Hydro bush

A technology of hydraulic bushings and liquid chambers, applied in liquid shock absorbers, elastic suspensions, cantilevers mounted on pivots, etc., can solve the problems of hydraulic bushing 2 functional limitations and the inability to ensure the length of flow path 52, etc. To achieve the effect of increasing the flow distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] A preferred embodiment of an embodiment of the present invention will be described in detail below with reference to the accompanying drawings. When describing the present invention, if the specific description of related known technologies makes the gist of the present invention obscure, the description will be omitted. In addition, the following terms are defined according to the functions in the present invention, and are slightly different from the intentions or usage habits of designers and manufacturers. Therefore, these terms must be defined based on the entire content of this specification. Parts denoted by the same drawing number (reference number) in the specification denote the same component

[0035] A hydraulic bush 1 of a preferred embodiment of the present invention is described below.

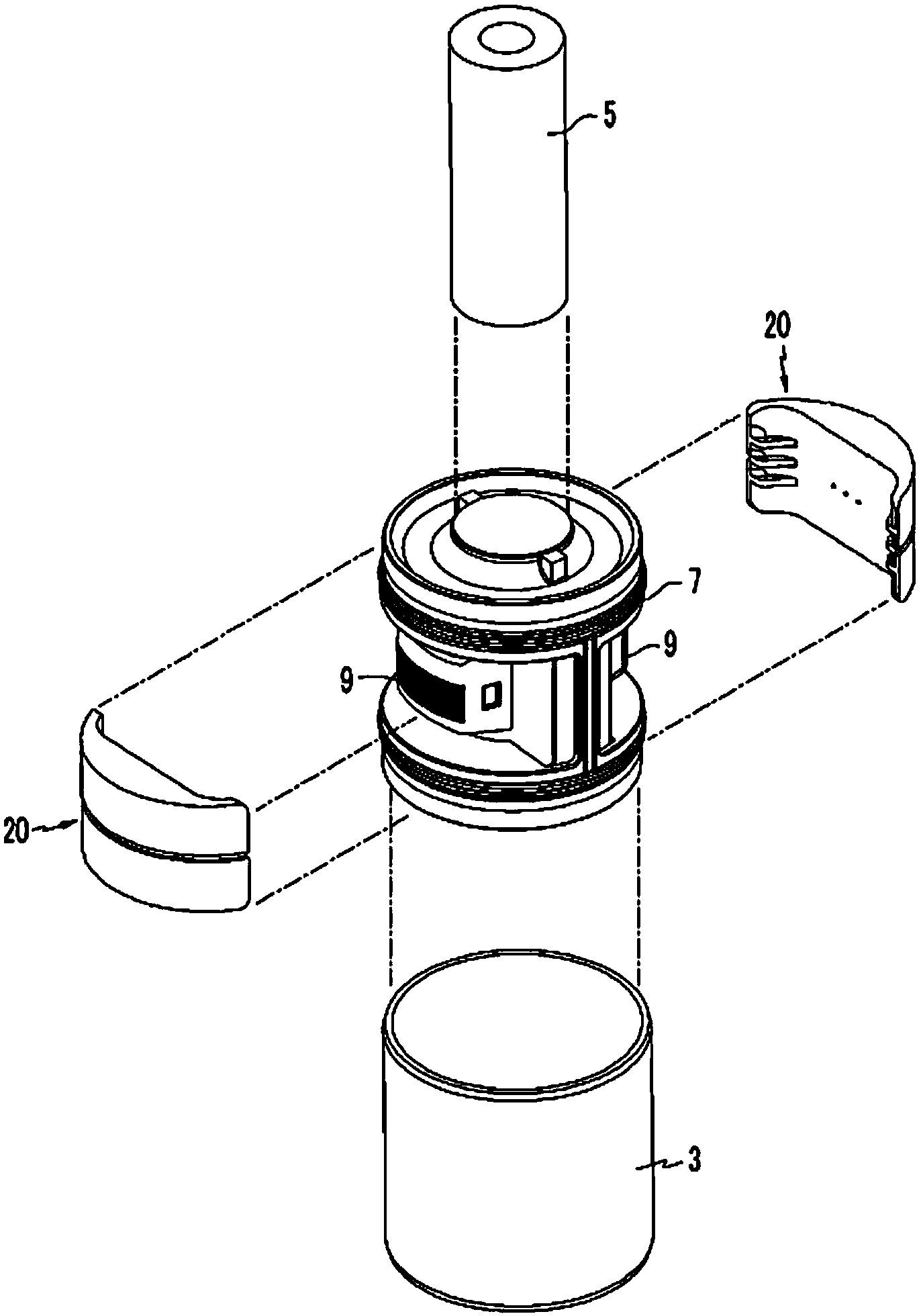

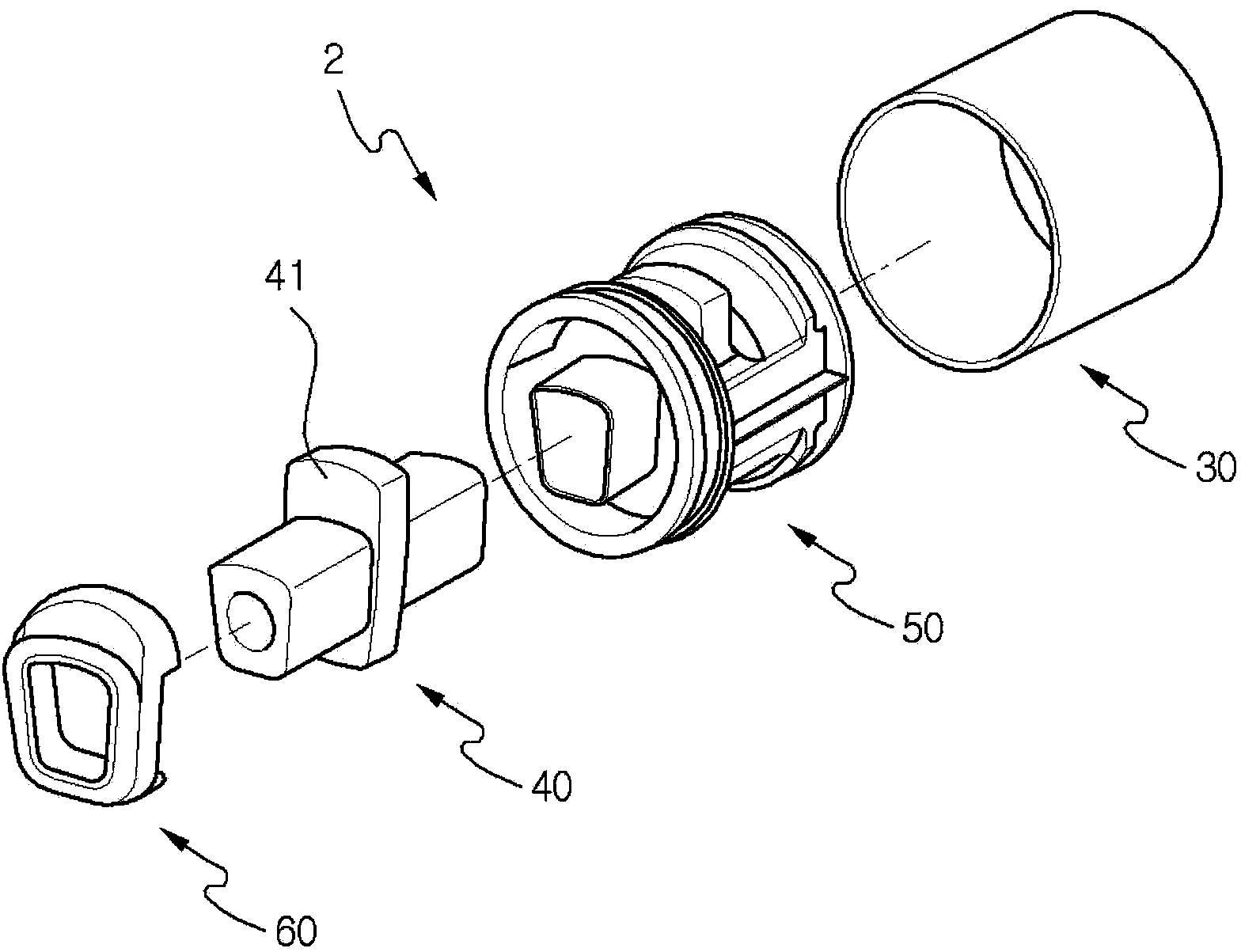

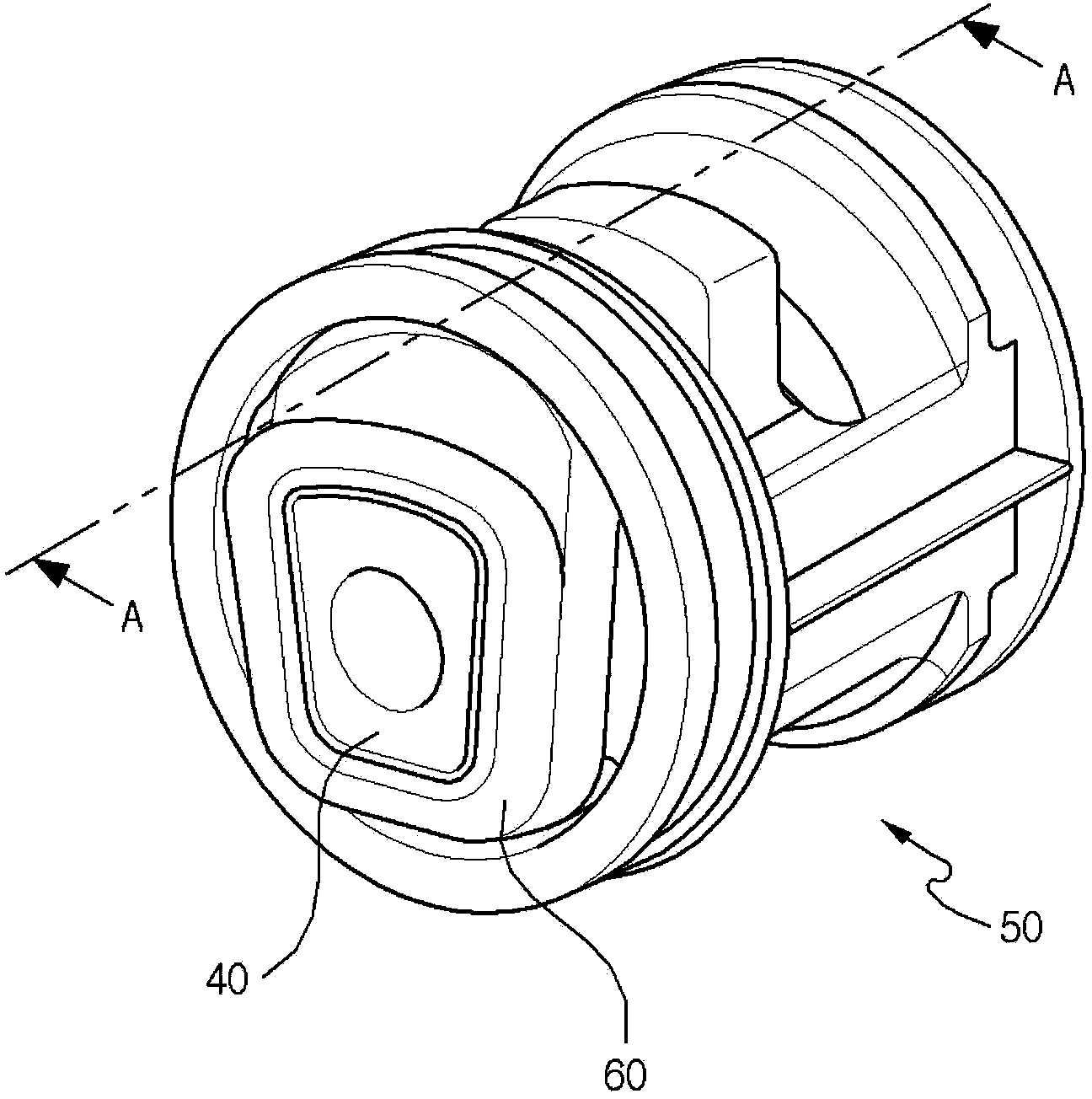

[0036] according to Figure 6 and Figure 7 , the hydraulic bushing 1 includes an outer tube 100, an inner tube 200 having a plunger 210 protruding from one side of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com