Patents

Literature

31results about How to "Adjustable working height" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

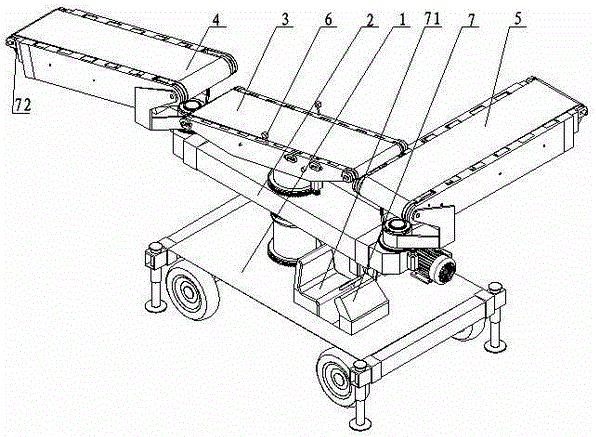

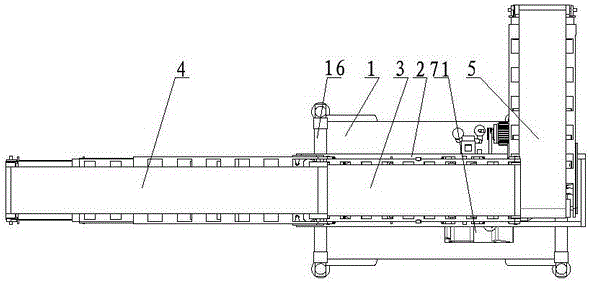

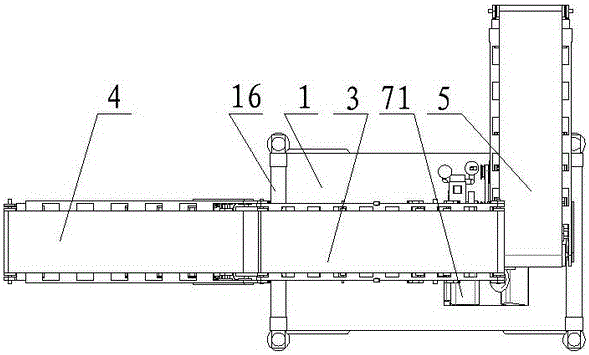

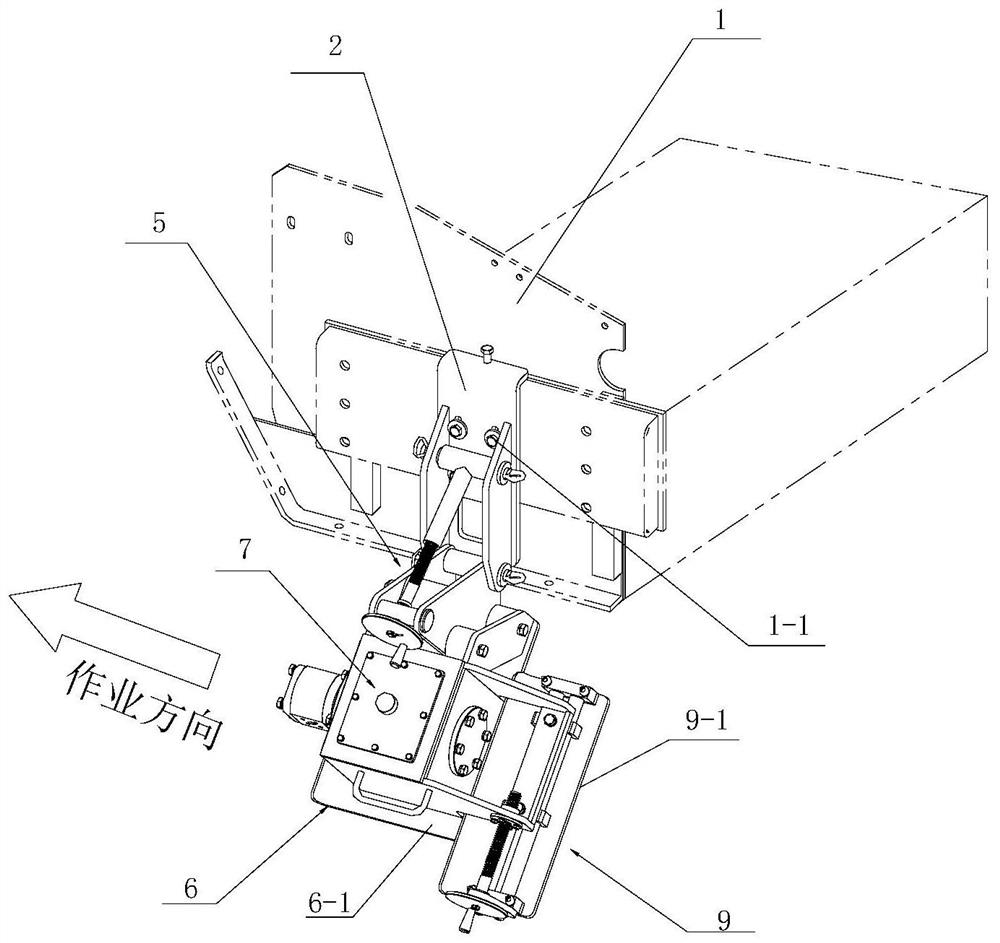

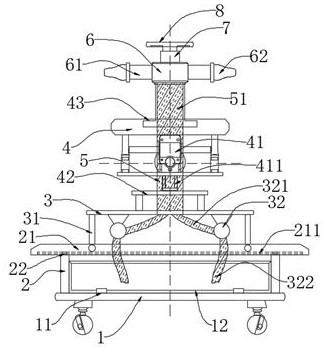

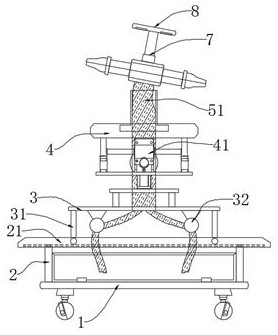

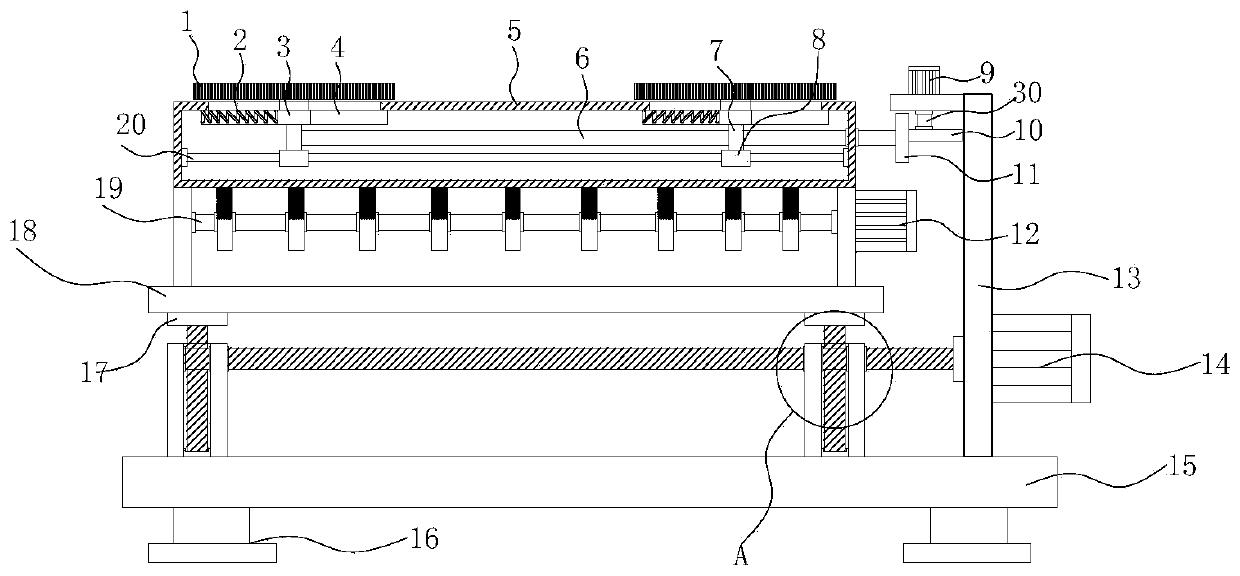

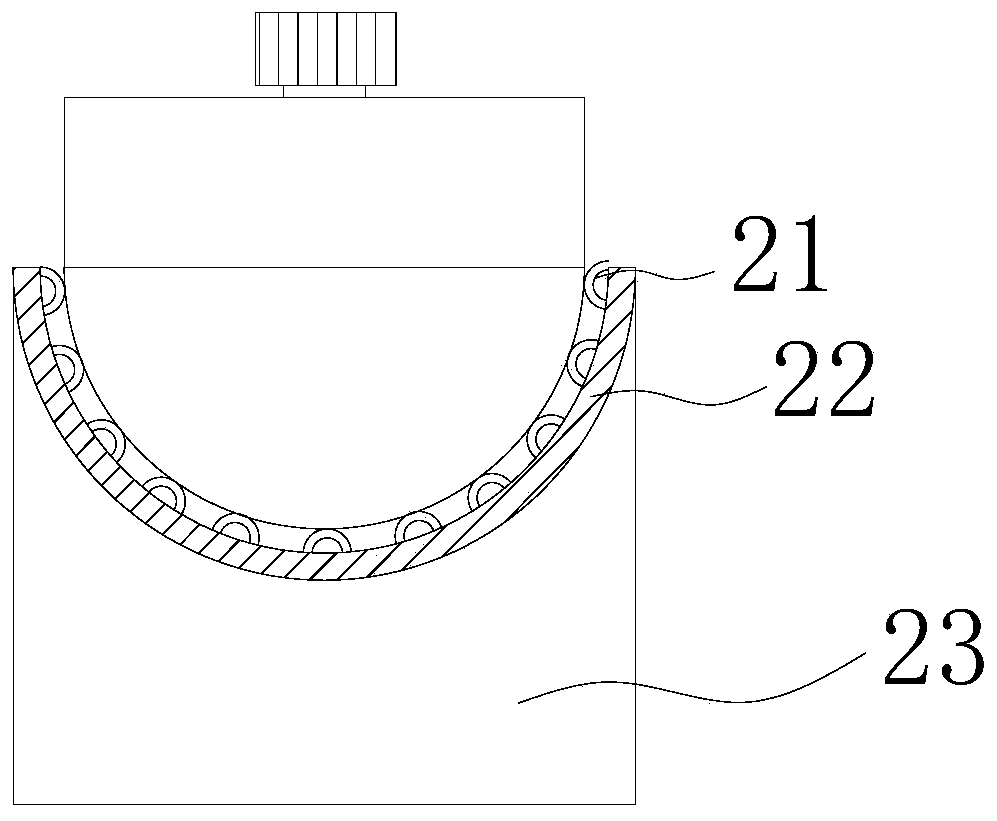

A derricking direction-changeable telescopic belt conveying bidirectional loader-unloader

InactiveCN106608551AAdjustable working heightRealize orientationConveyorsRollersControl systemStatistical analysis

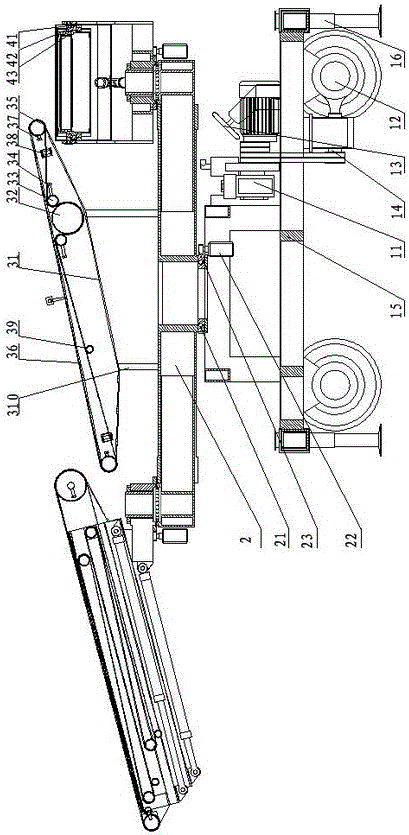

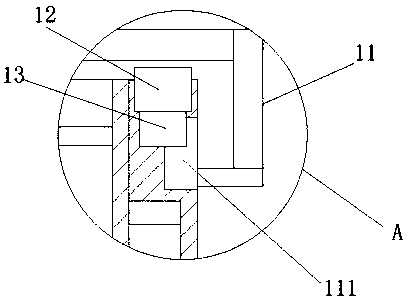

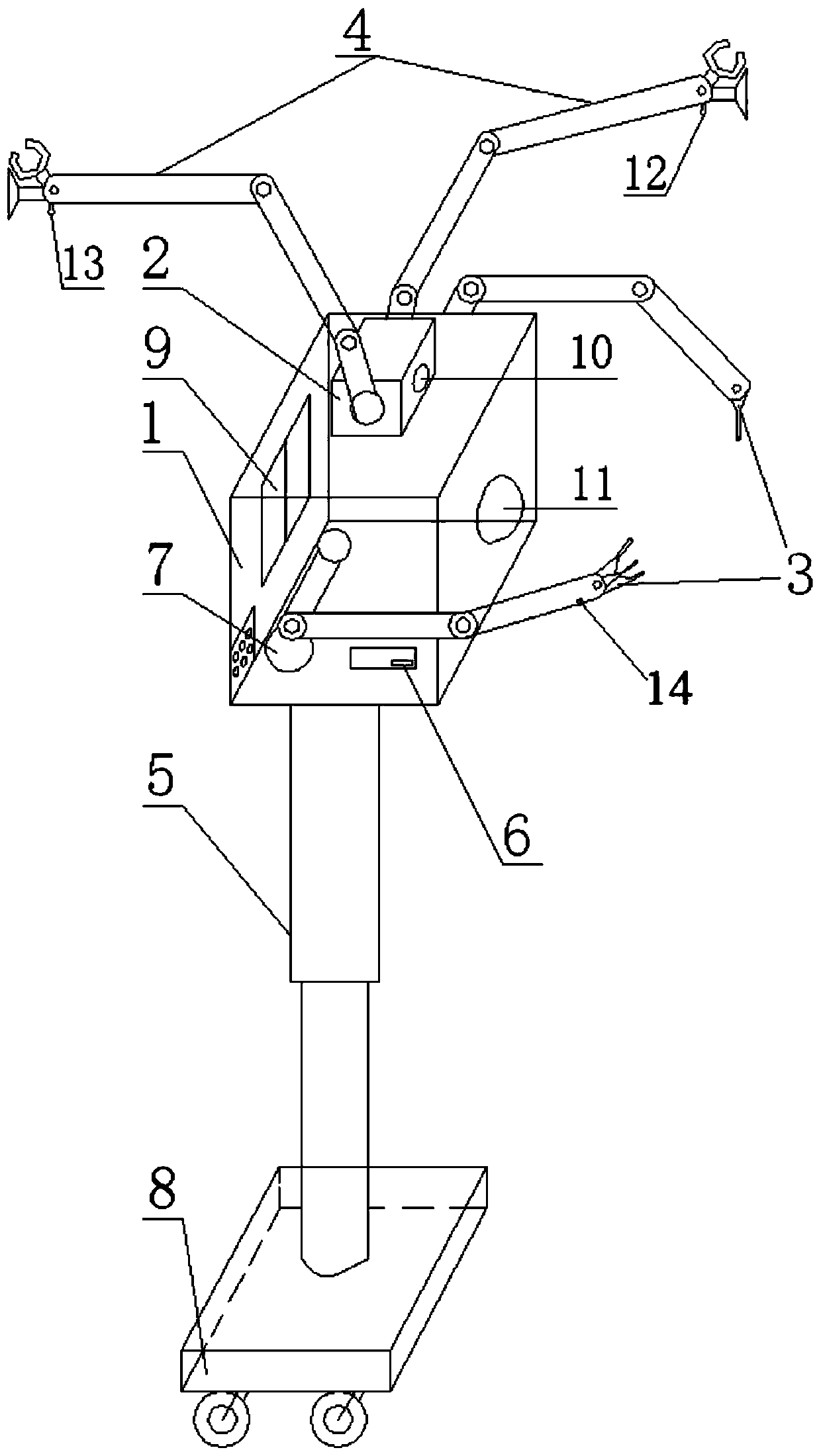

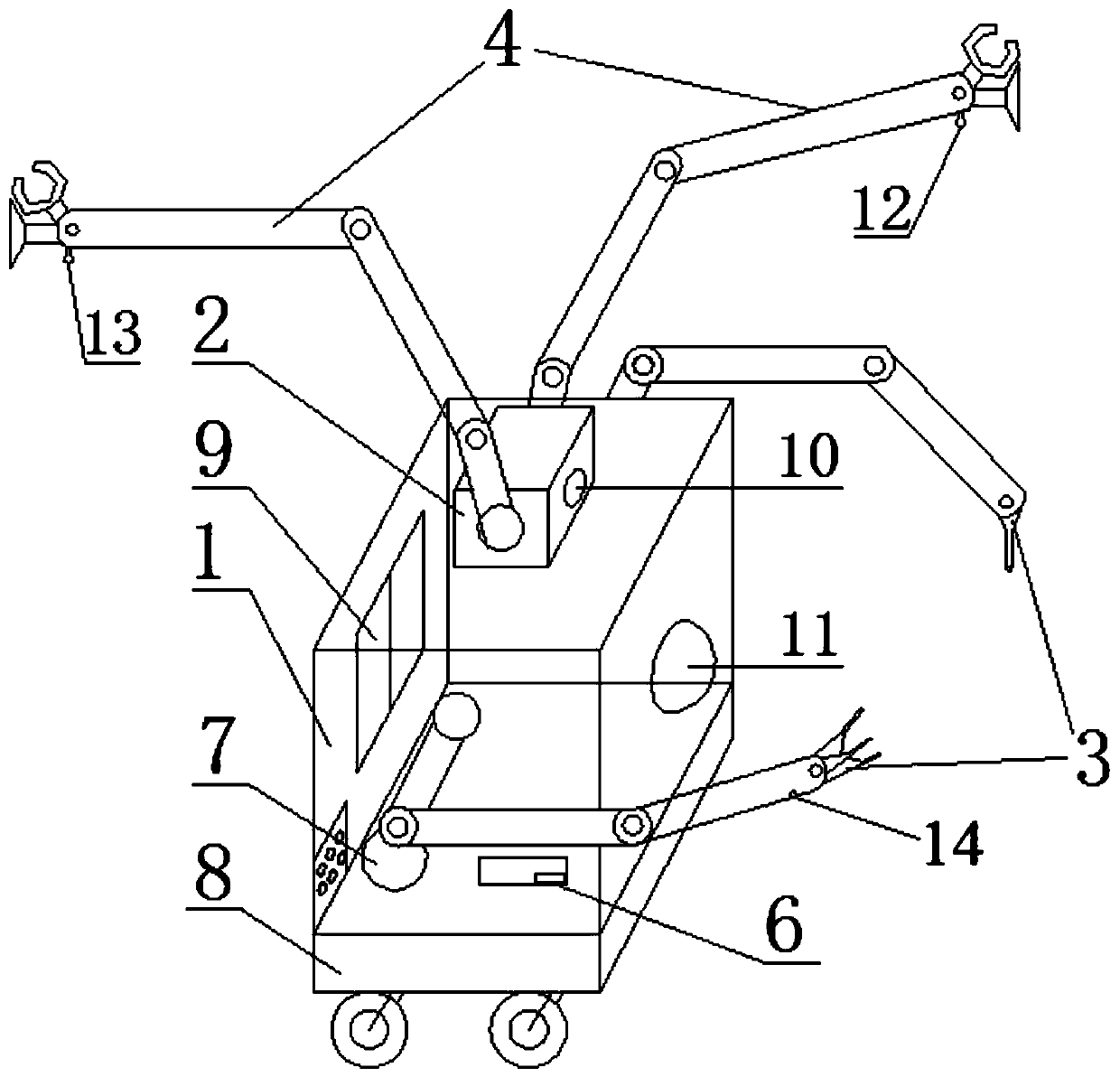

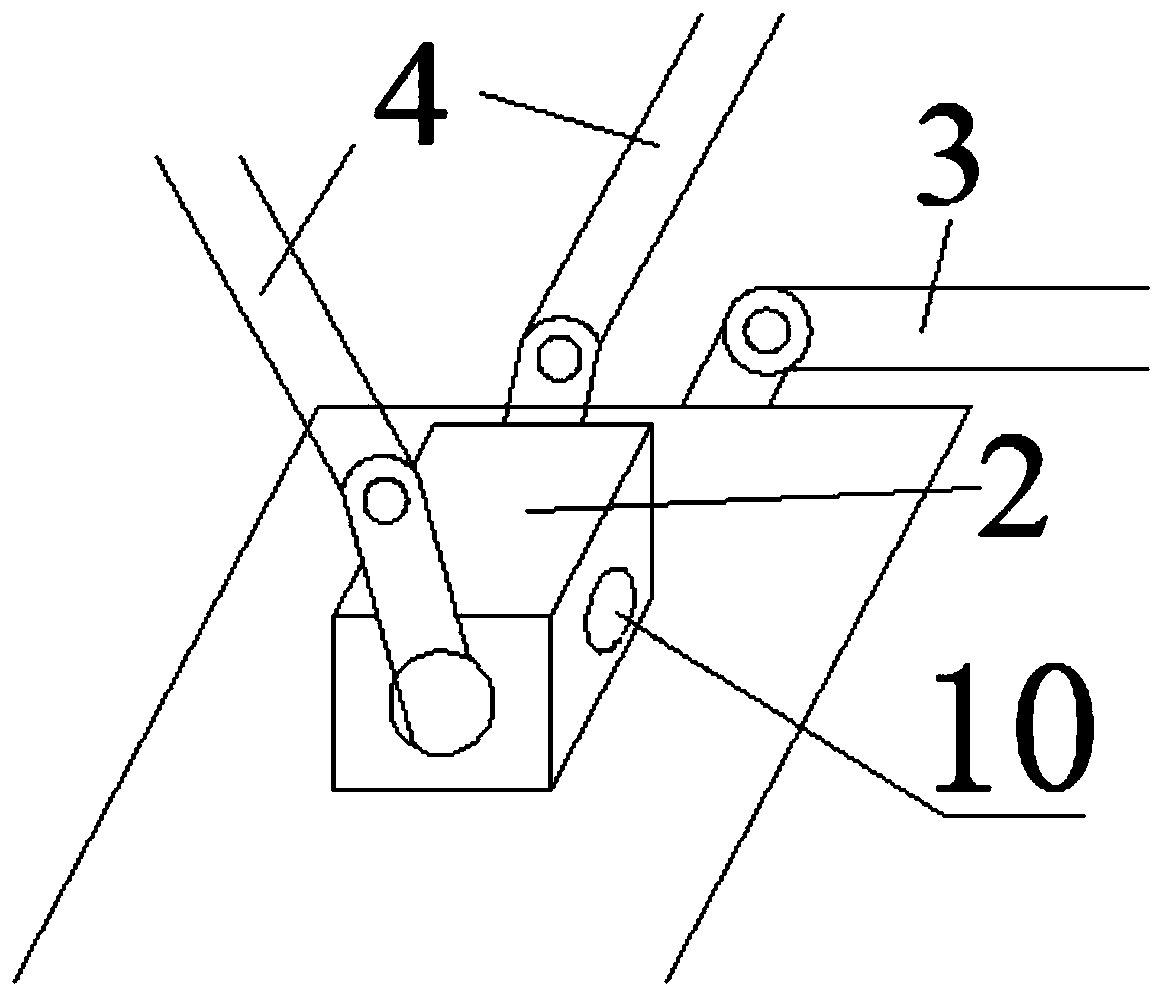

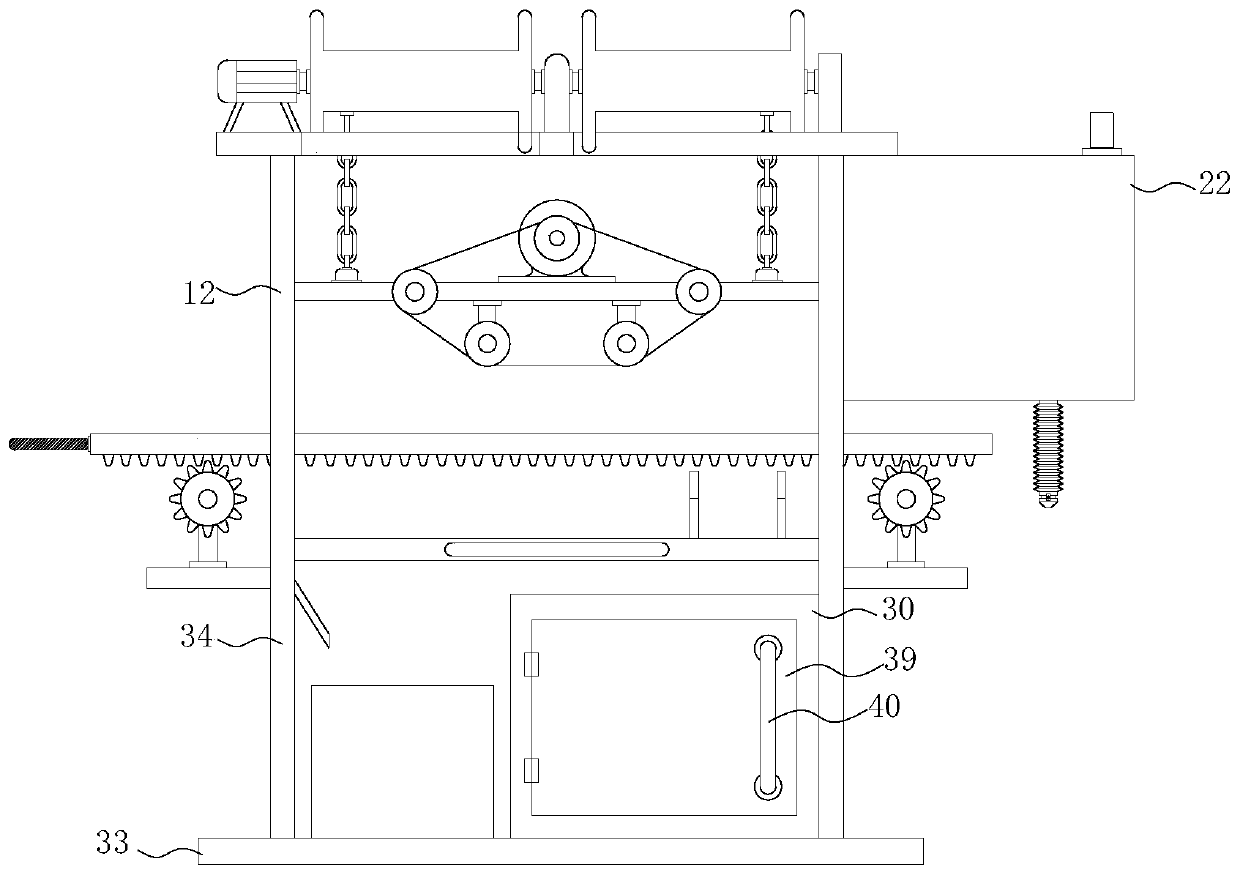

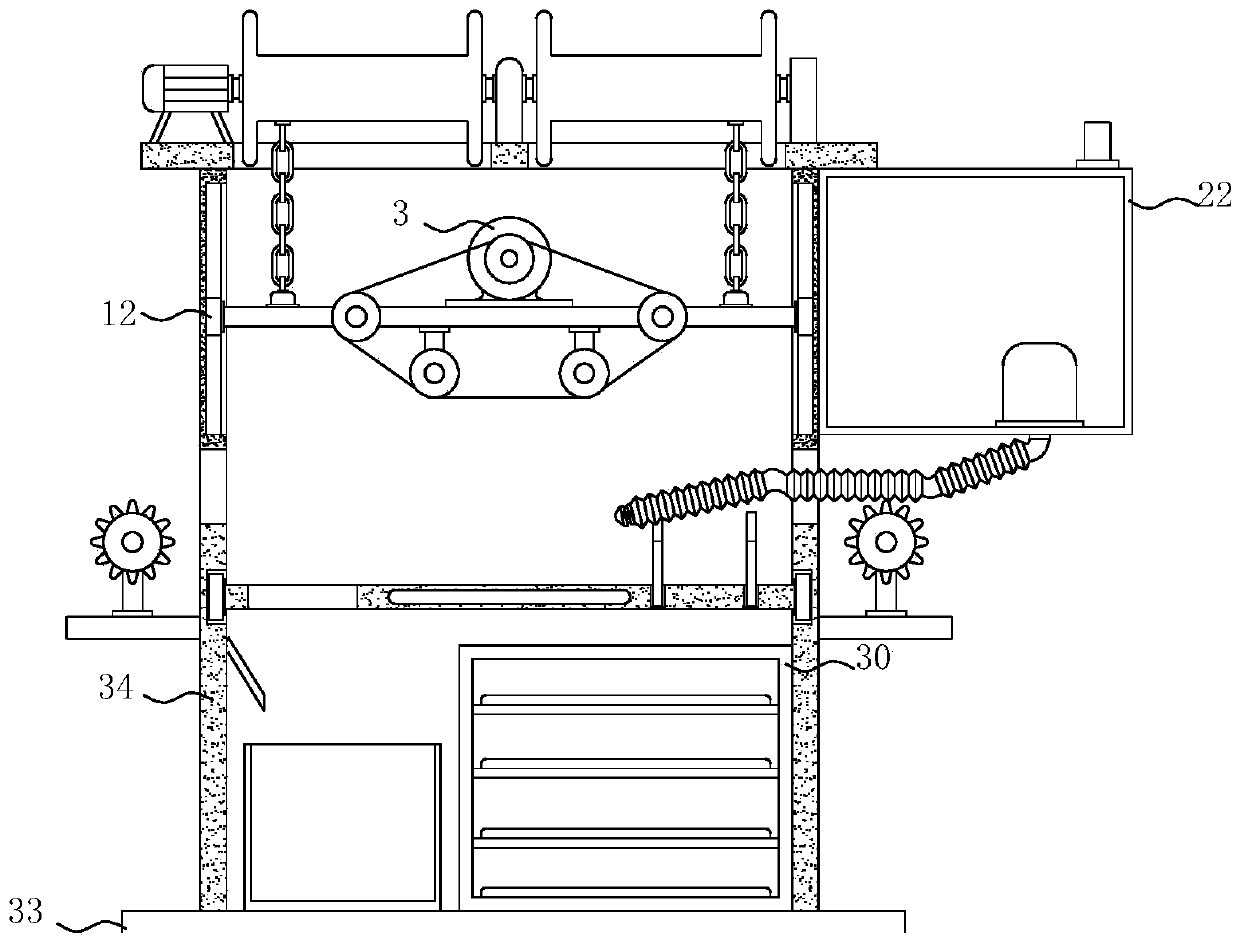

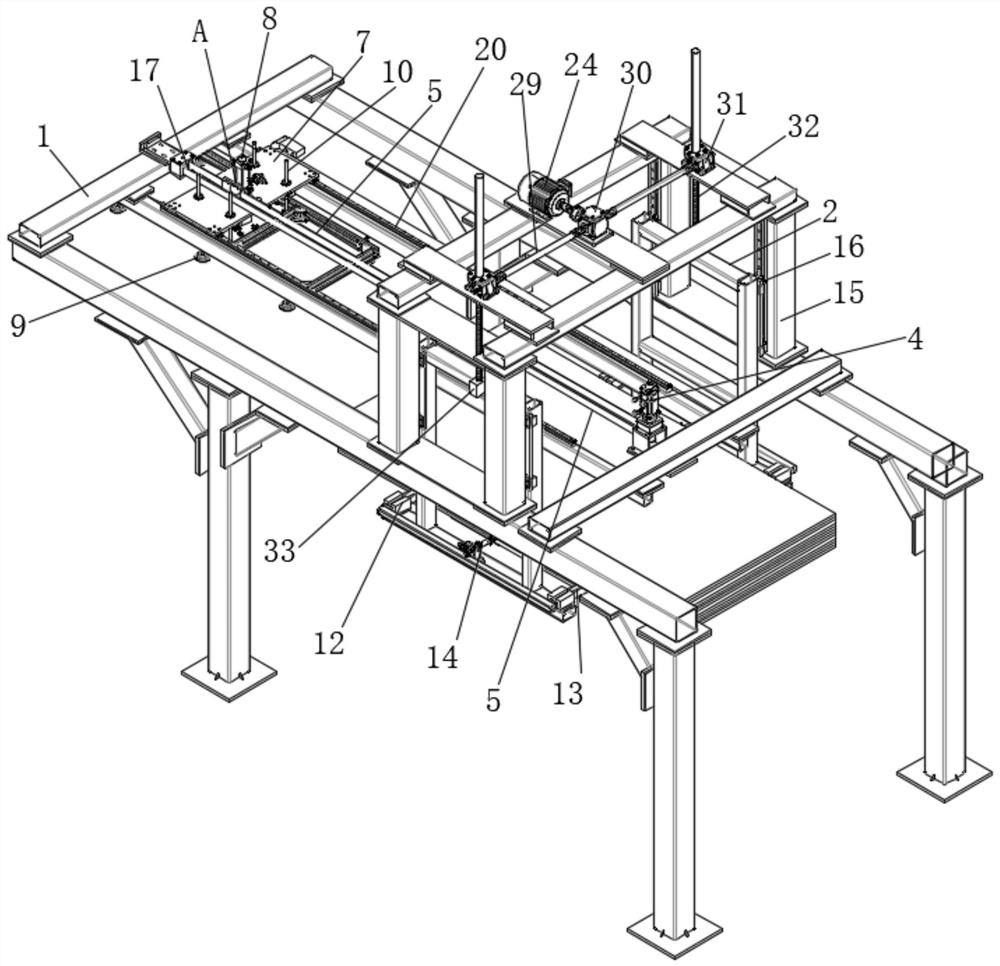

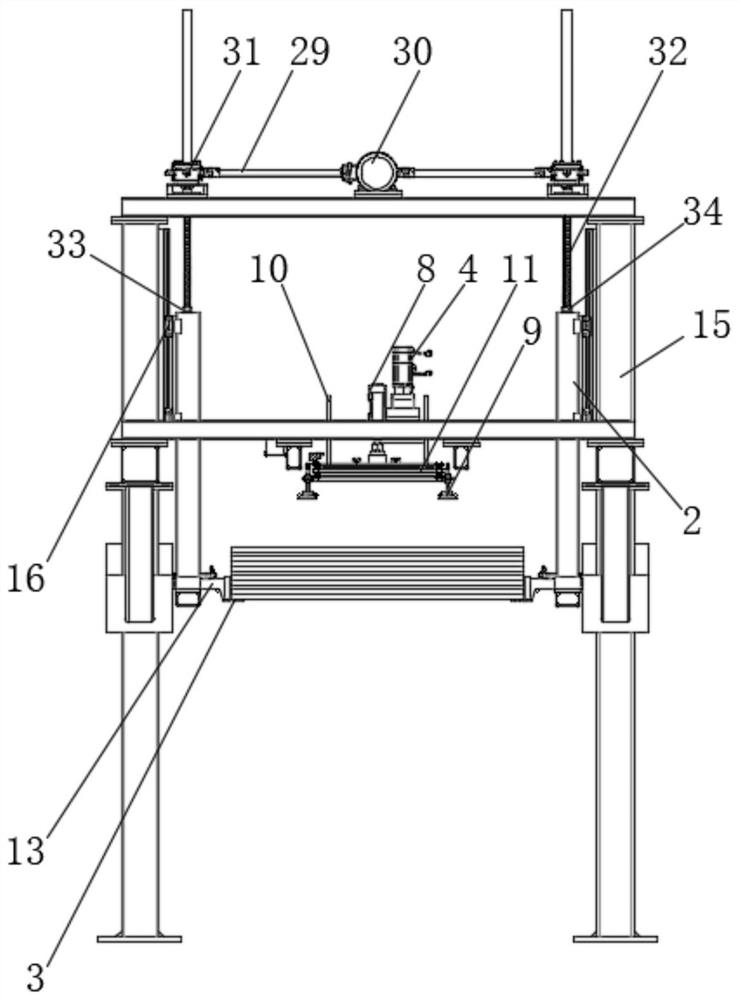

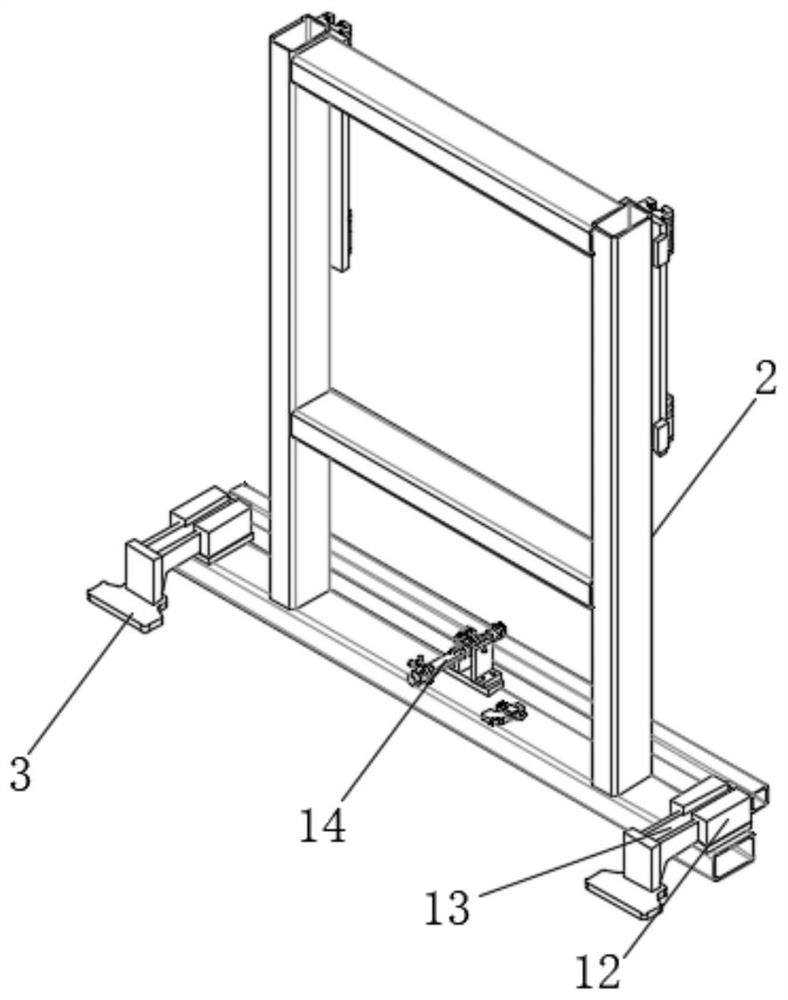

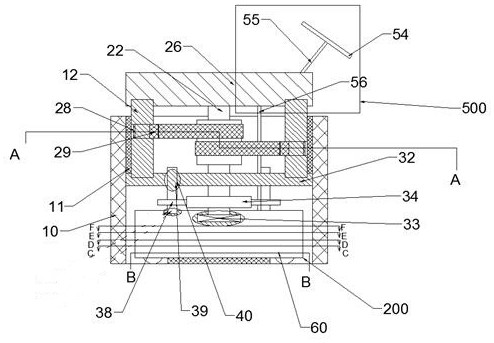

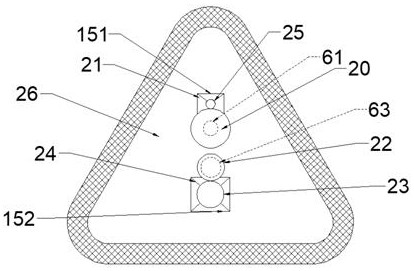

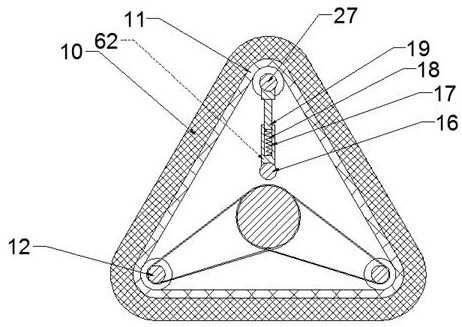

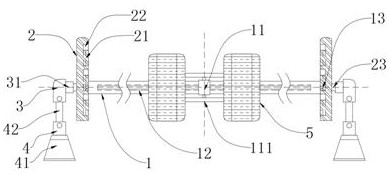

The invention provides a derricking direction-changeable telescopic belt conveying bidirectional loader-unloader and relates to the field of logistics transportation cargo loading and unloading mechanical equipment. The derricking direction-changeable telescopic belt conveying bidirectional loader-unloader comprises a vehicle having bearing and walking functions, a telescopic cross arm having lifting, telescoping and swinging functions, a middle transition conveyor which has a swinging function and is capable of inclined conveying, a first belt conveyor and a second belt conveyor having derricking, swinging and telescoping functions, a metering device having metering, displaying, storing and printing functions, and an operating control system used for complete machine operation of the loader-unloader. The derricking direction-changeable telescopic belt conveying bidirectional loader-unloader has the advantages of simple structure, reliable work, convenient and rapid movement and transfer, and wide operating scope; the derricking direction-changeable telescopic belt conveying bidirectional loader-unloader can reduce manually-assisted carrying, reduce workload, shorten operating time, increase loading and unloading working efficiency, reduce the cost of loading and unloading carrying, improve working environment and work conditions, guarantee economical, rapid, convenient and safe loading and unloading and transportation, allow change of the direction of logistics conveying, and realize forward and reverse loading and unloading, automatic metering statistical analysis, and loading and unloading quantity / weight recording, displaying and storing.

Owner:襄阳忠良工程机械有限责任公司

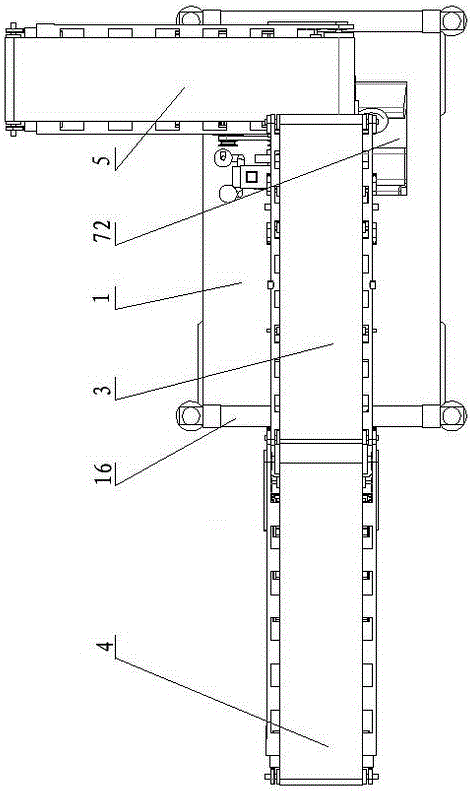

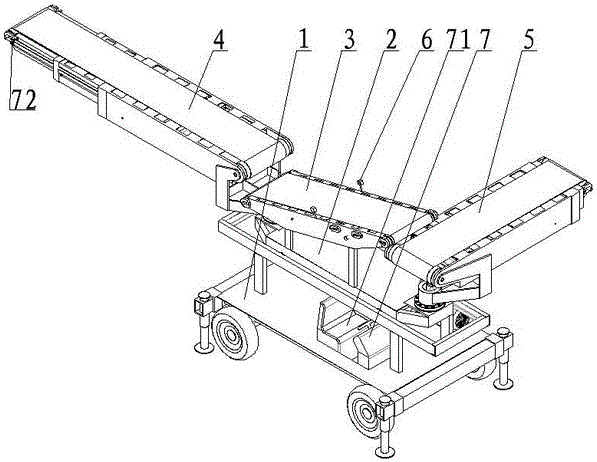

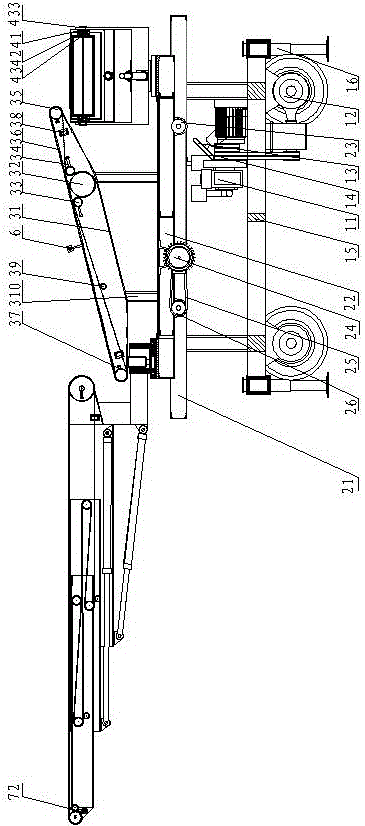

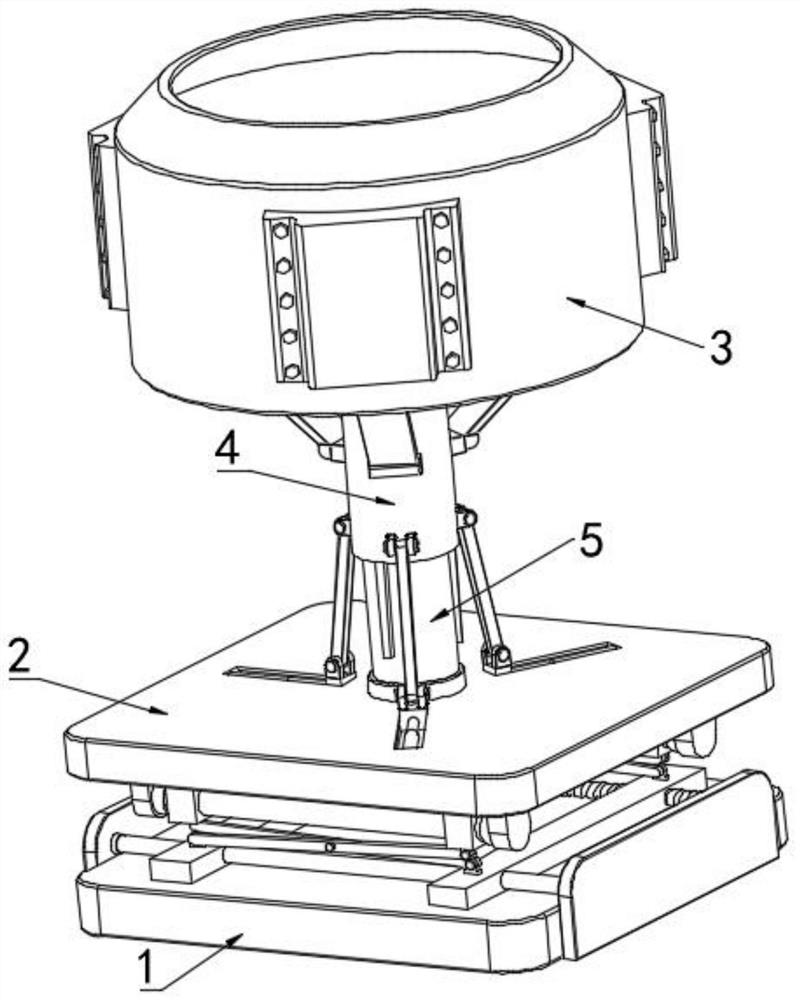

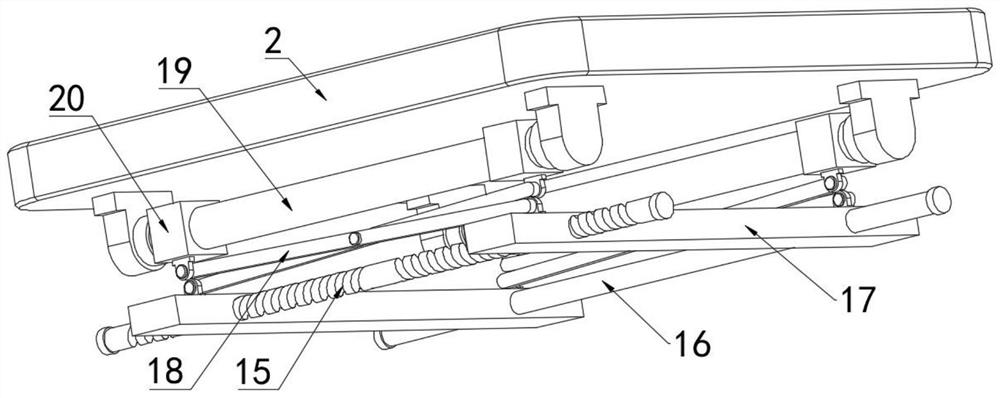

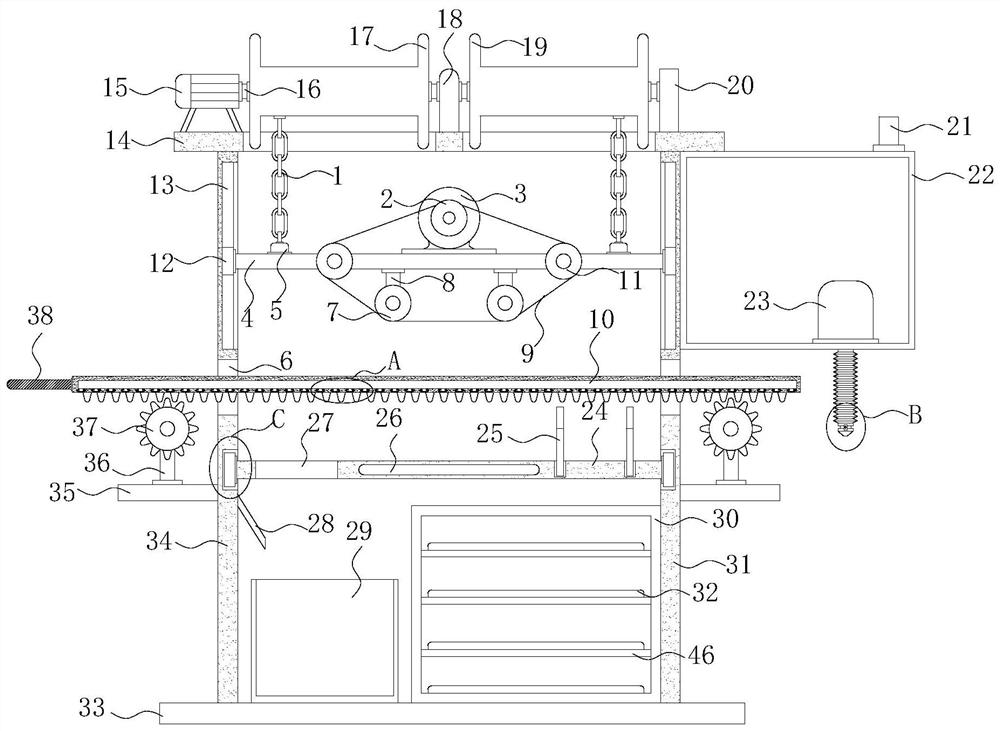

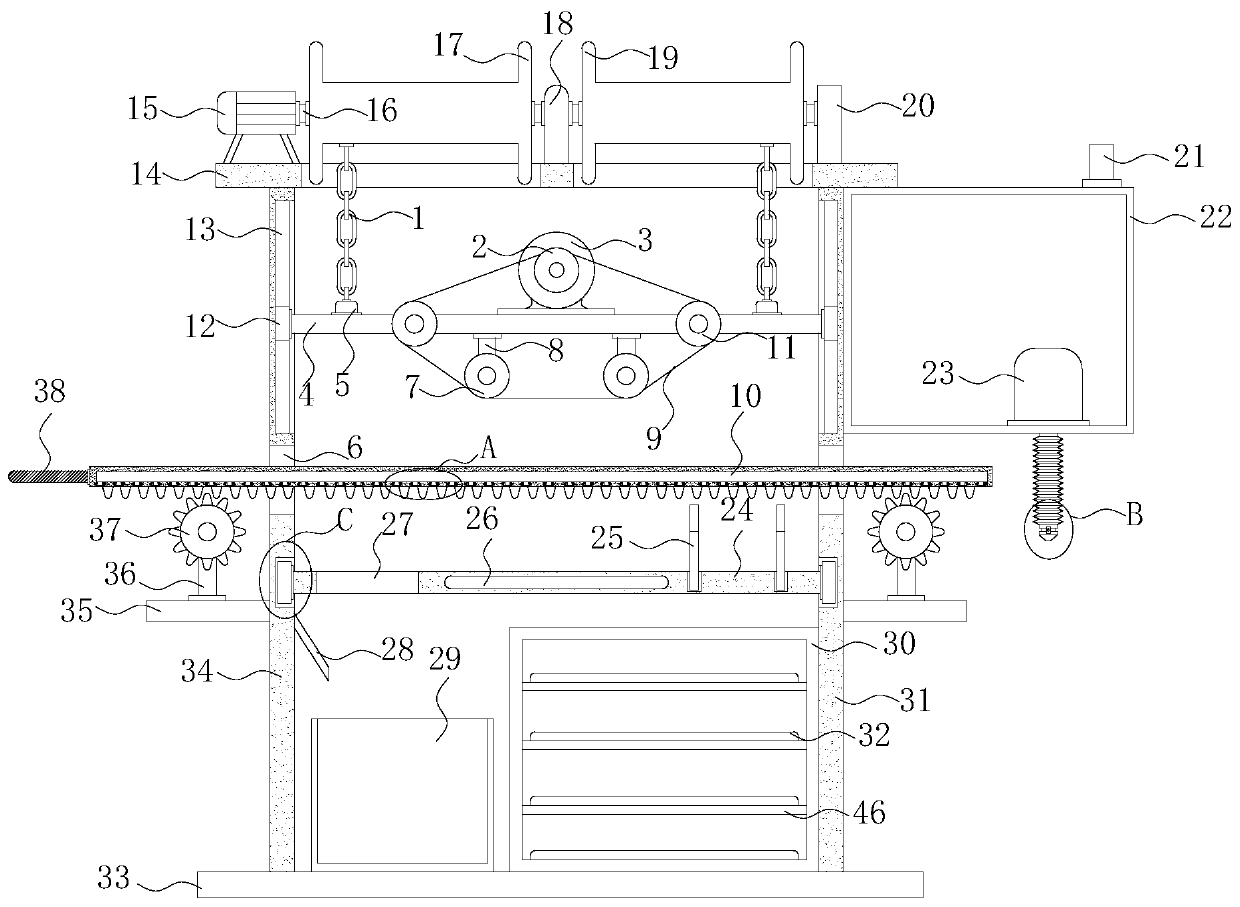

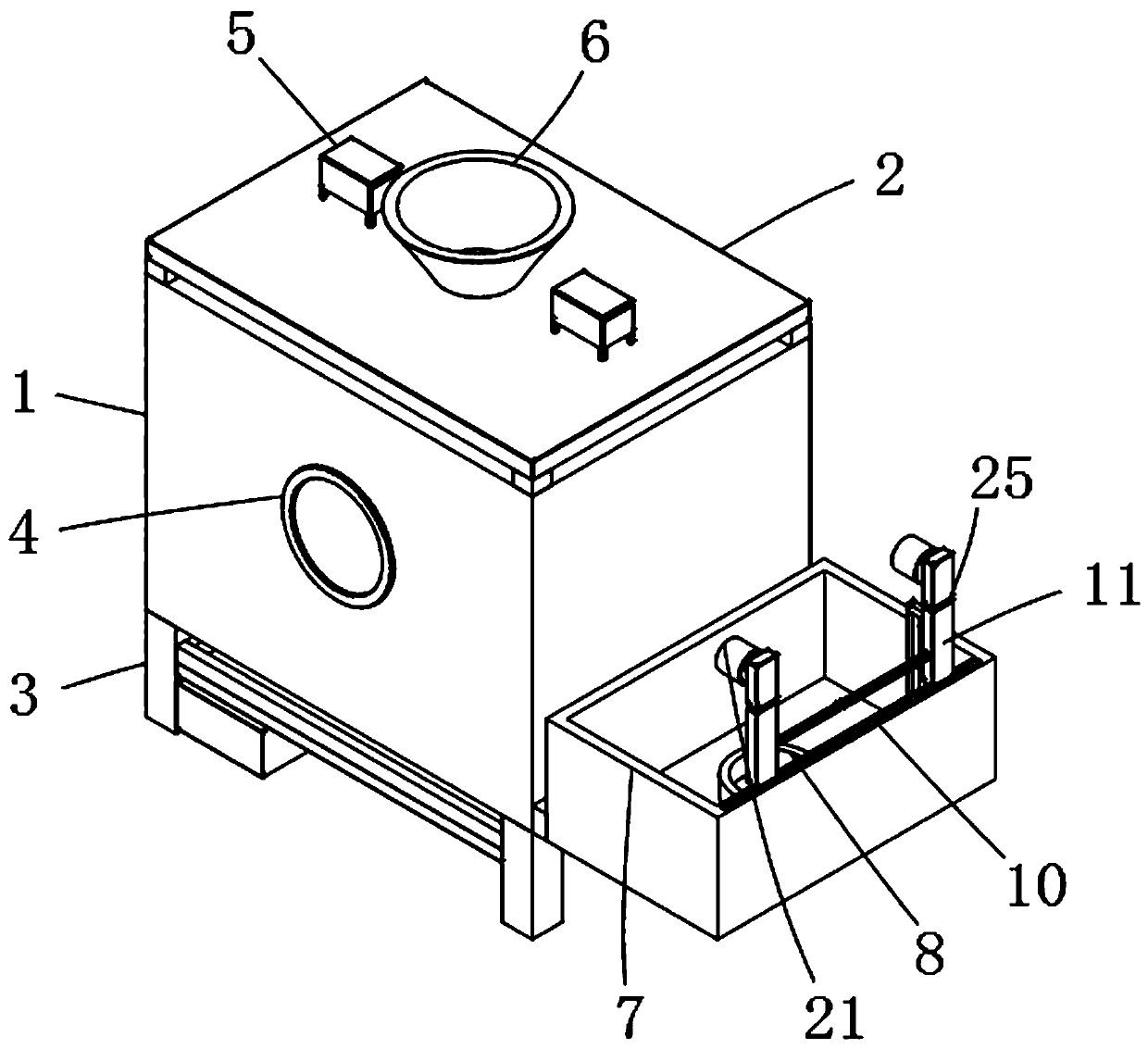

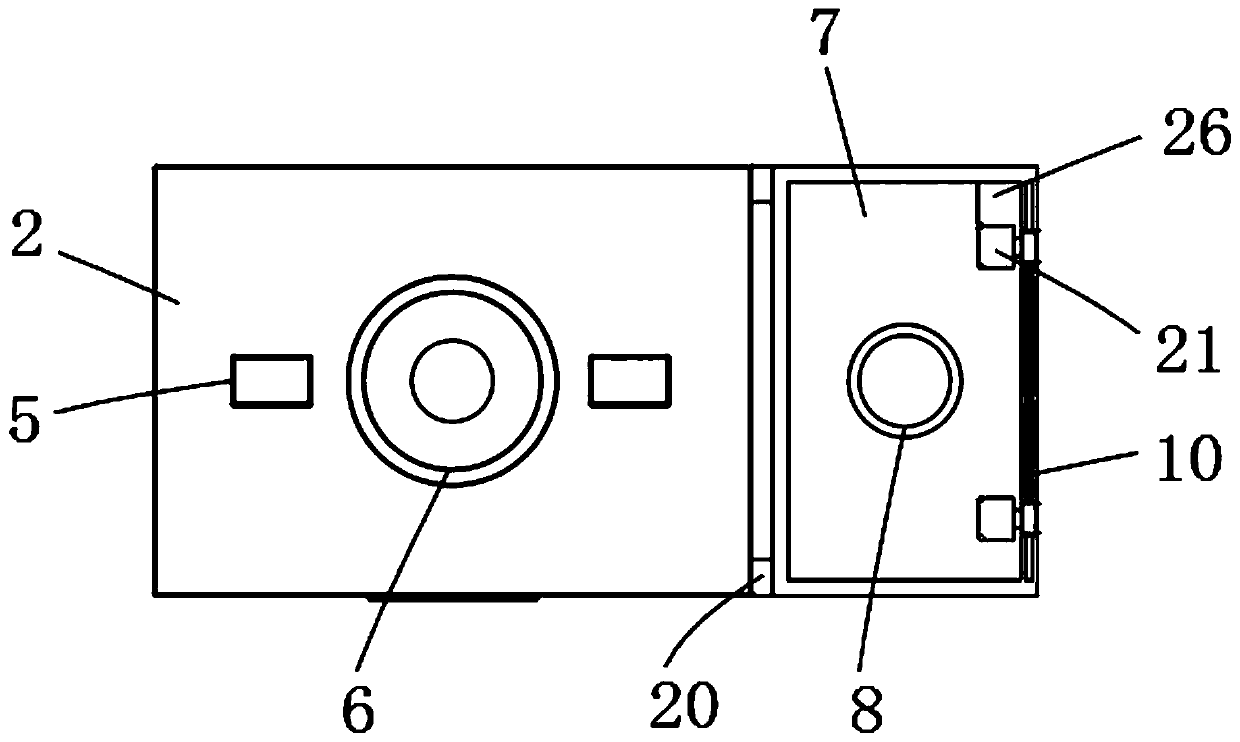

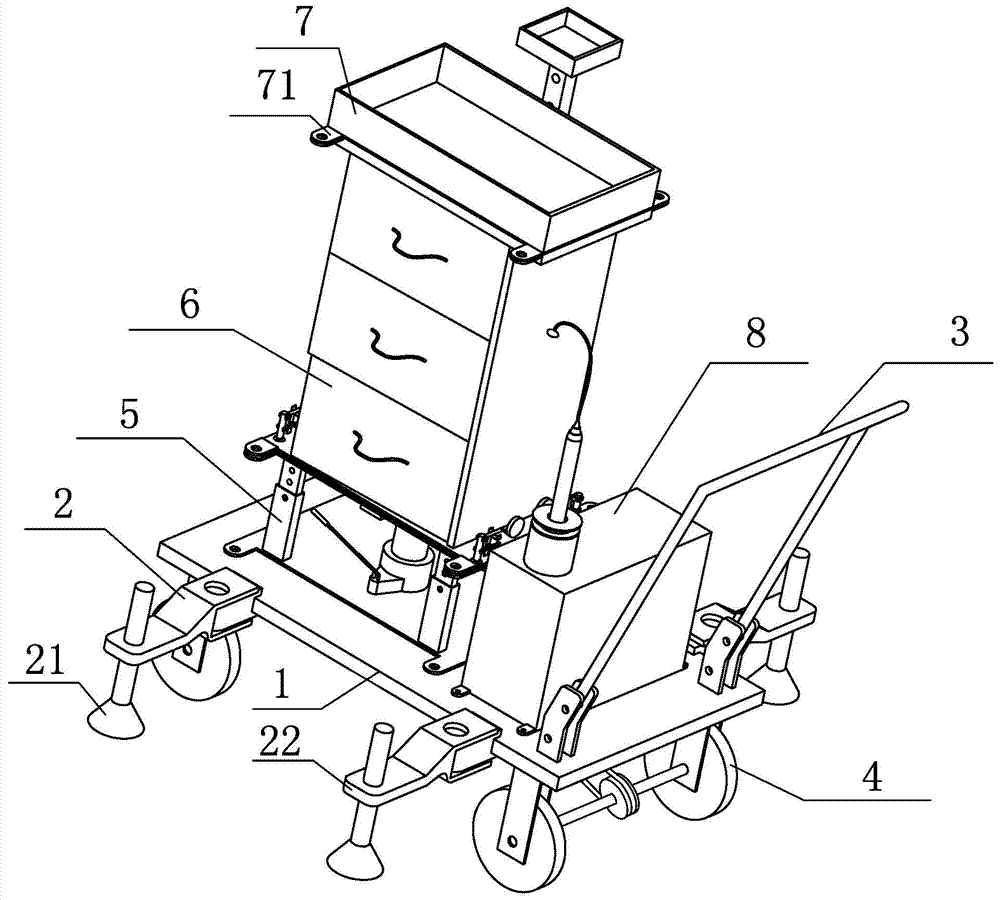

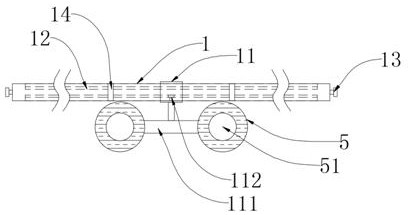

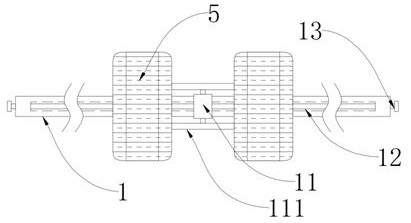

Amplitude-variable extensible belt turning conveying bidirectional loading-unloading machine

InactiveCN106629092AAdjustable workAdjustable postureConveyorsRollersWorking environmentMechanical equipment

The invention discloses an amplitude-variable extensible belt turning conveying bidirectional loading-unloading machine and relates to the field of logistics transportation cargo loading-unloading mechanical equipment. The loading-unloading machine is composed of a vehicle, a sliding platform, a middle transition conveyor, a first belt conveyor, a second belt conveyor, a metering device and an operation control system, wherein the vehicle has bearing and walking functions, the sliding platform has a sliding function, the middle transition conveyor is capable of achieving inclined conveying, the first belt conveyor and the second belt conveyor have amplitude changing, swing rotation and extending functions, the metering device has metering, display, storage and printing functions, and the operation control system is used for operation of the whole loading-unloading machine. According to the amplitude-variable extensible belt turning conveying bidirectional loading-unloading machine, the structure is simple, work is reliable, movement and place transfer are convenient and fast, the operation range is large, manual auxiliary carrying can be reduced, the labor intensity is lowered, operation time is shortened, the loading-unloading work efficiency is improved, the loading-unloading carrying cost is reduced, the working environment and labor conditions are improved, it is ensured that loading-unloading transportation is economical, fast, convenient and safe, the logistics transportation direction can be changed, forward and reverse bidirectional loading and unloading are achieved, and the loading-unloading number and weight can be automatically counted, recorded, displayed and stored.

Owner:襄阳忠良工程机械有限责任公司

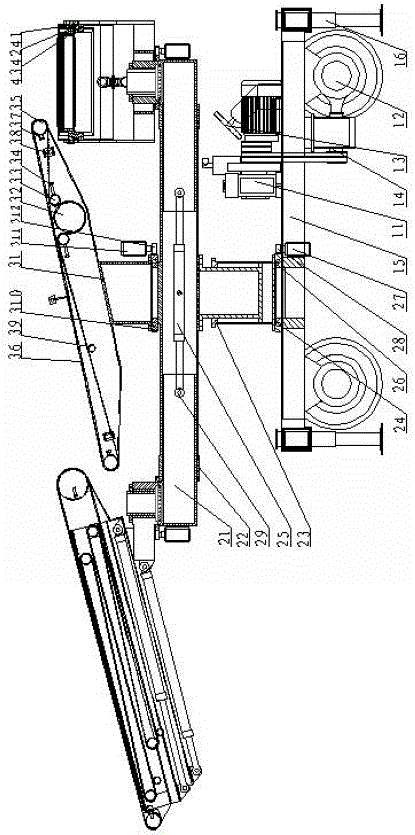

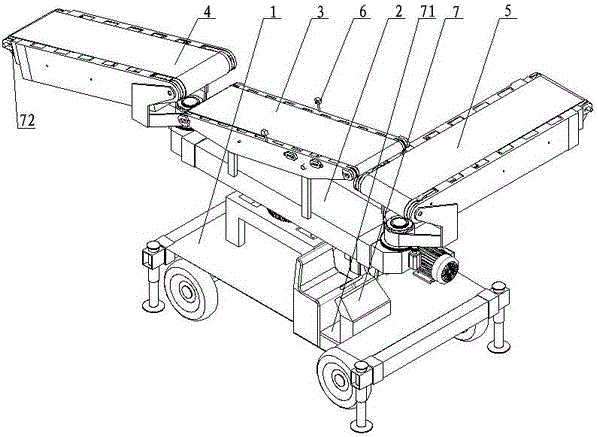

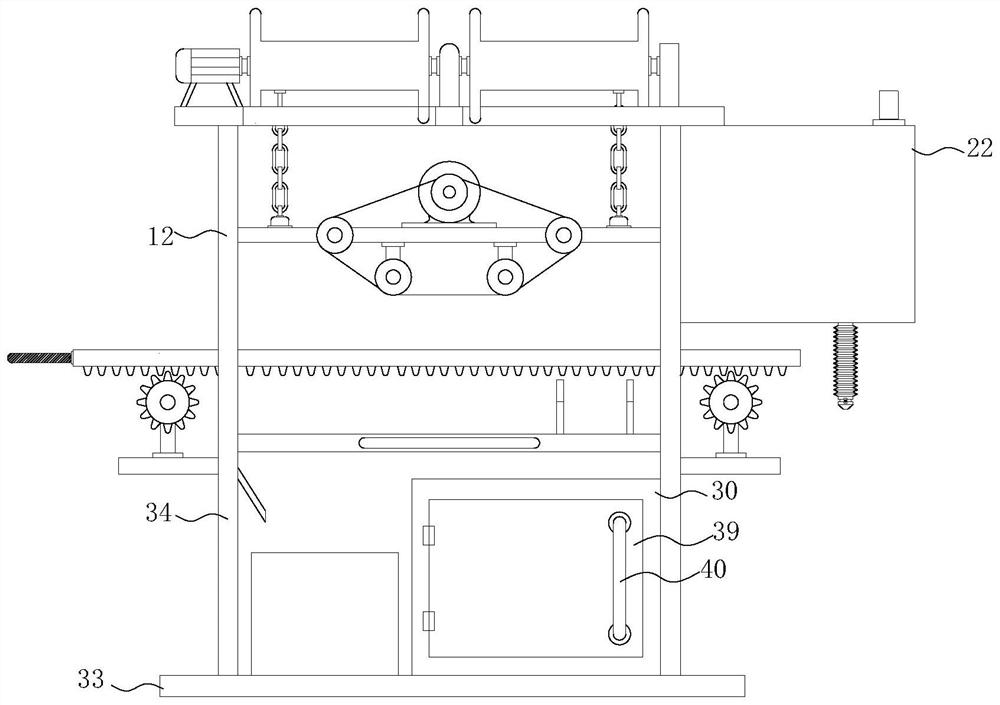

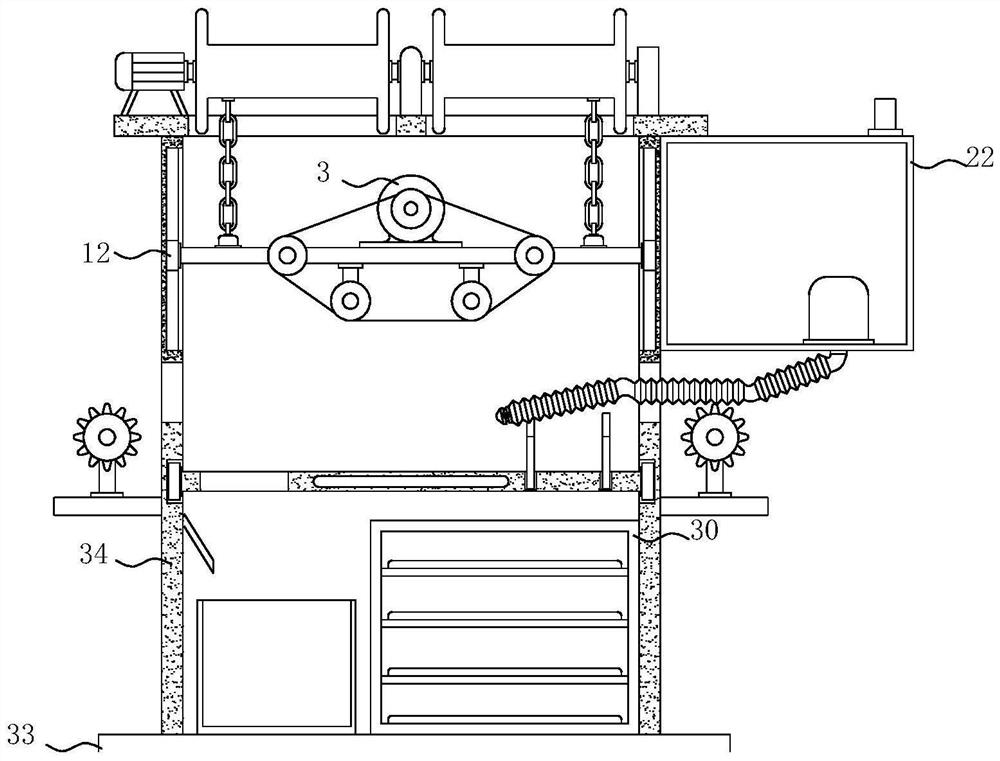

Telescopic belt conveying two-way loading/unloading machine

The invention discloses a telescopic belt conveying two-way loading / unloading machine, and relates to the field of logistics transportation goods loading / unloading mechanical equipment. The telescopic belt conveying two-way loading / unloading machine consists of a vehicle with bearing and walking functions, a rotating arm with a swing rotating function, a middle transition conveyor capable of aslant conveying, a belt conveyor 1 with amplitude change, swing rotating and extension functions, a belt conveyor 2, a metering device with metering, displaying, storage and printing functions, and an operation control system for operating the whole loading / unloading machine. The telescopic belt conveying two-way loading / unloading machine is simple in structure, reliable in work, convenient and fast in movement and transfer and wide in operation range, can reduce manual auxiliary carrying, relieves the labor intensity, shortens the operation time, improves the loading / unloading efficiency, reduces the loading / unloading carrying cost, improves the working environment and labor conditions, guarantees economical, fast, convenient and safe loading / unloading transportation, can change the logistics conveying direction, realizes forward / reverse two-way loading / unloading, and can automatically meter, count and record the loading / unloading number and weight for displaying and storage.

Owner:襄阳忠良工程机械有限责任公司

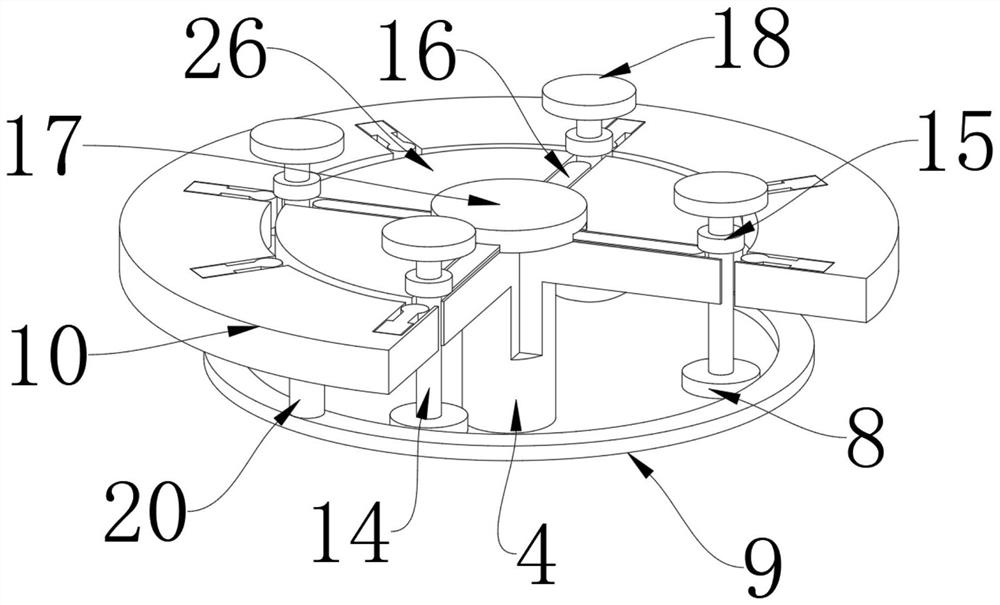

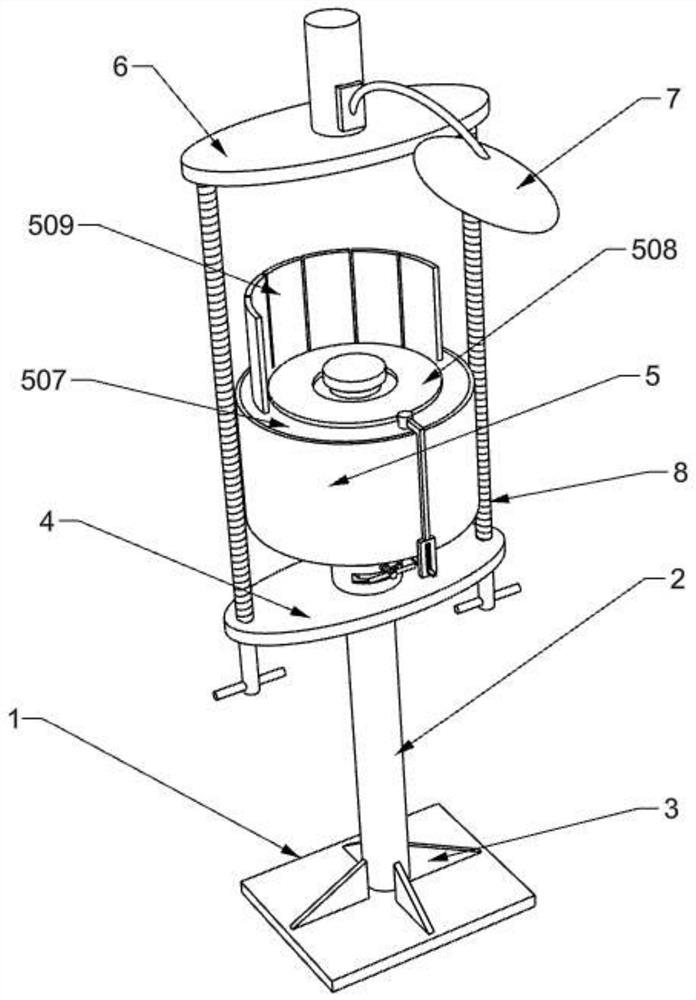

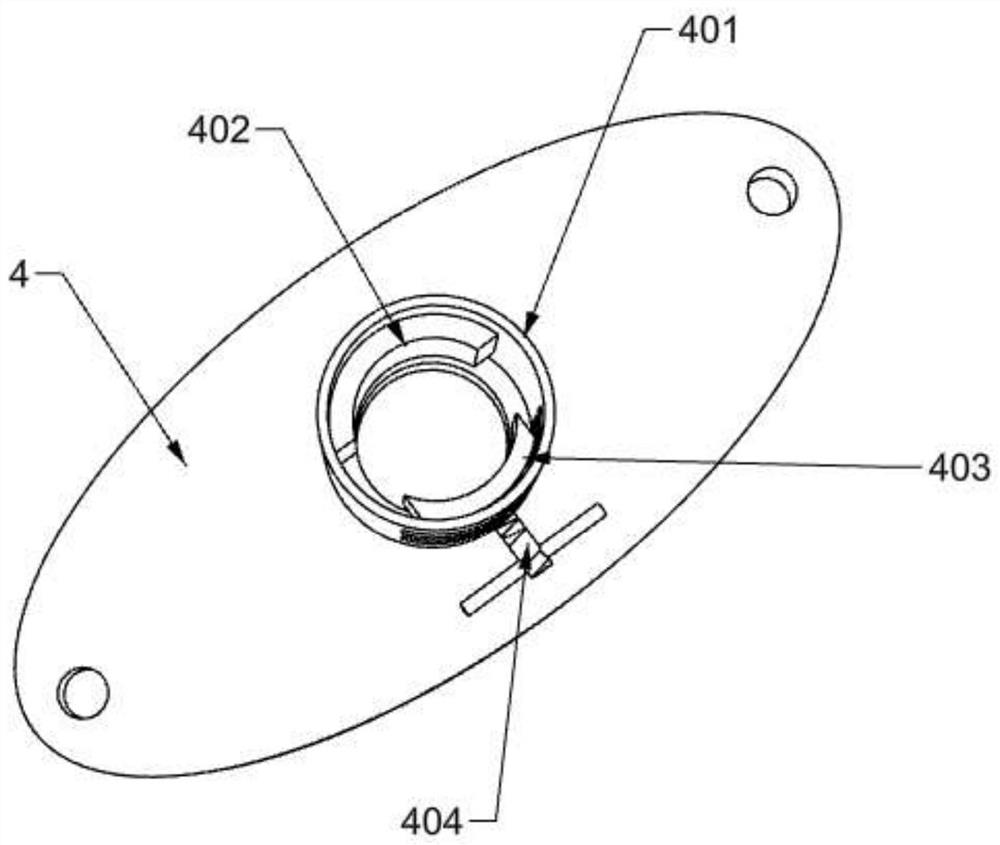

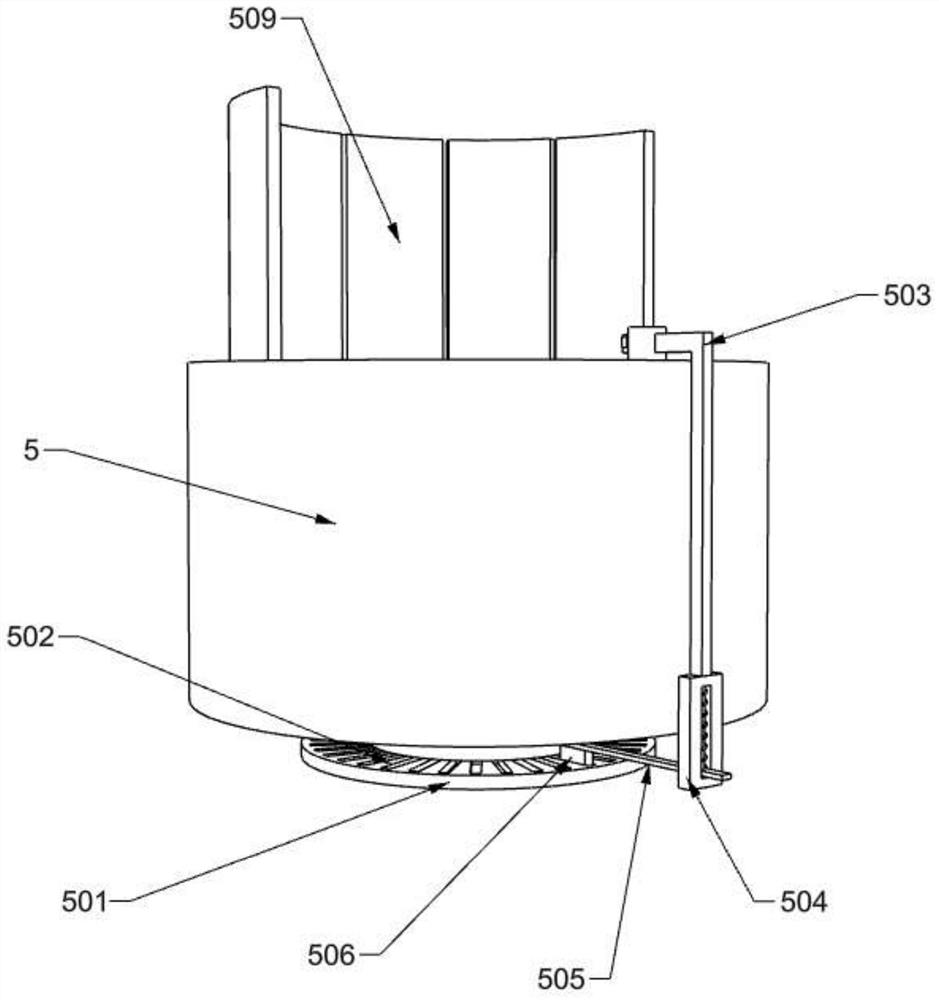

Adjustable device for art display

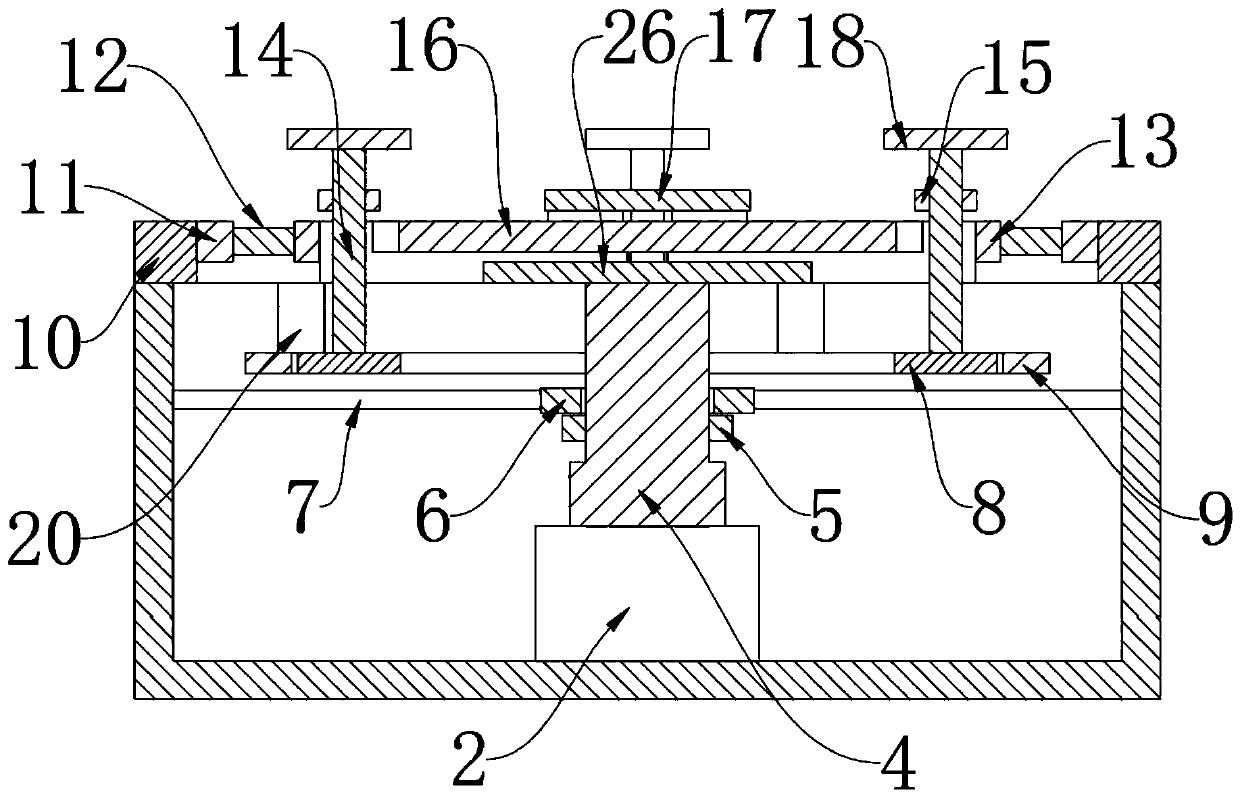

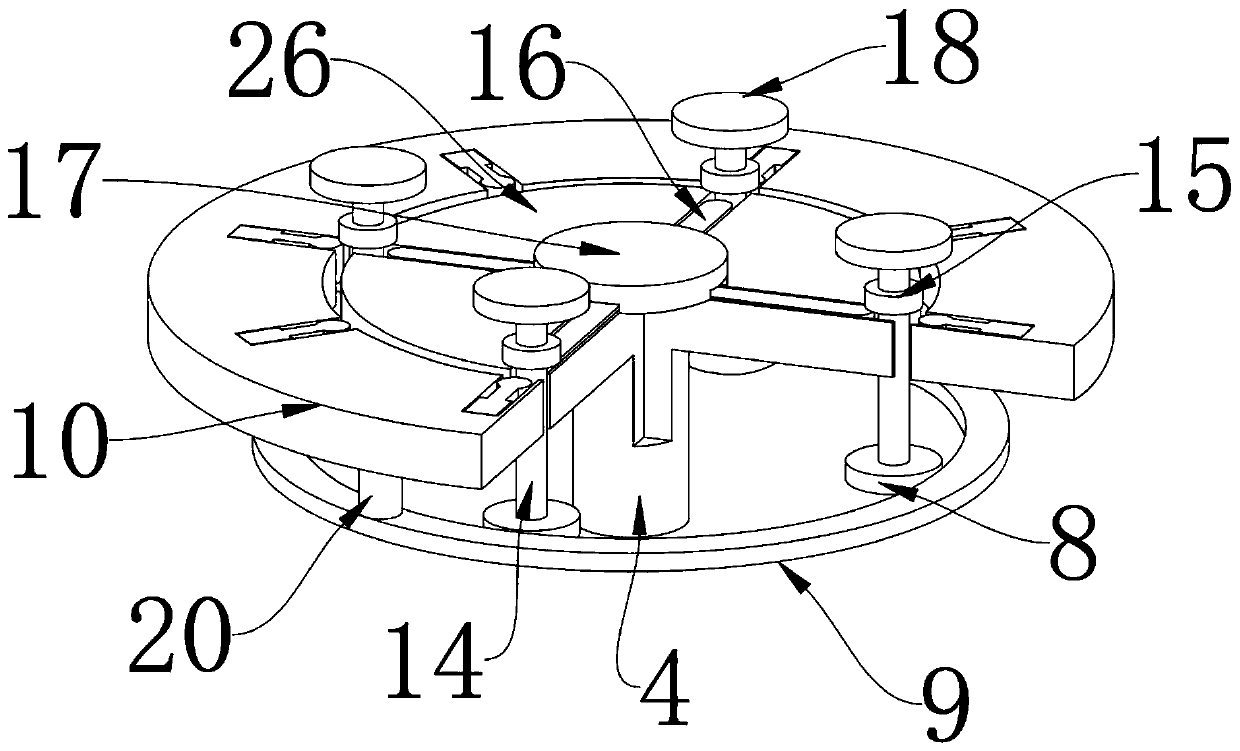

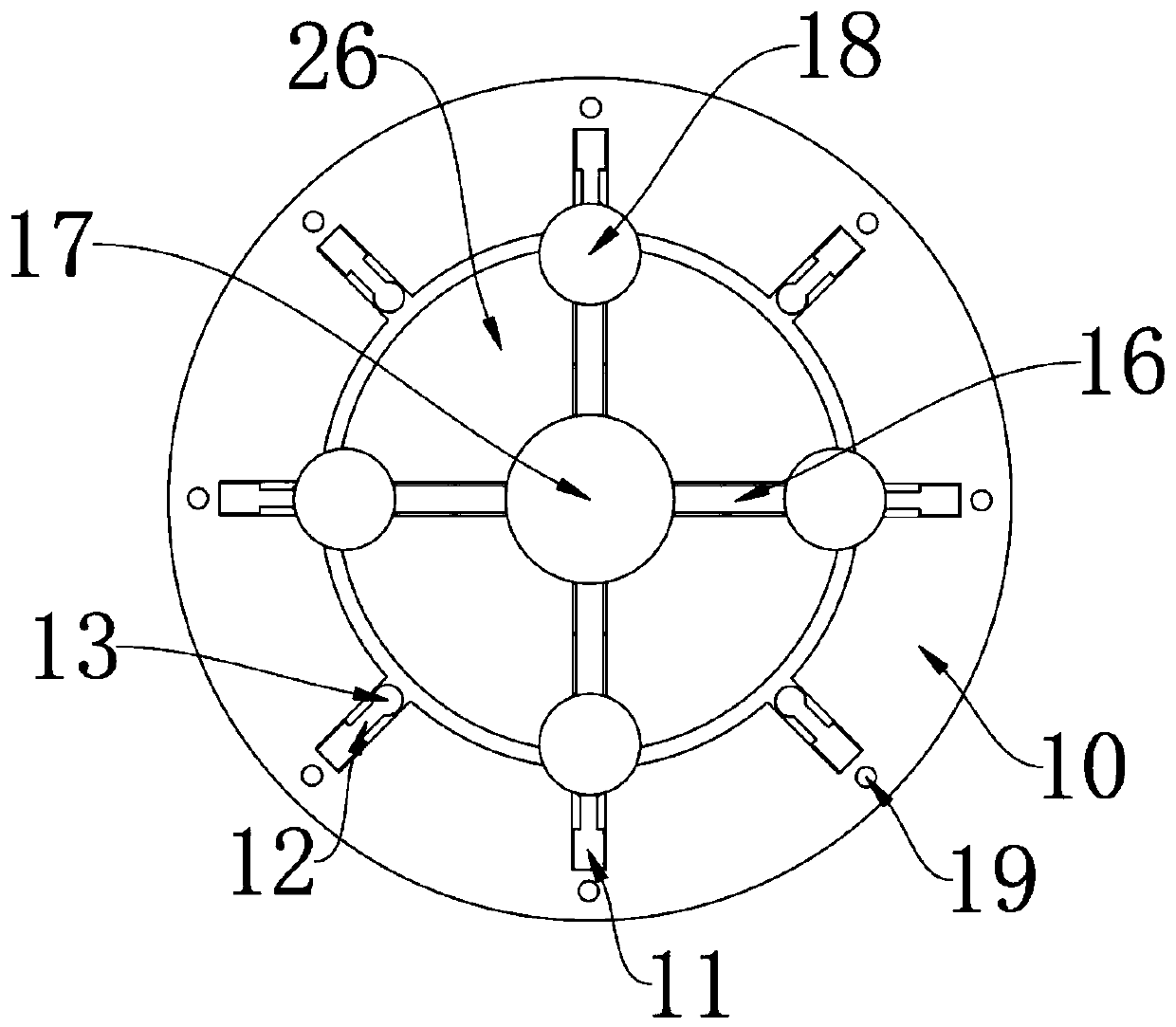

The invention discloses an adjustable device for art display, relating to the field of display devices. Driven by a power source, a rotating shaft drives a turntable to rotate, and an exhibition standis enabled to revolve around the rotating shaft; under the action of a gear and a gear ring, the exhibition stand rotates while revolving, enabling audiences to view more conveniently; when the audience wants to carefully watch a certain exhibit, a control switch is pressed down, at the moment, a telescopic rod is pushed into a notch in a table board under the action of a spring rod, thus, the exhibition stand can stay still so that audiences can watch the exhibition stand conveniently; the exhibition stand is provided with a fluorescent lamp used for illumination and a protective cover usedfor protection, baffles and clamping plates are each provided with a plastic layer so that exhibits can be prevented from being scratched, and the adjustable device is adjustable in working height andmore convenient to use through the arrangement of a lifting mechanism.

Owner:武汉市此方智能环境设计工程有限公司

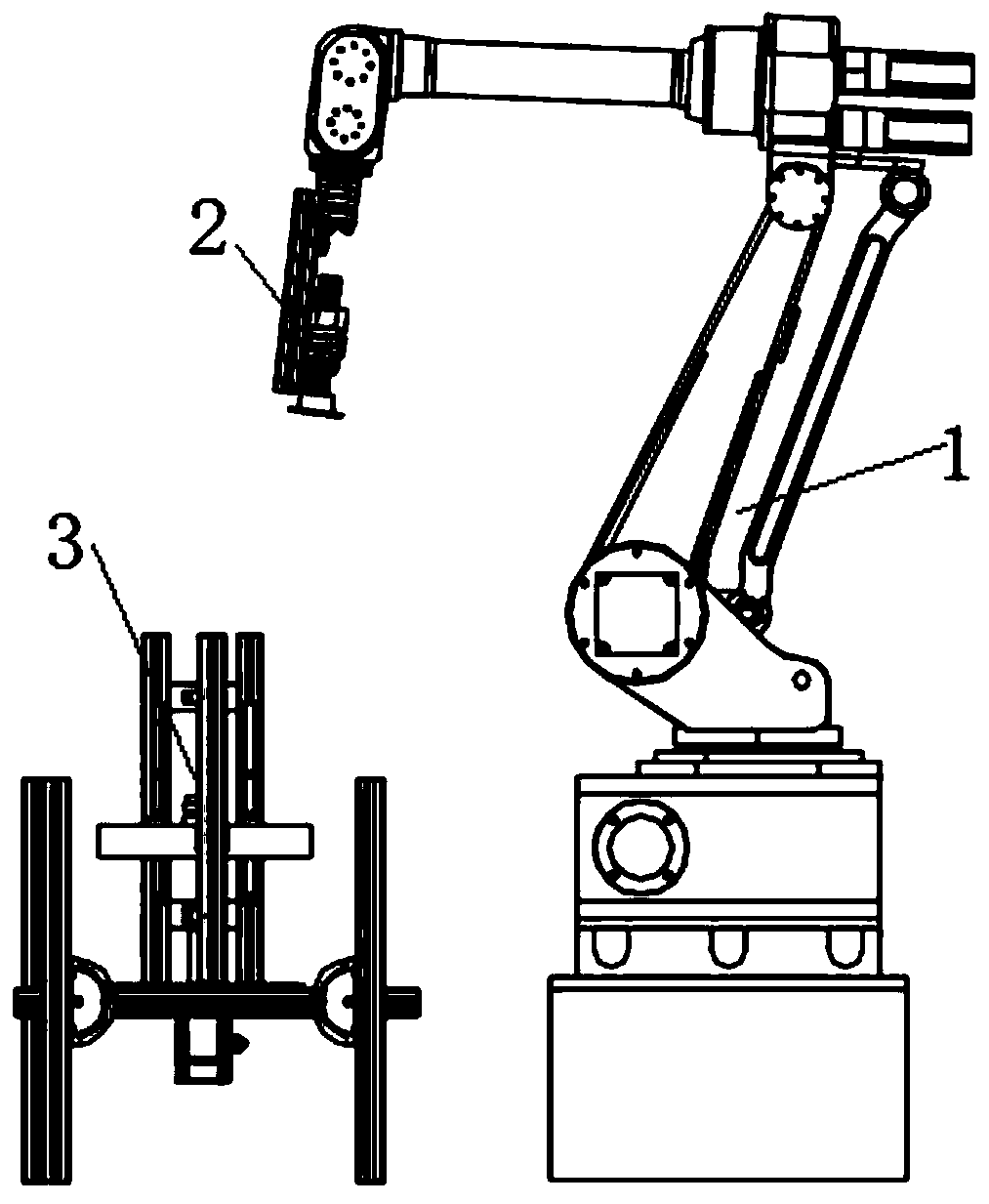

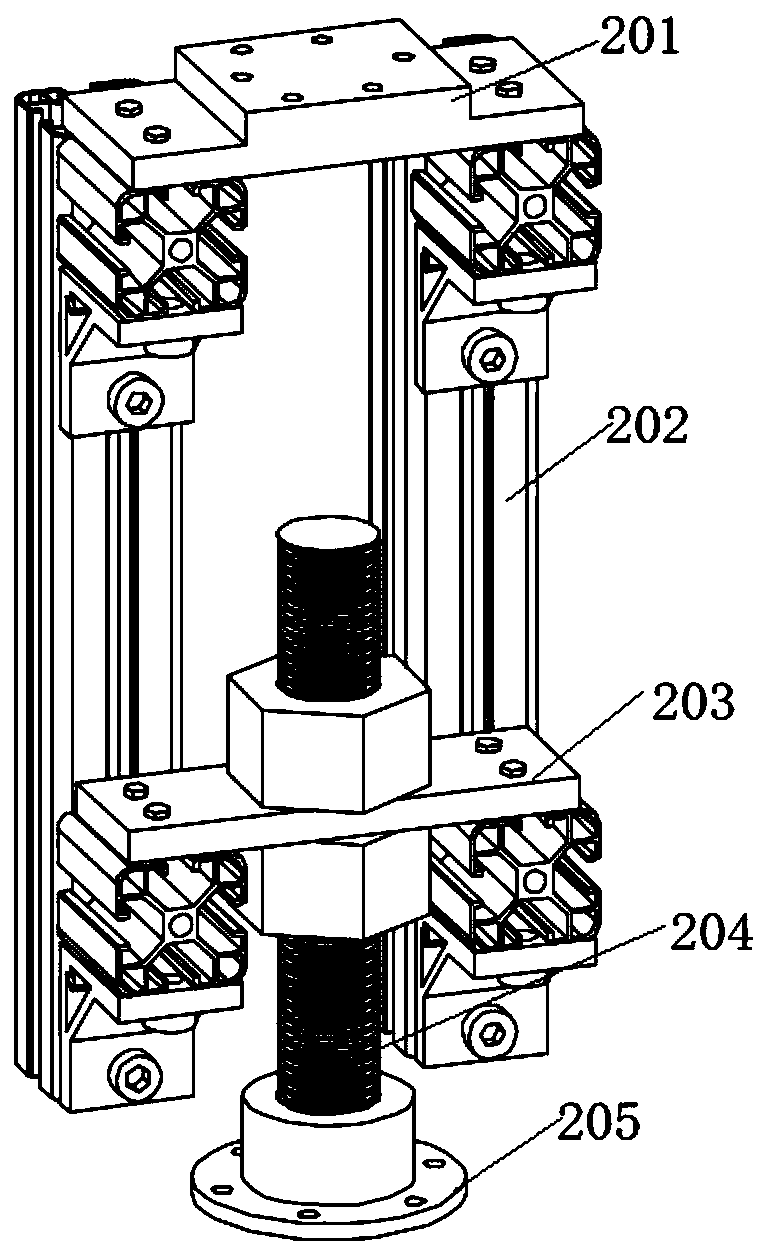

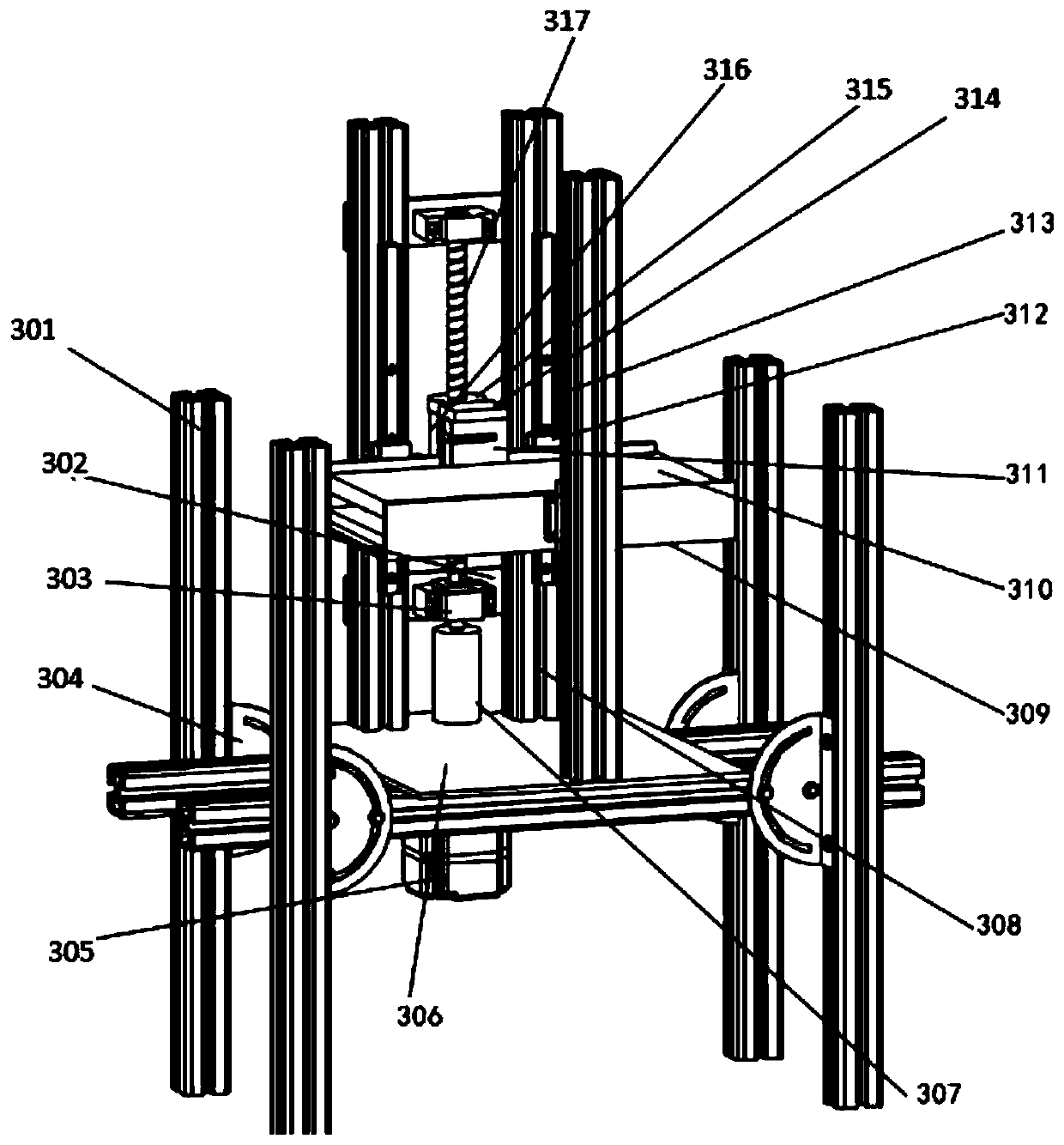

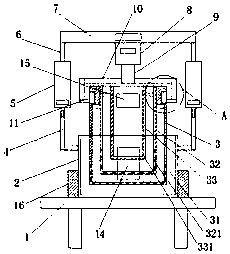

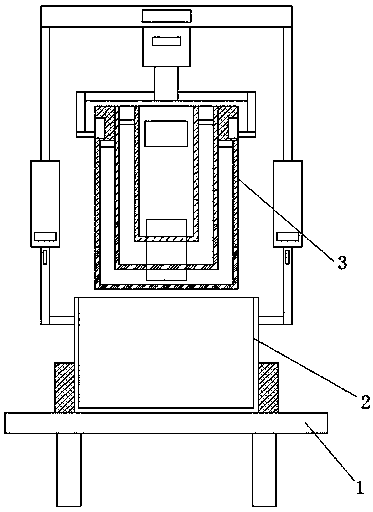

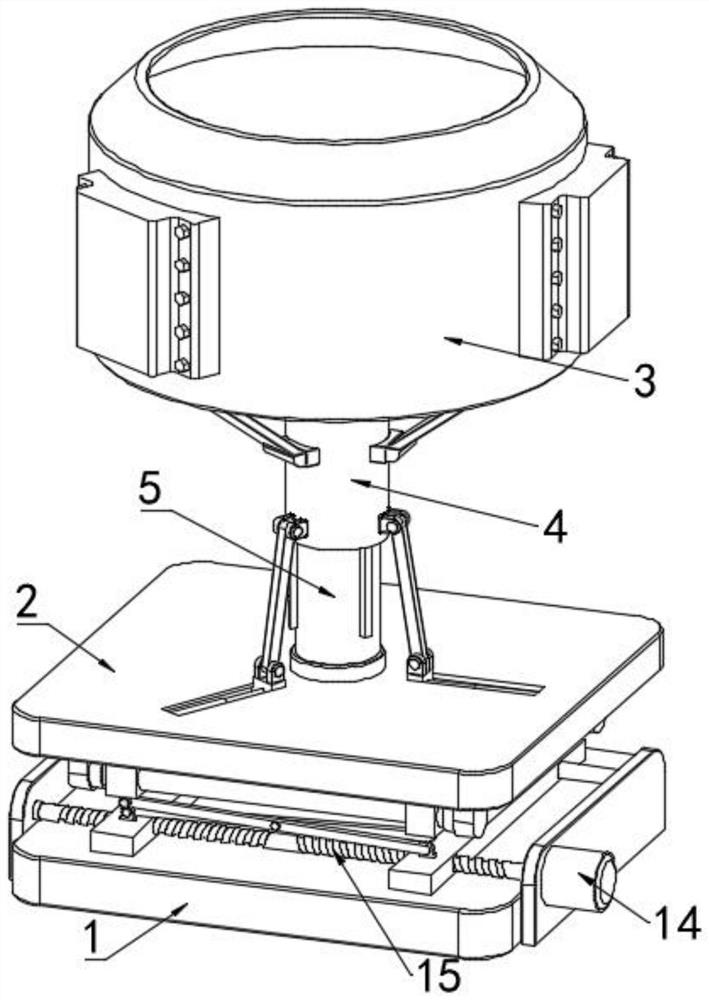

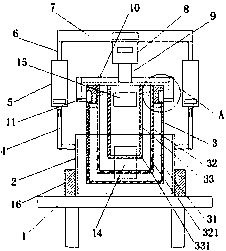

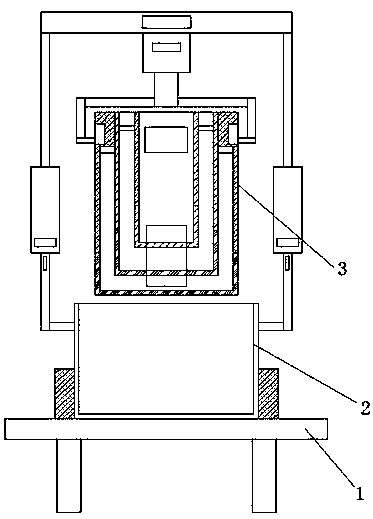

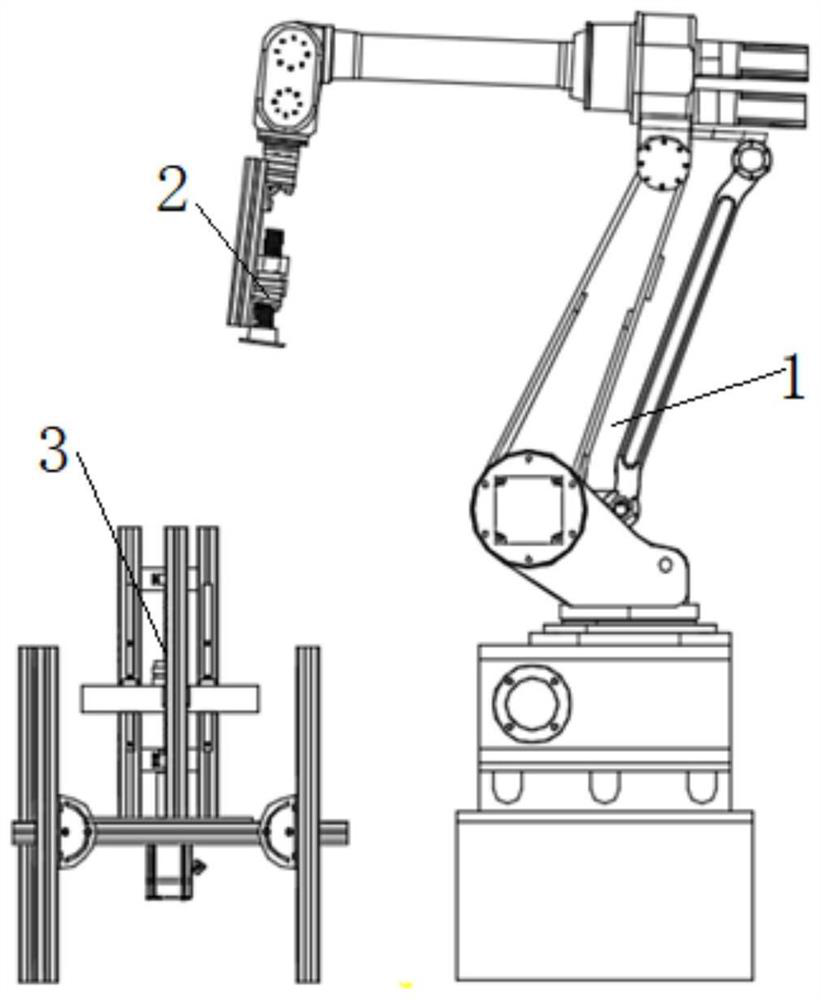

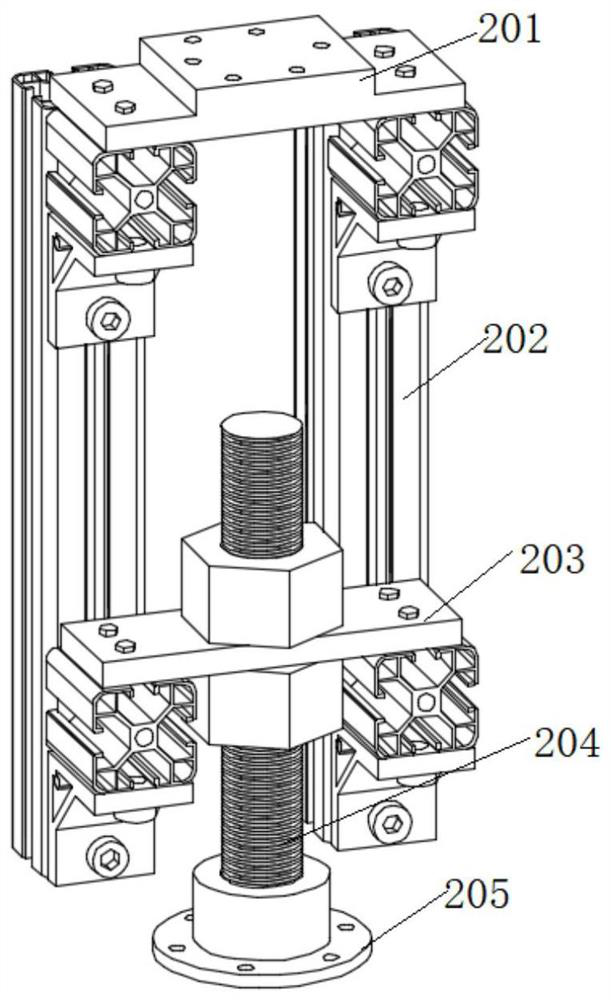

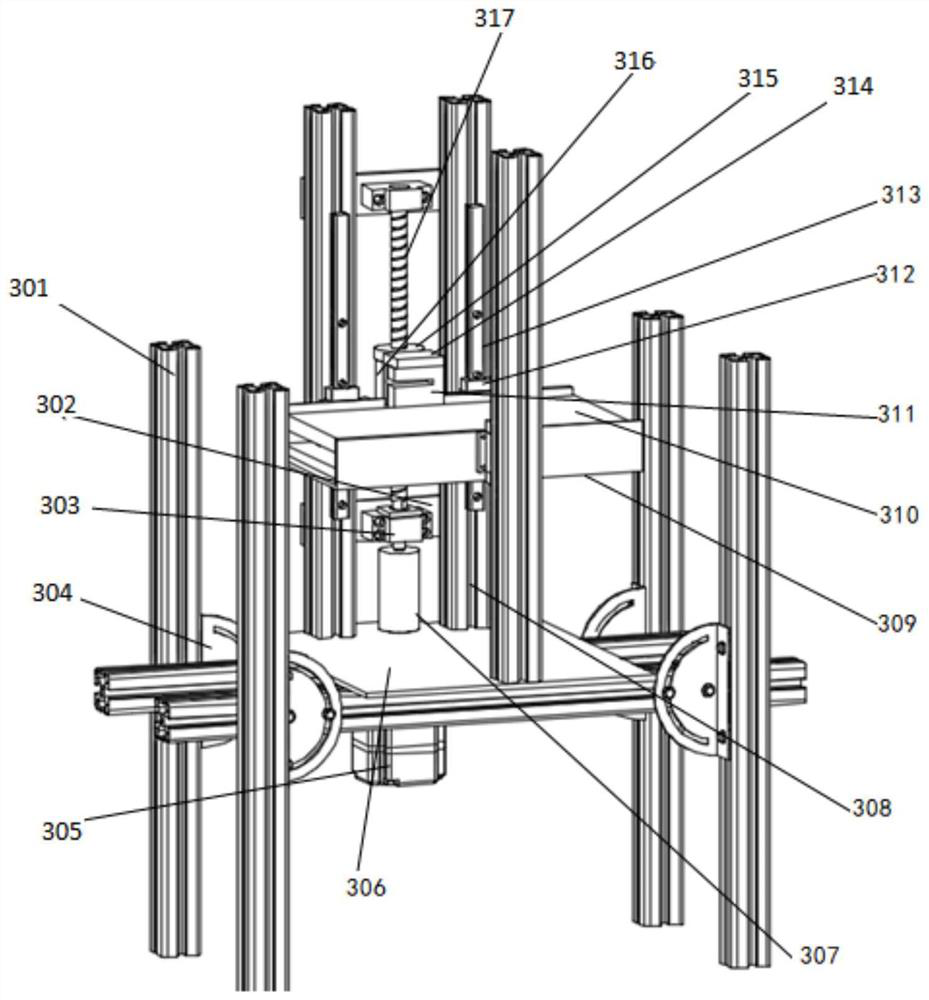

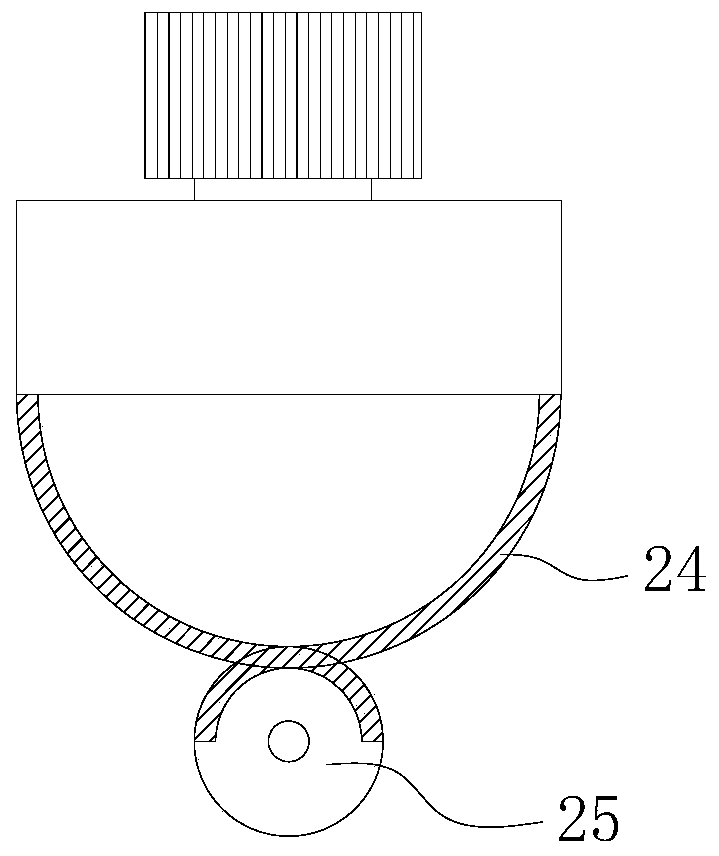

Industrial robot based knee-joint prosthesis testing device and testing methods

ActiveCN111588522ASimple structure to useFlexible and convenient controlArtificial legsKnee JointEngineering

The invention belongs to the technical field of prosthesis testing, and specifically relates to an industrial robot based knee-joint prosthesis testing device and testing methods. The device includesan industrial robot, a Bionic thigh and a ground reaction force module. The device can realize the prosthesis testing under environments of horizontally walking at different speeds, going up and downslopes and going up and down stairs by simulating the movement of the residual limbs of patients with knee amputation within a gait cycle; the device can adjust the ground reaction force on the foot of prosthesis, so that the inputting of the ground reaction force during prosthesis testing can be more accurate, and accurate testing environments can be provided for the intelligent keen joints assembled on an interface; and as the industrial robot is used, a testing system can be more convenient and flexible in using and simpler in structure.

Owner:JILIN UNIV

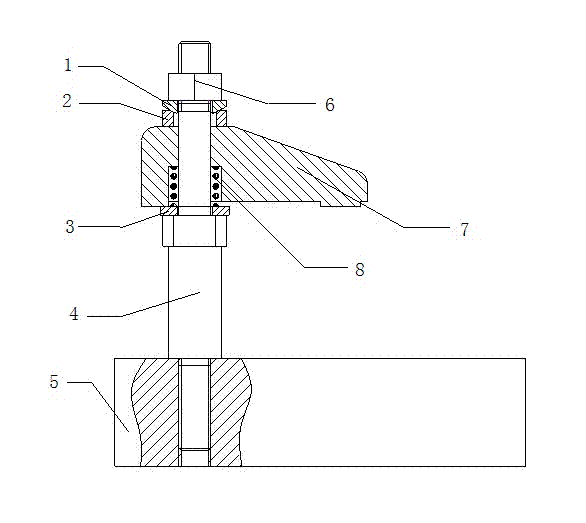

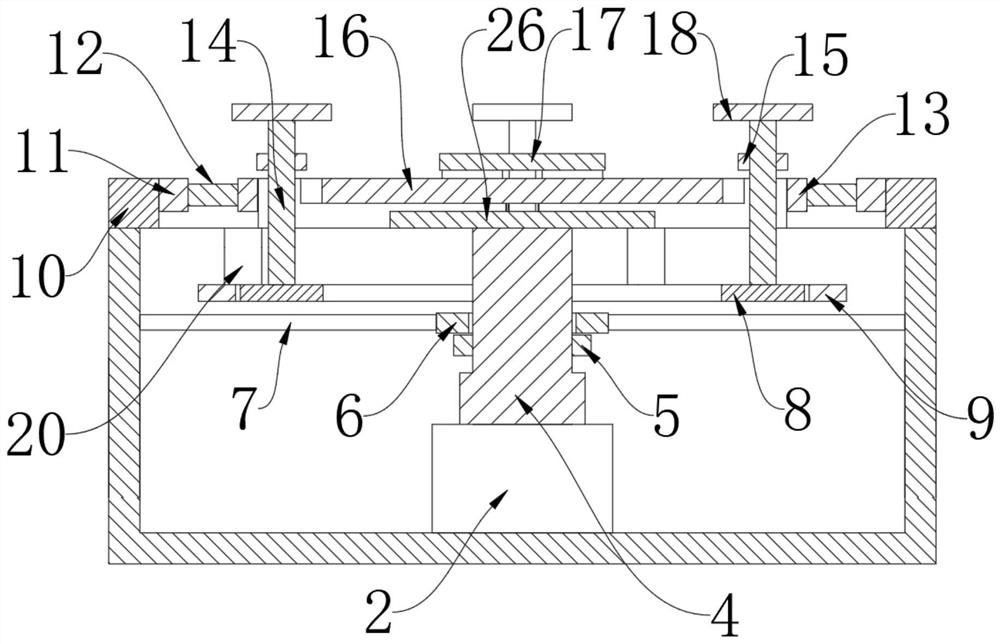

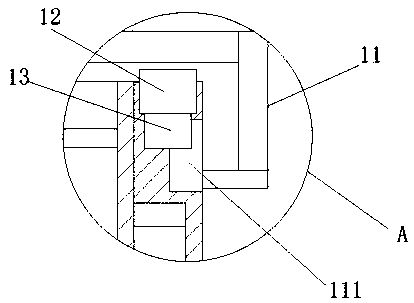

Self-adjustment compressing device

InactiveCN102922326AVersatilityAdjustable working heightPositioning apparatusMetal-working holdersEngineeringSelf adjustment

The invention discloses a self-adjustment compressing device which comprises a hex nut, a fixture and a stud which is fixed on the fixture. Two sides of a protruding portion of the middle of the stud are cut, and the protruding portion is processed into a flat shape. An eccentric pressing plate is arranged on the stud, a spacer is arranged on the lower end surface of the eccentric pressing plate which is connected with the spacer through a strong spring, and a tapered washer is arranged on the upper end surface of the eccentric pressing plate. A spherical washer is arranged between the hex nut and the tapered washer. According to the self-adjustment compressing device, the operation height of the device can be adjusted by increasing or decreasing the number of the spacers, so that the device has generalities in a certain range; and workpieces can be detached by lifting the eccentric pressing plate under the action of the strong spring after the process, so that the device is convenient and rapid.

Owner:常熟天地煤机装备有限公司

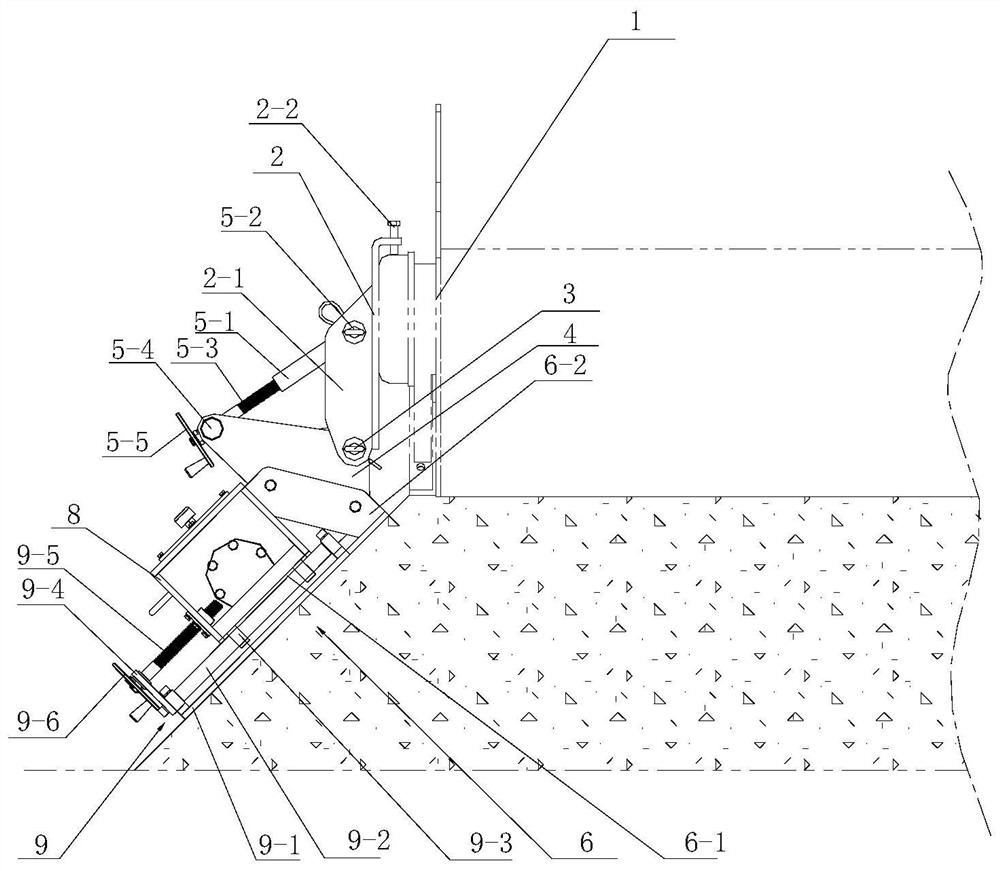

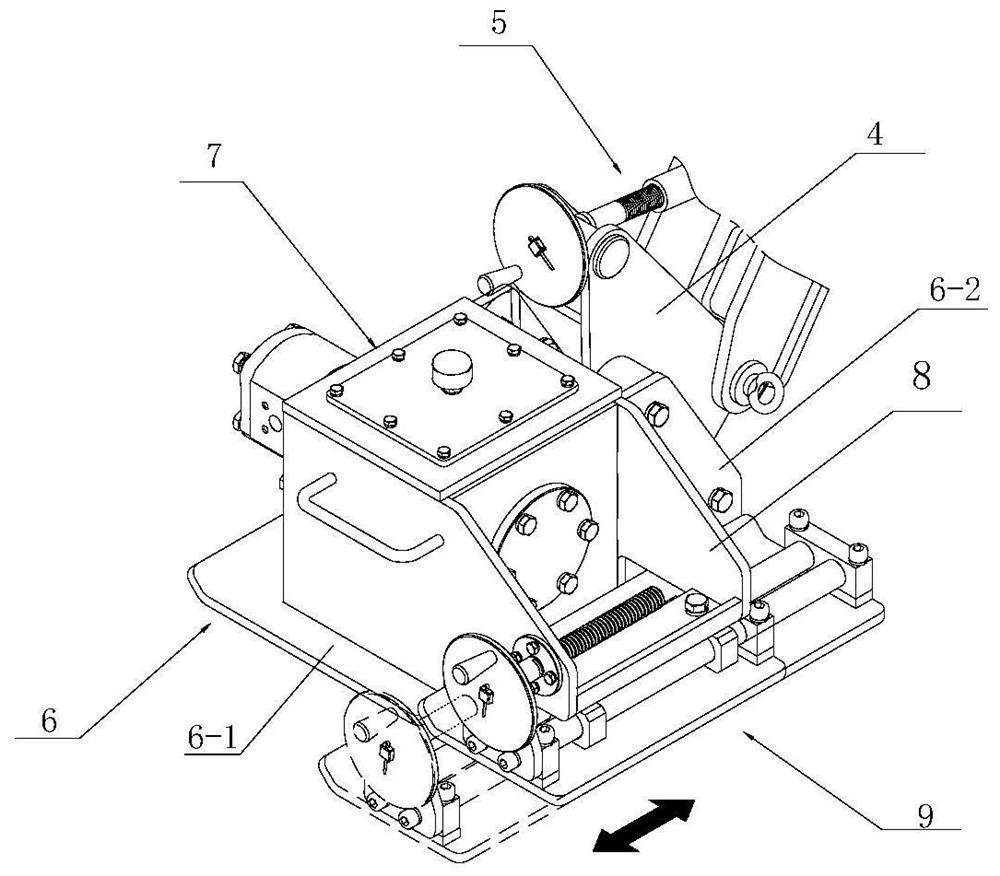

Side slope vibrating and compacting device of paver

The invention discloses a side slope vibrating and compacting device of a paver. The side slope vibrating and compacting device is fixedly mounted on the outer side of an ironing plate and is characterized by comprising a mounting bracket fixedly connected with the ironing plate, a rotary hanging bracket is mounted at the lower end parts of two mounting vertical plates of the mounting bracket through a first pin shaft in a hinged manner, a threaded telescopic adjusting assembly used for adjusting the included angle between the rotary hanging bracket and the ground is installed between the upper end of the rotary hanging bracket and the upper ends of the installation vertical plates, the outer side of the lower part of the rotary hanging bracket is connected with a vibrating and compacting assembly through a shock absorber, the vibrating and compacting assembly comprises a fixed bottom plate, the fixed bottom plate is fixedly connected with the rotary hanging bracket through a connecting plate, a vibration excitation device used for generating excitation force is arranged on the fixed bottom plate, a rib plate is fixedly installed on the fixed bottom plate, and a telescopic bottom plate assembly used for adjusting the operation width of the vibrating bottom plate is installed on the rib plate. The side slope vibrating and compacting device has the characteristics of vibrating compaction, adjustable exciting force, adjustable compaction surface width, adjustable compaction surface angle, adjustable device height position and the like, and has the advantages of wide application range, convenience in installation and adjustment, novel concept, low manufacturing cost, reliable performance and the like.

Owner:TIANJIN ENG MACHINERY INST

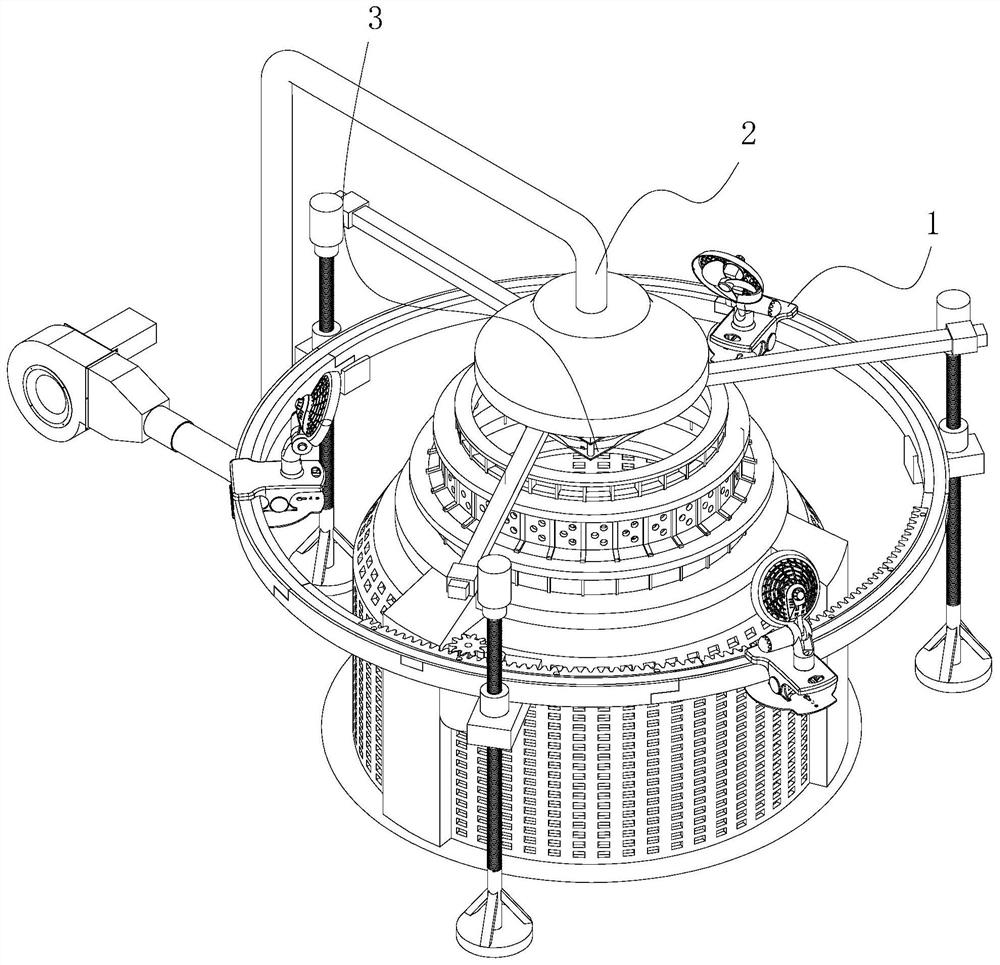

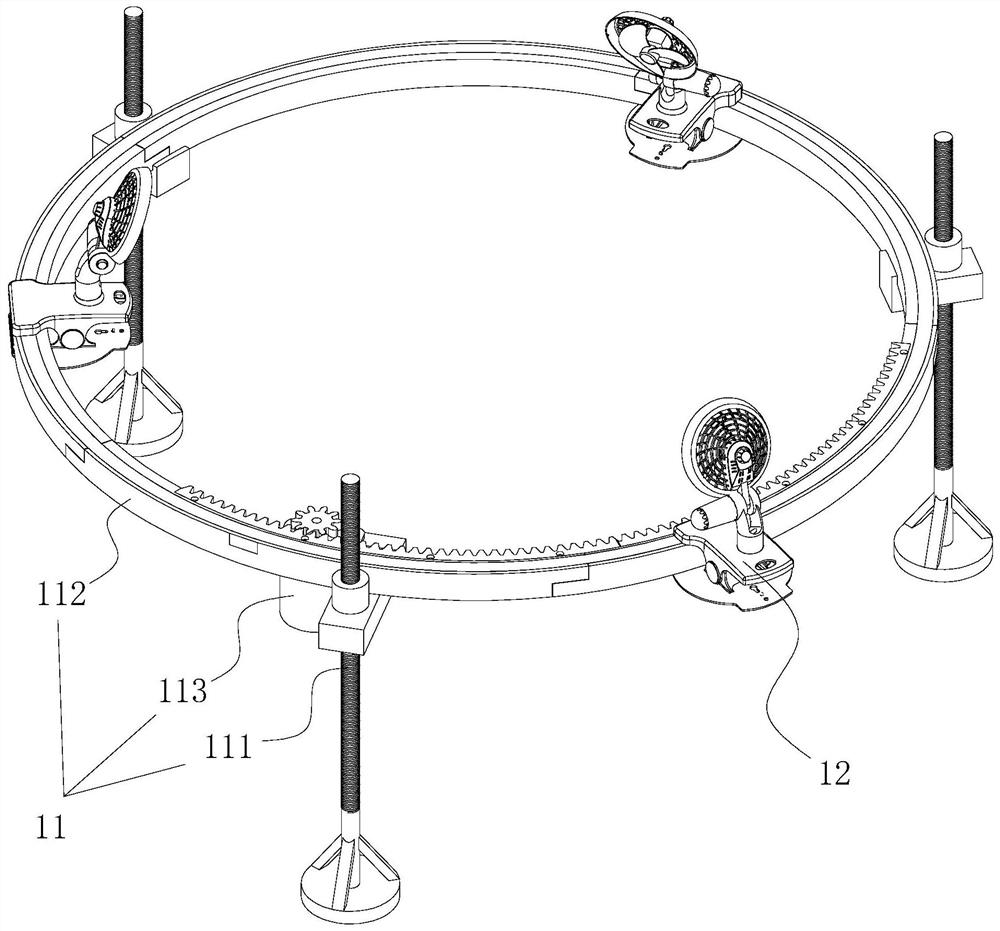

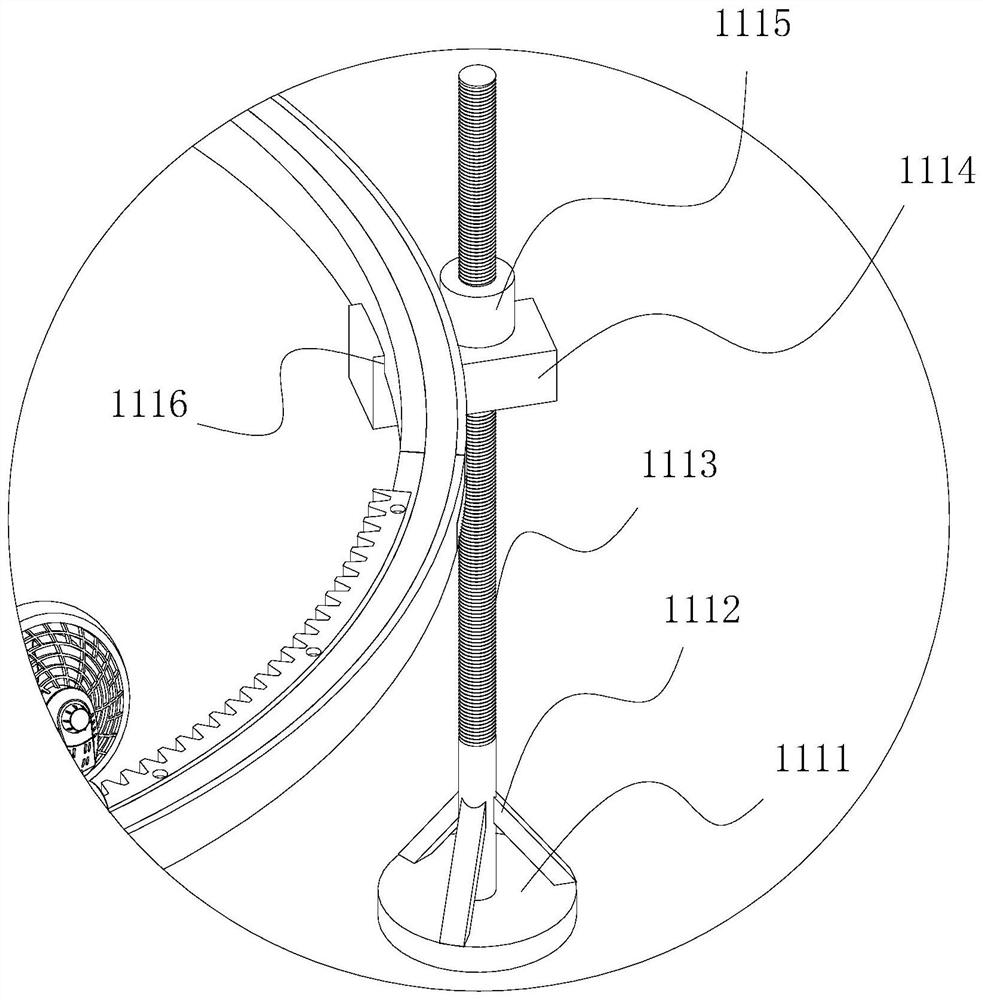

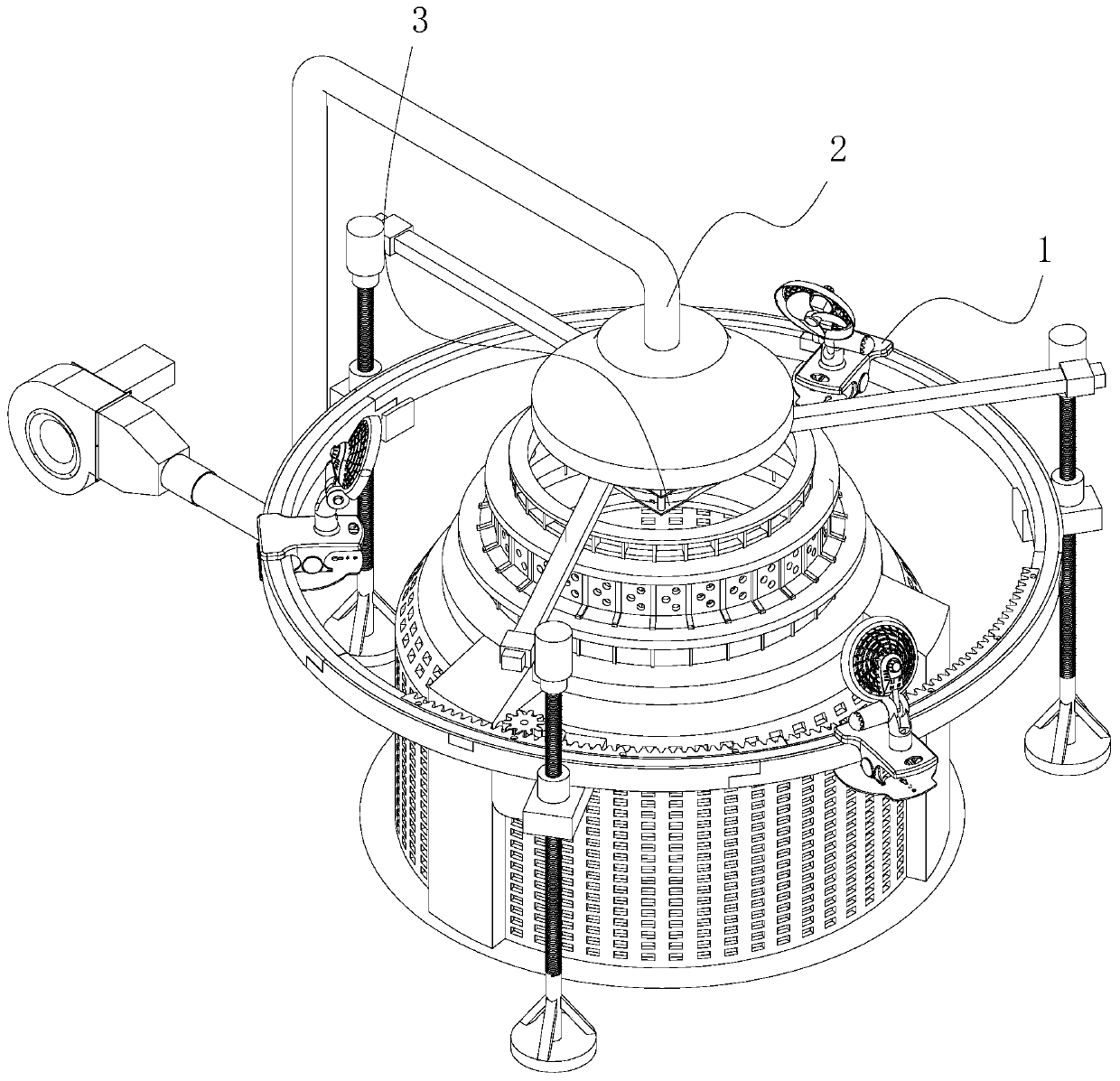

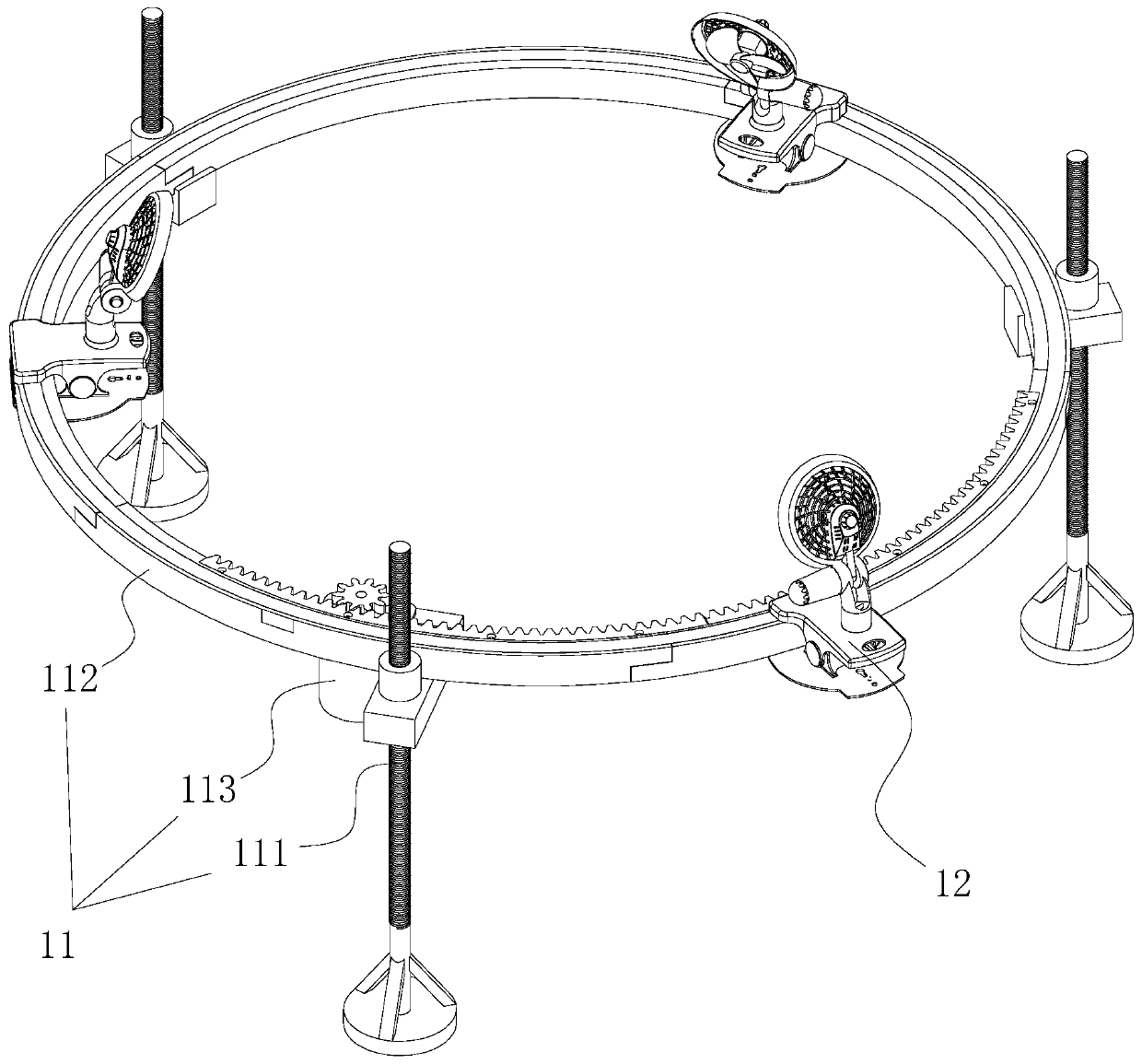

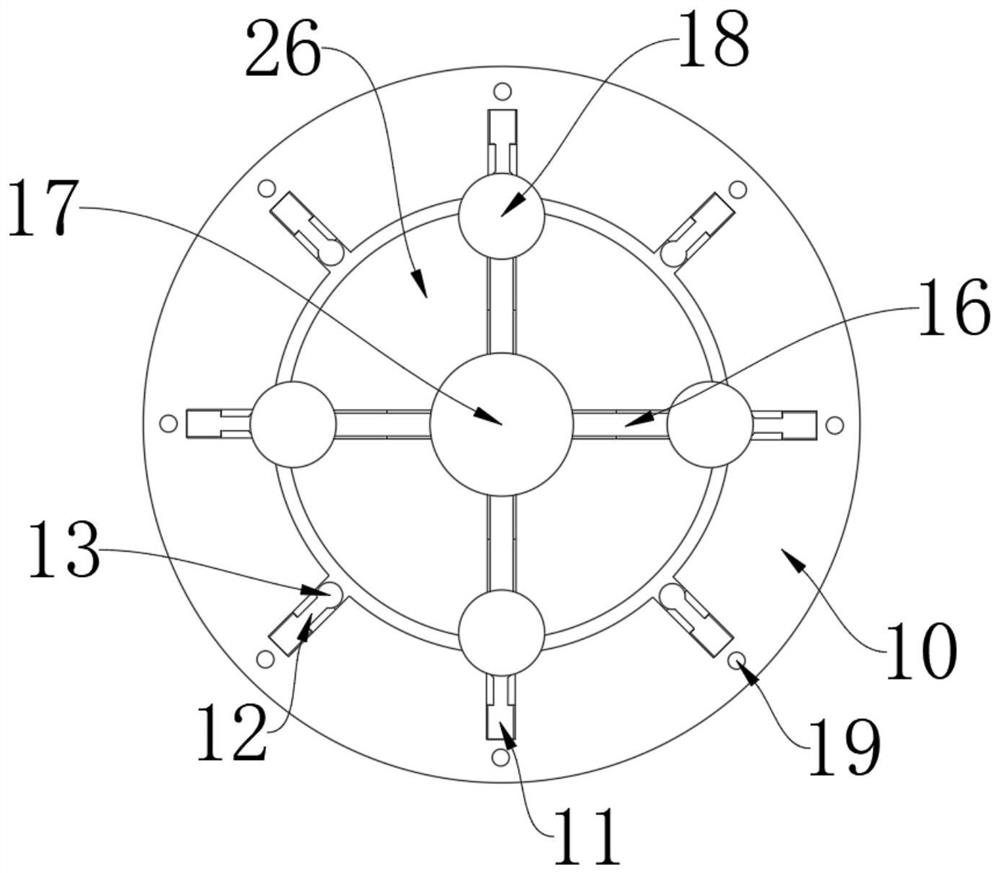

A dust removal device for large circular knitting machine

ActiveCN110629395BAvoid secondary pollutionGuaranteed dust removal performanceKnittingYarnDust control

The invention discloses a dust removal device for a circular knitting machine, relates to the technical field of textile production equipment, and overcomes the shortcoming that dust cannot be reasonably removed in the prior art. The technical scheme mainly includes that the dust removal device comprises a blowing dust removal component and an air draft dust collection component, wherein the blowing dust removal component is circumferentially arranged around the axis of the circular knitting machine and used for performing blowing dust removal on a transmission device of the circular knittingmachine and yarns, and the air draft dust collection component is arranged on the upper portion of the circular knitting machine and used for collecting and filtering airflow after dust removal together with dust.

Owner:杭州晨宇布业织造有限公司

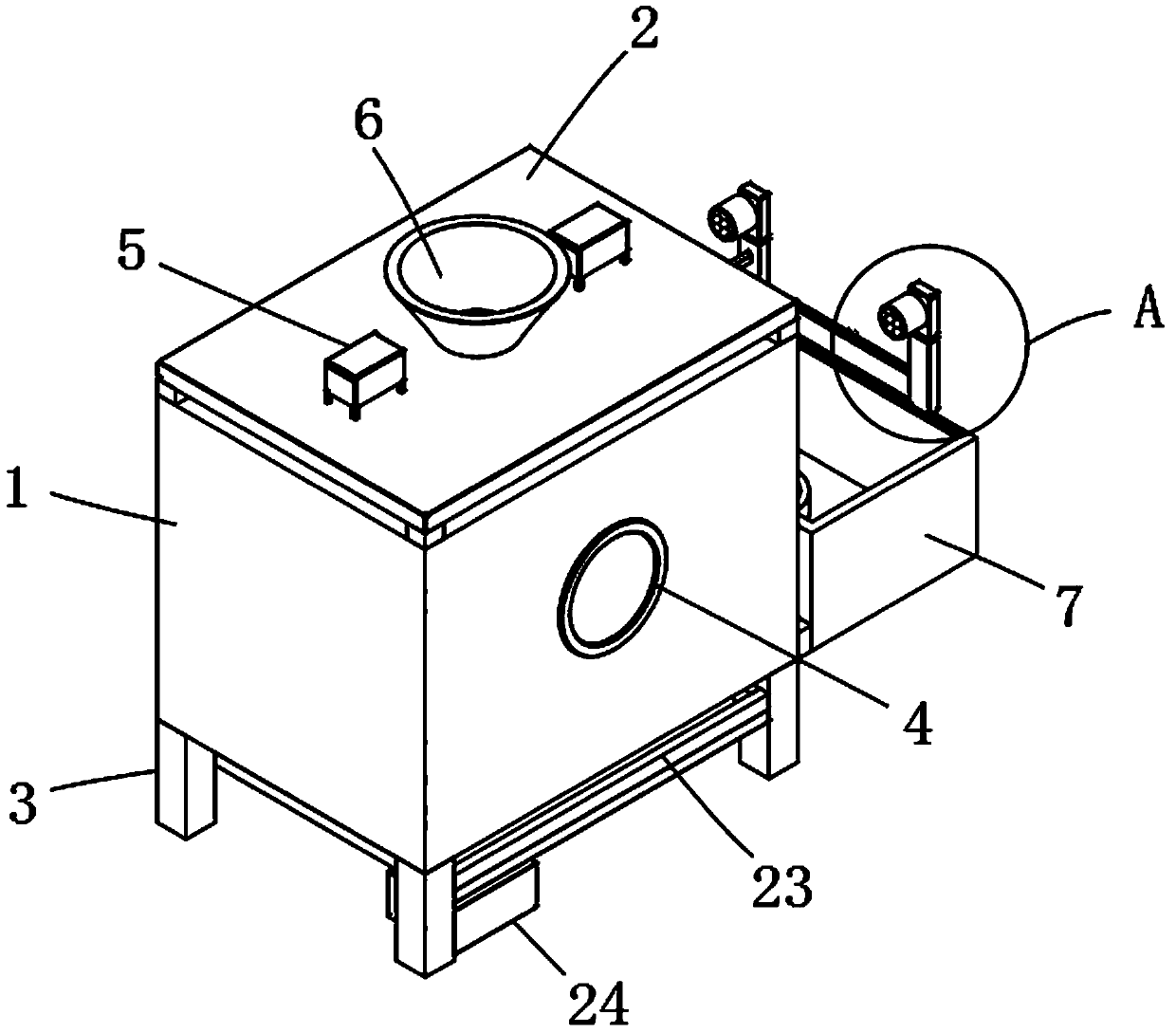

Centrifugal selection device for producing raw materials of graphene chip

ActiveCN108550536AIncrease varietyQuality improvementSemiconductor/solid-state device manufacturingCvd grapheneRivet

The invention discloses a centrifugal selection device for producing raw materials of a graphene chip. The device comprises a work bench and a centrifugal cylinder. A collection box is arranged on thework bench. Limiting plates are arranged on four sides of the collection box and welded to the work bench. Support racks are welded on two sides of the collection box. Pushing rod motors are installed on the top ends of the support racks through rivets. Output ends of the pushing rod motors are in key connection with pushing rods. Installation plates are welded on top ends of the pushing rods. During working, material feeding can be performed in real time at a material feeding opening, and meanwhile, only the materials pass through a third screening plate can enter the collection box and be collected, so best raw materials are collected in the collection box. A moving door is arranged on the centrifugal cylinder, and is in the closed sealing state when the centrifugal cylinder is working.When the working is finished, the centrifugal cylinder can be taken out from the collection box and then the movable door is opened to collect and process the raw materials at three degrees.

Owner:温州翰轩林工业设计有限公司

Four-arm multifunctional building robot

PendingCN109703016AImprove efficiencyClear division of laborAdditive manufacturing apparatus3D object support structuresEngineeringMultiple function

The invention discloses a four-arm multifunctional building robot. The four-arm multifunctional building robot comprises a robot body, a head portion, a power supply power system, a material supplyingsystem, a moving system, a computer intelligent system, a 3D printing system, a fixing system, a lifting system, a head portion monitor, a robot body monitor, a left fixing monitor, a right fixing monitor and a paint filling device; the 3D printing system comprises a left printing arm, a printing sprayer head, a right printing arm and a multifunctional machining mechanical gripper; and the fixingsystem comprises a left fixing arm, a left fixing gripper, a right fixing arm and a right fixing gripper. The robot has the four-arm system capable of achieving cooperative work, the left fixing armand the right fixing arm are used for fixing the position of the robot, the printing sprayer head on the left printing arm conducts main printing work, the multifunctional machining mechanical gripperon the right printing arm conducts machining and repairing work, the synergistic effect is achieved, clear division of work is achieved, and the 3D printing efficiency is greatly improved.

Owner:HEBEI UNIV OF TECH

Dust removal device for circular knitting machine

ActiveCN110629395AAvoid secondary pollutionGuaranteed dust removal performanceKnittingYarnTextile production

The invention discloses a dust removal device for a circular knitting machine, relates to the technical field of textile production equipment, and overcomes the shortcoming that dust cannot be reasonably removed in the prior art. The technical scheme mainly includes that the dust removal device comprises a blowing dust removal component and an air draft dust collection component, wherein the blowing dust removal component is circumferentially arranged around the axis of the circular knitting machine and used for performing blowing dust removal on a transmission device of the circular knittingmachine and yarns, and the air draft dust collection component is arranged on the upper portion of the circular knitting machine and used for collecting and filtering airflow after dust removal together with dust.

Owner:杭州晨宇布业织造有限公司

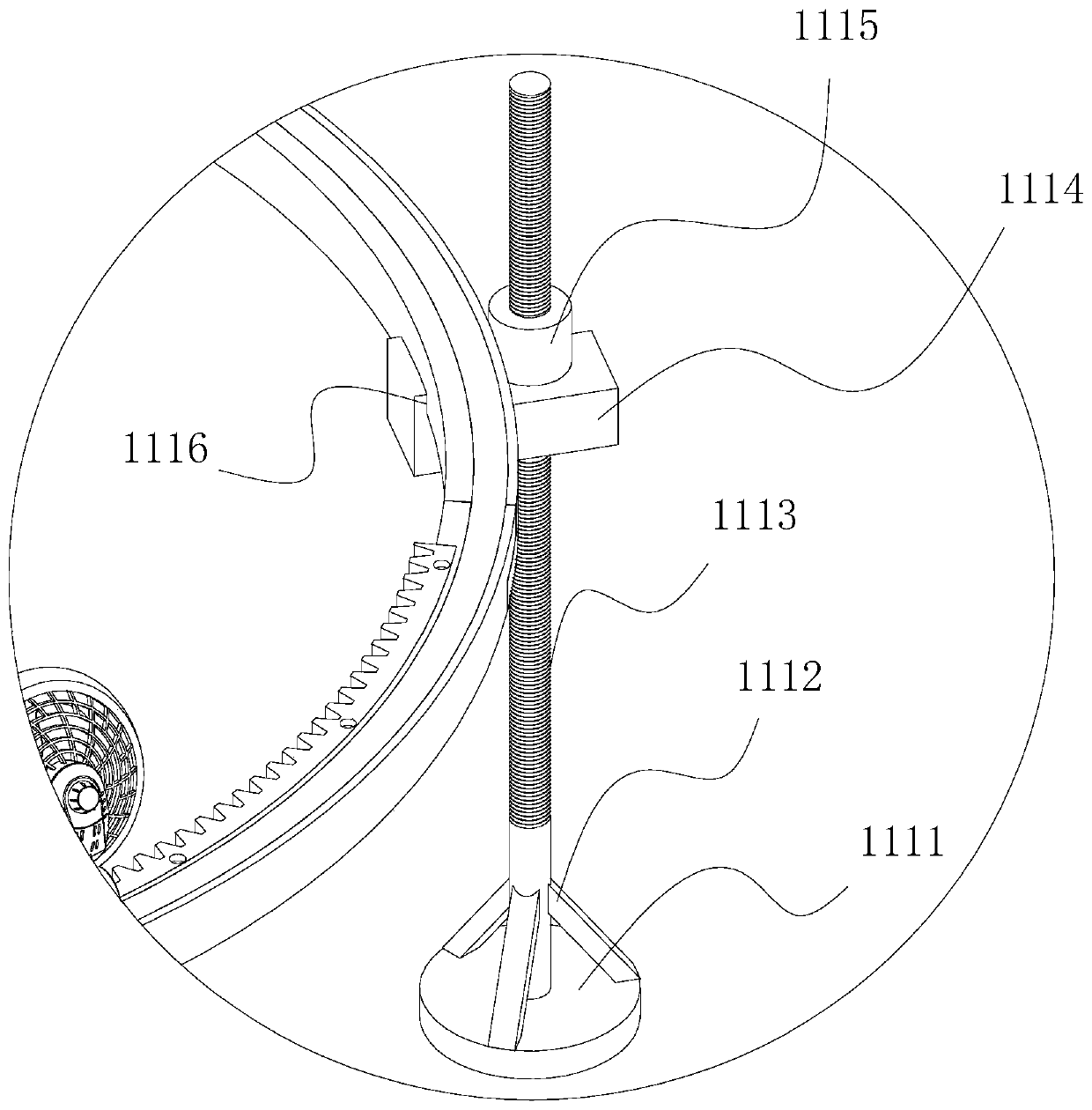

Stable circular knitting machine seat

The invention relates to a stable circular knitting machine seat. The machine seat comprises a base, a transverse plate arranged above the base and a mounting seat arranged above the transverse plate; and the mounting seat is used for mounting a circular knitting machine. During use, the circular knitting machine is assembled on the mounting seat; if vibration is generated in the working process of the circular knitting machine, a sliding sleeving mechanism and an elastic buffering mechanism are triggered at same time, and the elastic buffering mechanism buffers the vibration, so that the stability of the mounting seat is guaranteed; when the working height of the circular knitting machine needs to be adjusted, if a threaded lifting mechanism works in the forward direction, the transverse plate is driven to ascend in the vertical direction, so thatthe heights of the mounting seat and the circular knitting machine are increased; on the contrary, if the threaded lifting mechanism works in the reverse direction, the transverse plate vertically descends, so that the working height of the circular knitting machine is reduced; good stability of the machine seat is guaranteed through mutual cooperation of all the mechanisms; and the working height of the circular knitting machine also can be adjusted in the using process.

Owner:绍兴纽卡纺织品有限公司

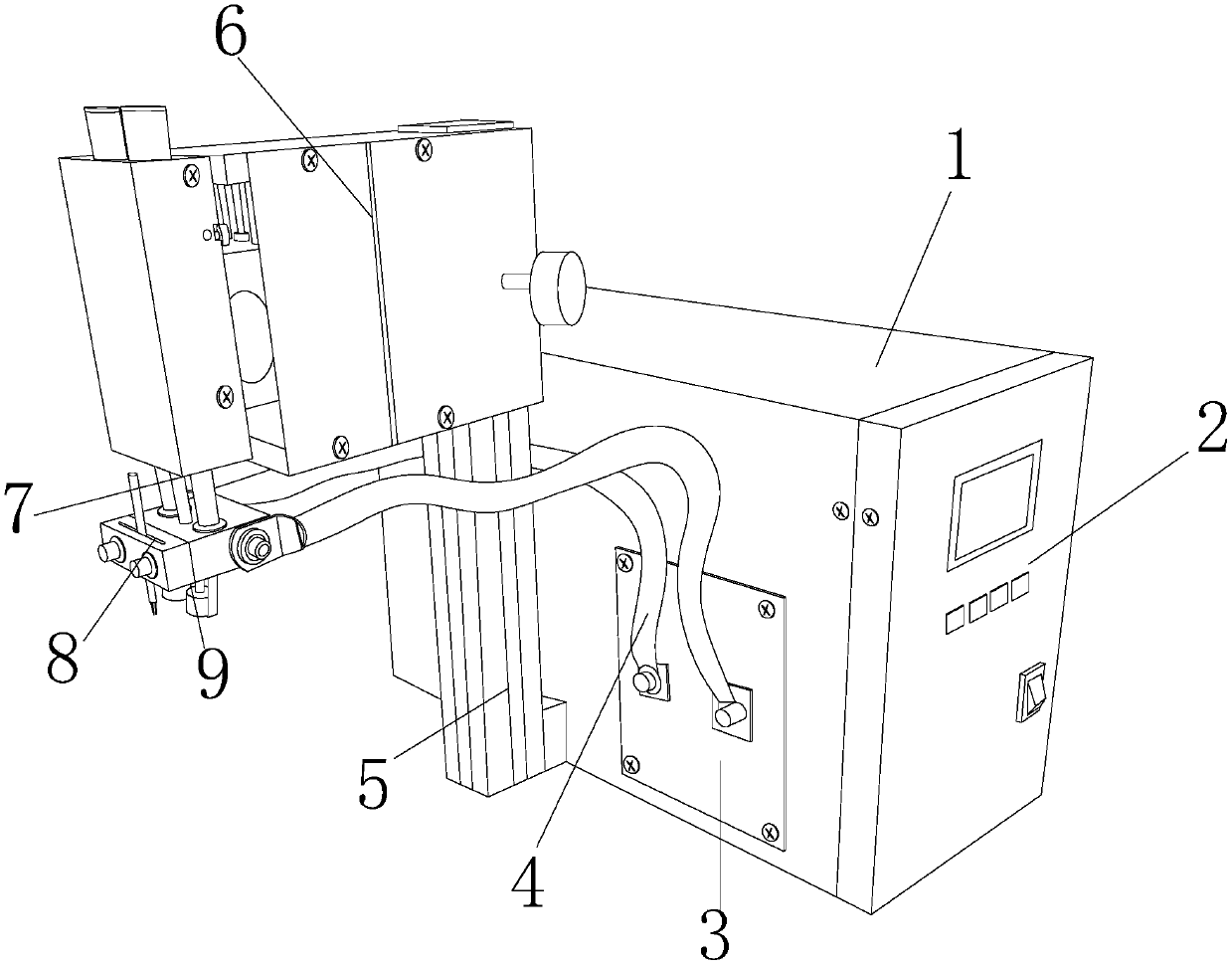

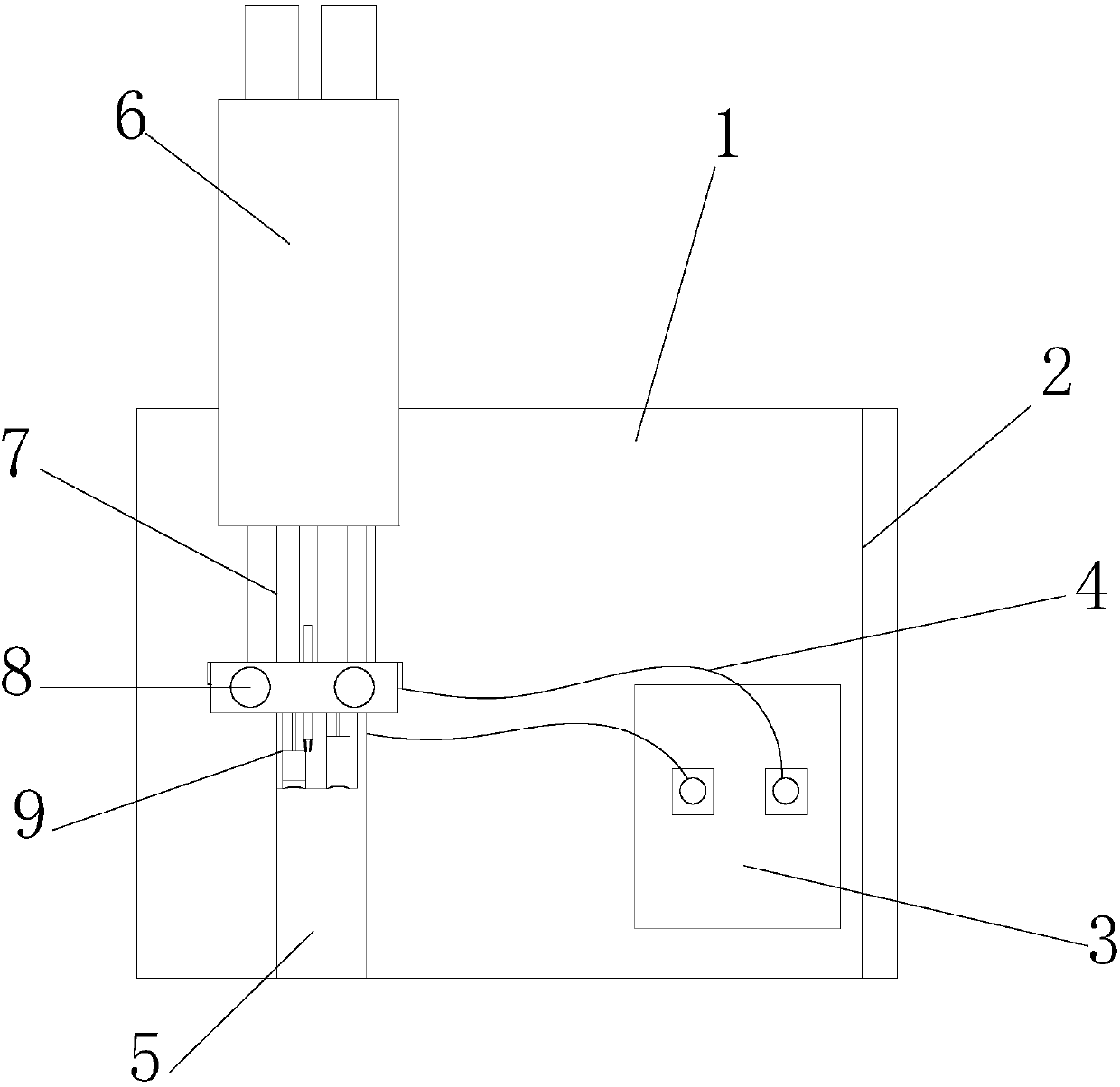

Lithium battery cap pressure welding device

InactiveCN107790863AEasy to compress and sealIncrease productivityResistance electrode holdersCell lids/coversElectricityElectrical battery

The invention discloses a lithium battery cap pressure welding device. The lithium battery cap pressure welding device structurally comprises a machine case, a control panel, a sealing connecting plate, welding wire pipes, a lifting rod, a welding control machine head, a telescopic rod, a welding head and a battery cap pressing and covering device. The machine case is a cuboid, the control panel is arranged at the front end of the machine case, and the rear portion of the control panel and the front portion of the machine case are buckled and connected through nuts in a locked manner. The sealing connecting plate is welded to the lower right position of the left side of the machine case and electrically connected with the welding wire pipes. One ends of the welding wire pipes are connectedto the left side and the right side of the welding head correspondingly, and the other ends of the welding wire pipes are electrically connected with the machine case through the sealing connecting plate. The lifting rod is arranged at the middle end of the left side of the machine case and arranged on the left side edge of the sealing connecting plate. The lithium battery cap pressure welding device has the beneficial effects that by means of the lithium battery cap pressure welding device, a vertical pressing device can be used for tightly pressing a cap and a pipe shell, the sealing performance is good, the safety quality is improved, manual operation is not needed, cost is reduced, the production efficiency of enterprises is improved, profits are increased, and convenience and practicability are achieved.

Owner:黄思珍

Water sprinkling cooling system for landscape garden planning area

InactiveCN112916231AAdjustable working angleAdjustable working heightLighting and heating apparatusLiquid spraying apparatusEnvironmental engineeringMechanical engineering

The invention relates to the technical field of garden water sprinkling cooling, in particular to a water sprinkling cooling system for a landscape garden planning area, which solves the problems that in the prior art, water sprinkling equipment for a landscape garden planning area is poor in flexibility and cannot flexibly assist in water sprinkling cooling work in the planning area. The water sprinkling cooling system comprises a supporting plate, wherein stand columns are arranged on the two sides of the upper surface of the supporting plate, adjusting rods are fixedly connected to the tops of the stand columns, a liquid supply box is arranged on the upper surface of the supporting plate, a functional plate is arranged at the tops of the stand columns, adjusting grooves are formed in the lower surface of the functional plate, and one ends of the adjusting rods are located in the adjusting grooves. According to the water sprinkling cooling system, a water sprinkling fulcrum with an adjustable operation angle and an adjustable operation height is provided, and a convenient operation mode is provided for water sprinkling cooling work in the planning area by combining the adjustable operation angle and the adjustable operation height in use; besides, expansion adjustment of the horizontal operation position of the equipment can be performed; and furthermore, the water sprinkling fulcrum can be pulled out through a control handle to intervene in operation for water sprinkling work, and the flexibility of water sprinkling operation of the equipment is higher.

Owner:东营科技职业学院

A kind of outer surface wire drawing treatment device for aluminum product processing and production

ActiveCN111037418BMeet drawing requirementsAdjustable working heightGrinding carriagesGrinding drivesElectric machineryEngineering

The invention discloses an outer surface wire drawing treatment device for aluminum product processing and production, and relates to the technical field of aluminum product outer surface wire drawing. The outer surface of the aluminum product is wire-drawn for processing and production, including a bottom plate, the top outer surface of the bottom plate is welded with a second side frame and a first side frame, and the top of the second side frame and the first side frame are welded. There is a top plate, the top outer surface of the top plate is welded with a motor support frame, a positioning block and a clamping block, the top of the motor support frame is welded with a second motor, the outer wall of one side of the clamping block is rotated with a rotating shaft, and the free end of the rotating shaft It penetrates the positioning block and is welded with the output shaft of the second motor. The outer surface of the rotating shaft is welded with the first winding drum and the second winding drum, and the inside of the second side frame and the first side frame are provided with slides. groove. The invention can perform wire drawing work on aluminum products with different thicknesses, thereby improving the fault tolerance rate.

Owner:佛山市三水长河实业有限公司

External surface wire drawing treatment device for aluminum product processing and production

ActiveCN111037418AMeet drawing requirementsAdjustable working heightGrinding carriagesGrinding drivesElectric machinerySupport plane

The invention discloses an external surface wire drawing treatment device for aluminum product processing and production, and relates to the technical field of aluminum product external surface wire drawing. The external surface wire drawing treatment device comprises a bottom plate, wherein a second side frame and a first side frame are welded on the top outer surface of the bottom plate, a top plate is welded on the tops of the second side frame and the first side frame, a motor support frame, a positioning block and a clamping block are welded on the top outer surface of the top plate, a second motor is welded on the top of the motor support frame, a rotating shaft is rotationally arranged on the outer wall of one side of the clamping block, the free end of the rotating shaft penetratesthrough the positioning block and is welded with an output shaft of the second motor, a first winding roller and a second winding roller are welded on the outer surface of the rotating shaft, and sliding grooves are formed in the second side frame and the first side frame. The external surface wire drawing treatment device for aluminum product processing and production can perform wire drawing work on aluminum products with different thicknesses, and improves the fault tolerance rate.

Owner:佛山市三水长河实业有限公司

Movable wind power generation energy storage device

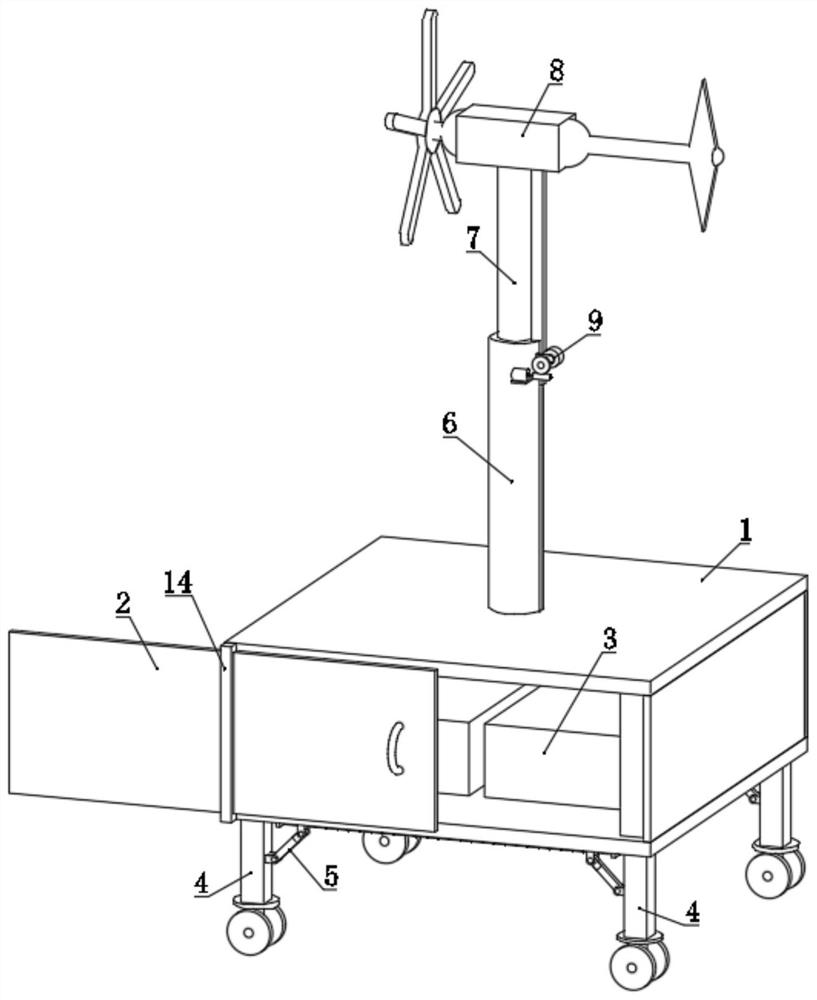

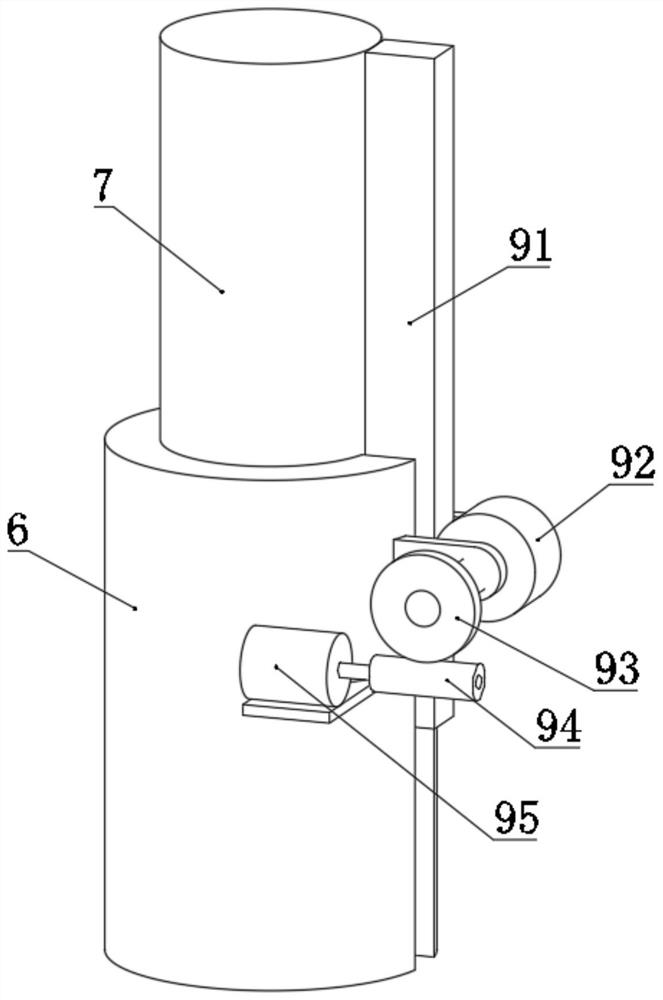

PendingCN113833610AEliminate failure problemsEliminate damageWind energy with electric storageWind motor supports/mountsControl theoryBattery pack

The invention discloses a movable wind power generation energy storage device, and belongs to the field of wind power generation. The movable wind power generation energy storage device comprises an energy storage box, wherein the front side of the energy storage box is provided with a box door, the energy storage box is internally provided with a storage battery pack, the upper side of a top plate of the energy storage box is provided with a casing pipe, and the upper side of the casing pipe is slidably provided with a lifting rod; and the top end of the lifting rod and a wind power generation device are installed, the wind power generation device comprises a wind wheel and a power generator, the wind wheel and an input shaft of the power generator are installed, and a lifting mechanism is jointly installed at the outer side of the casing pipe. According to the movable wind power generation energy storage device, damping of the storage battery pack can be achieved, faults and damage of the storage battery pack caused by vibration during moving are avoided, the working height of the wind wheel in the wind power generation device can be adjusted during power generation, wind energy can be utilized more efficiently, when the storage battery pack needs to be replaced and overhauled, the storage battery pack can be conveniently moved to the box door, and operation of personnel is facilitated.

Owner:CHINA THREE GORGES UNIV

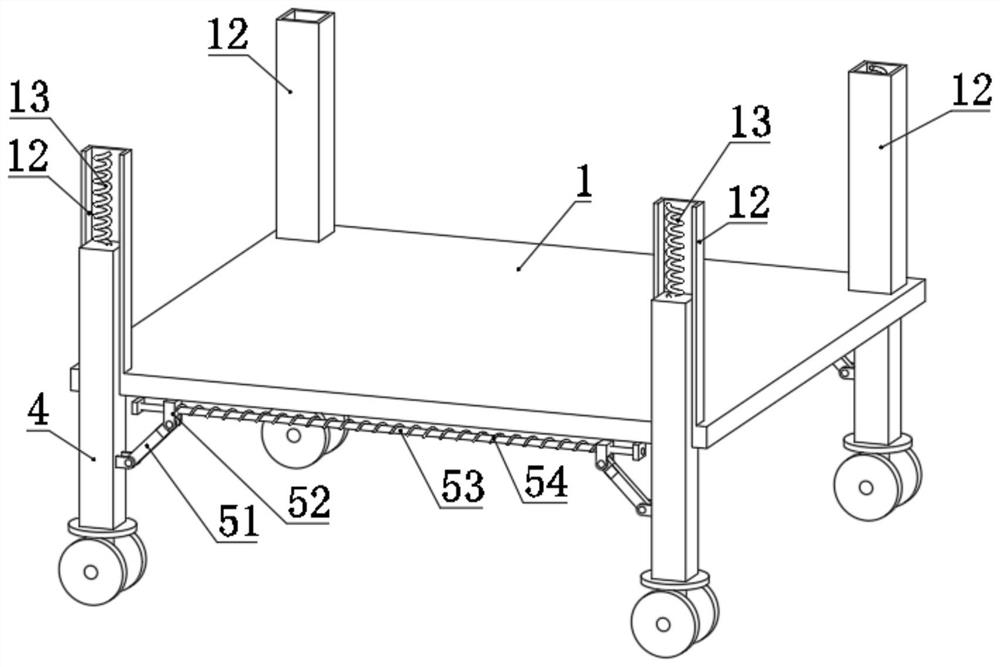

Board feeding device

PendingCN112124959AAdjustable working heightMeet operational requirementsStacking articlesConveyor partsMechanical engineeringWood plank

A board feeding device is used for solving the technical problem of low board conveying and feeding efficiency in the prior art mentioned in the background art, and comprises a support, a clamping assembly, a conveying assembly and an adsorption assembly. The clamping assembly comprises two opposite connecting frames and two opposite support plates; the two connecting frames are slidably connectedwith the support and can slide in the vertical direction; the two support plates are slidably connected with the two connecting frames in a one-to-one correspondence manner and can slide in the transverse direction for placing and clamping a board; the conveying assembly is arranged on the support and connected with the adsorption assembly for directionally conveying the adsorption assembly; andthe adsorption assembly is arranged on the support for adsorbing the board placed on the support plates. The board feeding device is rapid and easy to operate and mainly used for feeding the board.

Owner:JIAXING QUNLUN MACHINERY

An adjustable art display device

The invention discloses an adjustable device for art display, relating to the field of display devices. Driven by a power source, a rotating shaft drives a turntable to rotate, and an exhibition standis enabled to revolve around the rotating shaft; under the action of a gear and a gear ring, the exhibition stand rotates while revolving, enabling audiences to view more conveniently; when the audience wants to carefully watch a certain exhibit, a control switch is pressed down, at the moment, a telescopic rod is pushed into a notch in a table board under the action of a spring rod, thus, the exhibition stand can stay still so that audiences can watch the exhibition stand conveniently; the exhibition stand is provided with a fluorescent lamp used for illumination and a protective cover usedfor protection, baffles and clamping plates are each provided with a plastic layer so that exhibits can be prevented from being scratched, and the adjustable device is adjustable in working height andmore convenient to use through the arrangement of a lifting mechanism.

Owner:武汉市此方智能环境设计工程有限公司

Wood smashing device for building construction

InactiveCN111437948AImprove the effect of post-processingImprove cleaning efficiencyWood working apparatusCleaning using liquidsDrive shaftArchitectural engineering

The invention discloses a wood smashing device for building construction, and relates to the technical field of building machinery. The wood smashing device comprises a box, a cover plate and supporting legs, the cover plate is connected to the upper end of the box in a buckling mode, the multiple supporting legs are fixedly connected to the bottom end of the box, a feeding opening is formed in the surface of the box, an electric push rod is installed on the upper surface of the cover plate, and a push plate is arranged in the box. The output end of the electric push rod penetrates through thecover plate to stretch into the box to be connected with the push plate, a drive motor is installed at the bottom end of the box, a drive shaft is connected to the output end of the drive motor, anda smashing rod is arranged at the bottom end of the interior of the box. A first telescopic shaft is connected to one end of the drive shaft, the smashing rod is connected with the first telescopic shaft, an undertake slot is formed in the lower part of the box, a filter screen is arranged on the inner surface of the bottom end of the box, and the filter screen is located below the smashing rod. According to the wood smashing device for the building construction, the smashing rod is used for transversely cutting and smashing woods, the push plate in the box is used for longitudinal extrusion,so that the woods are more concentrated, the fineness is high during smashing, and later further processing is facilitated.

Owner:陈元定

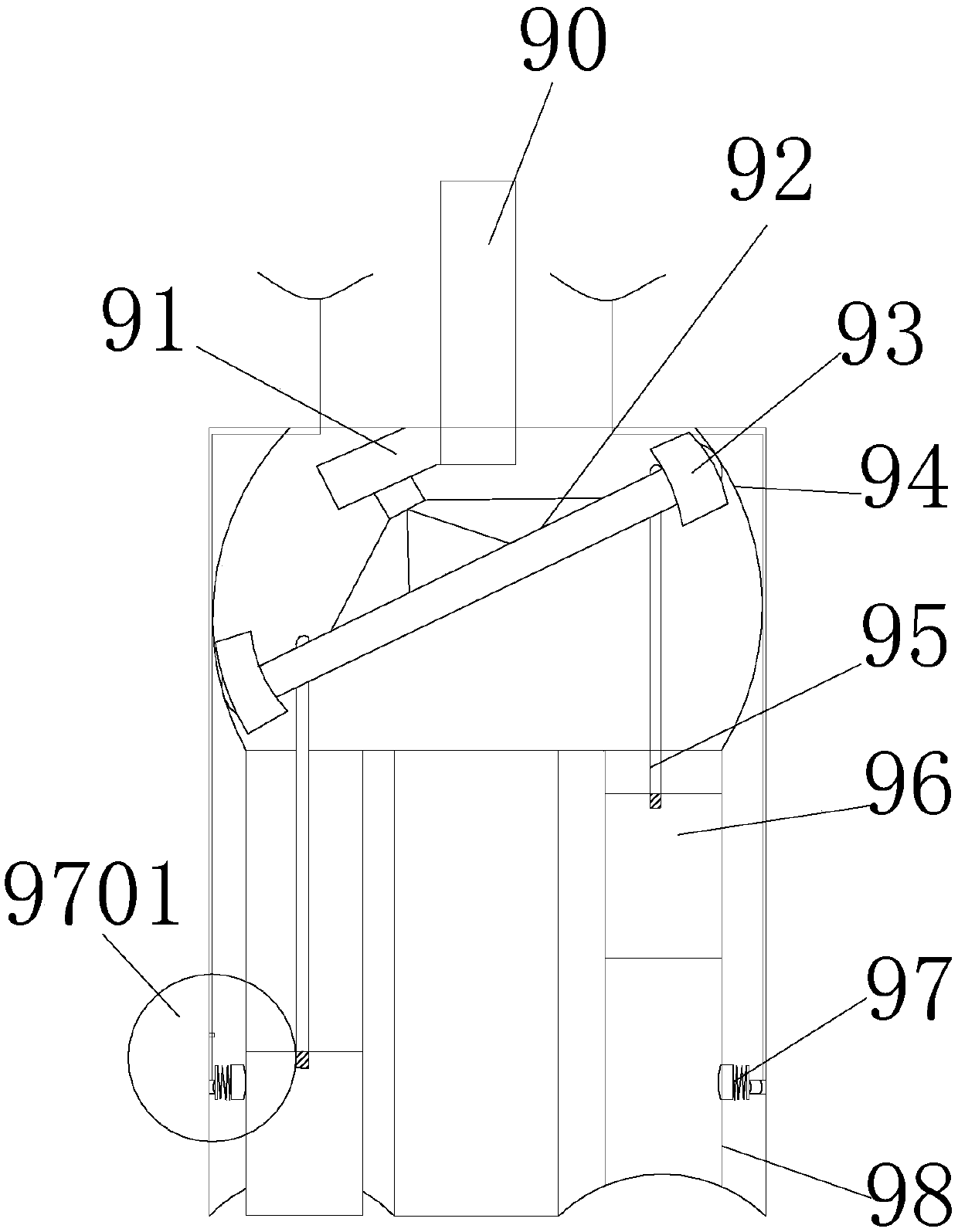

Solar intelligent street lamp adopting LoRa technology

PendingCN113653988AAdjustable working heightReceive morePhotovoltaic supportsMechanical apparatusEngineeringMechanical engineering

The invention discloses a solar intelligent street lamp adopting LoRa technology, which comprises a base, the upper end of the base is fixedly connected with a fixed rod, the outer side of the fixed rod is provided with a clamping mechanism, the clamping mechanism comprises a fixed plate, the two sides of the fixed plate are in threaded connection with adjusting screw rods, the upper ends of the adjusting screw rods are rotatably connected with a moving plate, an illuminating lamp is mounted at the upper end of the moving plate, a mounting cylinder is arranged at the position, located at the upper end of the clamping mechanism, of the outer side of the fixed rod, a bottom plate is fixedly connected to the lower end of the mounting cylinder, and a fixing seat is arranged below the bottom plate. During working, a fixed cylinder is designed, the working height of the illuminating lamp and the solar panel can be adjusted by moving the fixed cylinder up and down, and the invention can be conveniently applied to more working scenes. And a arc-shaped plate is designed, and the arc-shaped plate rotates, so that the solar panel can ascend along with movement of the sun, the solar panel can receive more solar energy, and conversion of energy efficiency is improved.

Owner:中山市木林森户外照明有限公司

A centrifugal sorting device for raw materials for graphene chip production

ActiveCN108550536BAdjustable working heightAdjustable positionSemiconductor/solid-state device manufacturingElectric machineryGraphite

The invention discloses a centrifugal selection device for producing raw materials of a graphene chip. The device comprises a work bench and a centrifugal cylinder. A collection box is arranged on thework bench. Limiting plates are arranged on four sides of the collection box and welded to the work bench. Support racks are welded on two sides of the collection box. Pushing rod motors are installed on the top ends of the support racks through rivets. Output ends of the pushing rod motors are in key connection with pushing rods. Installation plates are welded on top ends of the pushing rods. During working, material feeding can be performed in real time at a material feeding opening, and meanwhile, only the materials pass through a third screening plate can enter the collection box and be collected, so best raw materials are collected in the collection box. A moving door is arranged on the centrifugal cylinder, and is in the closed sealing state when the centrifugal cylinder is working.When the working is finished, the centrifugal cylinder can be taken out from the collection box and then the movable door is opened to collect and process the raw materials at three degrees.

Owner:温州翰轩林工业设计有限公司

A kind of test device and test method of knee joint prosthesis based on industrial robot

ActiveCN111588522BSimple structure to useFlexible and convenient controlArtificial legsKnee JointEngineering

The invention belongs to the technical field of prosthesis testing, and in particular relates to a knee joint prosthesis testing device and testing method based on an industrial robot; the device includes an industrial robot, a bionic thigh and a ground reaction force module; The movement of the residual limb in a gait cycle can realize prosthetic testing in environments such as walking at different speeds, going up and down slopes, and up and down stairs, and can adjust the ground reaction force on the prosthetic foot, and the ground reaction force input during the prosthesis test It is more accurate, providing an accurate test environment for the intelligent knee joint assembled on the interface, and due to the use of industrial robots, this test system is more convenient and flexible to use, and the structure is simpler.

Owner:JILIN UNIV

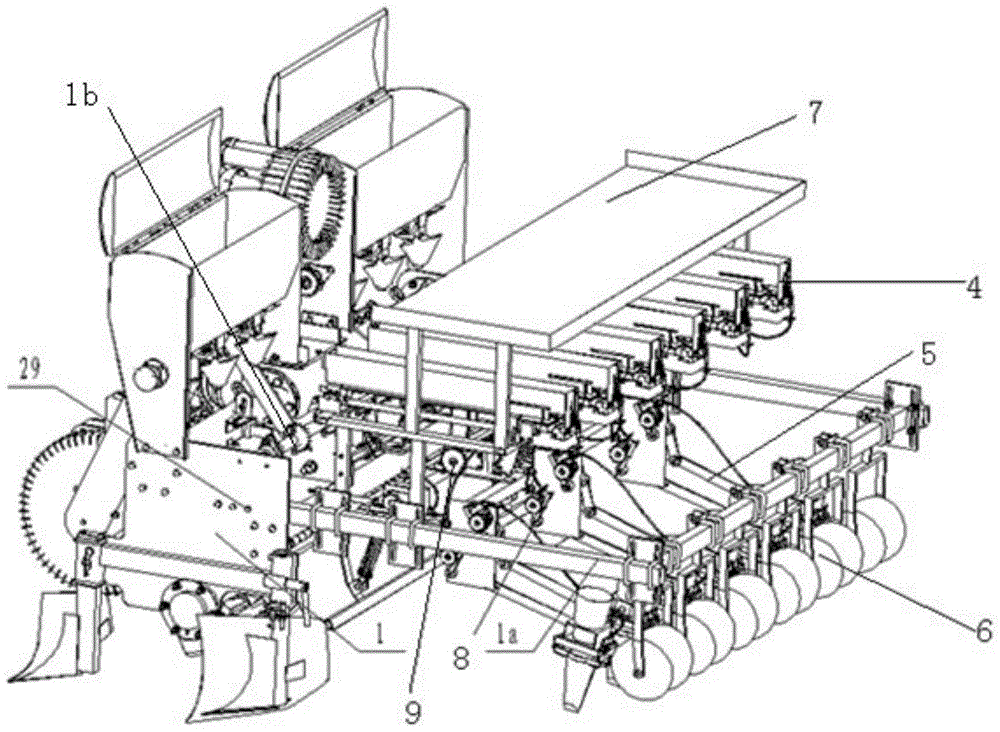

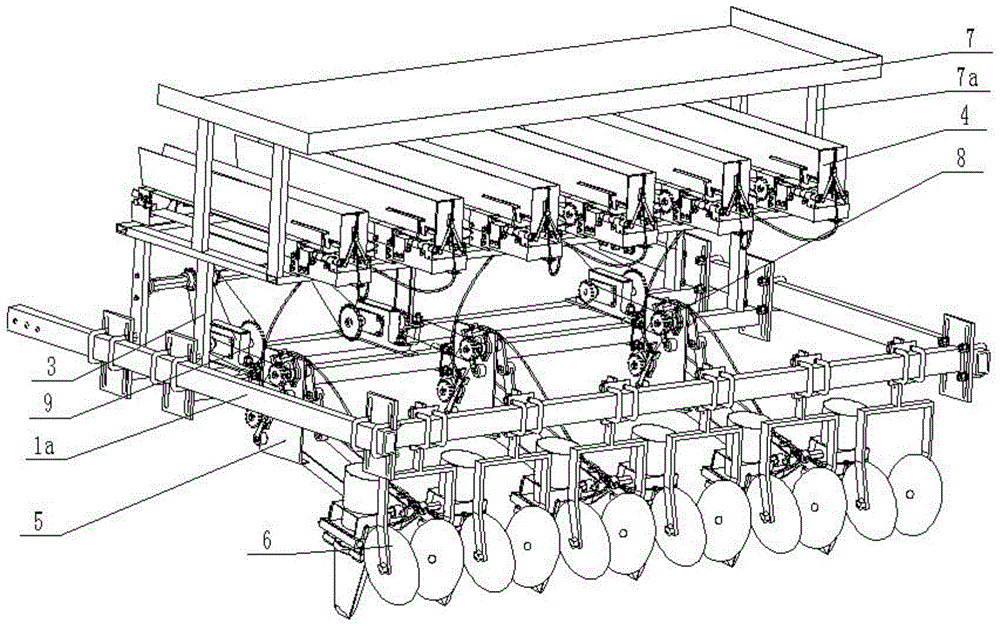

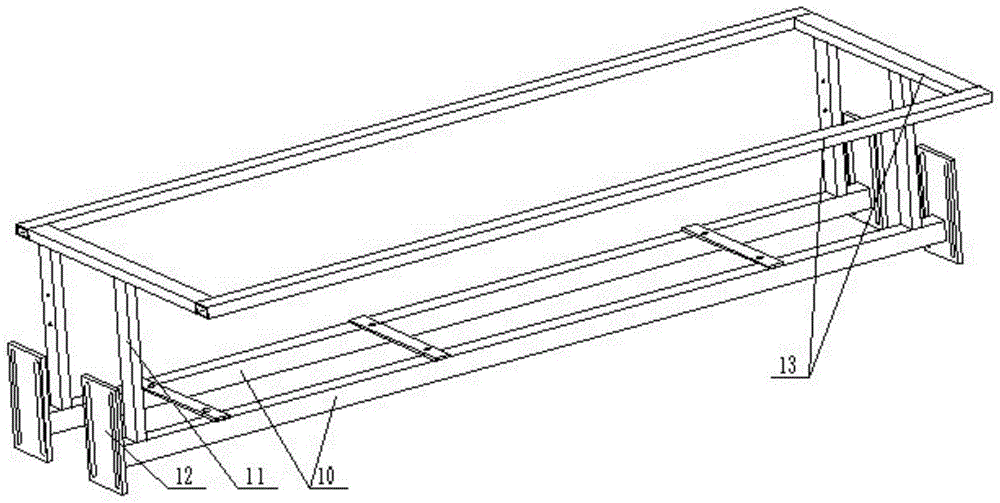

Integrated Rape Planter

ActiveCN104855015BReduce the number of landingsReduce the degree of rollingSpadesPloughsAgricultural engineeringRapeseed

The invention discloses an integrated type oilseed rape sowing and planting machine which comprises an earth covering and pressing device, a seedling separation device provided with a seedling separation power input end, and a planting device provided with a first planting power input end and a second planting power input end, and further comprises a planting subsidiary rack, two main side beams installed on a direct sowing main body, a transmission device used for transmitting the power of a power source and a cam control device used for controlling the seedling separation device and the planting device to open and close. The integrated type oilseed rape sowing and planting machine is a multifunctional multiple operation machine, can complete the operation steps of rotary tillage, fertilizer application, furrow opening, transplantation and earth covering and pressing, reduces the farming number of machines and tools effectively, relieves the rolling degree of the machines and tools to soil, and improves the use ratio of the direct sowing machine simultaneously.

Owner:HUAZHONG AGRI UNIV

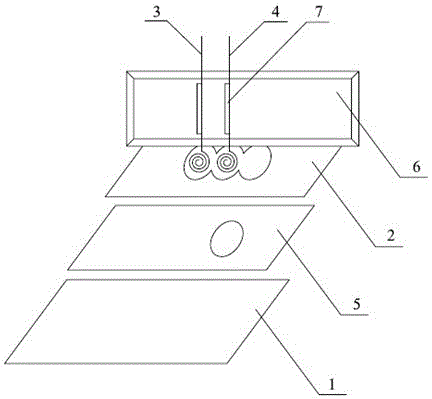

An electrochemical reaction cell for dark-field microscopic observation

InactiveCN103808777BEasy to makeLow costMaterial electrochemical variablesElectrochemical responseGlass chip

The present invention relates to an electrochemical reaction cell that can be used for dark-field microscopic observation, including an electrochemical reaction cell and an electrochemical element, wherein the electrochemical reaction cell is an insulating thin layer with holes installed on an ITO glass sheet. There are two holes on the insulating thin layer and the two holes are connected; the electrochemical element includes a counter electrode and a reference electrode, and the counter electrode and the reference electrode are respectively positioned and installed in the holes on the insulating thin layer. The electrochemical reaction cell of the present invention has the advantages of simple manufacture, low cost, reusable use, convenient operation, long-term working height adjustable, etc., and is more suitable for dark electric field operation.

Owner:NANJING UNIV

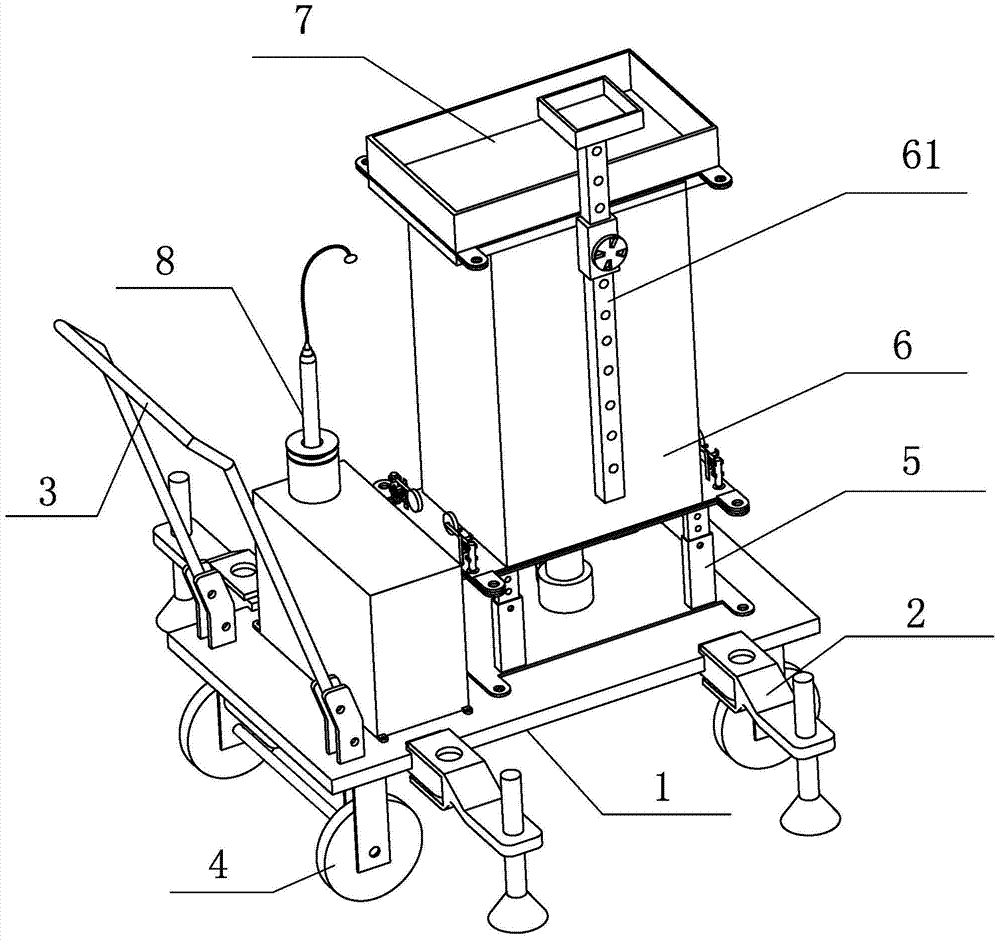

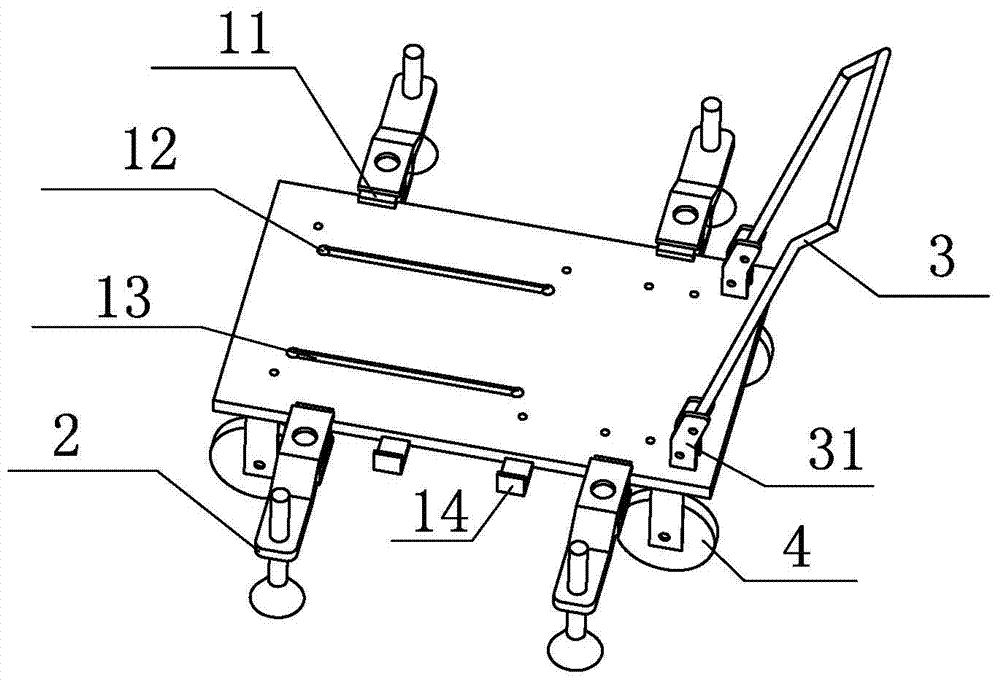

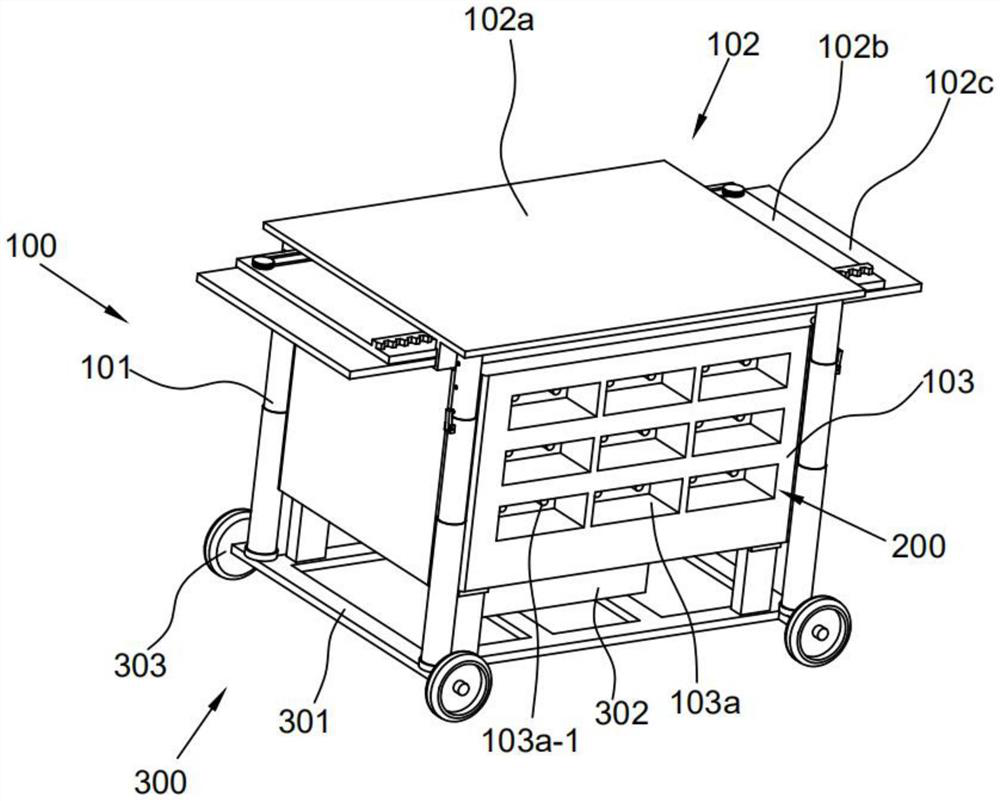

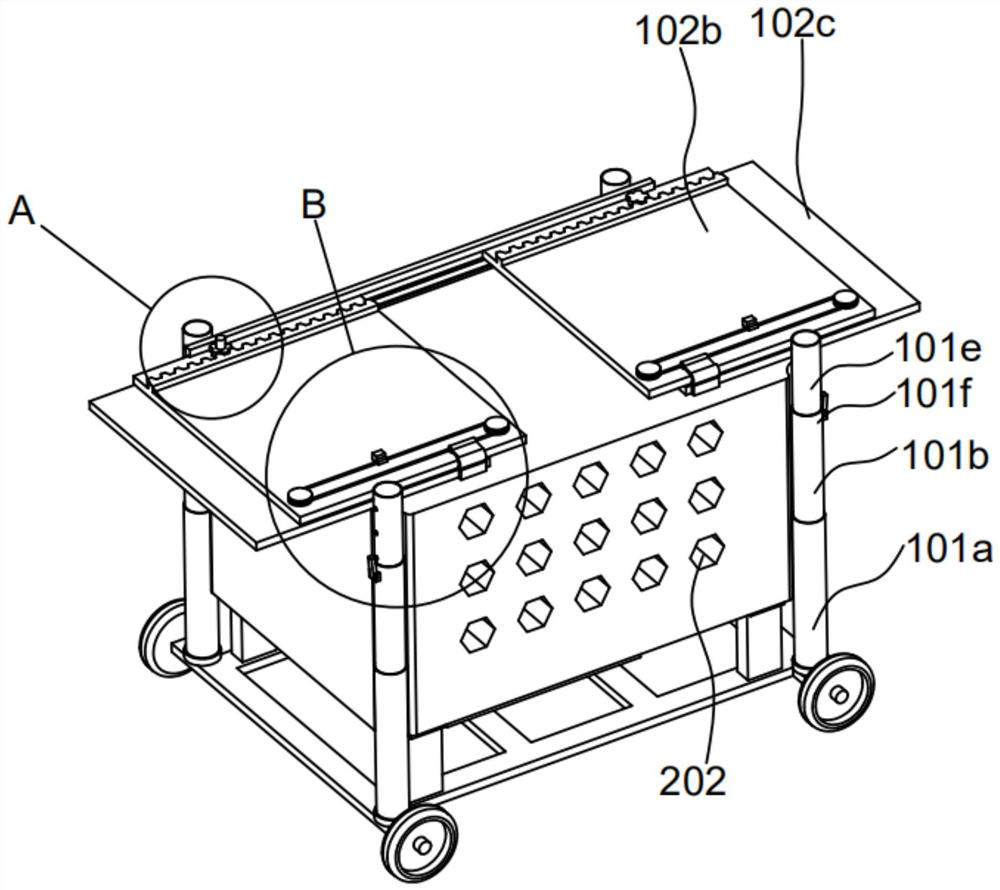

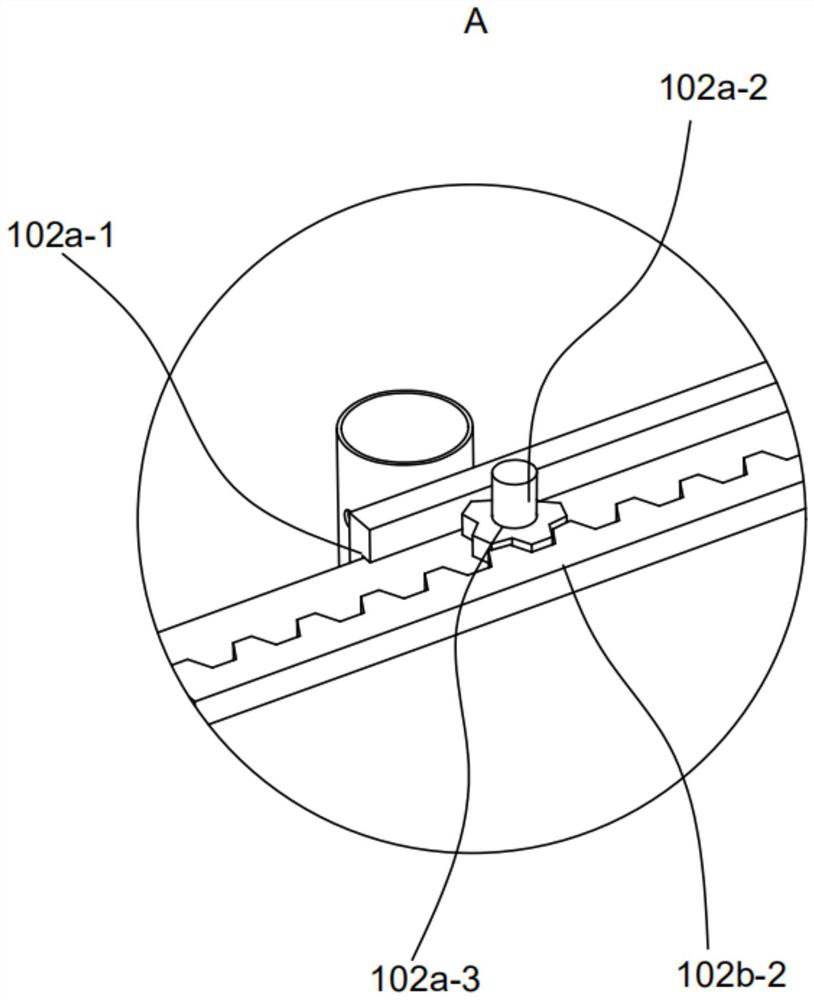

Electric power construction site construction multifunctional trolley

ActiveCN105109530BEasy to replaceAdjustable working heightLifting devicesHand carts with multiple axesArchitectural engineeringElectric power

The invention relates to a construction multifunctional trolley on a power construction site, which comprises wheels, a trolley bottom plate, a trolley push rod, a lifting device, a tool box, a tray device and an illuminating device. There are two sets of stable support mechanisms symmetrically arranged on the left and right sides of the bottom plate of the trolley. The lifting device, tool box and pallet device are listed on the trolley in sequence from bottom to height. The lighting device is located at the rear end of the trolley adjacent to the lifting device. . The stable support mechanism on the bottom of the trolley makes the trolley super stable during operation and at the same time enables the trolley to have a certain leveling function; the trolley has the functions of providing tool storage, material transportation, lighting and a certain degree of climbing operations and other functions, which can largely meet the needs of on-site operators, improve the efficiency of on-site construction, and reduce the labor intensity of construction operations.

Owner:RES INST OF ECONOMICS & TECH STATE GRID SHANDONG ELECTRIC POWER +1

A device for cleaning the side walls of a pool

ActiveCN111545495BEasy to cleanAdjustable working heightCleaning using toolsCleaning using liquidsGear wheelElectric machinery

A device that can clean the side wall of a pool, including an upper end cover, a reversing mechanism is provided on the upper side of the upper end cover, a steering cavity is provided in the reversing mechanism, a swing cavity is provided on the upper end surface of the upper end cover, and the A swing motor is provided in the swing cavity, a swing gear is provided on the shaft of the swing motor, a through hole is provided on the front side of the upper end cover of the swing gear, a swing shaft is rotated in the through hole, and the swing shaft is rotated in the through hole. A large swing gear is fixed on the end face of the shaft, and the large swing gear meshes with the swing gear. Using the present invention, the device is placed in a pool with cleaning and started. Due to its special shape, the side walls of most pools can be cleaned. , including right-angled side walls, sharp-angled side walls of a certain depth, all convex pools and some concave side wall pools, and the working height of the side wall of the device can be adjusted to adapt to most shapes of pools, and the bottom of the pool is also cleaned at the same time , no need to manually clean the narrow area of the special-shaped pool, and clean the pool efficiently.

Owner:日照经济技术开发区海洋发展有限公司

Abdominal region moxibustion fixing device for traditional Chinese medicine care

InactiveCN112294646AAdjustable adsorption depthAdjustable working heightDevices for heating/cooling reflex pointsHuman bodyNursing care

The invention relates to the technical field of traditional Chinese medicine moxibustion and particularly relates to an abdominal region moxibustion fixing device for traditional Chinese medicine care. The disadvantage in the prior art that auxiliary supporting members for moxibustion are relatively poor in flexibility and cannot better meet moxibustion requirements under different conditions. Theabdominal region moxibustion fixing device comprises a supporting part, wherein a guiding groove is formed in the external surface of the supporting part, a guiding rod is arranged inside the guidinggroove, one side of the guiding rod is connected with a ferrule, a connecting frame is arranged at the outer side of the ferrule, moxibustion sleeves are separately mounted at the two ends of the connecting frame, moxibustion pore passages are formed inside the moxibustion sleeves, a shaft block is arranged at one side of a linkage block, and a linkage bar is movably arranged on the shaft block.According to the abdominal region moxibustion fixing device, equipment can be globally adsorbed to a human body by using a sucker, the moxibustion sleeves are used for carrying out moxibustion auxiliary supporting and can be adjusted on the supporting part, the linkage block and a pillar plate are also connected through a shaft block, flexible adjustment can be carried out as required, and the adaptability of the equipment during operation is improved.

Owner:庄艳青

Cloth-processing cloth filament finishing device capable of ensuring uniform distribution of cloth filaments

The invention discloses a cloth-processing cloth filament finishing device capable of ensuring uniform distribution of cloth filaments, and relates to the technical field of cloth processing. The cloth-processing cloth filament finishing device capable of ensuring uniform distribution of the cloth filaments comprises a base. Support legs are fixedly mounted at the bottom of the base. Fixing seatsare fixedly mounted at the top of the base. A vertical sliding hole is formed in each fixing seat. A vertical threaded rod is arranged in each vertical sliding hole, and is slidably connected with thecorresponding fixing seat. A transverse threaded rod located on the middle upper portion of each fixing seat is rotatably mounted in the corresponding fixing seat, and is meshed with the corresponding vertical threaded rod. The cloth-processing cloth filament finishing device has the advantages that through interactive use of reset springs, first sliders, sliding grooves, clamping grooves, support plates, racks, half gears and a second motor, and through the design of adjustability in transverse positions and angles, the device is applicable to more cloth processing devices; the cloth filaments are distributed evenly, and accordingly, the quality of produced cloth is improved to a certain degree.

Owner:湖州创塑新材科技有限公司

Mobile power supply multifunctional platform device

ActiveCN113193622AEasy to chargeAdjustable working heightElectric powerArrangements for several simultaneous batteriesMobile chargeEngineering

The invention provides a mobile power supply multifunctional platform device which comprises a supporting module, wherein the supporting module comprises four vertically-arranged supporting rods, a panel is arranged on the supporting rods, and a containing box is arranged in the supporting rods; a charging module which is arranged in the accommodating box body and comprises a power supply, a charging bin and a socket; a moving module which comprises a supporting frame arranged below the containing box, a driving unit is arranged on the supporting frame, and wheels are arranged below the supporting frame. The device provided by the invention is convenient to supply power outdoors, the device body can be operated to form a working platform capable of placing articles for operation, the working height can be adjusted, meanwhile, different charging supply pieces are arranged in the device, charging by a mobile phone USB can be convenient, a socket can also be used for charging, and the whole device adopts an insulating structure, is safe and reliable, is suitable for various scenes.

Owner:GUIZHOU POWER GRID CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com