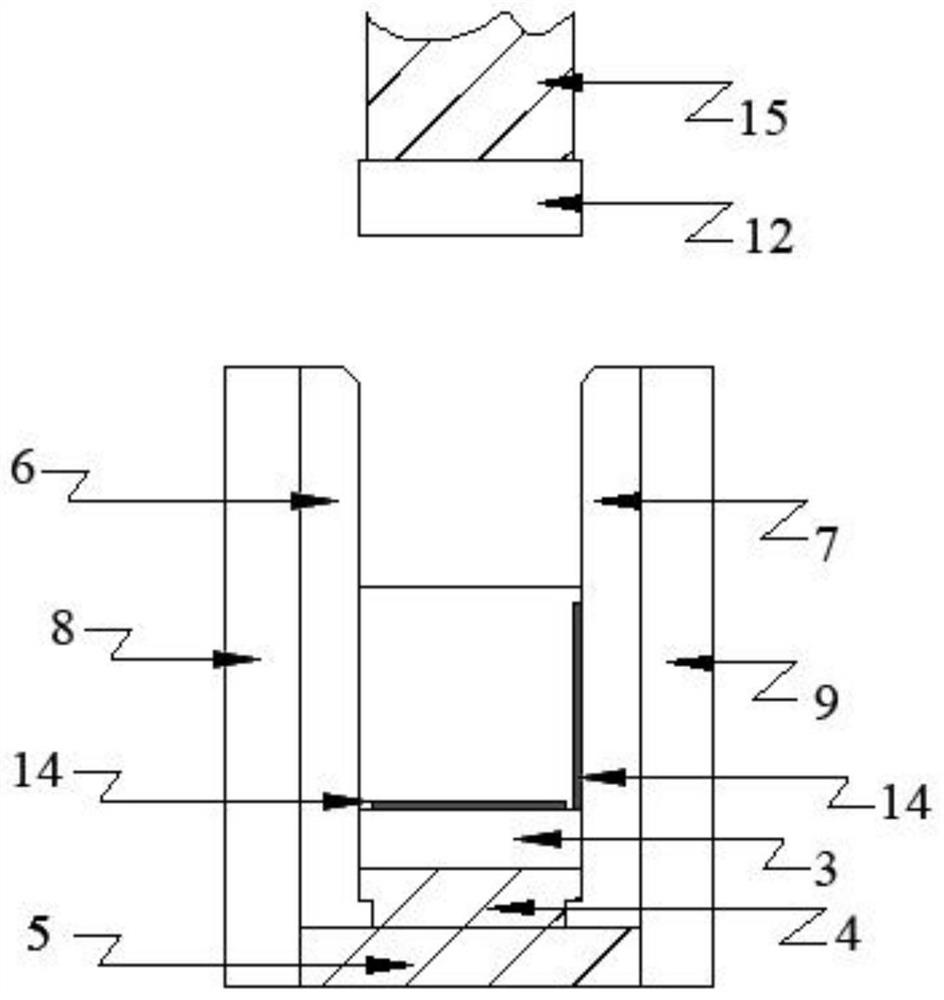

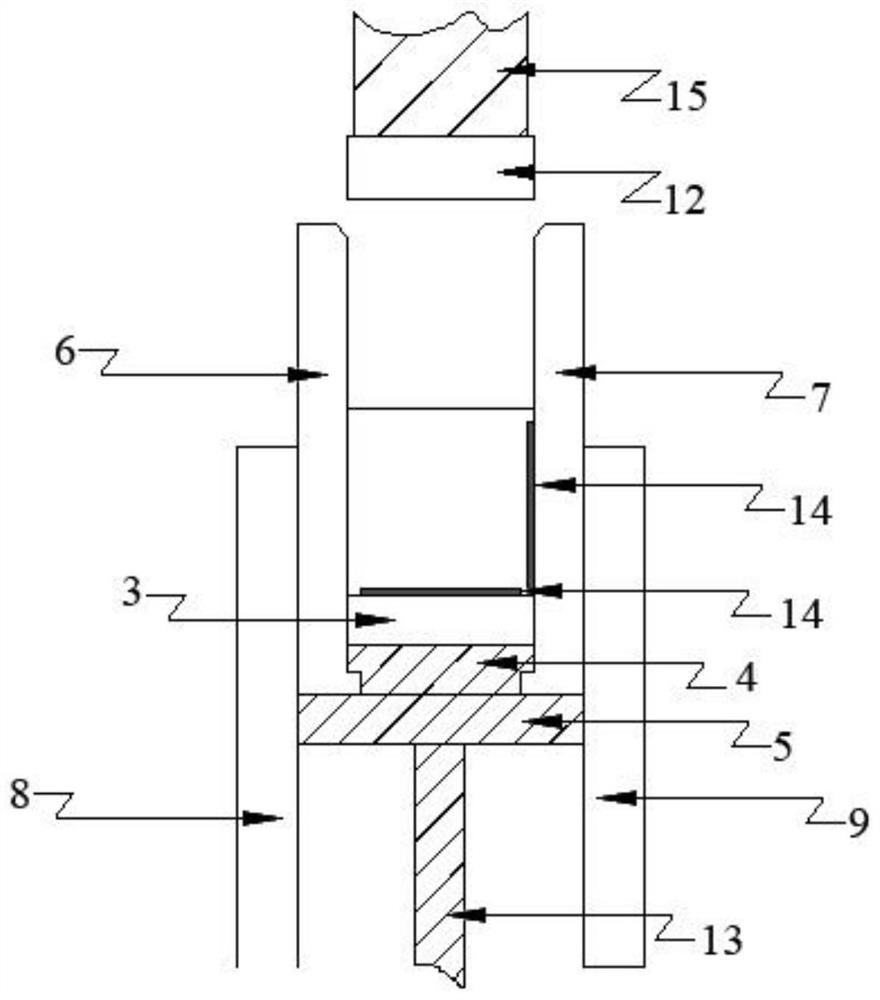

Full-flow-channel drift-diameter triple-eccentric metal lining sealing butterfly valve

PendingCN113757392ANo scour wearEven force up and downLift valveValve housingsDrive shaftButterfly valve

The invention discloses a full-flow-channel drift-diameter triple-eccentric metal lining sealing butterfly valve which comprises a valve body, a valve seat and a butterfly plate, a cavity is formed in the valve body, openings are formed in the two sides of the valve body to form a flow channel communicated with the cavity, the valve seat is installed at the openings, shaft holes are formed in the two ends of the valve body, a driving shaft connected with a power unit and a linkage shaft rotating along with the driving shaft are installed in the shaft holes respectively, the section of the butterfly plate is in a C shape along the center line of the shaft holes, the two ends of the butterfly plate are connected with the driving shaft and the linkage shaft respectively, and one side of the cavity is concave inwards relatively to form a concave cavity. The butterfly plate rotates between a closed state and a full-open state, wherein when the butterfly plate is in the close state, the butterfly plate makes sealing contact with the valve seat so that the flow channel can be blocked and broken, and when the butterfly plate is in the full-open state, the butterfly plate is located in the concave cavity to form a full-flow-channel full-open state. A full-fluid channel design is adopted, the inner diameter of the channel is consistent with the diameter of a pipeline, a butterfly plate pressing ring and a sealing ring cannot hinder media from passing when the butterfly plate is in the full-open state, the butterfly valve almost has zero flow resistance, the flow resistance coefficient is small, and the pressure drop is low.

Owner:北泽阀门集团有限公司

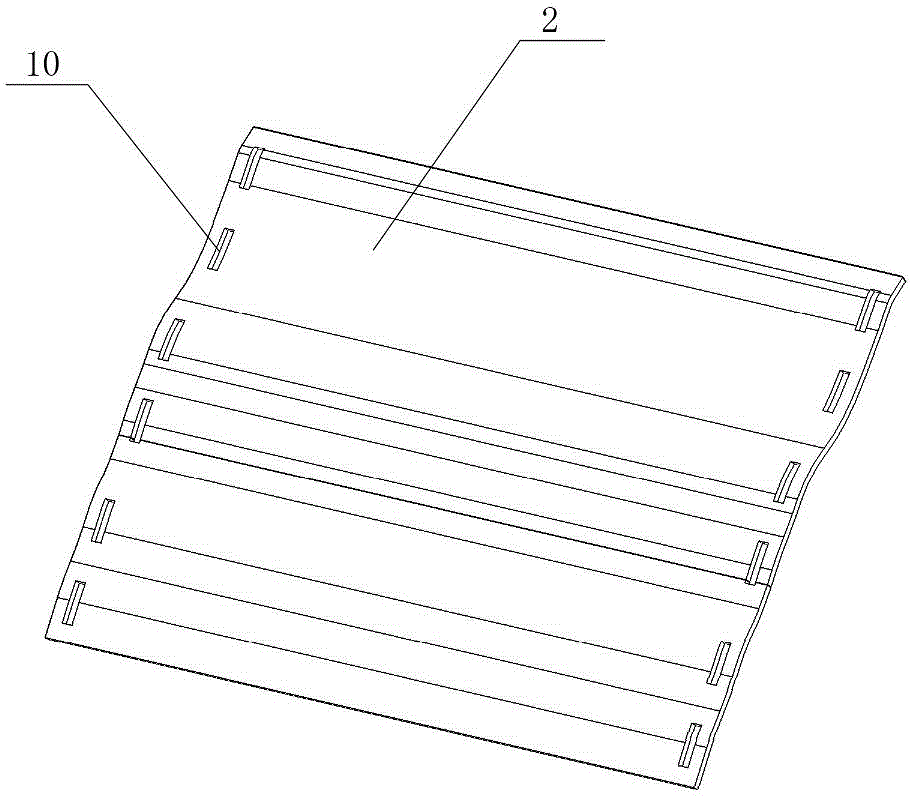

Preparation method of large-size metal-skin refractory bricks and movable mold of large-size metal-skin refractory bricks

ActiveCN113635433APress evenlyEven force up and downDischarging arrangementMould auxillary partsFire brickRefractory

The invention discloses a preparation method of large-size metal-skin refractory bricks and a mold of the large-size metal-skin refractory bricks, and belongs to the technical field of refractory materials. The mold comprises a mold sleeve, mold base plates, a mold bottom plate, a mold false bottom, a mold bottom supporting plate, mold movable side plates, mold side plates, mold end plates and a mold cover plate. According to the method, the refractory bricks are designed to be stressed up and down, so that the pressing stress uniformity is improved, sufficient pressure is guaranteed, and cracking is avoided; the metal skin wrapping firmness is improved by designing a metal skin special-shaped claw; metal skin is protected through a special mold; the mold movable side plates and the metal skin achieve synchronous movement, so that metal skin deformation or friction scratches are avoided; and meanwhile, a grinding tool is protected, and the service life of the grinding tool is prolonged, so that the preparation qualification rate and production efficiency are improved.

Owner:YINGKOU PUNAI MAGNESIUM MATERIALS CO LTD

Frictionless, easy-to-open transfer valve

ActiveCN105387224BExtended service lifeEven force up and downOperating means/releasing devices for valvesSlide valveEngineeringMechanical engineering

Owner:SHENZHEN XINYUREN TECH

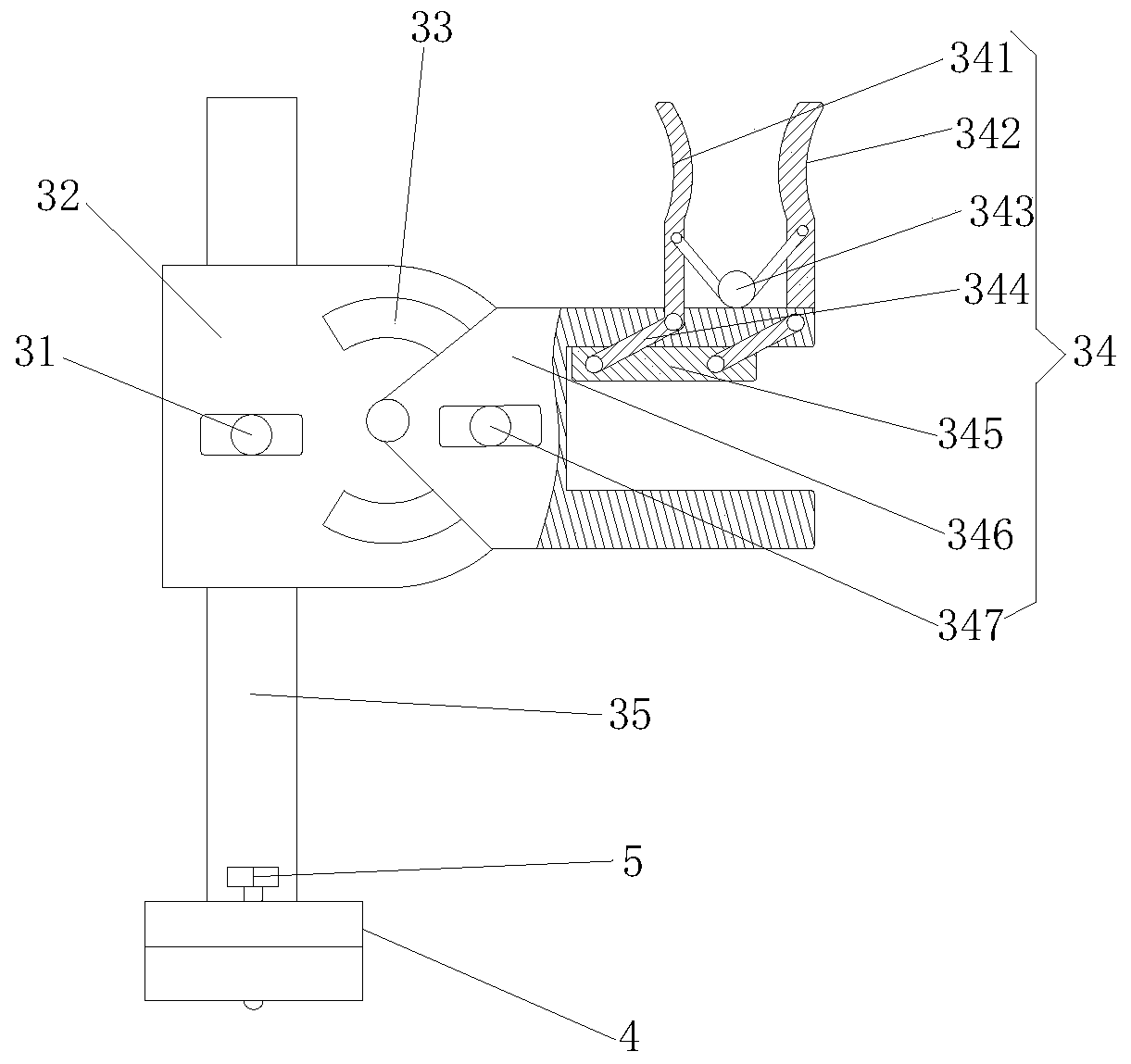

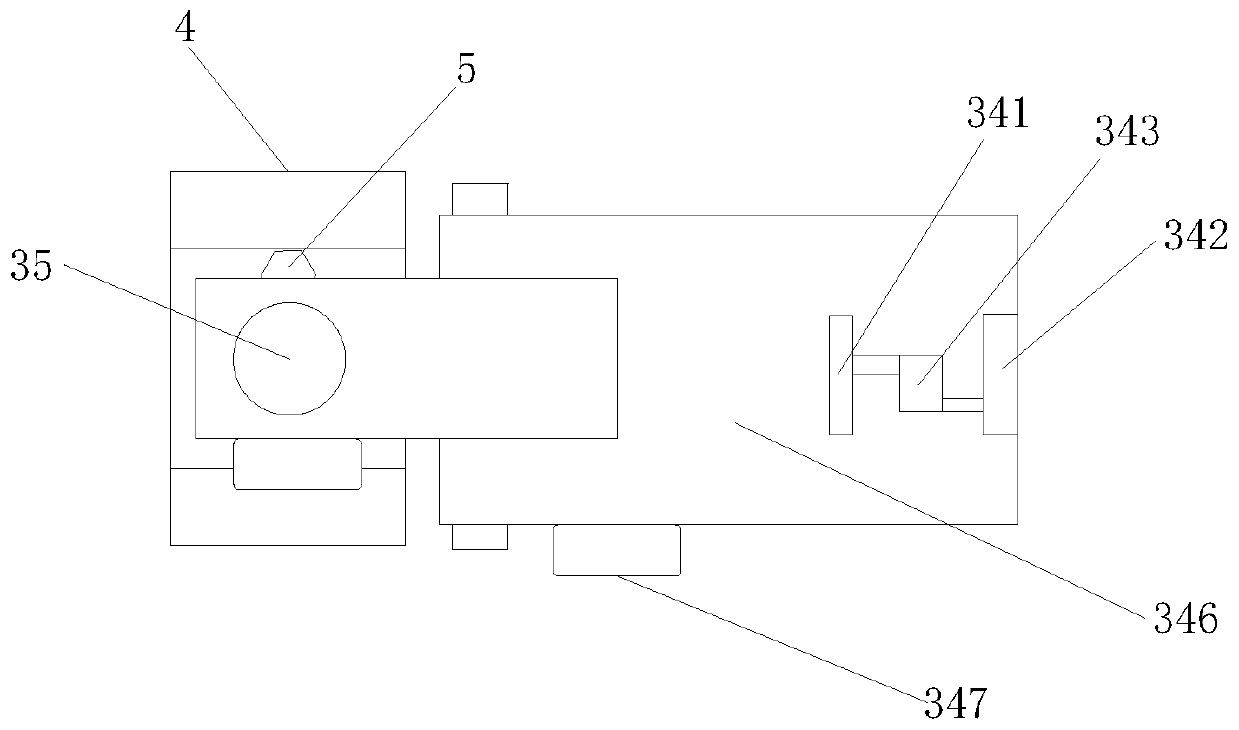

Tabletting, film laminating and knurling combined device for automobile body damping and vibration attenuation material

InactiveCN107116877AEasy to produceImprove labor efficiencyLamination ancillary operationsLaminationVibration attenuationKnurling

The invention relates to a tabletting, film laminating and knurling combined device for an automobile body damping and vibration attenuation material. The device comprises a tabletting machine, an outlet of the tabletting machine is provided with a plastic conveyor belt, and a spraying cooling water pipeline is disposed above the plastic conveyor belt, the tail end of the conveyor belt is provided with a film laminating apparatus, and a knurling apparatus is disposed behind the film laminating apparatus. According to the invention, combined tabletting, film laminating and knurling are carried out for pipelined molding of the automobile body damping and vibration attenuation material, the combined device is convenient for production, and improves the work efficiency. Each apparatus achieves independent motor control or linkage control, and the roller motion frequency can be adjusted at any time.

Owner:十堰风神汽车橡塑制品有限公司

A door and window assembly and fixing device

ActiveCN109209149BAdjust orientationAdjust pitch angleFrame fasteningStructural engineeringMechanical engineering

The invention discloses a door and window assembly fixing device. A fixed pedestal is included, chutes interlaced vertically and horizontally are formed in the fixed pedestal, the chutes are connectedwith slide blocks, the top of each slide block is provided with a fixing device, each fixing device comprises a connecting shaft, each connection shaft is rotationally connected with an adjusting plate, one side of the adjusting plate is rotationally connected with a locking mechanism via a rotating shaft, the locking mechanism comprises a U-shaped plate, the top of the U-shaped plate is providedwith an upper fixed plate, the upper fixed plate is in rotational connection with the U-shaped plate via two connecting rods in parallel, the top of the side, far from the connecting shaft, of the U-shaped plate is fixedly connected with a first handle, the top far from the first handle of the connecting rod is fixedly connected with a second handle, and a tensioning device is arranged between the first and second handles. Thus, the chutes interlaced vertically and horizontally are arranged, so that the fixing devices can be moved to random positions, and window / door frames in different shapes can be fixed.

Owner:六安市振宇模具有限公司

A movable partition structure made of bamboo skin

ActiveCN113374114BEven by forceEven force up and downWallsStructural engineeringMechanical engineering

Owner:ZHEJIANG SCI-TECH UNIV

Novel cushion block

InactiveCN107489229AEliminate shortcomingsImprove securityBuilding reinforcementsShock preventionCushion

The invention discloses a new type of block, which includes a block body (1), vulcanized rubber blocks (2) are arranged on the upper and lower surfaces of the block body (1), and the cross section of the block body (1) is trapezoidal (3 ), set two pulleys (4) under the block body (1), set two lifting frames (5) on both sides of the pulley (4), and set a locking device (6) on the upper part of the block body (1). Pressure gauges (7) are arranged on the top and bottom of the block body (1). The beneficial effects of the present invention are: the concrete block and the rubber block are used in combination to concentrate their advantages and eliminate the disadvantages. Good anti-slip and increased safety during use, the trapezoidal hollow setting is for better shock absorption, anti-crushing, and the setting of the block body as concrete will prevent corrosion, greatly increasing the service life and safety of the block sex.

Owner:JIANGYIN DONGREN MACHINERY

A climbing robot

A cable climbing robot comprises an outer frame and an inner climbing mechanism, wherein a ball screw with opposite turning directions at two ends is connected between upright tubes of each side face of the outer frame through bearings, and every two opposite ball screws are driven by a motor; each side face of the outer frame is provided with a slide block formed in a way that a cross rod connects two vertical rods, and slide block guide wheels at the upper and lower ends of the vertical rods are in contact with top rods and bottom rods of the outer frame; the outer sides of the two vertical rods both are fixedly provided with screw nuts; two pairs of clamping support plates are respectively fixed to two opposite pairs of cross rods, certain ends of the inner sides of the clamping support plates are hinged to guide rods with guide wheels, and extension springs are arranged between the guide rods and the clamping support plates, and the other ends of the clamping support plates are provided with guidance rods; the ends, extending inwards, of the guidance rods are hinged to balance beams, and pressure sensors and compression springs sleeve the guidance rods between the balance beams and the clamping support plates; the upper and lower ends of the balance beams are respectively provided with driven wheels and driving wheels connected with drive motors. The robot can be used for cables with great diameter differences, is good in clamping force and strong in cable climbing and obstacle crossing abilities.

Owner:SOUTHWEST JIAOTONG UNIV

Auxiliary nozzle for air-jet loom and air-jet loom

The invention discloses an auxiliary nozzle for an air-jet loom. The auxiliary nozzle for the air-jet loom comprises a nozzle body with an air flow chamber and a sprayer which is arranged on the nozzle body, wherein the sprayer comprises a first sprayer and a second sprayer which are arranged in parallel, a first air flow channel which is communicated with the air flow chamber is arranged in the first sprayer, a second air flow channel which is communicated with the air flow chamber is arranged in the second sprayer, rectangular blowholes are arranged on the first and the second sprayers, and the directions of the blowholes which are arranged on the first and the second sprayers are consistent. The auxiliary nozzle for the air-jet loom has strong injection capacity, specific performance in that the auxiliary nozzle for the air-jet loom is excellent in air flow stability on a flow channel section which is 250mm away from the blowholes, and can achieve 32m / s maximum speed of gas flow rate. Simultaneously, the first and the second sprayers respectively spray air from the upper and the lower sides of weft yarns, and enable the two sides of the weft yarns to evenly bear force, thereby being capable of perfectly maintaining kinematic velocity of the weft yarns, reducing fluctuation of the weft yarns, and guaranteeing stability of the weft yarns.

Owner:ZHEJIANG SCI-TECH UNIV

A cable crawling robot

InactiveCN104674654BLarge clamping forceClamp firmlyBridge structural detailsBall screwObstacle crossing

The invention relates to a cable climbing robot, which comprises an outer framework, clamping mechanisms and climbing mechanisms, wherein the clamping mechanisms and the climbing mechanisms are arranged on the outer framework; the outer framework is a cubic framework; each edge of the upper surface and the lower surface of the outer framework is respectively connected with an inner edge frame through a radial frame, and one clamping mechanism and one climbing mechanism are respectively arranged at each side surface of the outer framework; in each clamping mechanism, a ball screw is connected between vertical rods at the side surface of the outer framework, and two edges of the ball screw have opposite screwing directions; two screw nuts of the ball screw are respectively hinged to connecting rods; the other end of each of the two connecting rods is hinged to the back part of a clamping support plate, and rolling wheels are arranged at the upper end and the lower end of the clamping support plate and are matched with the radial frame; in each climbing mechanism, a guide rod is hinged to one end of the inner side of the clamping support plate; a guide wheel is arranged on the guide rod; a leading rod is arranged at the other end of the inner side of the clamping support plate, and is hinged to a balance beam; a pressure sensor and a compression spring sleeve the leading rod, and a driving wheel and a driven wheel are respectively arranged at the upper end and the lower end of the balance beam and are connected by a synchronous belt. The cable climbing robot has the advantages that the cable climbing robot can be used for cables with large diameter differences; the clamping force is good; the cable climbing capability and obstacle crossing capability are higher, and the seizure and slippage can be avoided.

Owner:SOUTHWEST JIAOTONG UNIV

Single-sided punching-free formwork supporting device applied to fabricated wall building

PendingCN112482748AGuarantee the construction qualityGuaranteed stabilityForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksArchitectural engineeringPunching

The invention discloses a single-face punching-free formwork supporting device applied to a fabricated wall building. The technical problems that when a fabricated wall is installed, a traditional formwork supporting method is adopted at a connecting gap, the construction quality is affected, operation is complex, the labor intensity is high, and the construction progress is slow are solved. According to the single-face punching-free formwork supporting device applied to the fabricated wall building, a supporting rod is adjustably connected with a supporting column, the supporting column is perpendicular to the ground through the supporting rod and is parallel to a prefabricated wall, the supporting column is in threaded connection with a lead screw opposite to the prefabricated wall, anda formwork body opposite to a connecting seam between the lead screw and prefabricated wall is arranged at the end, close to the wall, of the lead screw. According to the single-face punching-free formwork supporting device applied to the fabricated wall building, the formwork body can be stably fixed to the connecting seam, formwork supporting can be carried out on the connecting seam conveniently, no damage is caused to the wall face or the ground, the construction quality is guaranteed, and the formwork supporting stability is guaranteed; and meanwhile, formwork supporting operation of workers is easy, time is shortened, and labor is saved.

Owner:CHINA CONSTR SEVENTH ENG DIVISION CORP LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com