Novel sealing strip for building

A sealing strip and a new type of technology, applied in the directions of construction, sealing device, building structure, etc., can solve the problems of prefabricated corner and sealing head joint, high cost of prefabricated joint, and small grip of mating parts. Good flexibility, easy to compress and seal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

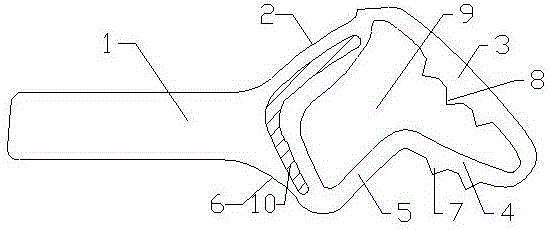

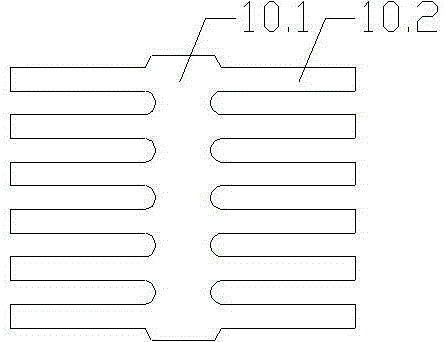

[0023] see Figure 1-2 , a new type of building sealing strip in the present invention includes a transverse section 1, a first inclined section 2, a second inclined section 3, a third inclined section 4, a fourth inclined section 5 and a fifth inclined section 6, the transverse section 1 The right end is connected with the left end of the first oblique section 2, the right end of the first oblique section 2 is connected with the left end of the second oblique section 3, the right end of the second oblique section 3 is connected with the right end of the third oblique section 4, and the third oblique section 4 The left end is connected with the right end of the fourth oblique section 5, the left end of the fourth oblique section 5 is connected with the right end of the fifth oblique section 6, the left end of the fifth oblique section 6 is connected with the right end of the horizontal section 1, the first oblique section 2, the The second inclined section 3 , the third inclin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com