Wood smashing device for building construction

A technology for building construction and crushing device, which is applied to wood processing appliances, cleaning methods using liquids, manufacturing tools, etc., can solve problems such as influence, poor treatment methods, waste of resources and environment, etc., and achieves wide cleaning area and resource utilization efficiency. high cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

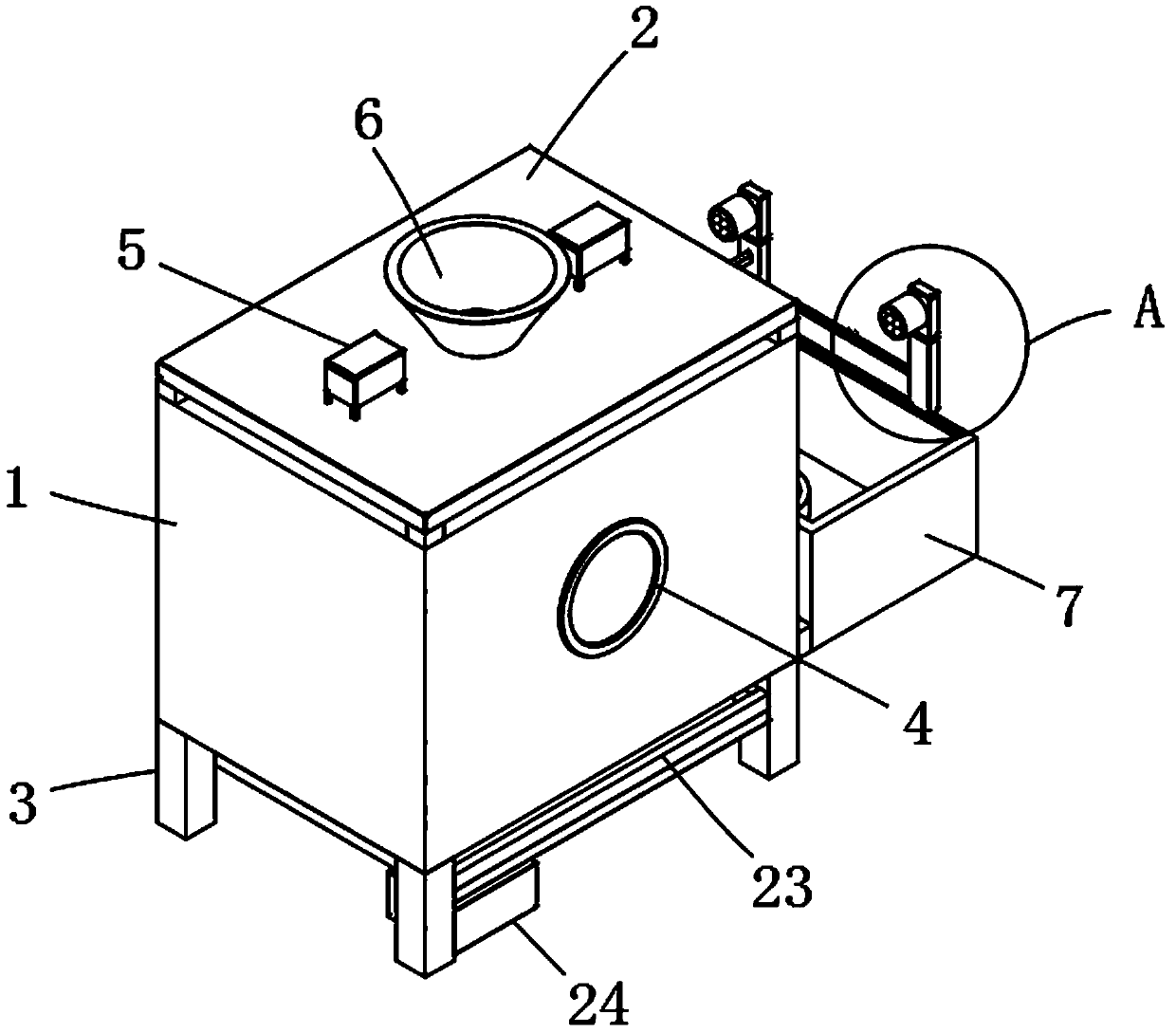

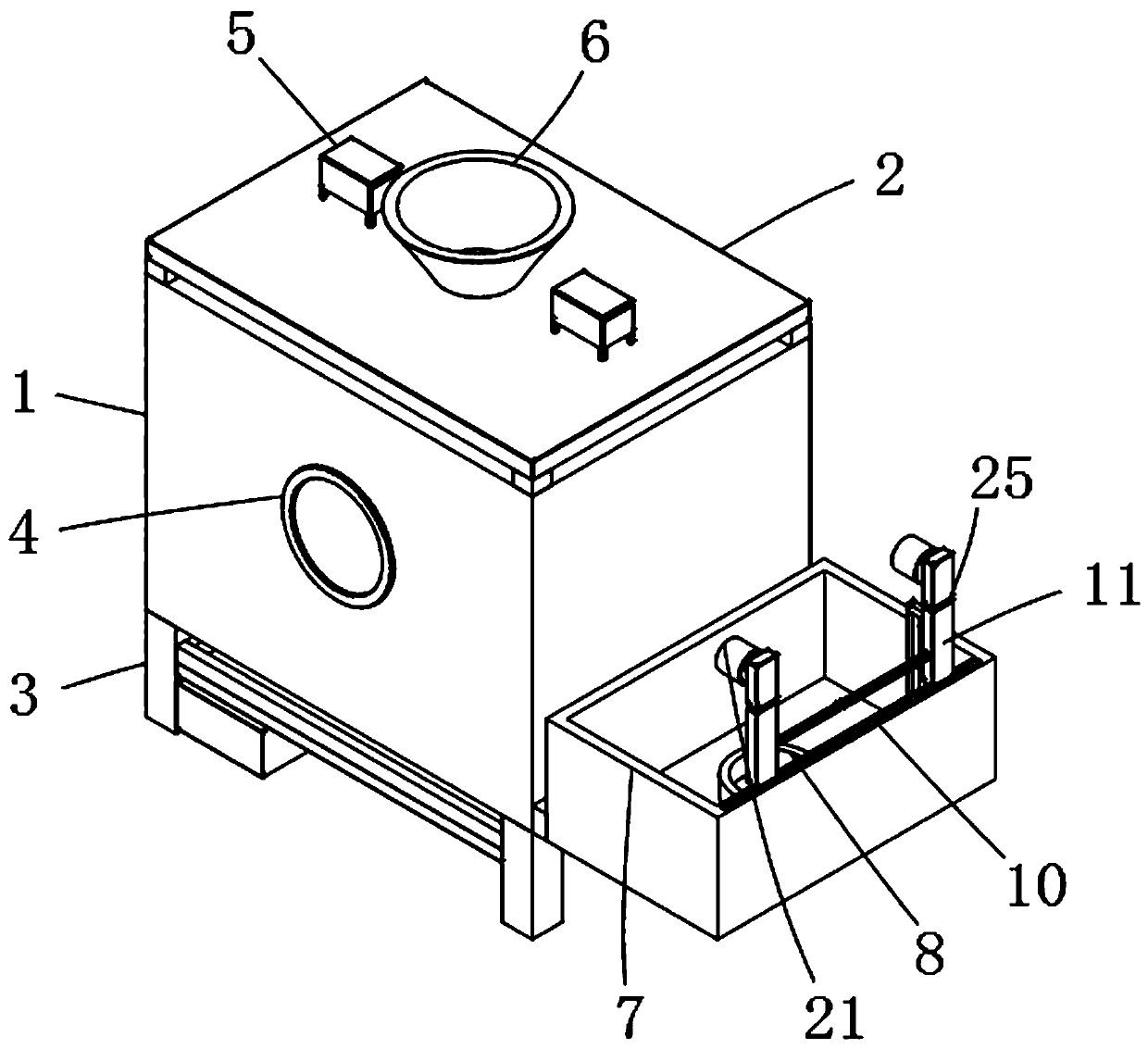

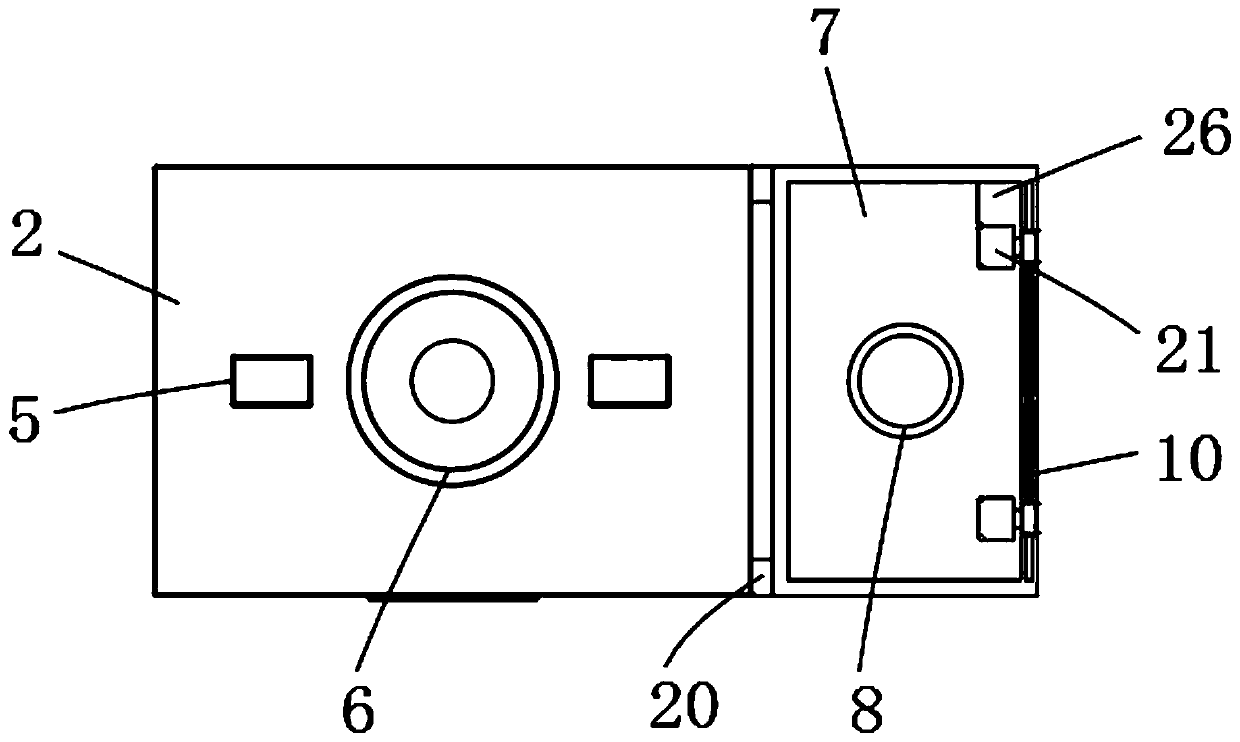

[0029] Please refer to Figure 1-8 Shown: a wood crushing device for building construction, including a box body 1, a cover plate 2 and support legs 3, the cover plate 2 is snap-connected to the upper end of the box body 1, and several support legs are fixedly connected to the bottom end of the box body 1 3. The surface of the box body 1 is provided with a feed port 6, the upper surface of the cover plate 2 is installed with an electric push rod 5, and the inside of the box body 1 is provided with a push plate 9, and the output end of the electric push rod 5 penetrates the cover plate 2 and extends into the box body 1 is connected with the push plate 9 inside, a drive motor 16 is installed at the bottom end of the box body 1, a drive shaft 17 is connected to the output end of the drive motor 16, a crushing rod 19 is arranged at the bottom end inside the box body 1, and a first A telescopic shaft 18, the crushing rod 19 is connected with the first telescopic shaft 18, the drivi...

Embodiment 2

[0031] Please refer to Figure 1-8Shown: cleaning tank 7 interior is provided with water pump 26, and the output end of water pump 26 is connected with guide tube 13, and guide rod 11 is connected with guide tube 13, utilizes water pump 26 to guide the cleaning water source of timber through guide tube 13 to The guide rod 11 is guided by the guide rod 11 to the spray nozzle 21 for spraying. The guide rod 11 is provided with two groups, and a shunt pipe 14 is connected between the two groups of guide rods 11. Spray cleaning efficiency, the observation port 4 is provided on one side of the box body 1, which is convenient for instant observation of the processing state of the wood, and the use of the lifting device is controllable. A fixed block 20 is connected between the box body 1 and the cleaning tank 7. The block 20 is connected and fixed, and the use stability is stronger. One end of the guide rod 11 is connected with a second telescopic shaft 25, which is convenient for ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com