Metallurgical boiler tail gas purification treatment device

A tail gas purification and treatment device technology, applied in the direction of climate sustainability, reduction of greenhouse gases, chemical instruments and methods, etc., can solve the problems of short contact time between flue gas and liquid, insufficient contact with liquid, residual harmful gas, etc. Achieve better absorption effect, less water content, and avoid secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

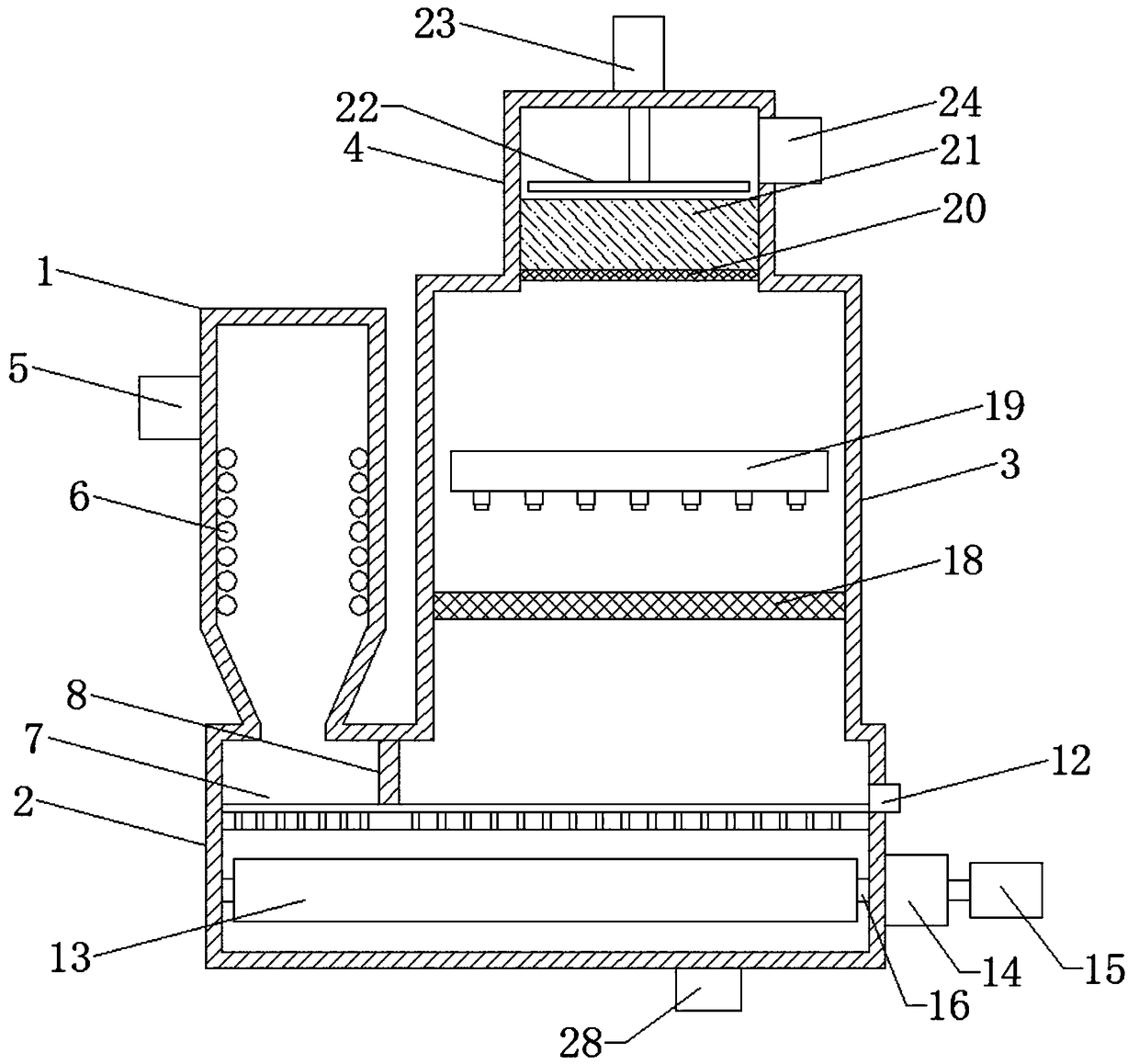

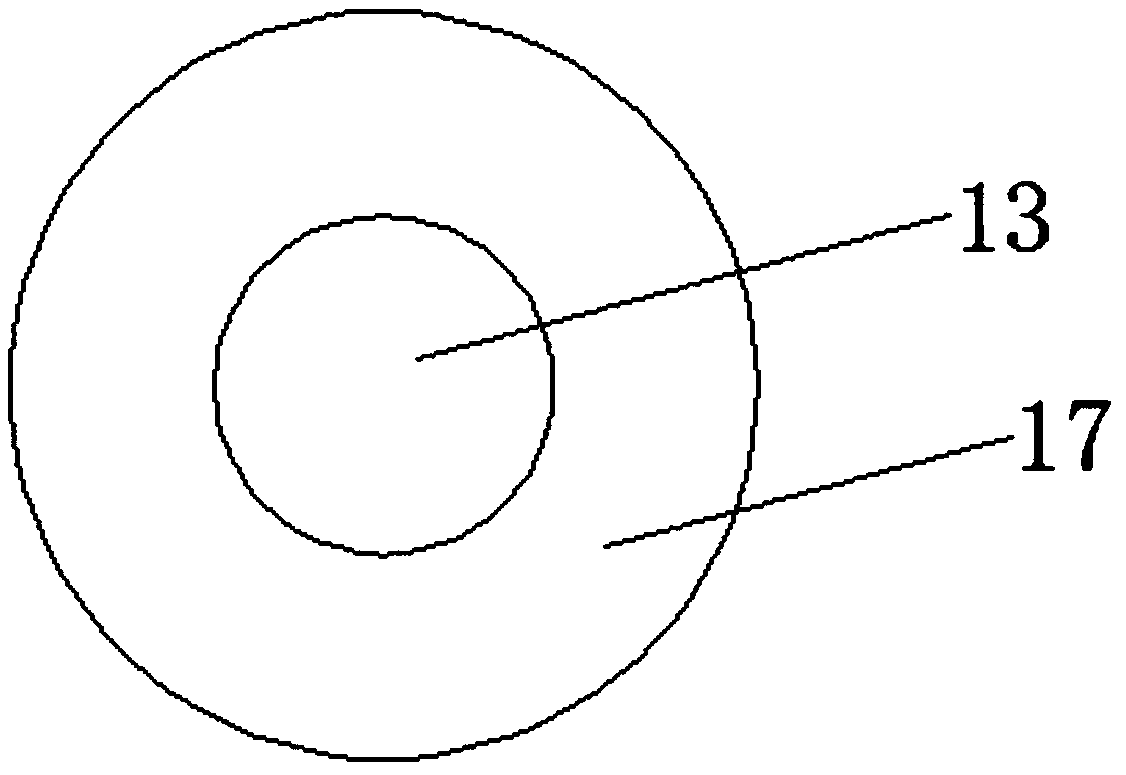

[0019] Please refer to the figure, in the embodiment of the present invention, a metallurgical boiler tail gas purification treatment device includes a heat exchange box 1, a contact box 2, a spray box 3, a dehumidification box 4 and a smoke inlet pipe 5; the heat exchange box 1 and The spray boxes 3 are arranged side by side on the contact box 2, and communicate with the upper sides of the two ends of the contact box 2 respectively; the heat exchange box 1 is connected with a smoke inlet pipe 5, and the boiler flue gas is sent into the heat exchange box 1 A heat exchange tube 6 is coiled on the inner wall of the heat exchange box 1, and flowing cooling water is passed into the heat exchange tube 6 to absorb and take away the heat in the flue gas to reduce the temperature of the flue gas.

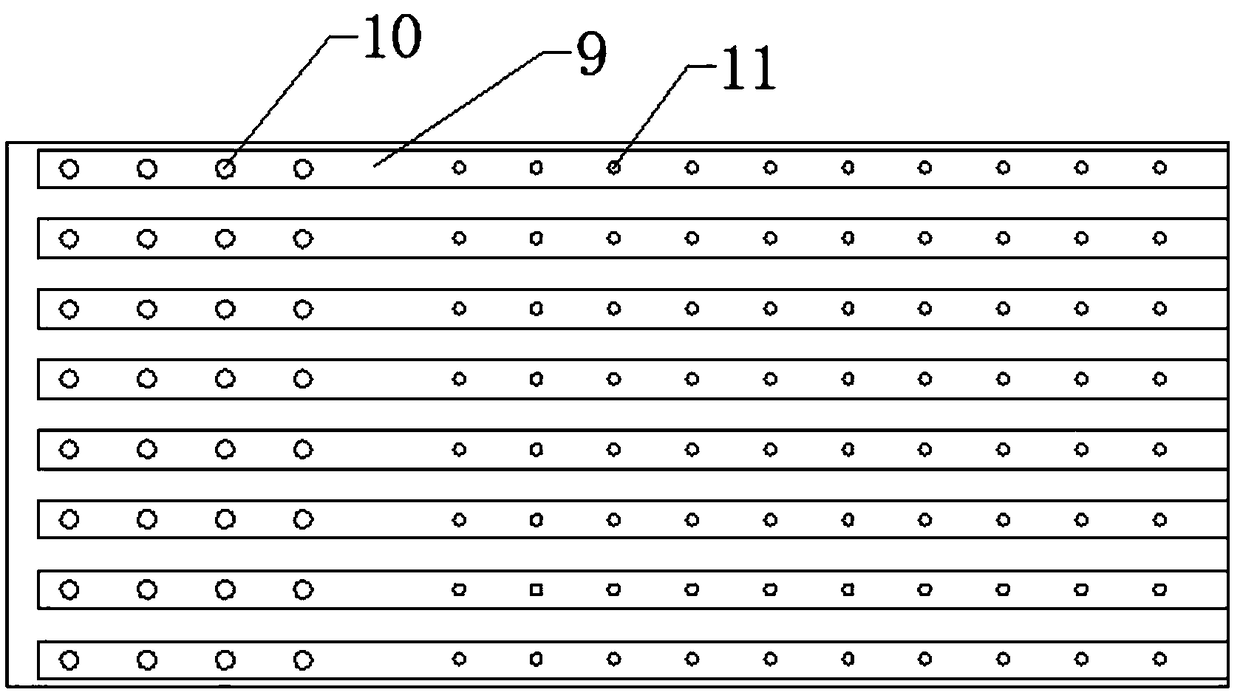

[0020] A horizontal spoiler 7 is arranged in the contact box 2, and the spoiler 7 divides the contact box 2 into upper and lower parts, on the upper surface of the spoiler 7 and between the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com