Self-adjustment compressing device

A pressing device and self-adjusting technology, applied in positioning device, clamping, support, etc., can solve the problems of reducing work efficiency and low work efficiency, and achieve the effect of improving work efficiency and being easy to rotate, fix and disassemble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The technical solution will be described in detail below through a best embodiment, but the protection scope of the present invention is not limited to the embodiment.

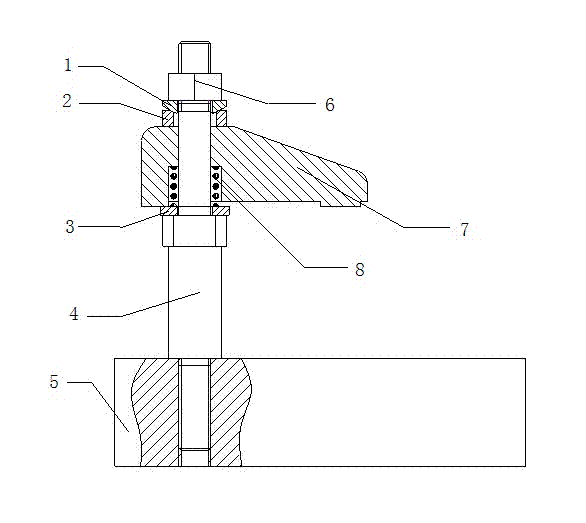

[0010] Such as figure 1 As shown, a self-adjusting pressing device includes a hex nut 6, a tooling fixture 5 and a stud 4 fixed on the tooling fixture 5, and an eccentric pressing plate 7 is arranged on the said stud 4, and the eccentric The lower end surface of the pressing plate 7 is provided with a gasket 3, the eccentric pressing plate 7 is connected with the gasket 3 through a strong spring 8, the upper end surface of the eccentric pressing plate 7 is provided with a tapered washer 2, and the hexagonal nut 6 and the tapered surface A spherical washer 1 is arranged between the washers 2 . The protruding part of the middle part of the stud 4 is cut on both sides and processed into a flat shape.

[0011] When replacing parts, due to the effect of the strong spring 8, it is not necessary to loosen th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com