Externally-assisted vibrating feeder

A feeding machine and excitation technology, applied in grain processing, etc., can solve problems such as high cost, and achieve the effects of cost reduction, weight reduction, and strong rhythm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

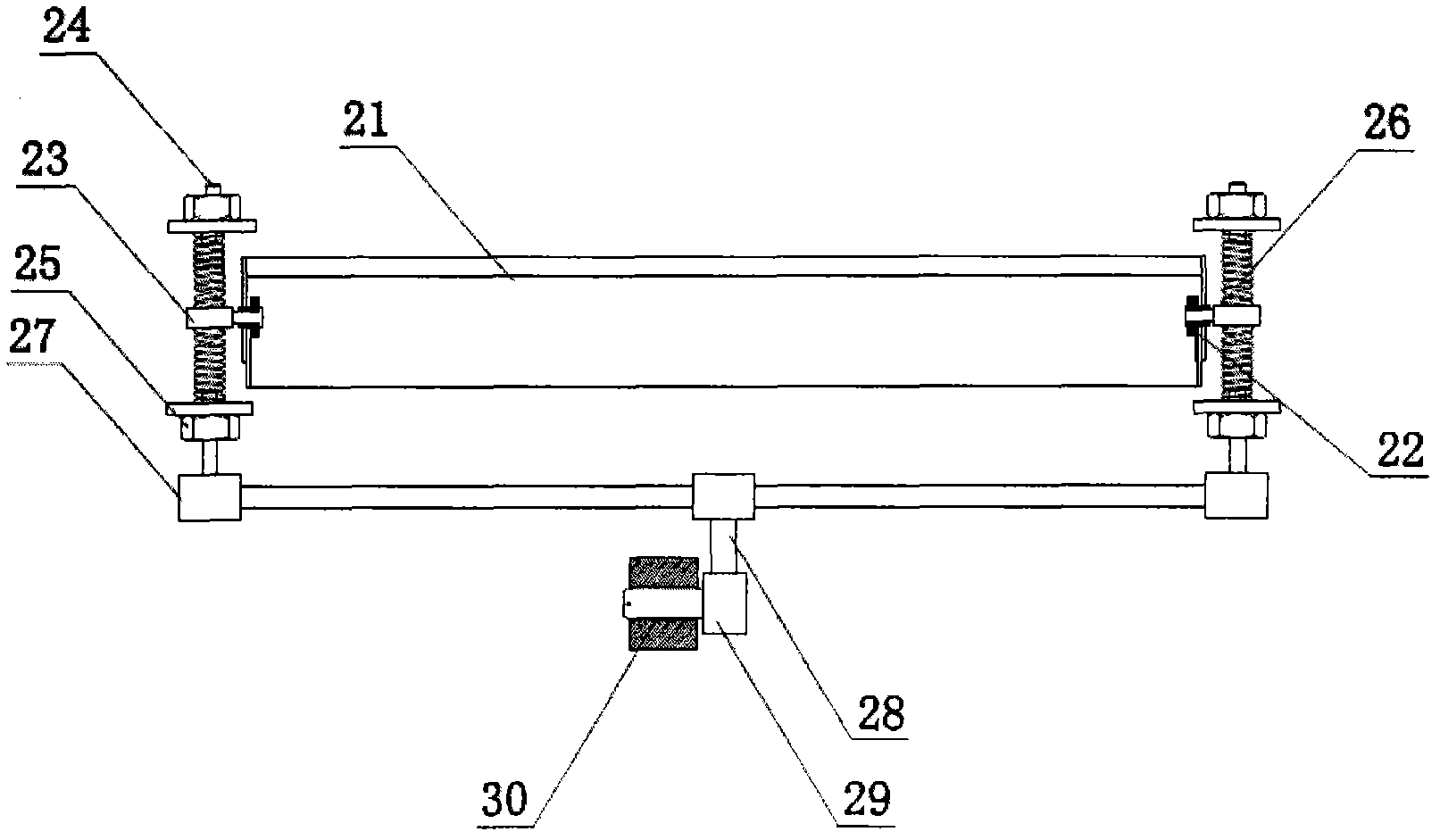

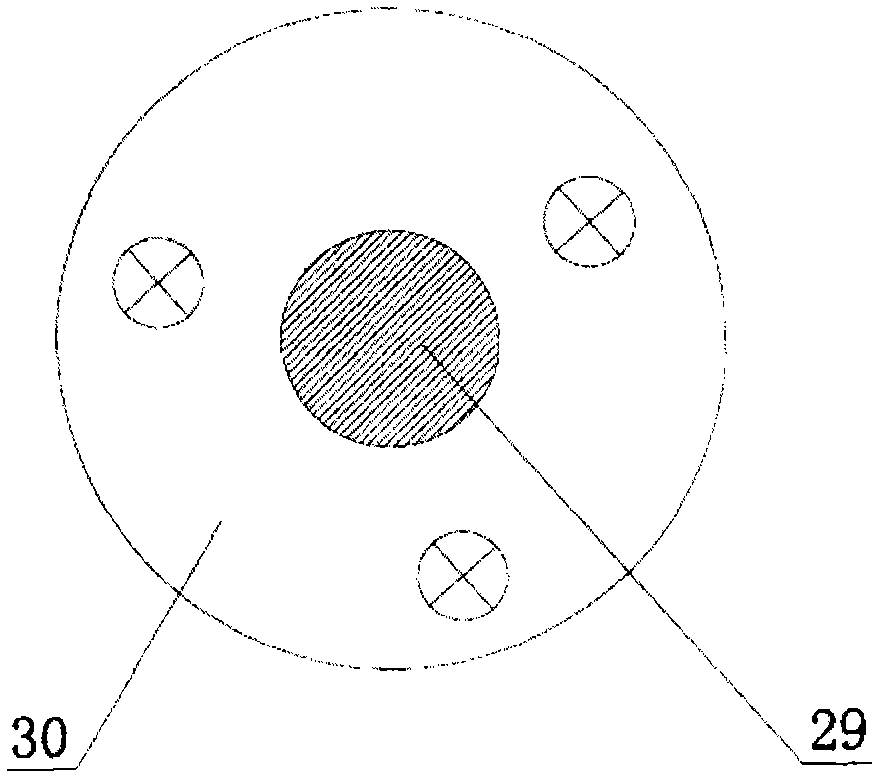

[0041] Embodiment 1: as figure 1 , figure 2 and image 3 As shown, a foreign-aided vibration feeding machine includes a feeding box body 21, two support seats 22 are fixed on both sides below one end of the feeding box body 21, and the side ends of the two support seats 22 are respectively axially connected with a slide block 23, the slide block 23 is slidably set on the threaded rod 24, and the screw rod 24 is located at the two ends of the slide block 23 respectively with a nut 25 for limiting, the two sides of the slide block 23 and the screw rod 24 between the two nuts 25 An exciting spring 26 is evenly sleeved, and one end of the exciting spring 26 leans against the side of the slide block 23 , and the other end leans against the side of the nut 25 .

[0042] The screw mandrels 24 located on both sides of the feeding box body 21 are connected together by a connecting bar 27, the screw mandrel 24 is vertically connected with the connecting bar 27, and a connecting verti...

Embodiment 2

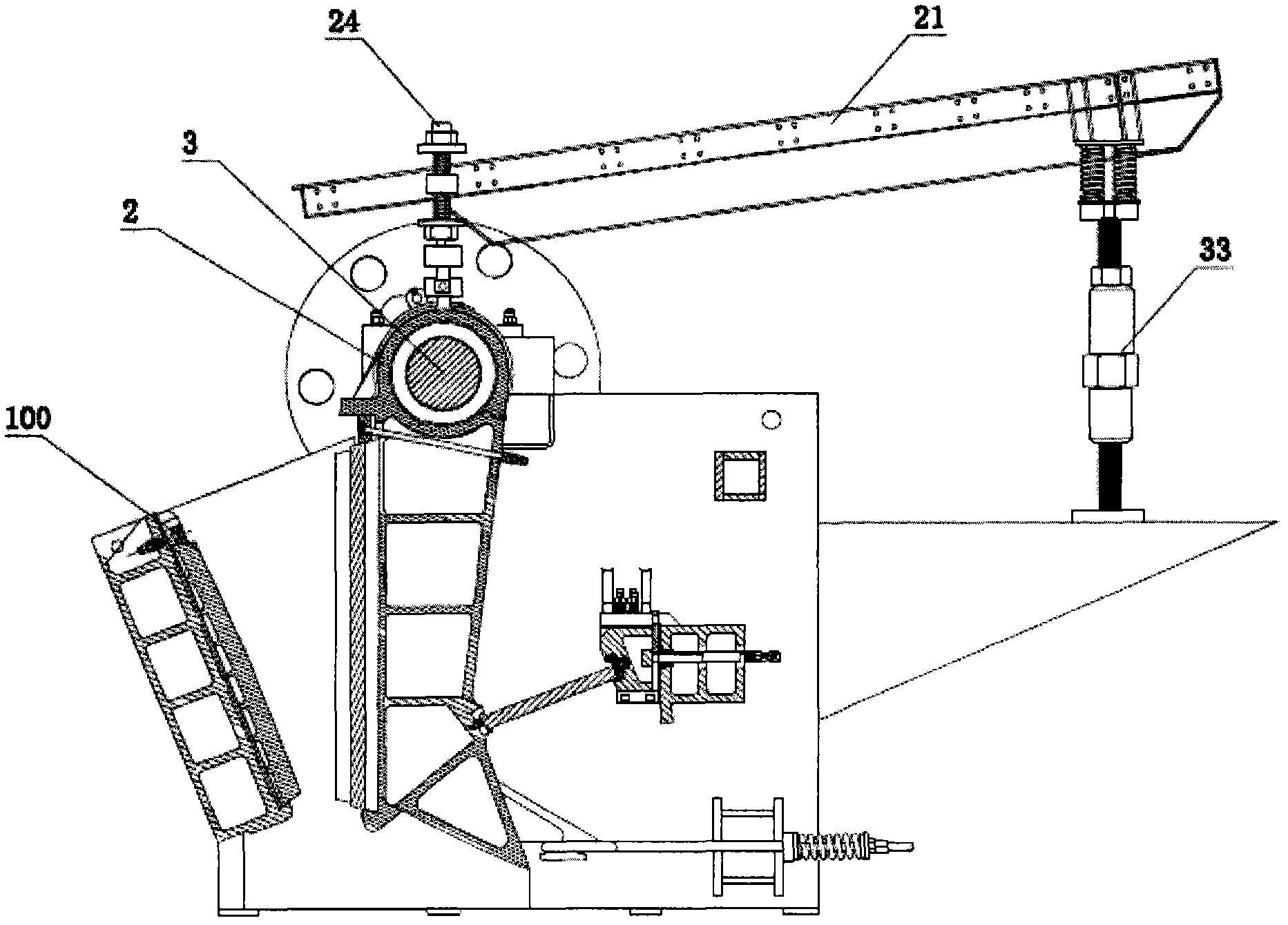

[0044] Embodiment 2: as Figure 4 , Figure 5 and Figure 6As shown, a foreign-aided vibration feeding machine includes a feeding box body 21, two support seats 22 are fixed on both sides below one end of the feeding box body 21, and the side ends of the two support seats 22 are respectively axially connected with a slide block 23, the slide block 23 is slidably set on the threaded rod 24, and the screw rod 24 is located at the two ends of the slide block 23 respectively with a nut 25 for limiting, the two sides of the slide block 23 and the screw rod 24 between the two nuts 25 An exciting spring 26 is evenly sleeved, and one end of the exciting spring 26 leans against the side of the slide block 23 , and the other end leans against the side of the nut 25 .

[0045] The screw rods 24 on both sides of the feeding box 21 are connected together by a connecting cross bar 27, the screw rod 24 is vertically connected to the connecting cross bar 27, and a connecting rod is vertical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com