A derricking direction-changeable telescopic belt conveying bidirectional loader-unloader

A belt conveyor and belt conveying technology, applied in the direction of conveyors, conveyor objects, loading/unloading, etc., can solve the problems of low efficiency, poor environmental conditions, labor and time consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

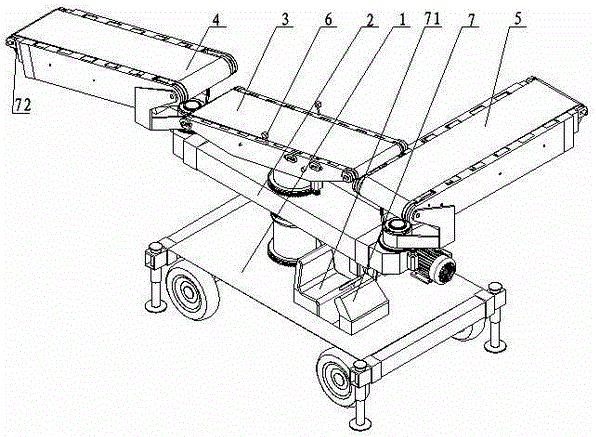

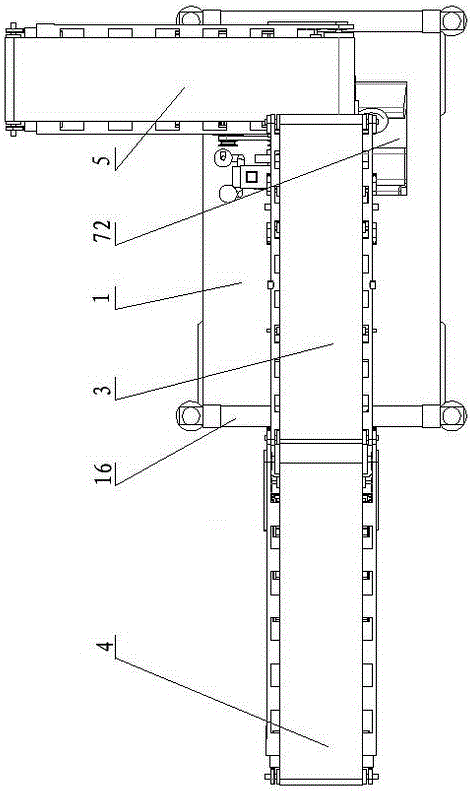

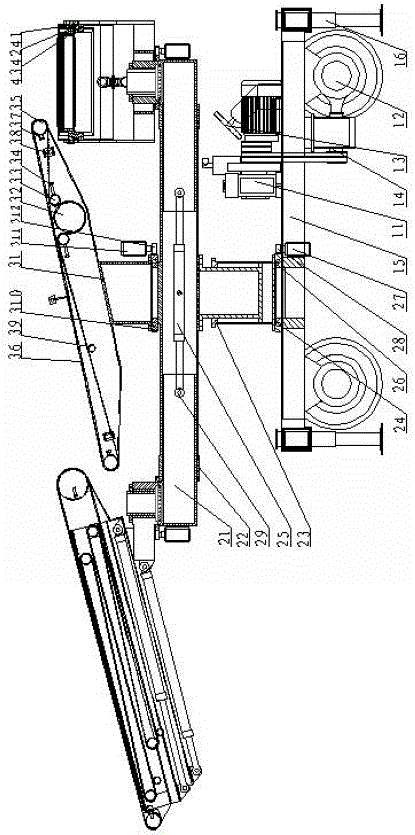

[0035] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, the present invention consists of a vehicle 1 with a walking function, a telescopic cross arm 2 with telescopic, lifting and swing functions, an intermediate transition conveyor 3 with a swing function and can be inclined to transport, a variable amplitude, swing and Belt conveyor one 4 with telescopic function, belt conveyor two 5, metering device 6 with metering, display and storage, printing functions and its manipulation control system 7 are composed. The telescopic cross arm 2 is fixed on the vehicle 1, belt conveyor 1 4 and belt conveyor 2 5 are installed at both ends of the telescopic cross arm 2, and the intermediate transition conveyor 3 is installed in the middle of the telescopic cross arm 2; the metering device 6 is fixedly installed On the intermediate transition conveyor 3 or any telescopic belt conveyor 1 4 and belt conveyor 2 5; the vehicle 1 is used as the loading and running ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com