Preparation method of large-size metal-skin refractory bricks and movable mold of large-size metal-skin refractory bricks

A technology of metal skin and refractory bricks, which is applied in the direction of manufacturing tools, mold auxiliary parts, ceramic molding machines, etc., can solve the problems of metal skin affecting refractory performance, increasing raw material costs, and short service life, so as to ensure uniformity of pressing and increase Coating firmness, effect of improving coating firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

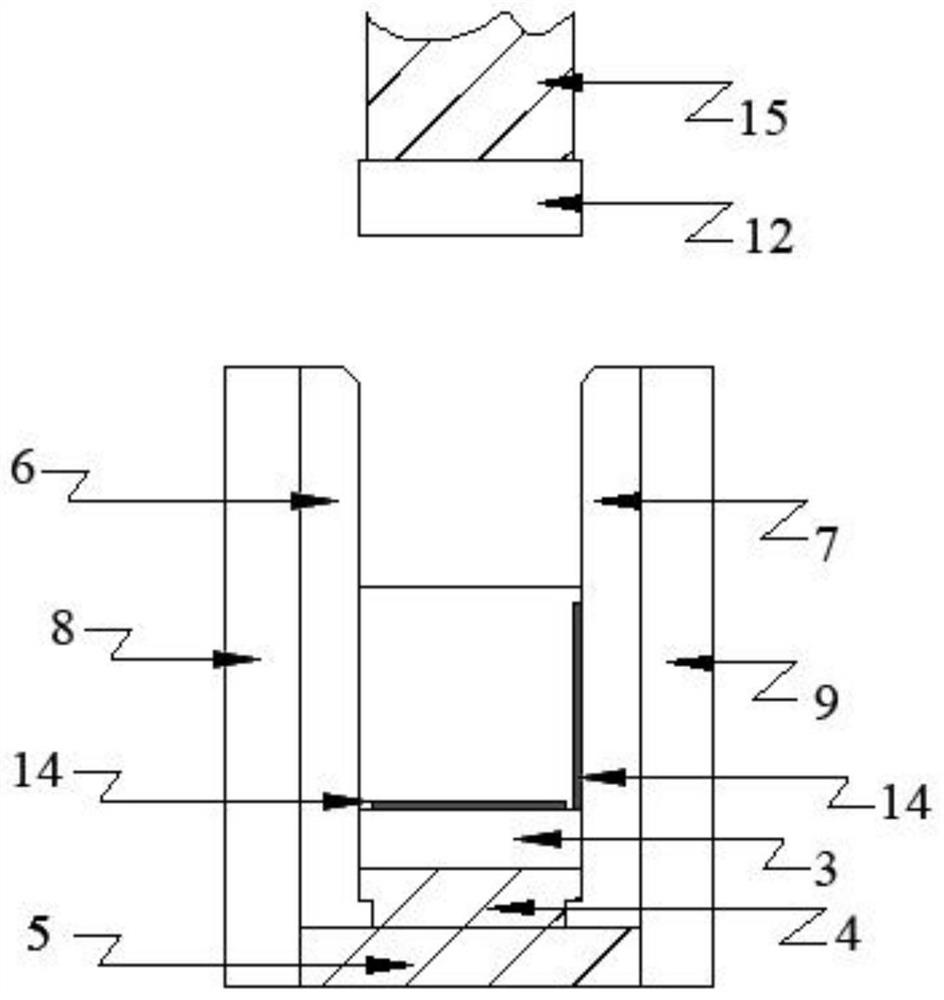

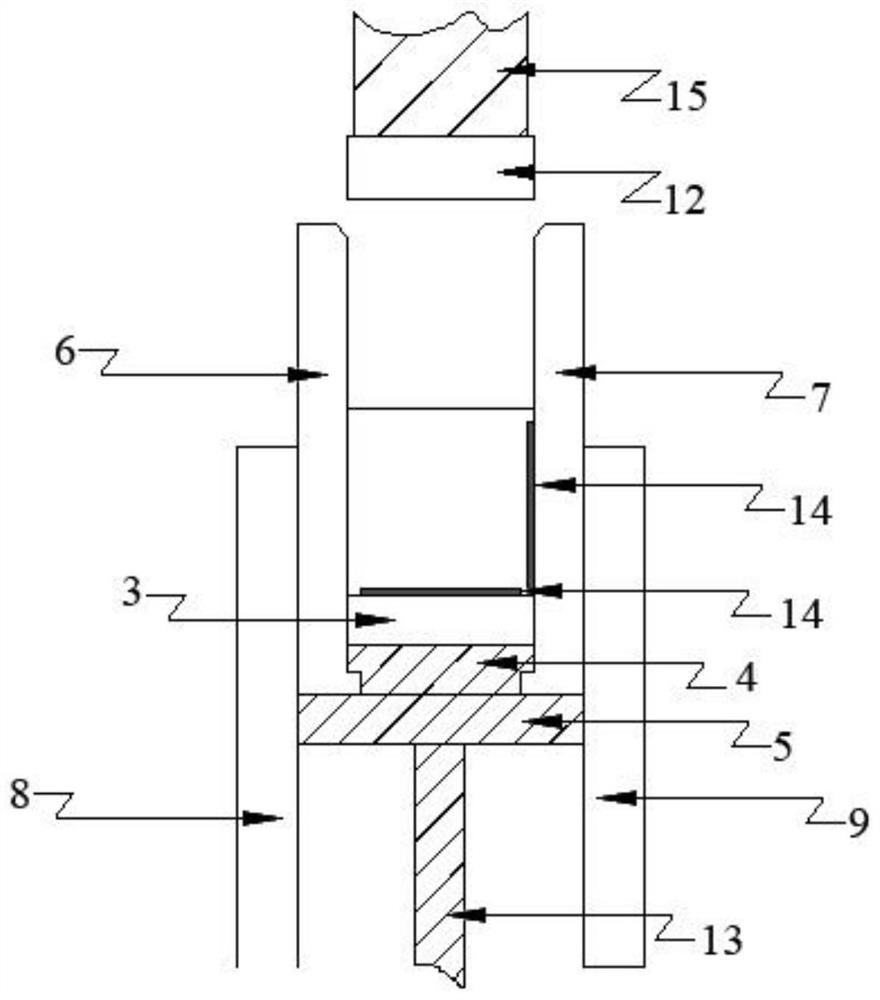

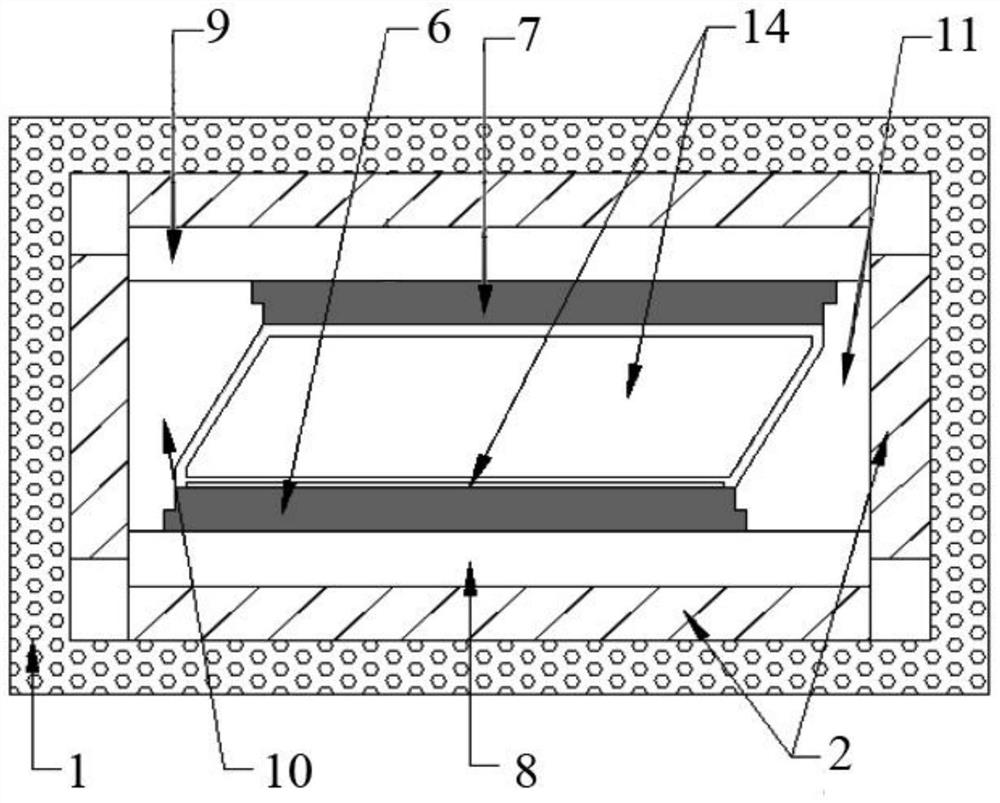

[0049] The following is combined with specific implementation cases and appended Figure 1-5 The present invention is further described, but the present invention is not limited to these examples.

[0050] In this embodiment, metal-skinned refractory bricks of different sizes are made for the furnace cap of a large-scale steelmaking converter. The metal-skinned refractory bricks are L-shaped iron-skinned magnesia-carbon bricks. The dimensions of the iron-skinned magnesia-carbon bricks are shown in Table 1 below:

[0051] Table 1 Finished size of iron sheet magnesia carbon brick

[0052]

[0053]

[0054] A method for preparing large-scale metal-skinned refractory bricks, comprising the steps of:

[0055] Step 1: Design the size of the prefabricated iron-skinned magnesia-carbon bricks, design the mold size and metal skin size according to the size of the iron-skinned magnesia-carbon bricks, the iron-skinned magnesia-carbon bricks are designed to be: the size of the iron ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com