Tabletting, film laminating and knurling combined device for automobile body damping and vibration attenuation material

A technology for vibration damping materials and automobile bodies, which is applied in lamination devices, laminations, vehicle parts, etc., and can solve the problems that the film cannot be knurled, and the film cannot be knurled at the same time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

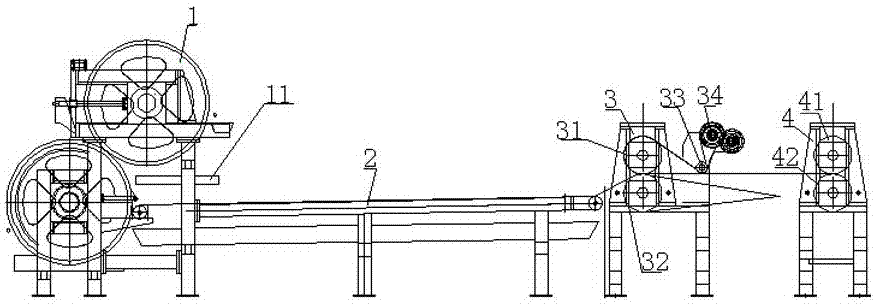

[0021] The present invention as figure 1 shown.

[0022] one A damping and shock-absorbing material pressing film coating knurling combination device for automobile body, comprising a tablet press 1, a conveyor belt 2 is provided at the exit of the tablet press 1, and a film coating device 3 is provided at the tail end of the conveyor belt 2, A knurling device 4 is provided behind the coating device 3 .

[0023] The conveyor belt 2 is a plastic conveyor belt.

[0024] There is the cooling water pipeline 11 of spraying above the plastic conveyor belt.

[0025] The laminating device 3 is an upper and lower roller rolling type, the upper roller is a burr roller 31, and the lower roller is a smooth round roller 32; there is also an extension roller 33 on the side of the lamination device 3; Film releasing device 34 is arranged.

[0026] The knurling device 4 is an upper and lower pair of rollers rolling knurling, wherein the upper roller is a smooth round roller 2 41, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com