Lithium battery cap pressure welding device

A technology for lithium batteries and caps, which is applied to battery caps/end caps, resistance welding equipment, battery pack components, etc., can solve the problems affecting the pressure welding effect of lithium battery caps, poor sealing between caps and tube shells, and low safety performance. and other problems, to achieve the effect of good sealing performance, increase profit, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

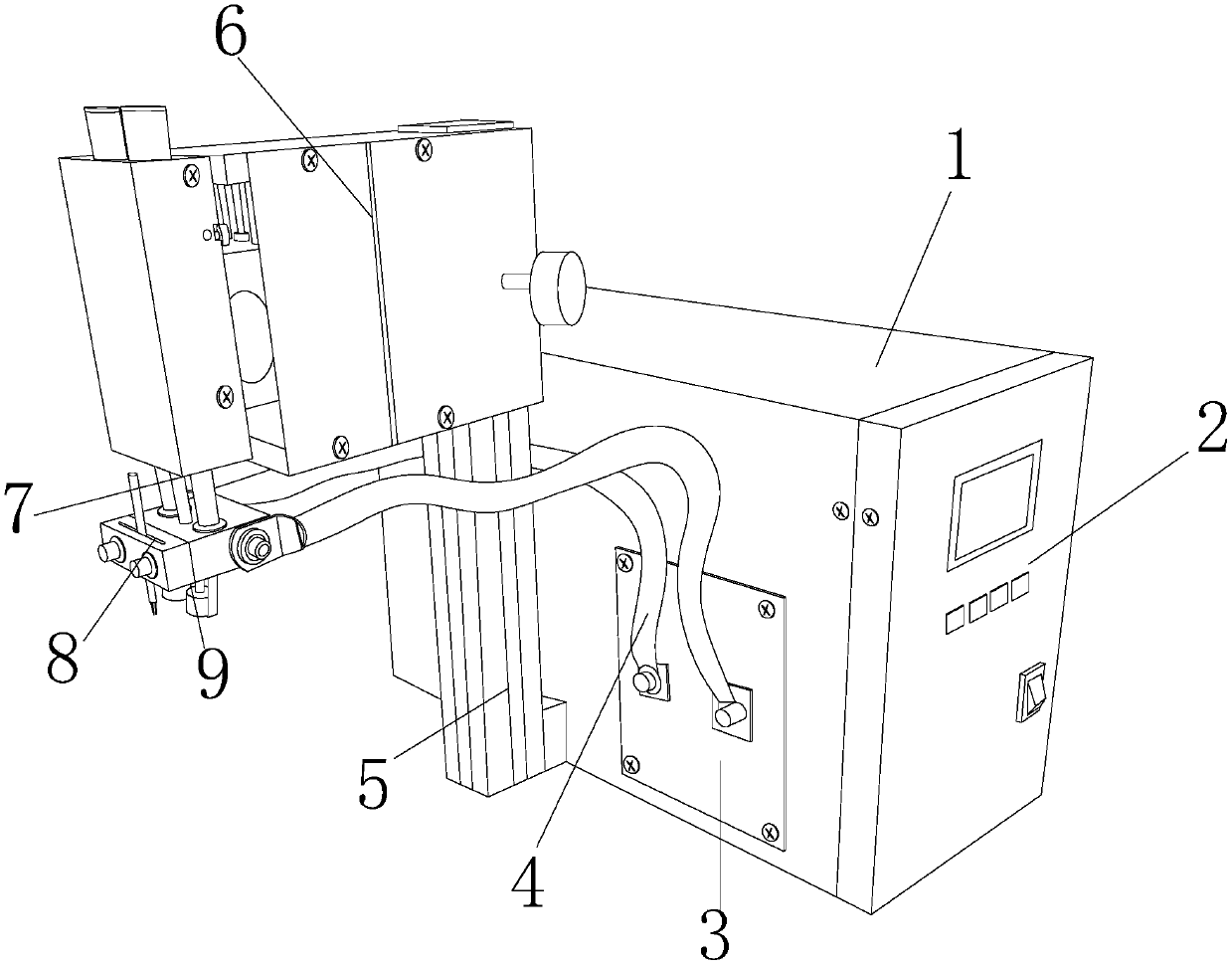

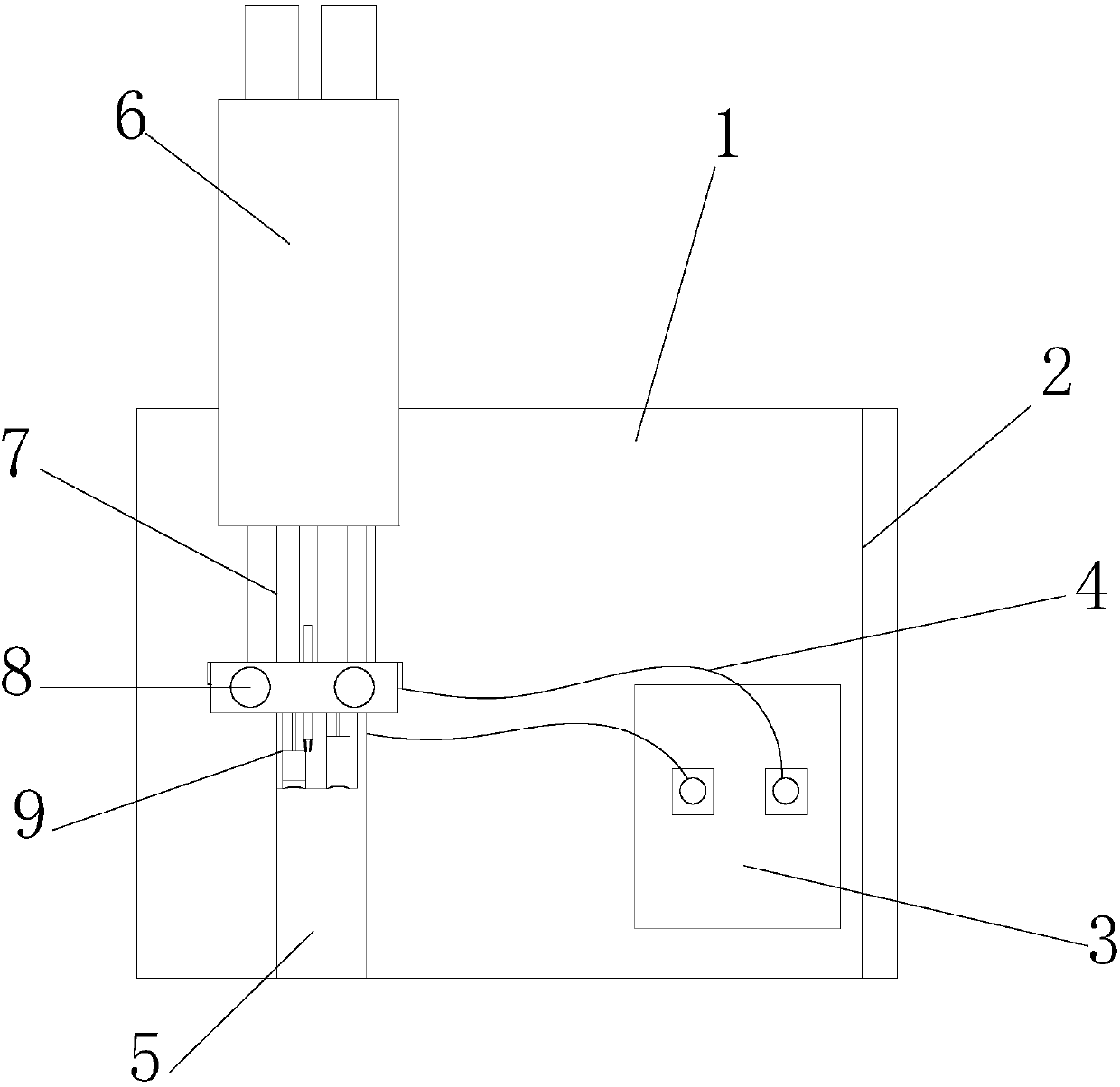

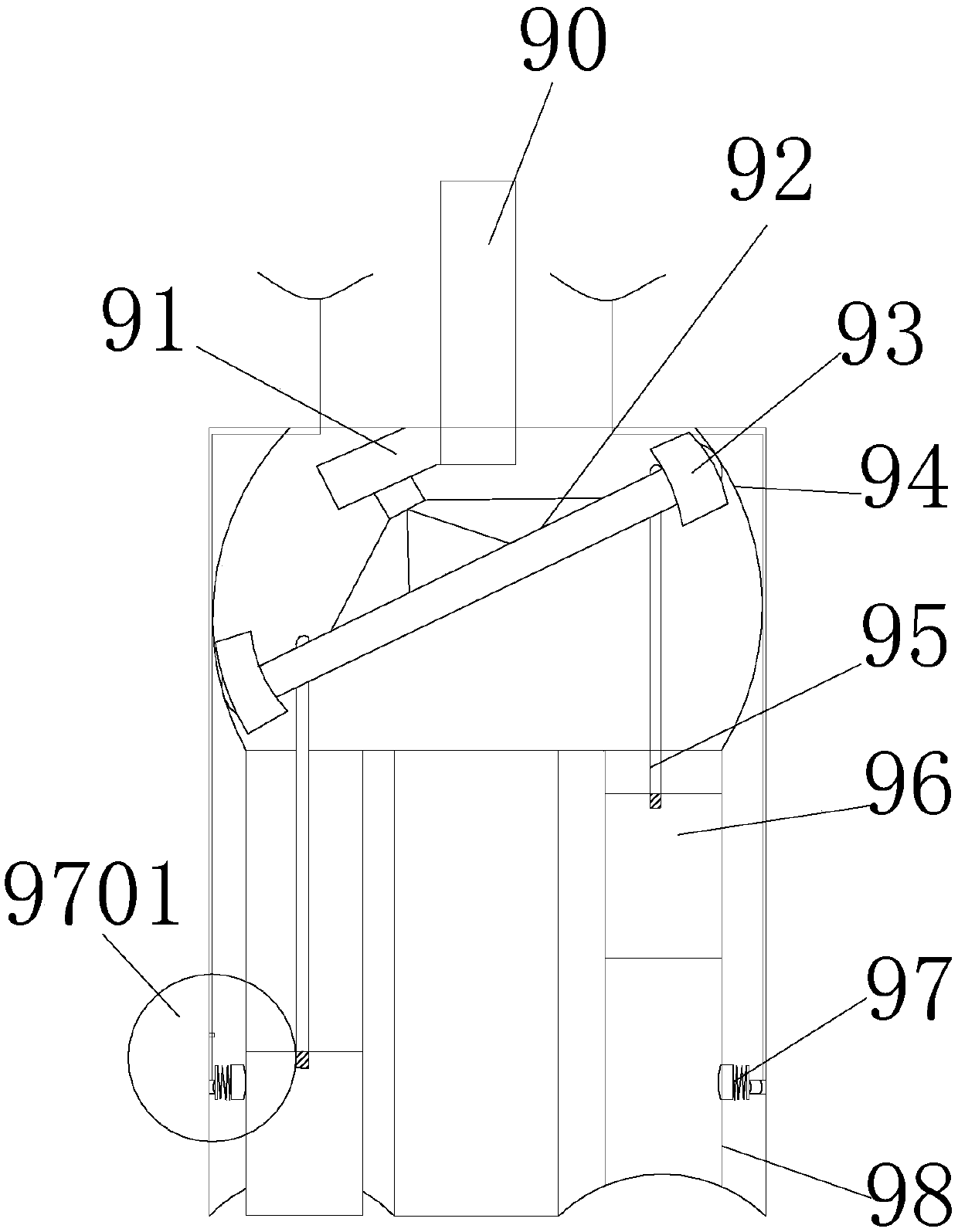

[0030] see Figure 1-Figure 7 , the invention provides a lithium battery cap pressure welding device: its structure includes a chassis 1, a control panel 2, a sealing connecting plate 3, a welding wire tube 4, a lifting rod 5, a welding control head 6, a telescopic rod 7, and a welding head 8 . The battery cap gland device 9, the chassis 1 is a cuboid, the front end is provided with a control panel 2, the rear of the control panel 2 is interlocked with the front of the chassis 1 and connected by nut locking, and the sealing connecting plate 3 is welded It is located at the lower right side of the left side of the chassis 1 and is electrically connected to the welding wire tube 4. One end of the welding wire tube 4 is respectively connected to the left and right sides of the welding head 8, and the other end is electrically connected to the chassis 1 through the sealing connecting plate 3. The lifting rod 5 is installed in the middle end of the left side of the chassis 1 and on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com