Integrated system for the close-down of the stocking on circular machines for tubular semifinished production in stitch and the device relative to it

一种管状制品、管状的技术,应用在机器的制品领域,达到减少时间及工作量、不浪费材料的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

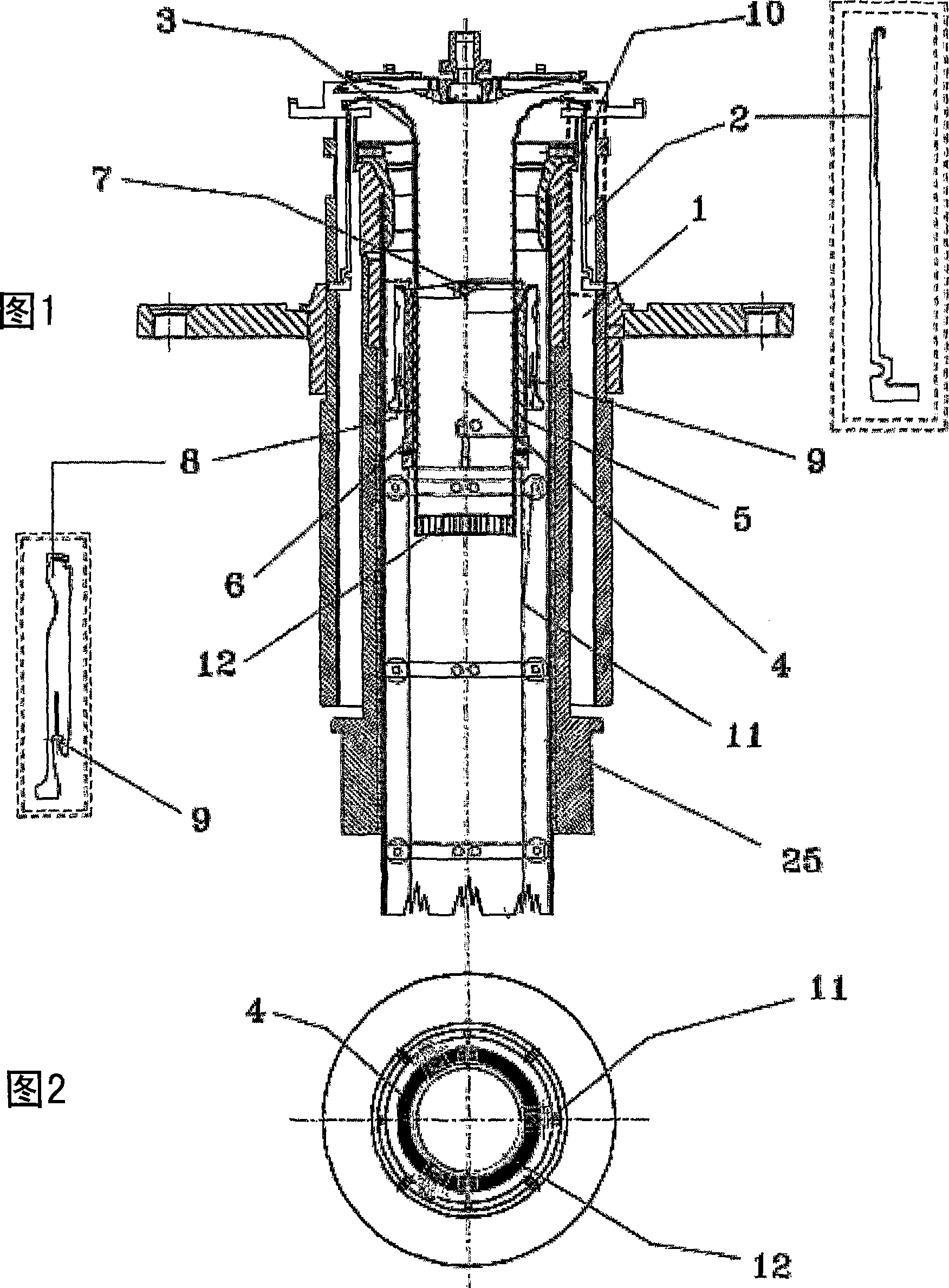

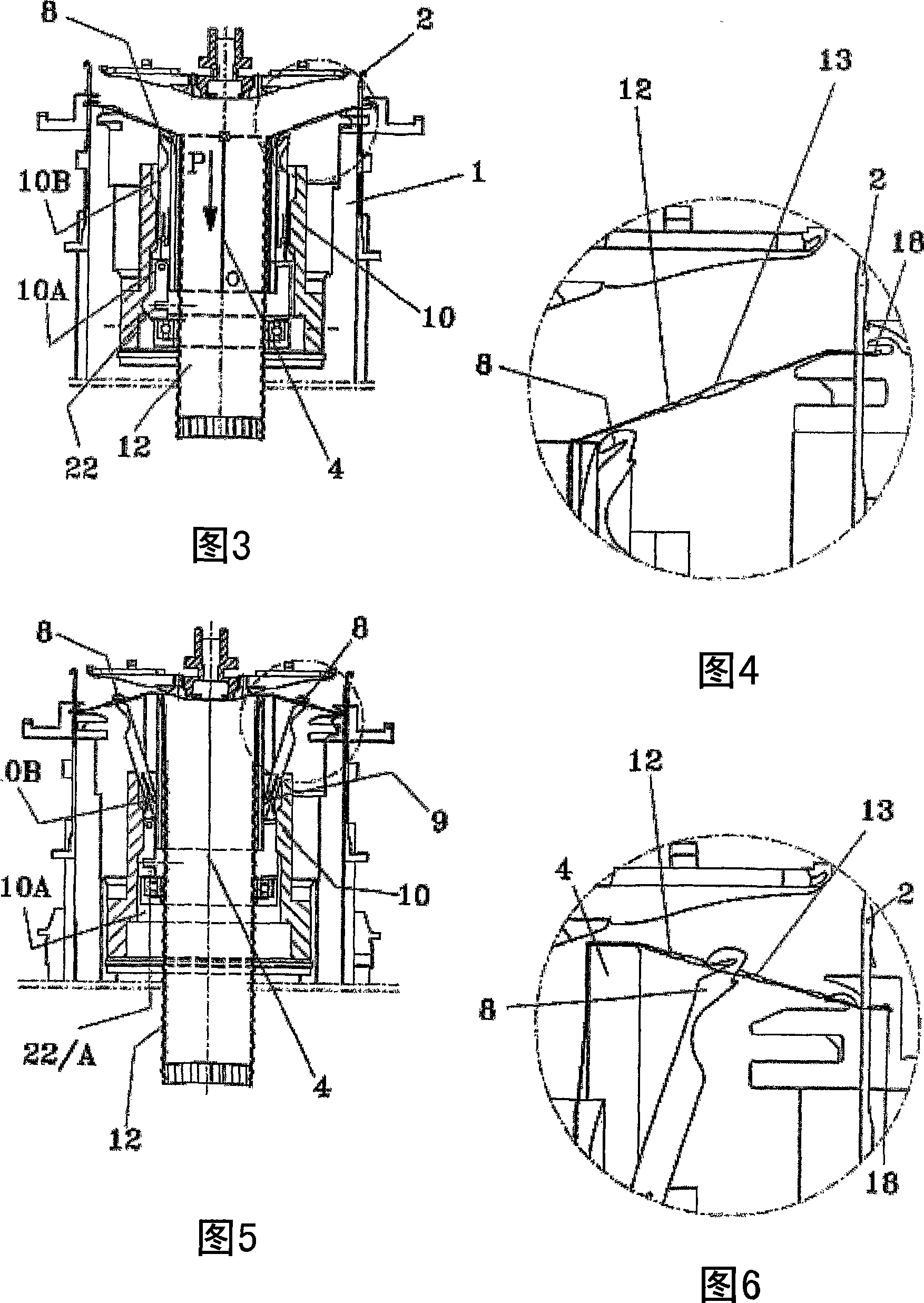

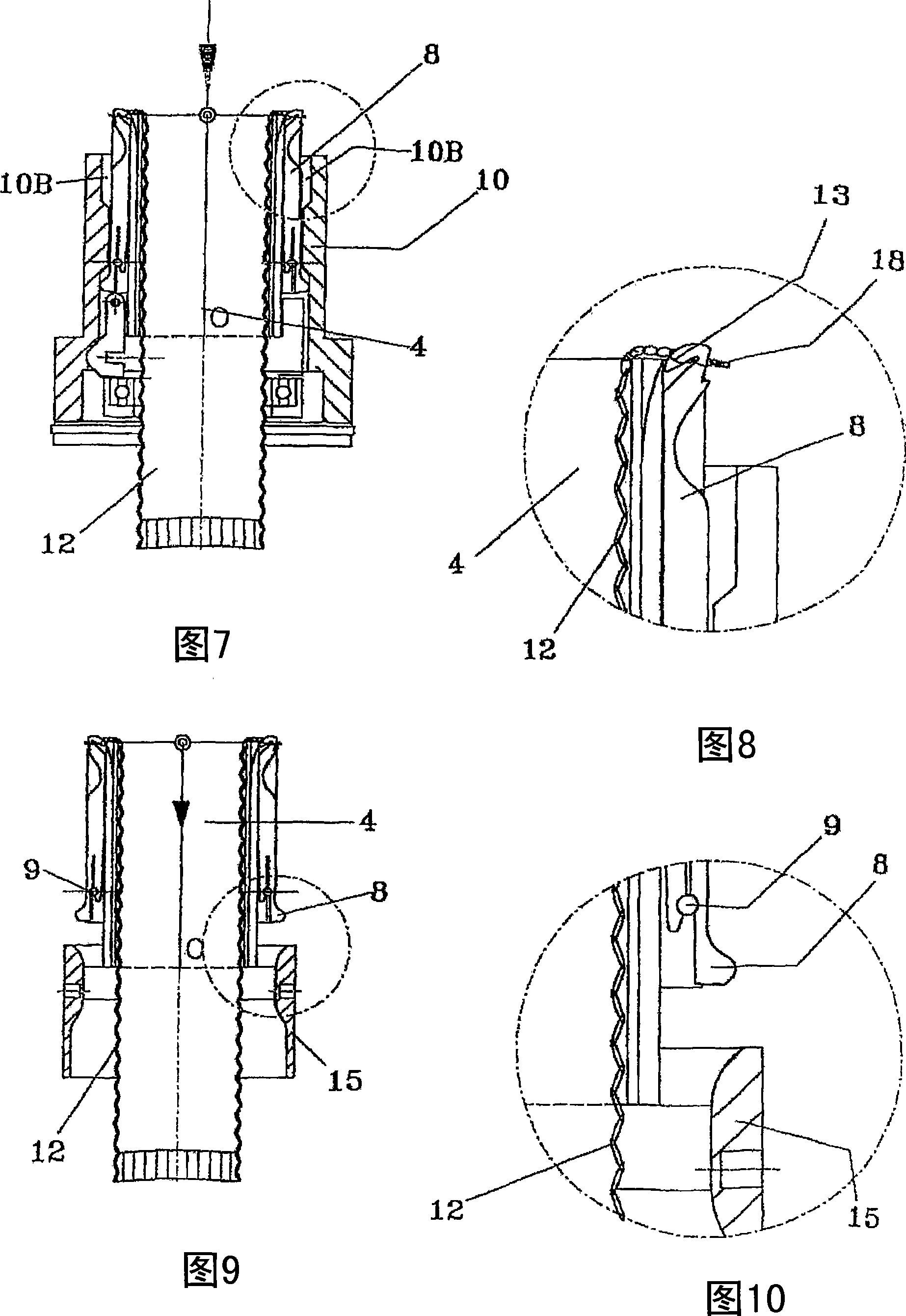

[0046] Referring to Figure 1- Figure 21 .

[0047] Said machine comprises a conventional tubular suture-making system, characterized in that a rotating ring of needles positioned in a conventional manner on a support cylinder is used to make the knitted tube. Due to the coaxial arrangement with respect to the aforementioned support cylinder, and thus the formation of the downward hollow sliding chamber, said hollow sliding chamber is suitably repositioned relative to the knitting machine by suitable means. Additional guides slide inside these tubes, inside the hollow stroke there is a guide system from the outer ring, which allows the same device to be accurately centered with respect to the making machine.

[0048] In one piece with the guide system there is provided a retraction mechanism 4 which essentially consists of a ring of retaining hooks 8 which is duly reduced in diameter and which is divided into two mirrored ones by a specific hinge 7 The reversible halves 5, 6,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com