Exhaust system for combustion engine, combustion engine and transportion means

An exhaust system, internal combustion engine technology, applied in gas passages, exhaust devices, machines/engines, etc., can solve problems such as improving exhaust gas resistance and fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

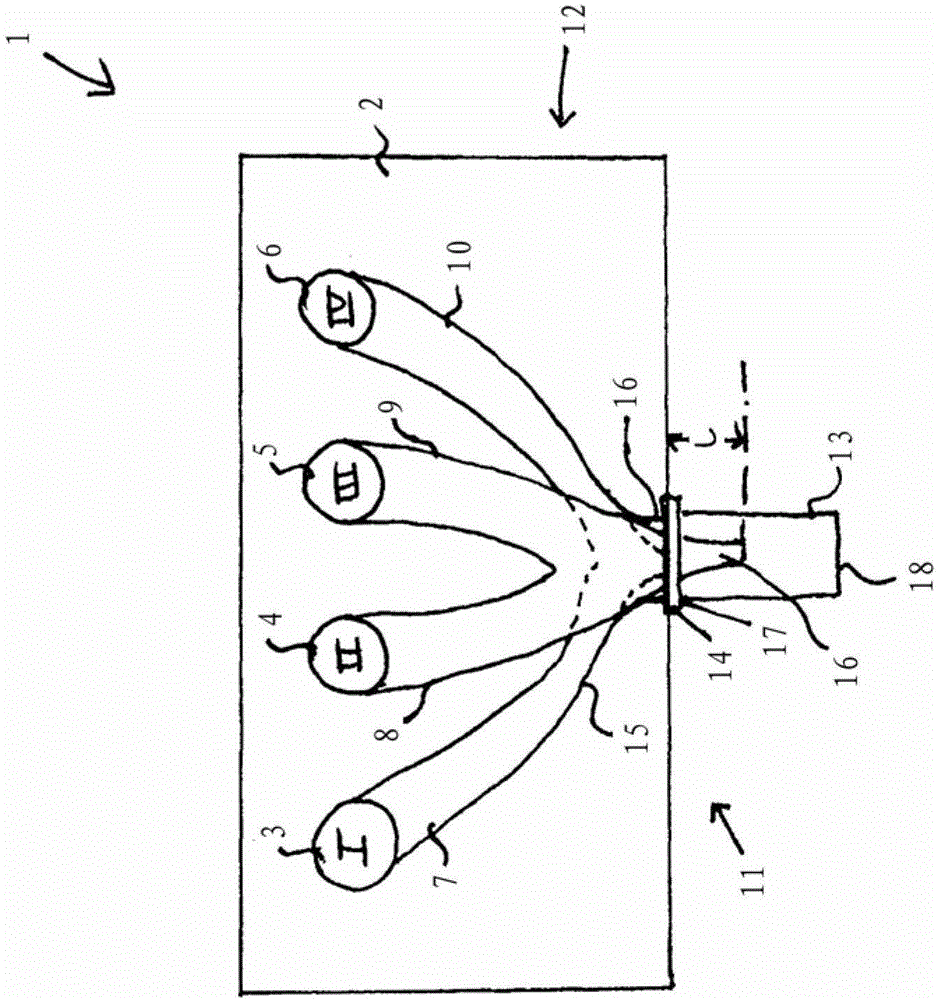

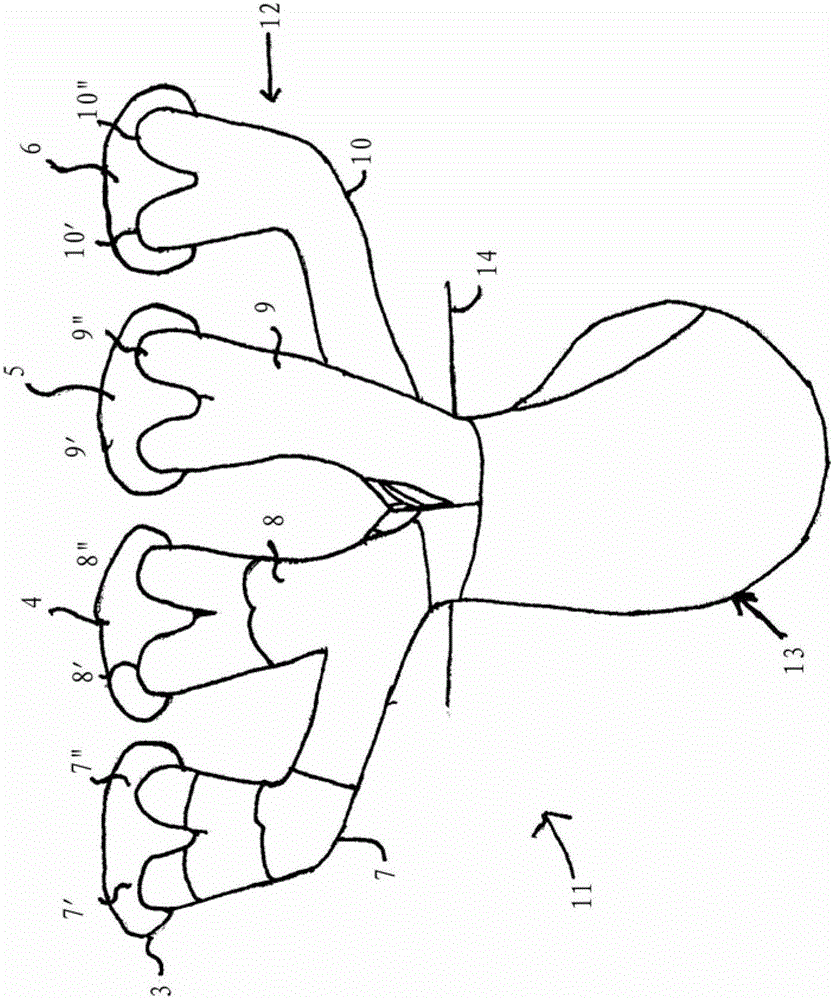

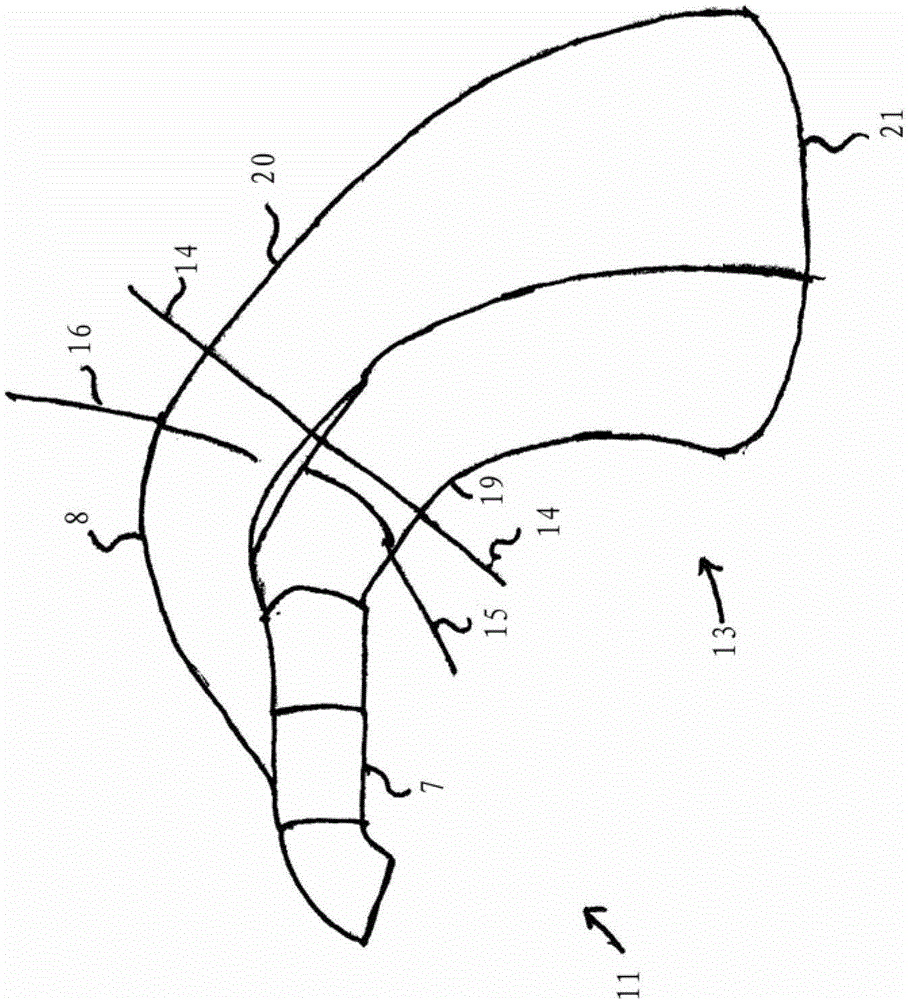

[0037] figure 1 A schematic plan view of the internal combustion engine 1 according to the first exemplary embodiment is shown. The internal combustion engine 1 has a cylinder head 2, in figure 1 Not shown in the engine block and the 4 cylinders 3, 4, 5, 6, which form the combustion chambers.

[0038] The four cylinders 3, 4, 5, 6 are respectively connected to the flow passages 7, 8, 9, 10 of the exhaust system 11 of the internal combustion engine 1, through which the exhaust gas produced by the combustion reaction in the cylinders passes. leads to figure 1 Catalyst not shown. The flow channels 7 , 8 , 9 , 10 are integrated in the cylinder head 2 and form part of an exhaust manifold 12 integrated in the cylinder head 2 . However, the exhaust system according to the invention is not restricted to internal combustion engines with 4 cylinders, but can also be used in internal combustion engines with fewer or more than 4 cylinders.

[0039] The exhaust system 11 has, in addit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com