A kind of oil pipe remote control transfer machine

A transfer machine and oil pipe technology, applied in the direction of drill pipe, casing, drill pipe, etc., can solve the problems of frame shaking and instability, unsuitable for automatic lifting and lowering of oil pipe, etc., to reduce labor intensity, improve construction safety, prevent Accidental slip effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0080] In order to make the purpose, technical solution and advantages of the present invention clearer, the implementation manners of the present invention will be further described in detail below.

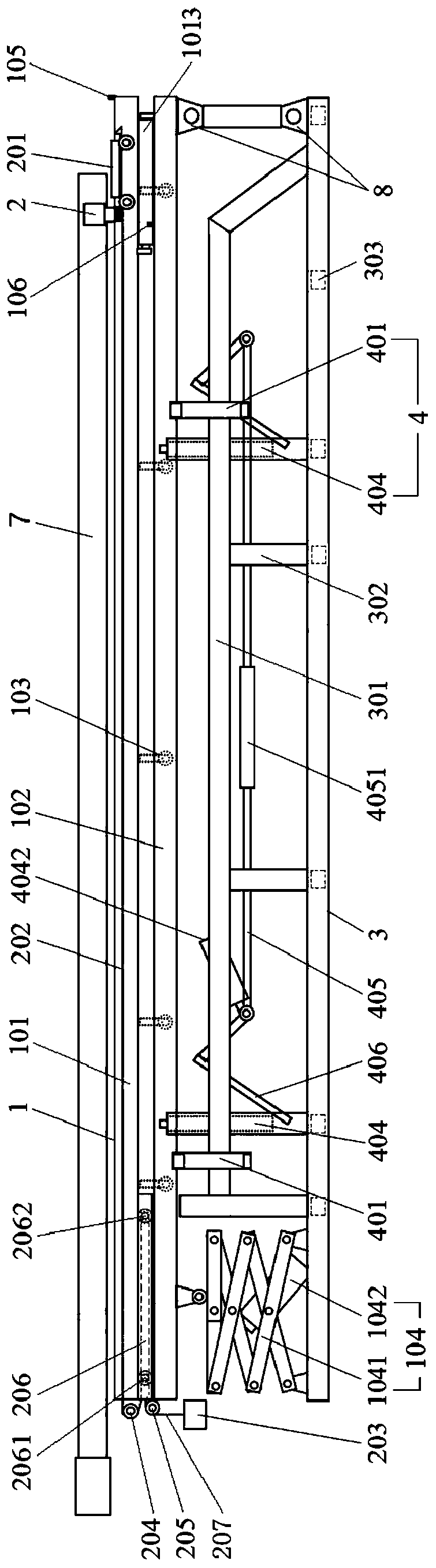

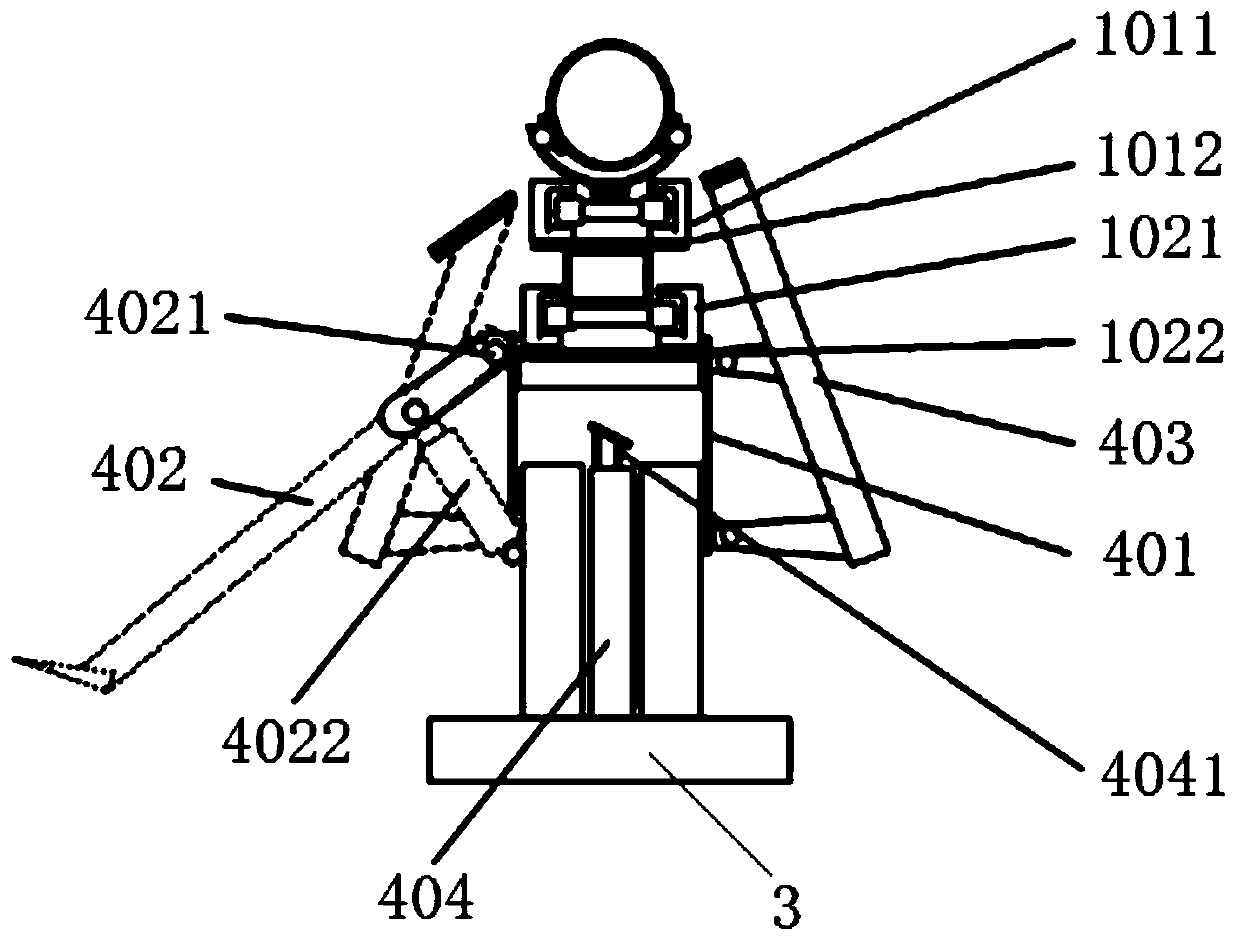

[0081] The embodiment of the present invention provides a remote control oil pipe transfer machine, as shown in the attached Figure 1-4 As shown, the transfer machine includes: a slideway assembly 1, an automatic return tackle 2, a main frame 3, a pick-and-place tube mechanism 4, an electronically controlled hydraulic device 5 and a hand-held remote controller 6.

[0082] Wherein, the slideway assembly 1 includes: a slideway 101 , a supporting guide rail 102 , a slideway roller 103 and a lift 104 . The slideway 101 includes: two slideway channel steels 1011 arranged symmetrically from left to right and a plurality of slideway connecting steel plates 1012 . The grooves of the slideway channel steel 1011 are arranged oppositely, and the bottom is welded together by the slideway ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com