Feeding and receiving device of punch press

A technology of a material receiving device and a punching machine, applied in the field of punching machines, can solve the problems of high cost, poor installation, use, complex structure, etc., and achieve the effects of low cost, improved production efficiency, and good continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

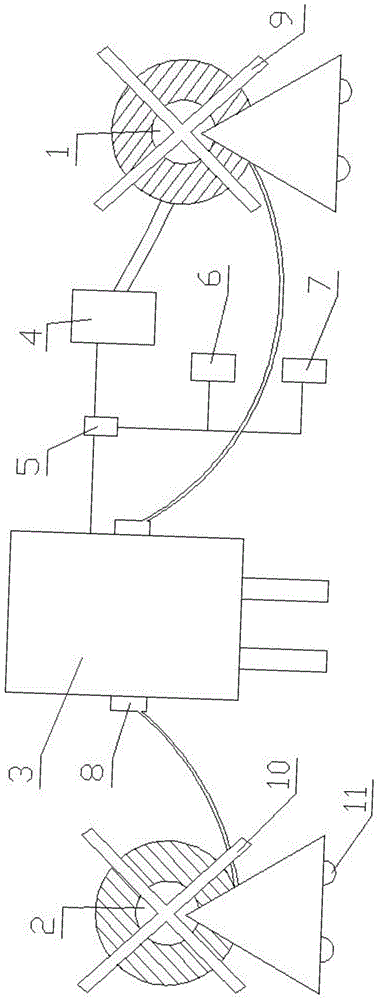

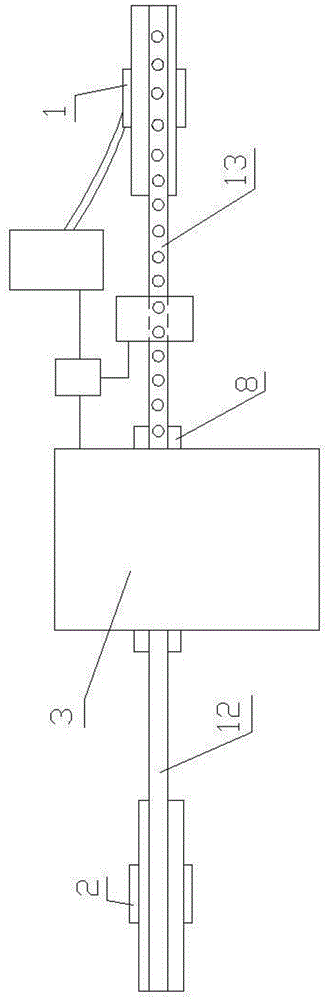

[0024] The present invention is described further below:

[0025] to combine figure 1 , figure 2 : A feeding and receiving device of a stamping machine, relating to a stamping machine 3, including first and second coils, first and second induction devices, a motor 4, a controller 5, and the motor 4 and the first coil 1 for transmission connection, the motor 4 is electrically connected to the controller 5, and the controller 5 is electrically connected to the stamping machine 3; the first reel 1 can continuously rotate clockwise or counterclockwise;

[0026] This technical solution is mainly aimed at recycling slender waste materials, such as steel strips. The raw material 12 is punched by a punching machine to form a waste material 13, and the waste material 13 is wound on the first coil 1; after the punching machine 3 punches a workpiece, the controller 5 The collected information is transmitted to the motor 4, the motor 4 starts, drives the first reel 1 to rotate, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com