Preparing method of slub AB yarn

A slub and snowflake technology, applied in yarn, textile and paper making, etc., can solve the problems of high cost of dyeing and chemical materials, more industrial sewage, and more cotton per ton of yarn, and achieve rich color changes, small sewage, and economical consumption. water saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

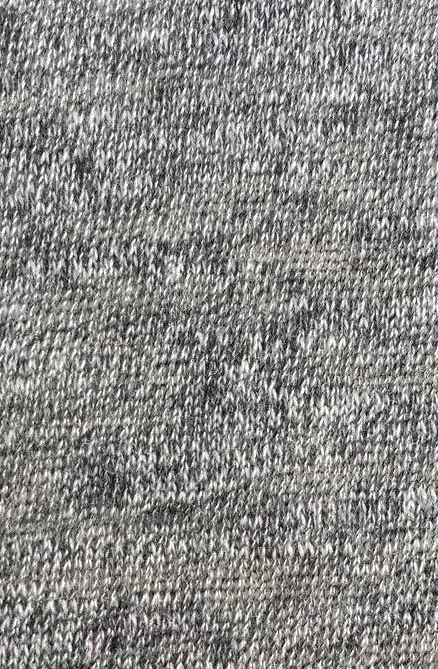

Image

Examples

Embodiment 1

[0036] Example 1 A production method of snowflake slub AB composite yarn

[0037] The production method of this kind of snowflake slub AB composite yarn, A roving raw material (cotton / viscose) and B roving raw material (colored polyester), are respectively separately and sequentially processed through opening and cleaning, carding, drawing and roving, and are separately made After roving, the two strands of A roving and B roving enter the spun yarn drafting area through the single eye bell mouth.

[0038] The production method of the snowflake slub AB composite yarn,

[0039] Include the following steps:

[0040] 1. Prepare A roving

[0041] 1. Select A roving raw material

[0042] The A roving raw material: cotton / viscose, cotton length 25mm, micronaire value 4.66, short fiber rate 25.3%, moisture regain 6.93%;

[0043] 2. Adopt the cleaning and carding process

[0044] Blowing: Beater speed is 480r / min, the distance between the dust bar and the dust bar is adjusted to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com