Heat-resisting building sealing strip

A sealing strip and construction technology, which is applied in the direction of construction, building components, sealing devices, etc., can solve the problems of small grip force of fitting parts, water leakage and air leakage, and affect the sealing effect, so as to facilitate compression and sealing, ensure the sealing effect, and improve the grip force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

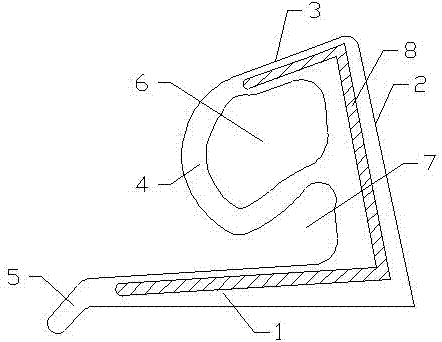

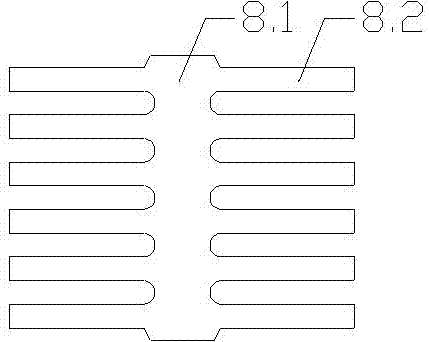

[0022] see Figure 1-2 , a heat-resistant building sealing strip in the present invention includes a transverse section 1, a first inclined section 2, a second inclined section 3 and an arc section 4, the outer side of the transverse section 1 is a straight edge, and the inner side is a hypotenuse, and the The outside of the first oblique section 2 is a straight edge, slanting to the upper left, and the inner side is a curved edge. The outer side of the second oblique section 3 is a straight edge, obliquely to the lower left, and the inner side is a curved edge. The horizontal section 1 and the first school section 2 and the second oblique section 3 are connected end to end, and the left end of the horizontal section 1 is provided with a foot 5, which is convenient for construction personnel to locate during installation. The arc section 4 is located on the inner side of the first oblique section 2, and the arc section 4 One end is connected with the left end of the second obl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com