Cooker hood

The technology of a range hood and an upper body is applied in the field of double-winder range hoods, which can solve the problems of blocked air movement, waste of packaging space, and reduced air intake and exhaust volume, etc., and achieves a reduction in packaging volume, cost, and simple packaging structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

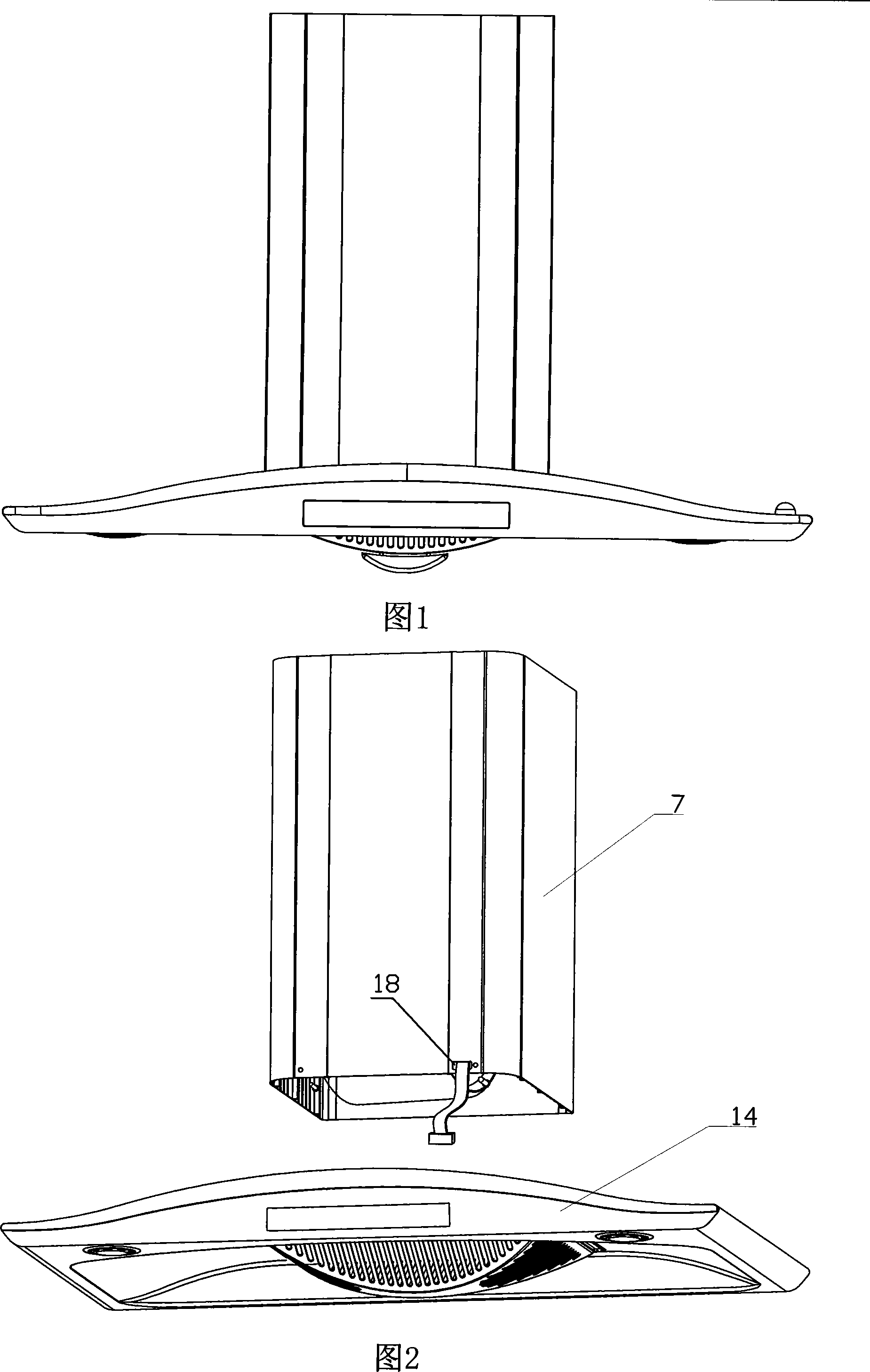

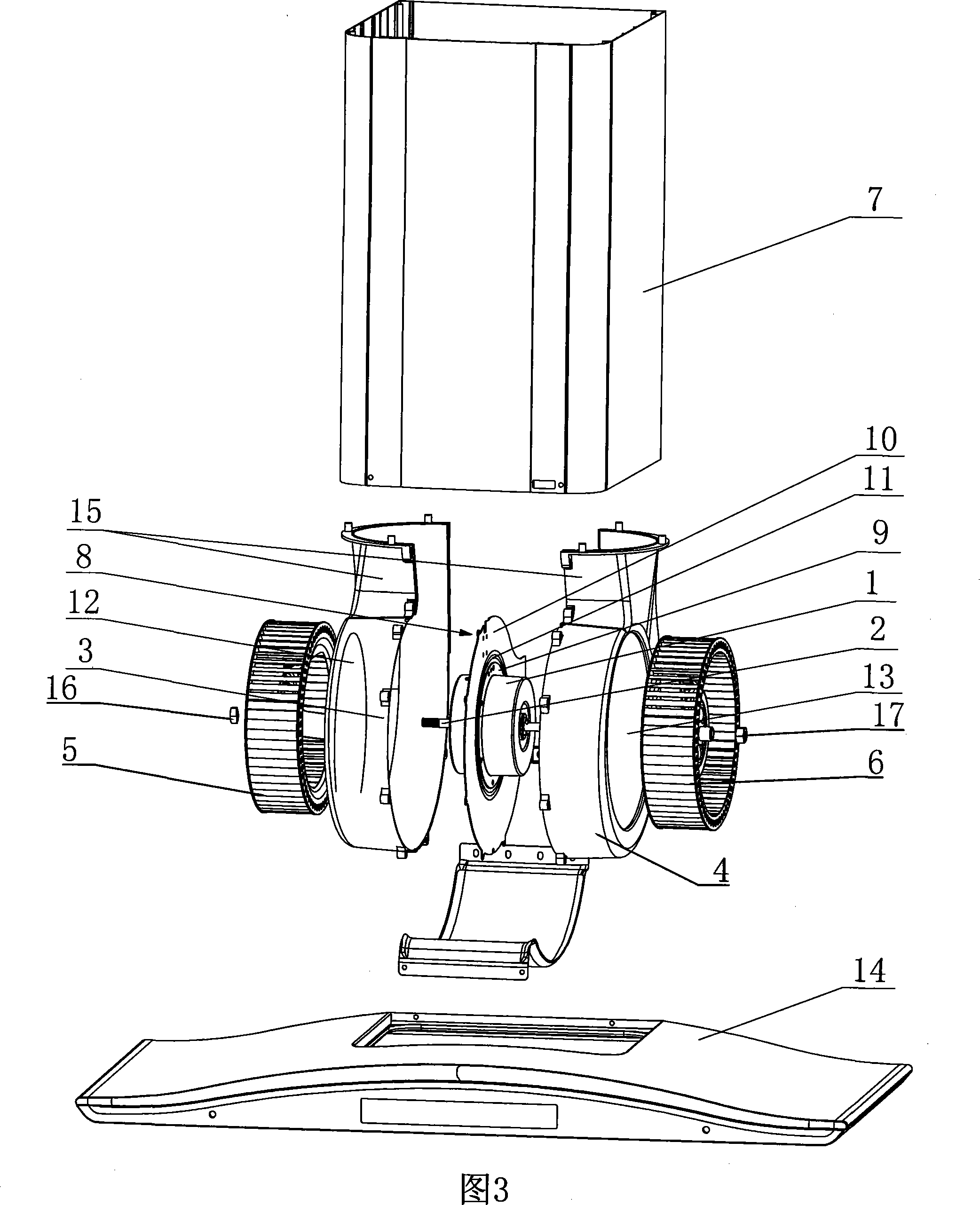

[0017] Now set forth the utility model in detail in conjunction with accompanying drawing:

[0018] As shown in accompanying drawings 1 and 4, the range hood includes a motor 1, a rotor shaft 2 mounted on the motor 1, left and right volutes 3, 4, left and right wind wheels 5, 6 and a bellows 7, An anti-vibration fixed ring 8 is arranged between the motor 1 and the left and right volutes 3 and 4. The anti-vibration fixed ring 8 is composed of an inner ring 9, an outer ring 10 and an anti-vibration elastic ring 11, and the anti-vibration elastic ring 11 is arranged on the inner ring 9 and the outer ring 10, the rotor shaft 2 of the motor 1 extends to both sides of the motor 1, and the left and right wind wheels 5 and 6 are fixed on the left and right ends of the rotor shaft 2, and the left and right volutes 3.4 The outer ring 10 in the anti-vibration fixing ring 8 is movably connected between the joint surfaces, and the volute is made of plastics, which avoids the use of metal m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com