Fly sewing machine

A technology for sewing machines and fabrics, which is applied in the direction of sewing machine components, cloth feeding mechanisms, sewing equipment, etc., which can solve problems such as the inability to sew the fabric and unstable conveying of the fabric, and achieve the effect of stable conveying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

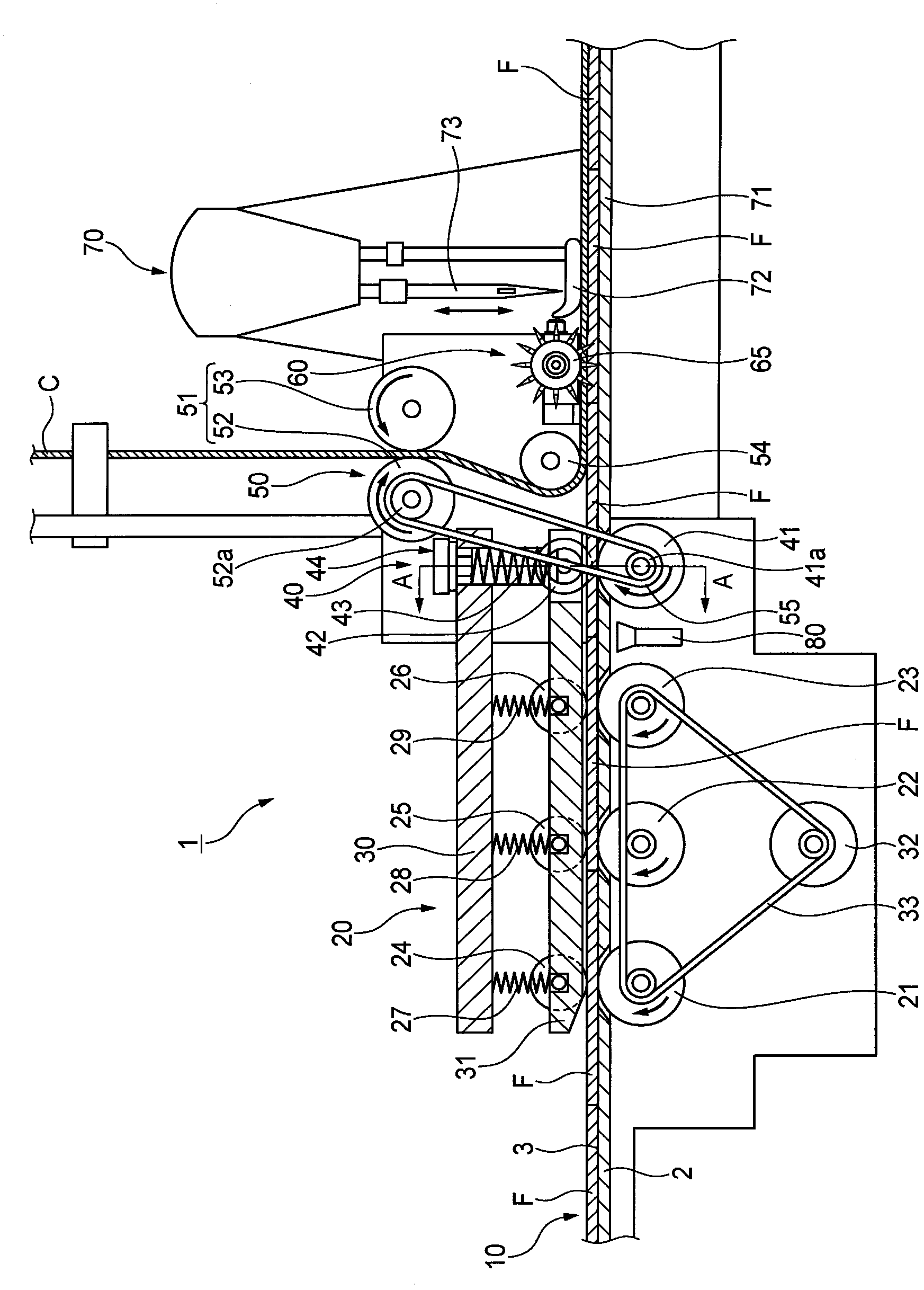

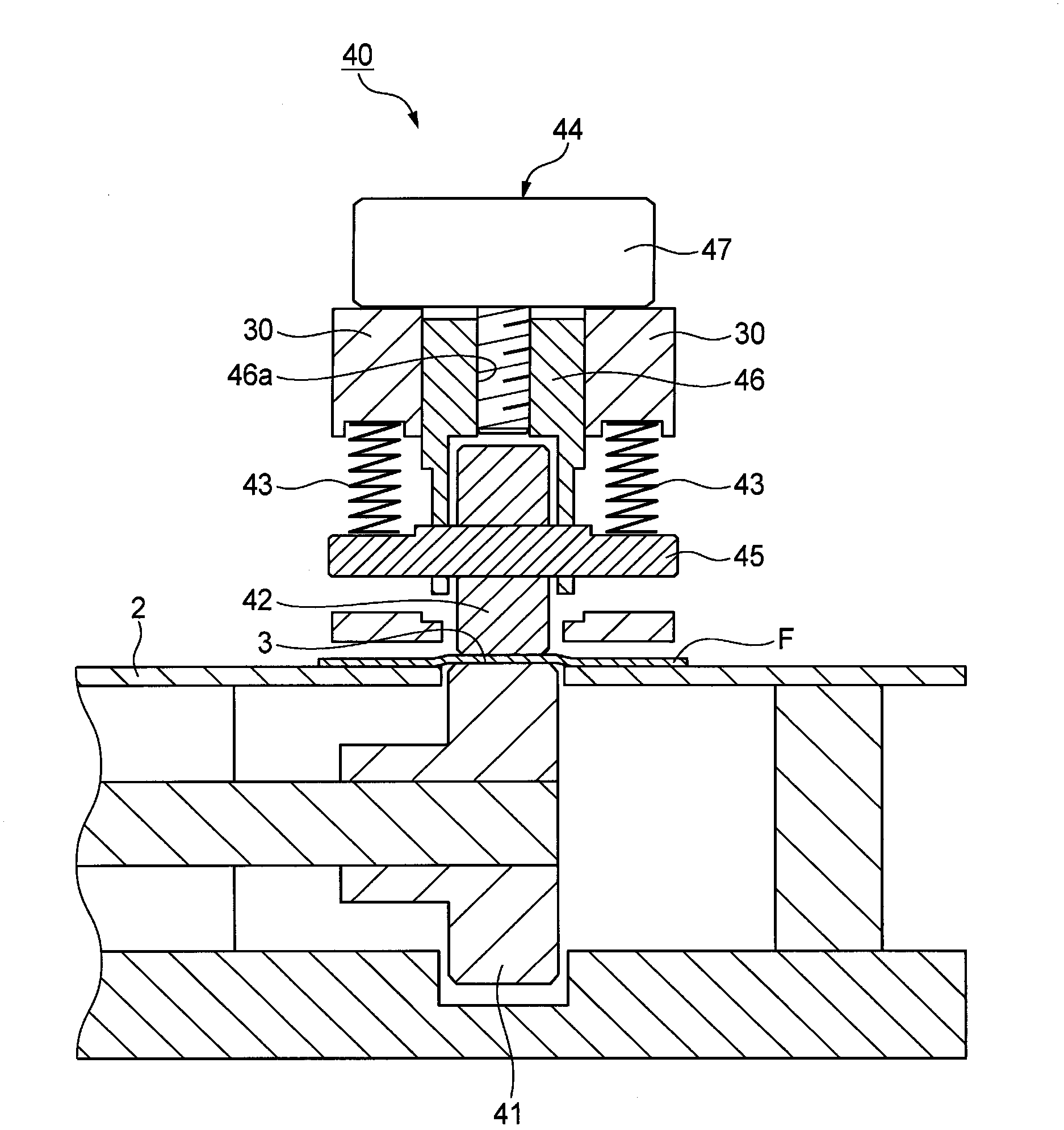

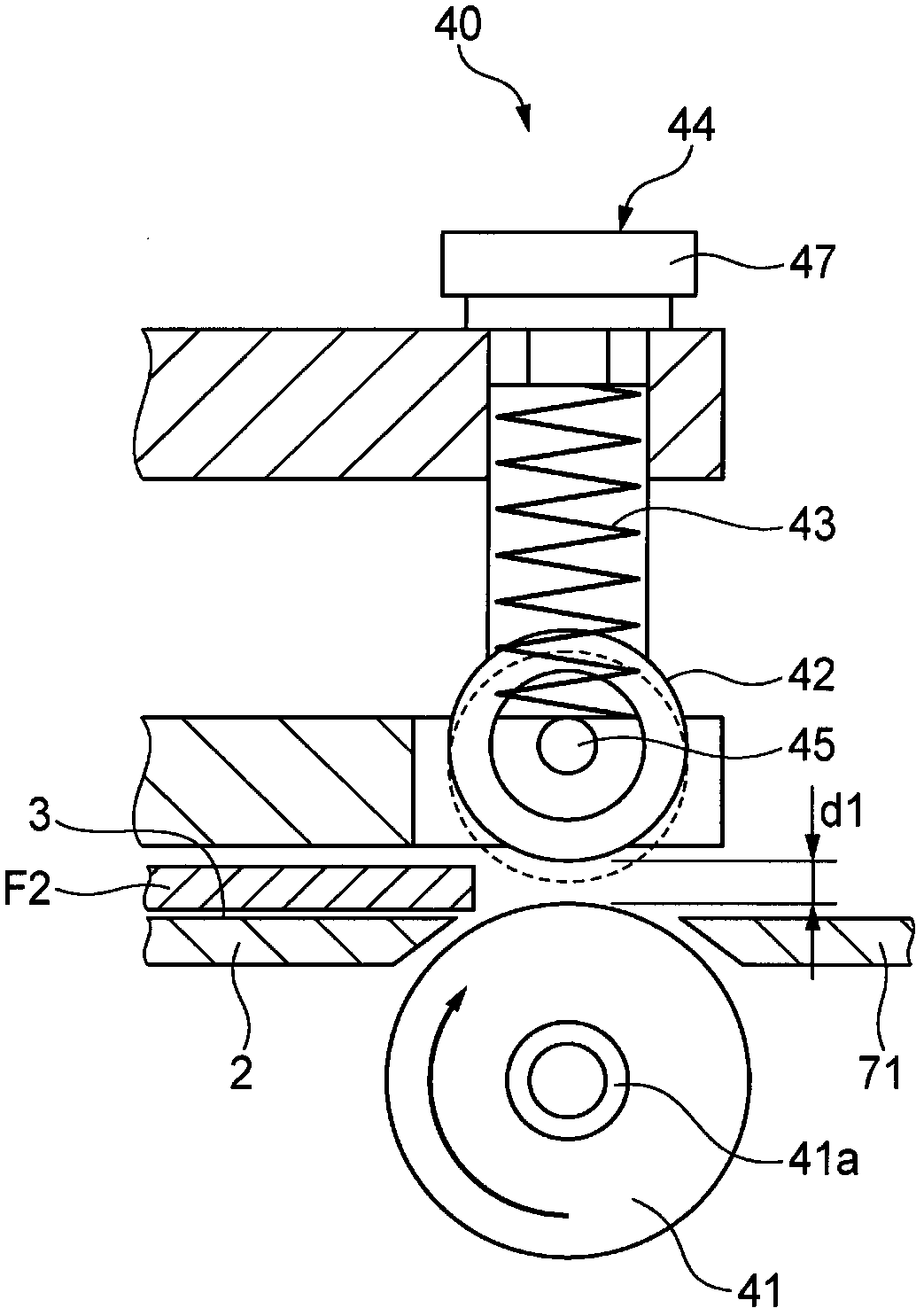

[0028] Hereinafter, one embodiment of the fly sewing machine of the present invention will be described in detail based on the drawings.

[0029] Such as figure 1 As shown, the fly sewing machine 1 of this embodiment has: a stand 2 on which a fly transfer path 3 for transferring the fly F is provided; In the transfer path 3; the fly transfer part 20 is arranged on the downstream side of the fly supply part 10, and the fly F replenished from the fly supply part 10 is sent to the downstream side; the long chain feed part 50 is arranged on the fly On the downstream side of the cloth transfer unit 20, the zipper chain C is fed onto the fly F sent out from the fly transfer unit 20; The overlapping fly F and the long zipper chain C in the long chain feeding part 50 are pressed and conveyed downstream; and the sewing part 7 is arranged on the downstream side of the auxiliary conveying part 60 and sews the fly F to the long zipper chain. on C.

[0030] The fly supply part 10 is com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com