Separation blade mechanism of capsule coffee maker

A technology for coffee machines and capsules, applied in the field of baffle mechanism, can solve problems such as limited selection of appliances and complex structure, and achieve the effects of reduced structural requirements, increased contact area, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

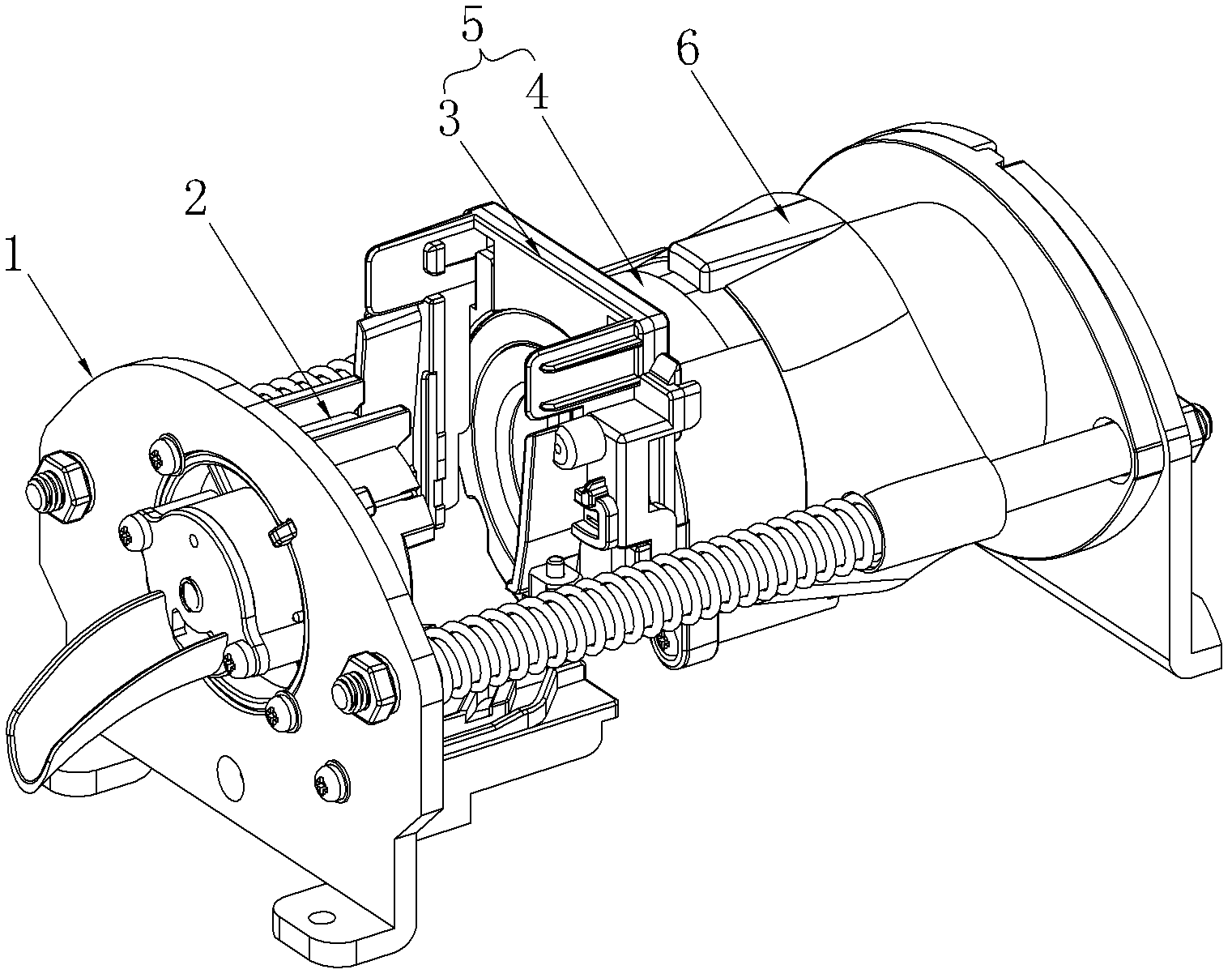

[0020] refer to figure 1 , the capsule brewing device of the capsule coffee machine, including a frame 1, a brewing part 5, a driving part 6, and a brewing chamber 2 that cooperates with the brewing part 5 to complete coffee brewing. The brewing part 5 includes a shutter mechanism 3 and a brewing mechanism 4.

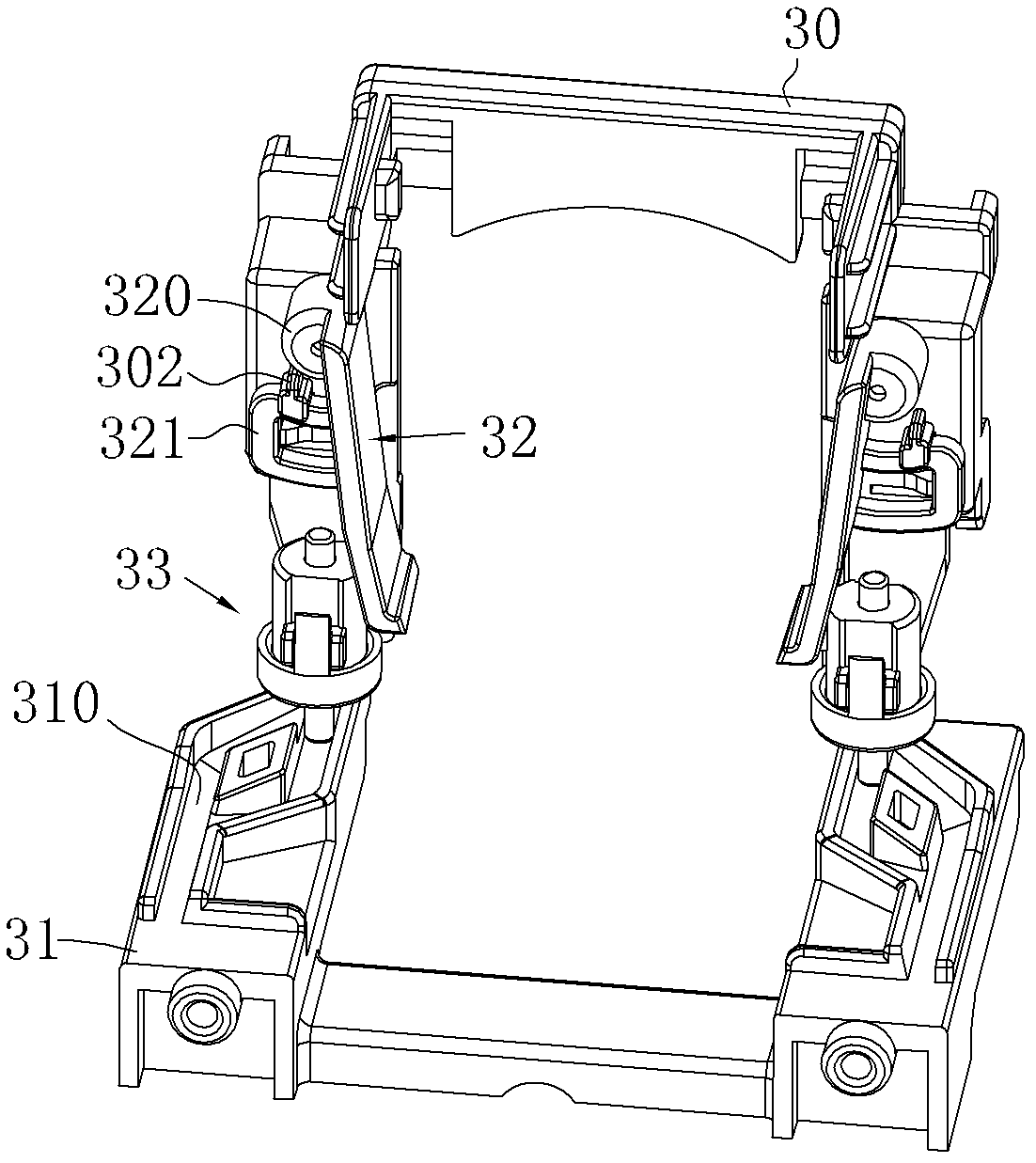

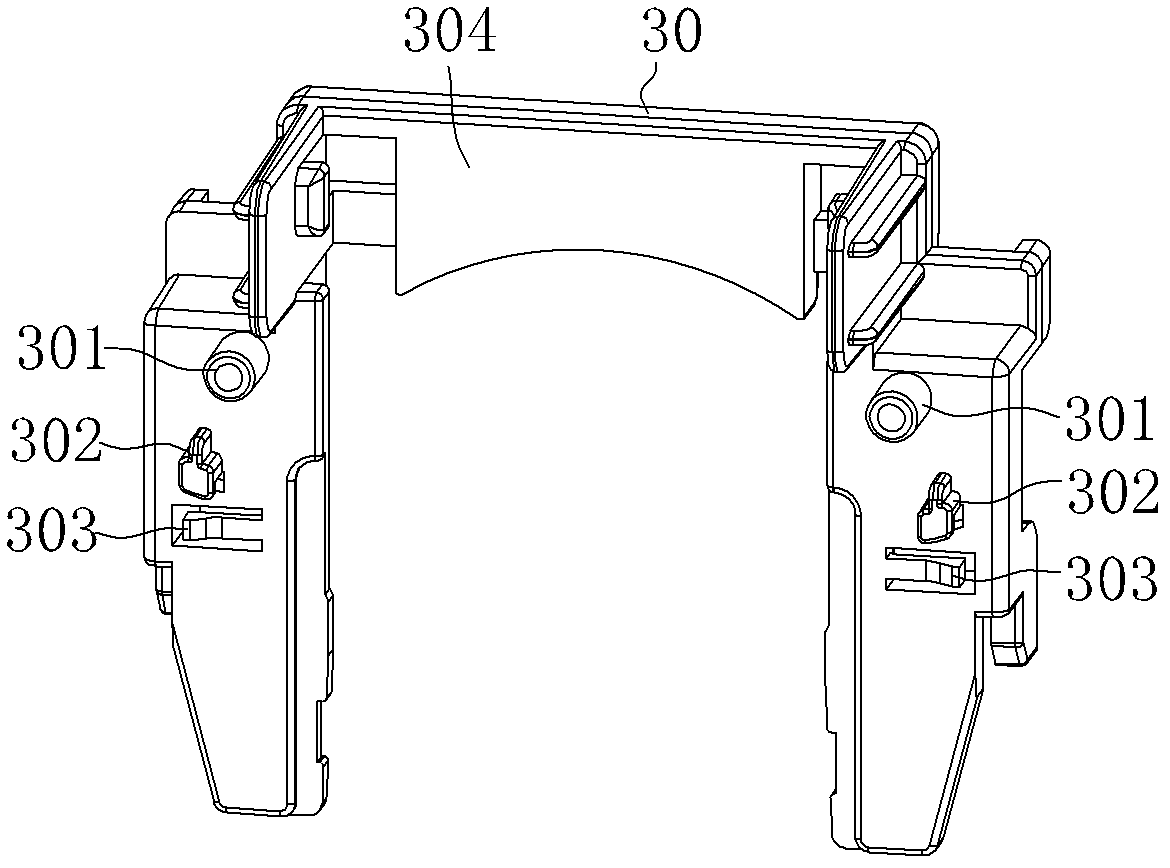

[0021] refer to image 3 The blocking mechanism 3 includes an introduction frame 30 and a blocking plate 32. The top of the introduction frame 30 is provided with an inlet 304, and the coffee capsule enters the blocking mechanism 3 from the inlet 304. Both sides of the introduction frame 30 are respectively provided with convex pins 301 for use. To rotate the connecting catch 32. In this embodiment, the catch mechanism 3 also includes a guide rail 31, and the lower end of the catch is slidably connected to the guide rail through a sliding needle assembly 33. Specifically, a slide groove 310 is designed on the guide rail 31, and the slide groove 310 is designed to be in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com