Paper tube finish cutting equipment with continuous loading and unloading functions

A paper tube and functional technology, which is applied in the field of paper tube precision cutting equipment, can solve the problems of not being able to effectively improve cutting efficiency, labor intensity, low cutting efficiency, and automatic loading and unloading.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

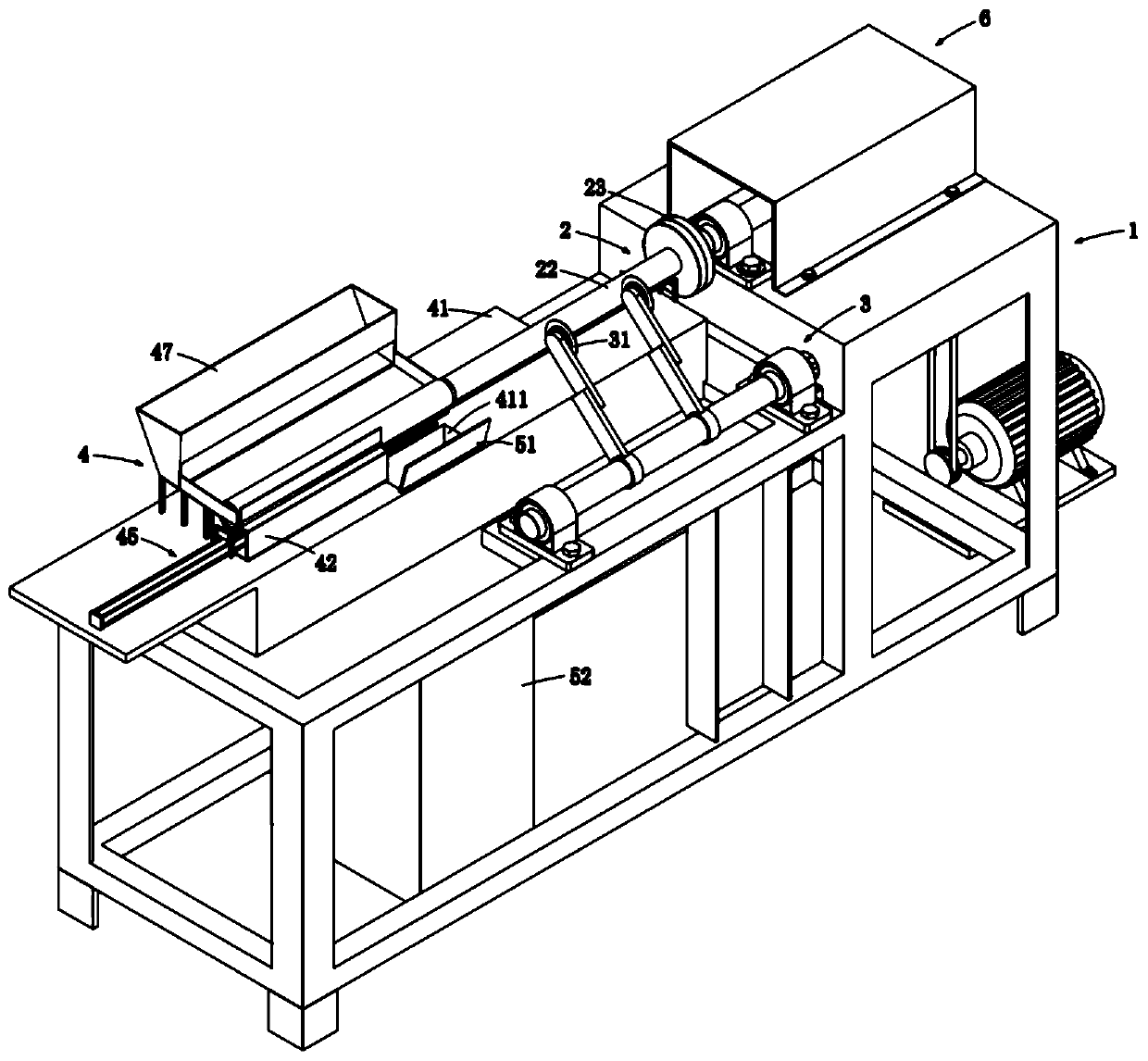

[0043] Such as Figure 1 to Figure 11 As shown, a paper tube fine cutting equipment with continuous loading and unloading function, including:

[0044] Rack 1;

[0045] Rotation assembly 2, the rotation assembly 2 is arranged on the upper surface of the frame 1, which includes a support assembly 21 provided at the end of the frame 1, a rotation roller 22 with one end rotatably mounted on the support assembly 21, and A limit block 23 close to the supporting assembly 21 and arranged on the rotating roller 22;

[0046] Cutting assembly 3, the cutting assembly 3 is located on one side of the rotating roller 22, it includes a number of cutting knives 31, and a drive assembly 32 that drives the cutting knives 31 to move toward the rotating roller 22 in the circumferential direction, the There is a distance between the cutting knife 31 and the paper tube to be cut on the rotating roller 22;

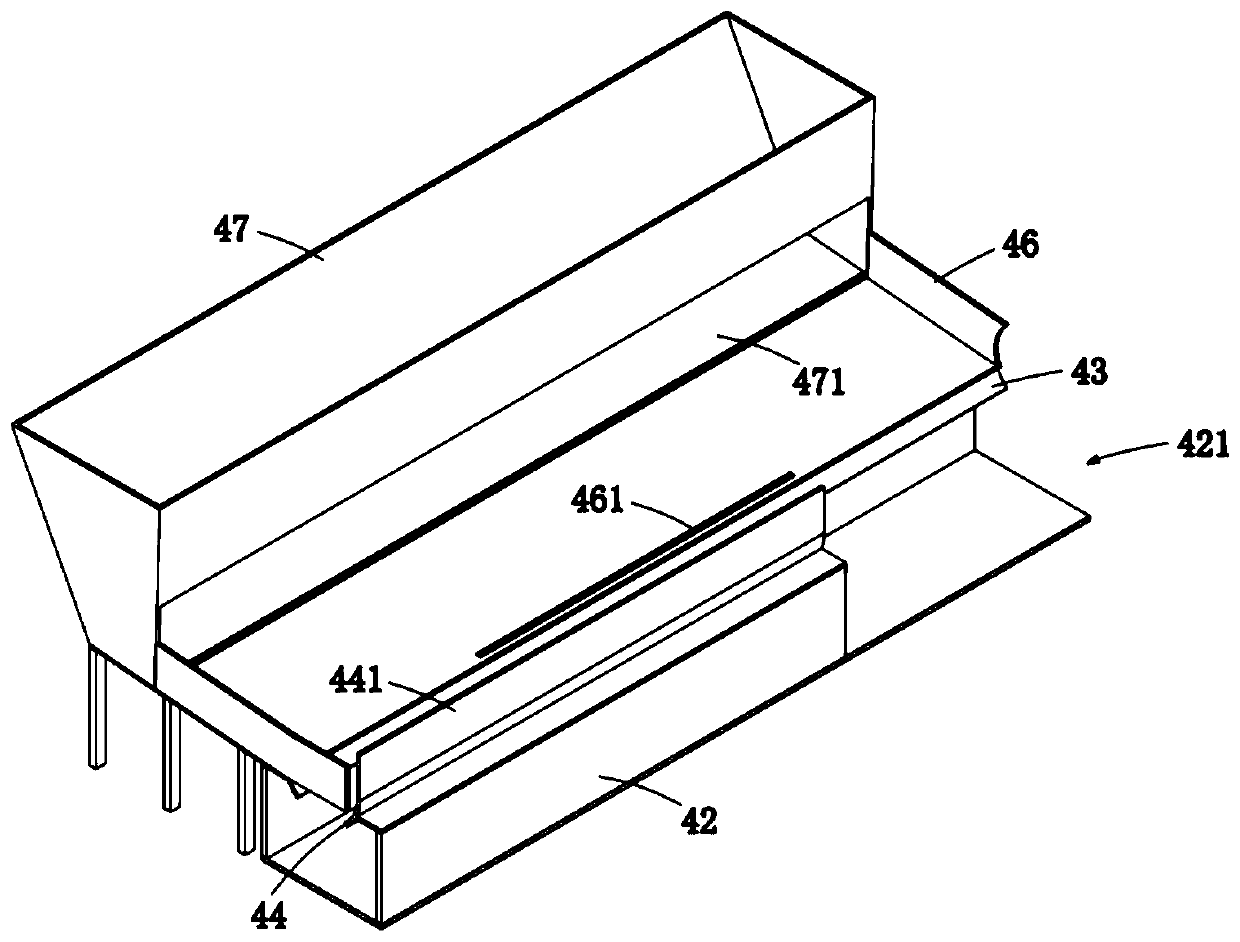

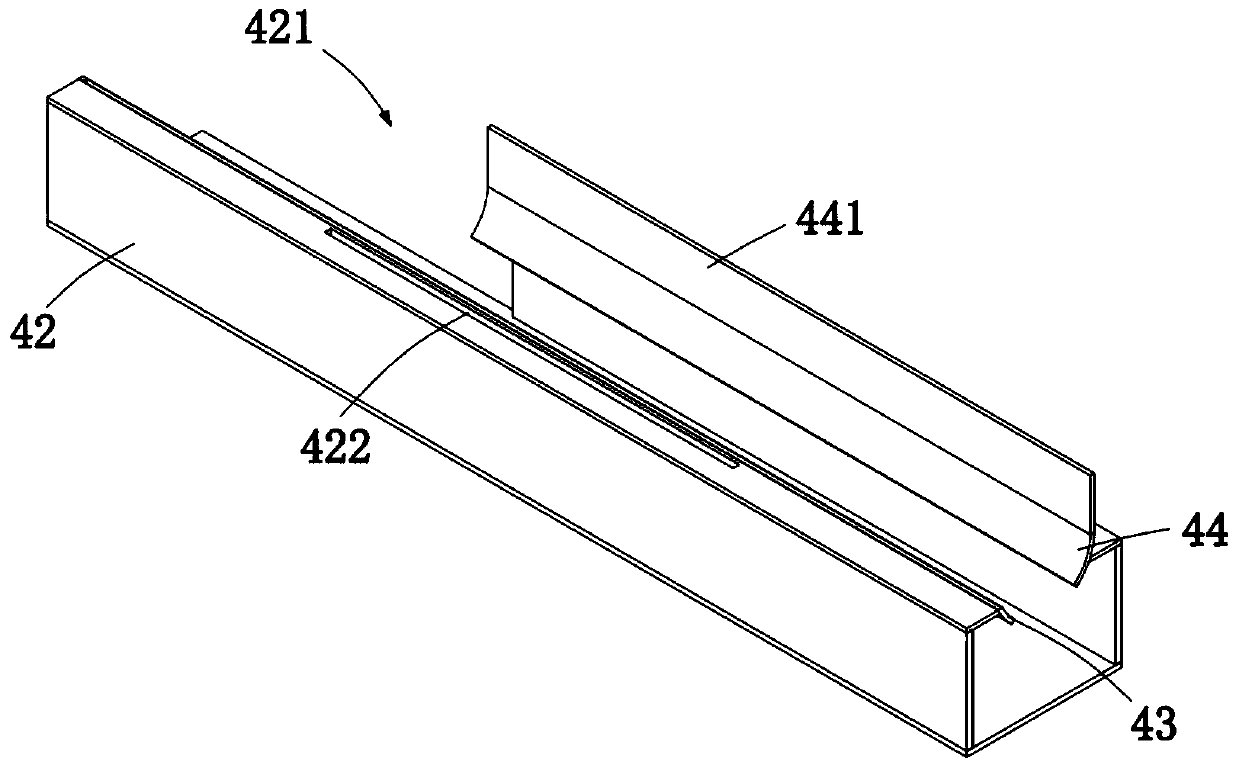

[0047] The automatic feeding part 4, the automatic feeding part 4 includes a supporting t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com