Variable bearing disk club-footed pile forming equipment

A technology for forming equipment and bearing plates, which is applied to drilling equipment, drilling equipment and methods, sheet pile walls, etc., can solve problems such as easy shearing of the pin shaft, uneven force on the upper and lower sides of the support arm, and difficult maintenance, etc., to achieve even force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

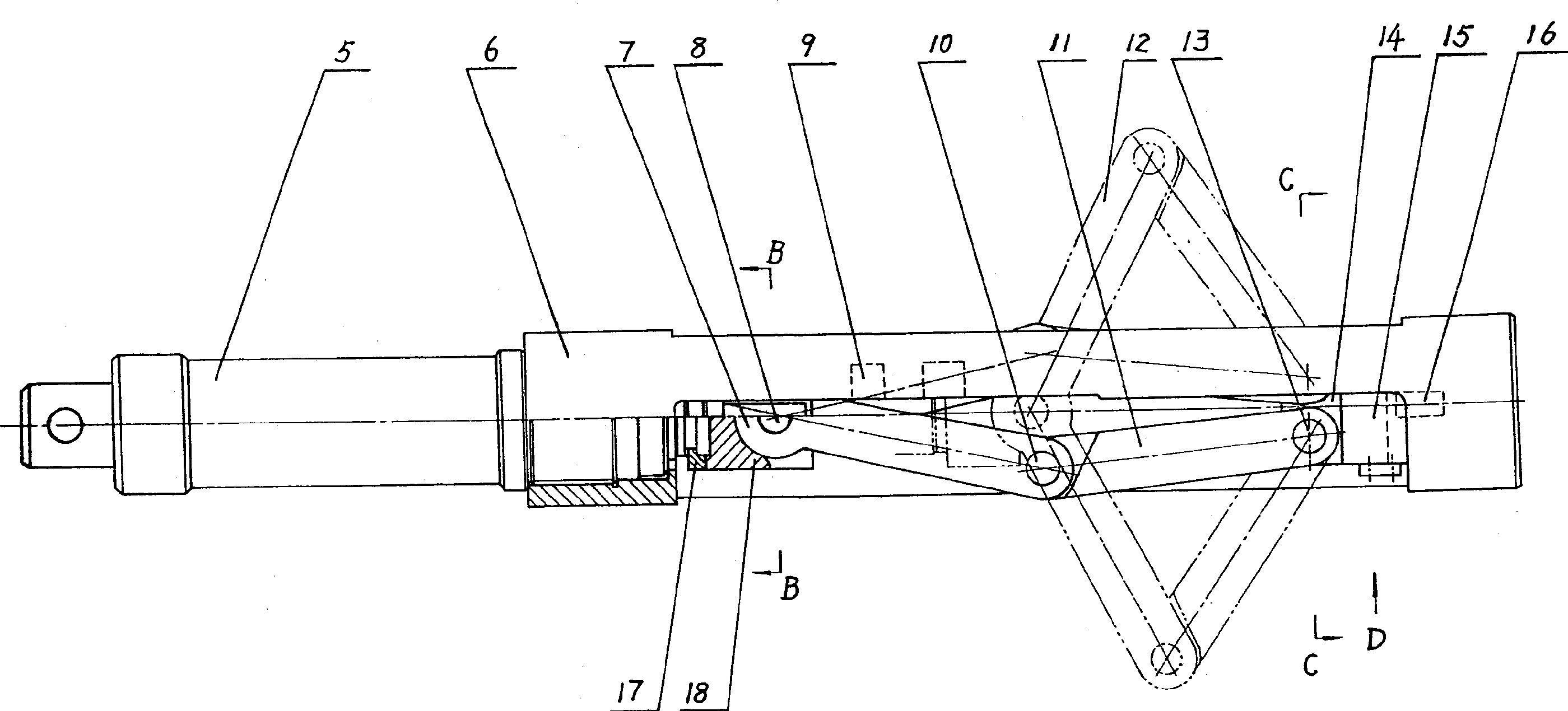

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

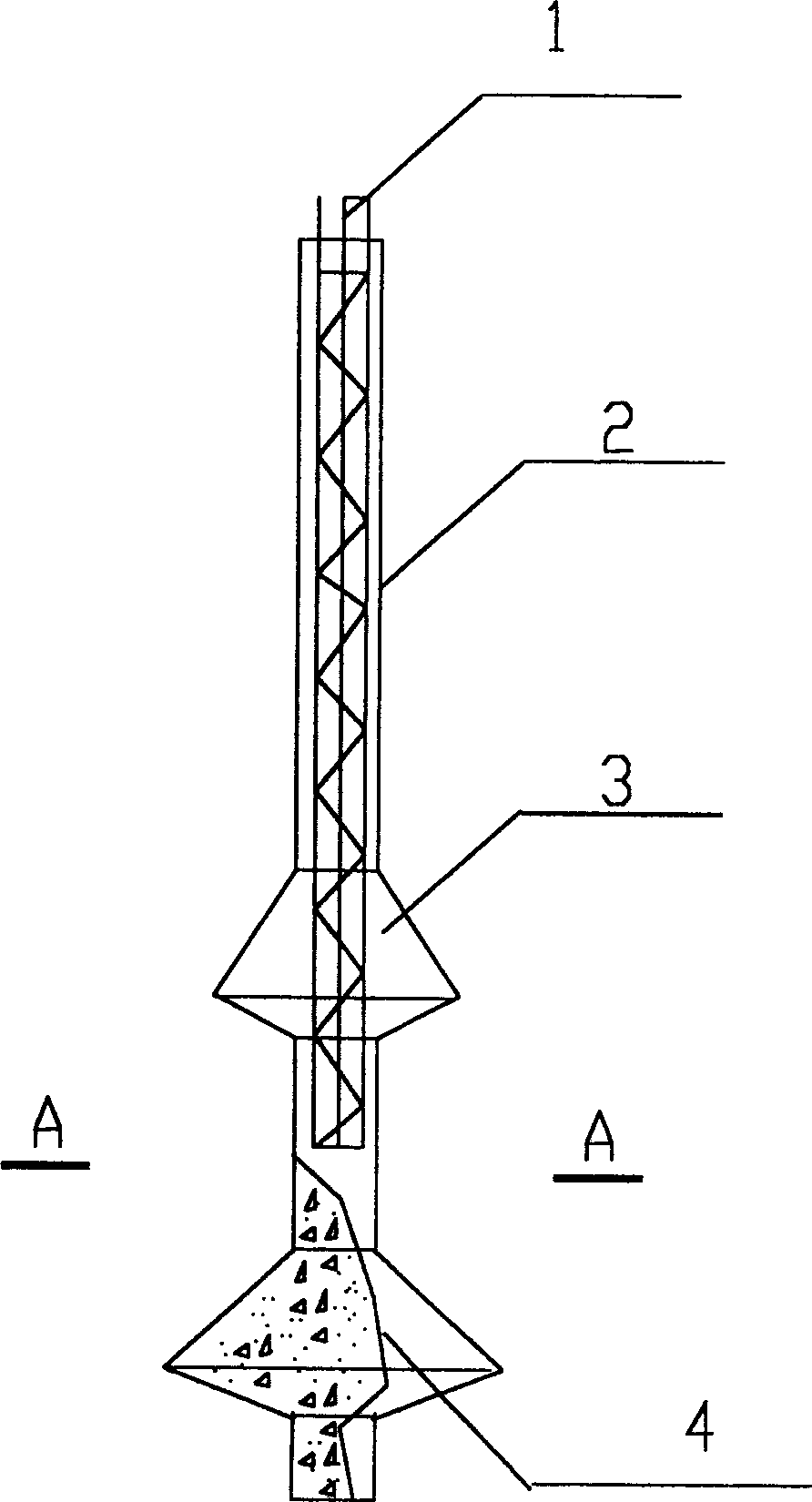

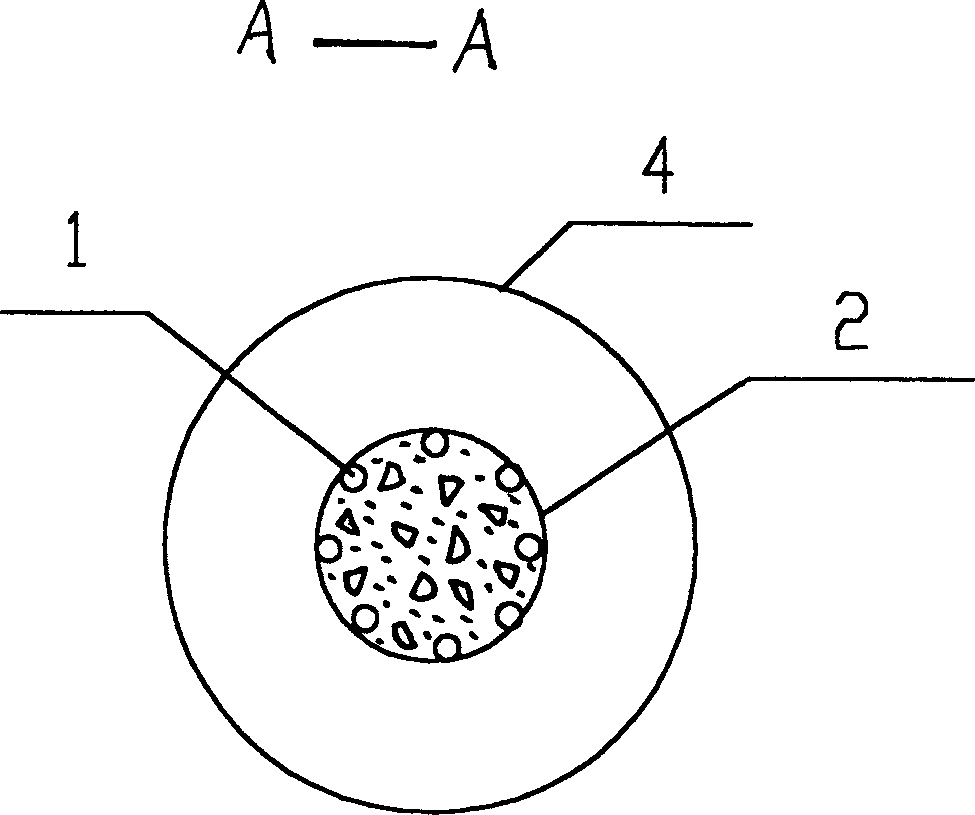

[0017] Such as figure 1 , figure 2 As shown, the variable bearing plate expansion bottom pile in this embodiment includes a pile column 2 made of steel cage 1 and concrete, wherein: it also includes two bearing plates 3 and 4 of different diameters, The bearing disc 3 of small diameter is arranged at the middle part of pile 2, and the bearing disc 4 of large diameter is arranged at the bottom of pile 2.

[0018] The above-mentioned piles can also be made of lime soil, gravel, and construction waste. Several bearing plates can also be arranged on the above-mentioned piles, which are located at different positions of the piles.

[0019] The diameter and number of bearing plates of the present invention can be determined according to the properties of the pile body soil layer.

[0020] The forming method of the above-mentioned variable bearing plate e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com