Four-arm multifunctional building robot

A multifunctional and robotic technology, applied in the field of 3D printing, can solve the problems of single function of the printing arm and printing nozzle, the failure to repair the finished product in time, and the low degree of fineness of the structural components, so as to effectively use the working area and improve the printing efficiency Low, the effect of improving printing work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Specific examples of the present invention are given below. The specific embodiments are only used to further describe the present invention in detail, and do not limit the protection scope of the claims of the present application.

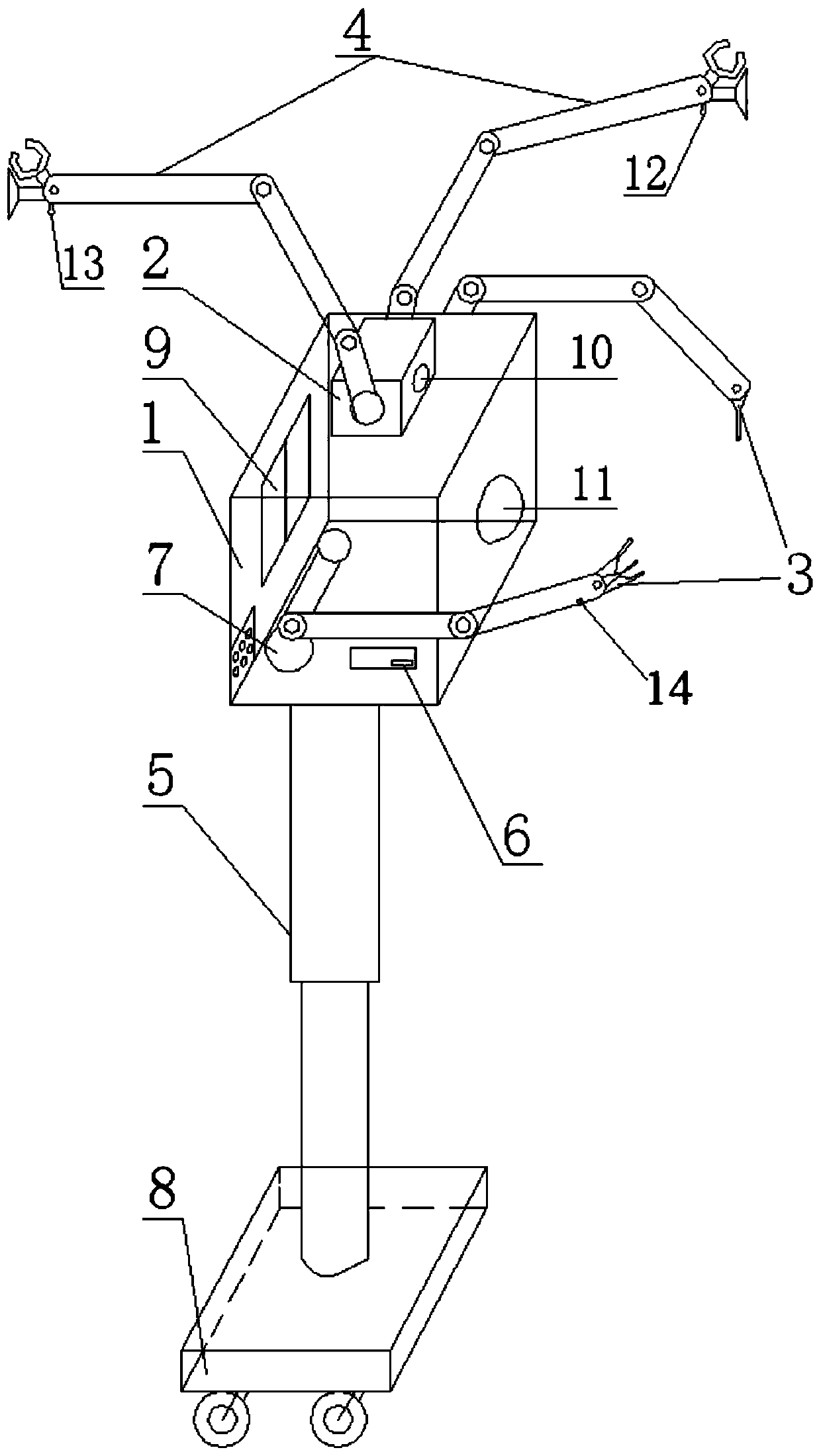

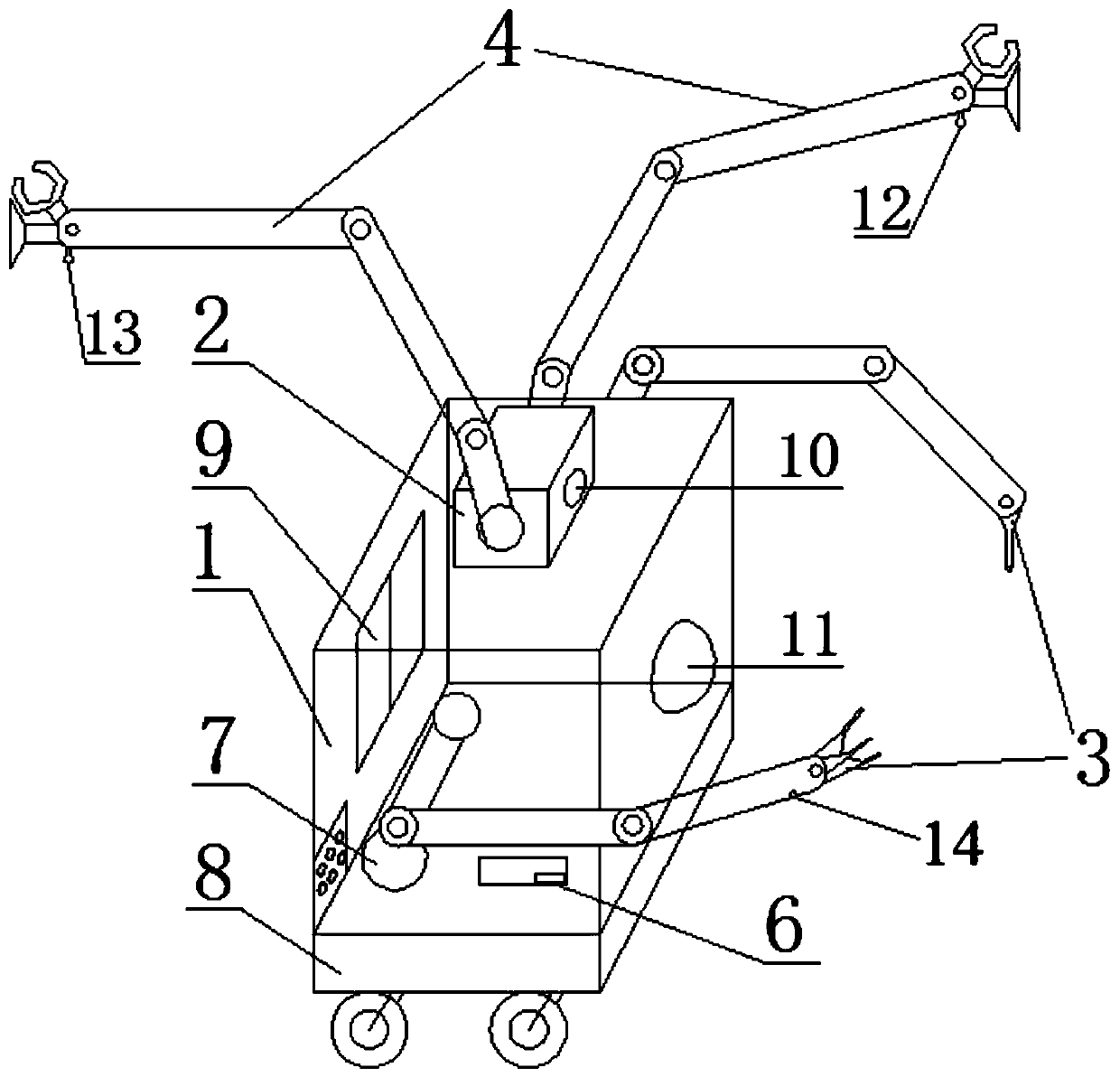

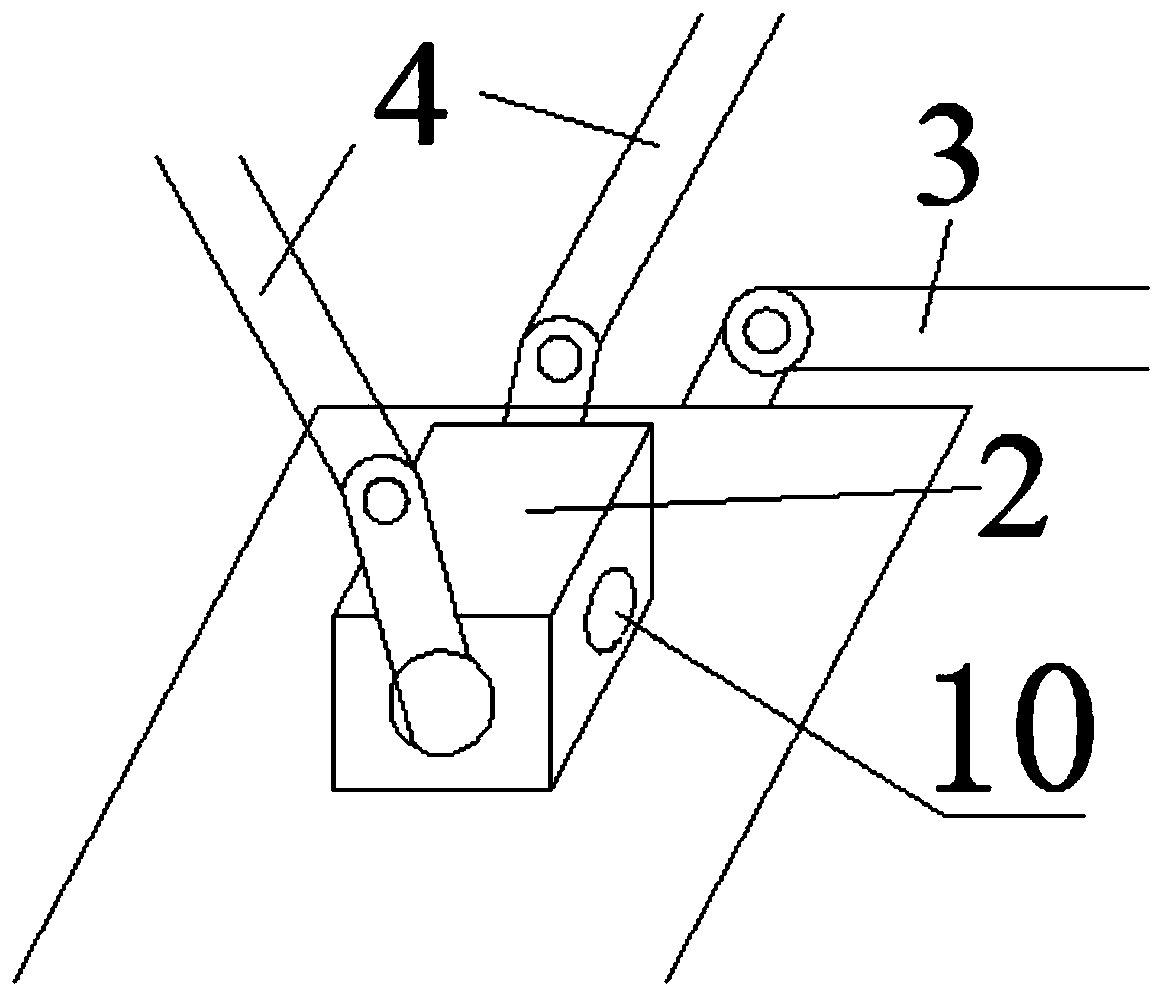

[0027] The invention provides a four-arm multifunctional construction robot (robot for short, see Figure 1-5 ), including a body 1, a head 2, a power supply system 6, a material supply system 7, a mobile system 8 and a computer intelligent system 9; it is characterized in that the robot also includes a 3D printing system 3, a fixing system 4, a lifting system 5, Head monitor 10, fuselage monitor 11, left fixed monitor 12, right fixed monitor 13 and paint filling device 14; Described 3D printing system 3 comprises left print arm 3-1, print nozzle 3-2, The right printing arm 3-3 and the multifunctional processing mechanical claw 3-4; the fixing system 4 includes a left fixing arm 4-1, a left fixing claw 4-2, a right fixing arm 4-3 and a rig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com