LED packaging structure and manufacturing method

A technology for LED packaging and manufacturing methods, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems affecting the reliability of the electrical connection between the chip and the substrate, poor contact, manufacturing bottlenecks, etc., to achieve convenient operation, improve precision, and reduce manufacturing. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

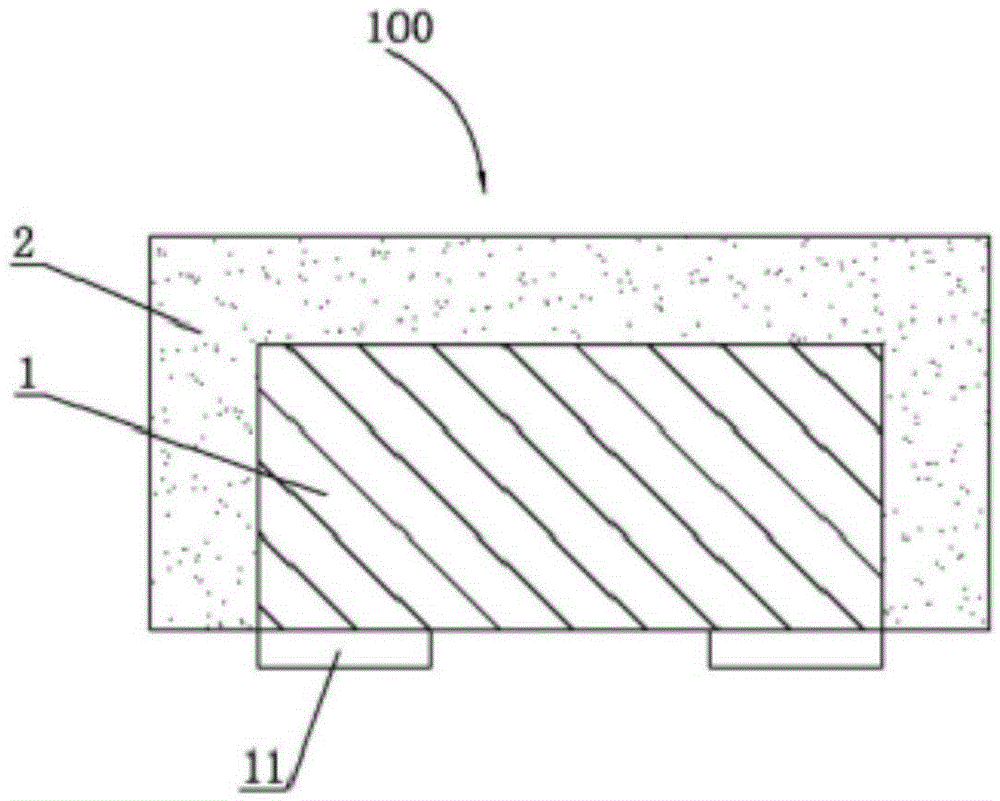

[0059] Such as figure 1 As shown, the LED packaging structure 100 includes a flip chip 1, the flip chip 1 includes a flip chip body and an electrode 11, the electrode 11 is arranged at the bottom of the flip chip body, and the electrode 11 protrudes from the bottom surface of the flip chip body. The side surface and the top surface of the flip chip body are coated with encapsulation glue 2, and the encapsulation glue 2 is fluorescent glue. The lower surface of the encapsulant 2 is higher than the lower surface of the electrode 11 . In this embodiment, the lower surface of the encapsulant 2 is flush with the lower surface of the flip chip body.

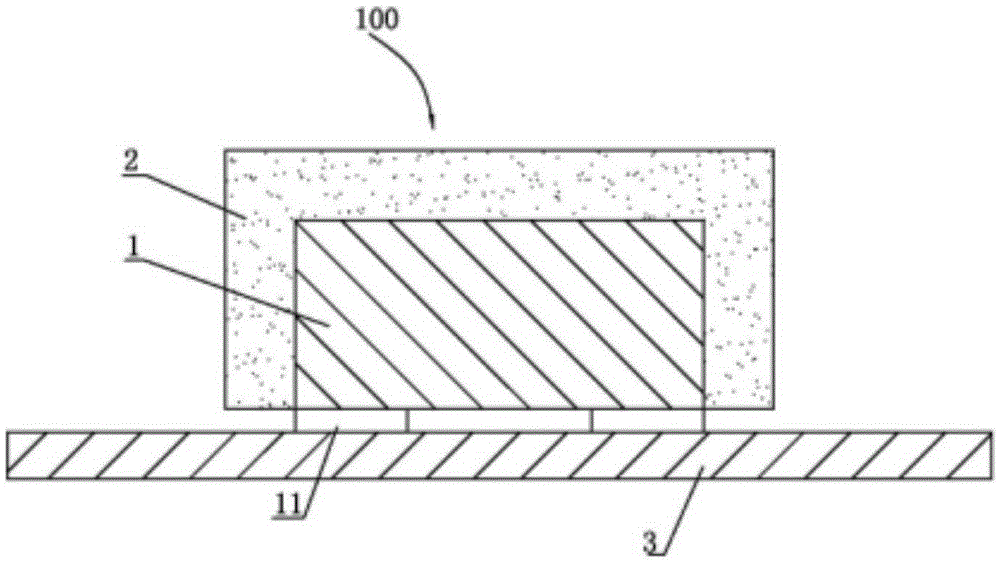

[0060] Such as figure 2 As shown, since the lower surface of the encapsulant 2 is higher than the lower surface of the electrode 11, in the process of fixing the LED package structure 100 to the substrate 3, a space is formed between the lower surface of the encapsulant 2 and the substrate 3, so even if the encapsulation The glue 2...

Embodiment 2

[0062] Such as figure 2 As shown, the LED device includes an LED packaging structure 100 and a substrate 3 .

[0063] The LED packaging structure 100 includes a flip chip 1, the flip chip 1 includes a flip chip body and electrodes 11, the electrodes 11 are arranged at the bottom of the flip chip body, and the electrodes 11 protrude from the bottom surface of the flip chip body. The side surface and the top surface of the flip chip body are coated with encapsulation glue 2, and the encapsulation glue 2 is fluorescent glue. The lower surface of the encapsulant 2 is higher than the lower surface of the electrode 11 . In this embodiment, the lower surface of the encapsulant 2 is flush with the lower surface of the flip chip body.

[0064] Such as figure 2 As shown, since the lower surface of the encapsulant 2 is higher than the lower surface of the electrode 11, in the process of fixing the LED package structure 100 to the substrate 3, a space is formed between the lower surf...

Embodiment 3

[0066] The method for manufacturing the LED package structure of the above-mentioned embodiment 1 is:

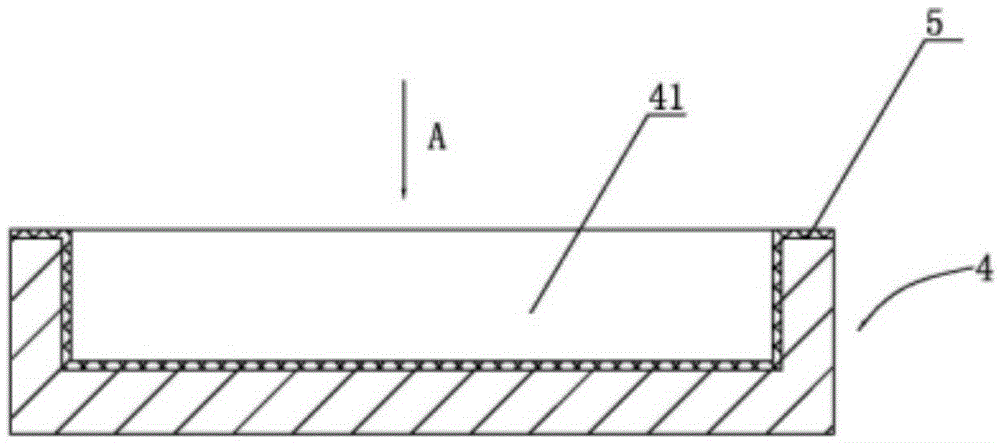

[0067] (1) if image 3 with Figure 4 As shown, a glue-carrying device is provided. In this embodiment, the glue-carrying device is a glue-carrying platform 4. The glue-carrying platform 4 has a glue cavity 41. On the glue-carrying platform, a first isolation film 5 is laid. The first isolation film 5 is a UV film, the thickness of the first isolation film 5 is h 5 . Set the orthographic projection area of the glue chamber 41 as S 1 , the above orthographic projection refers to along image 3 The direction of the projection in the A direction. Such as Figure 4 As shown, the encapsulation glue 2 is injected into the glue cavity 41, the encapsulation glue 2 is a semi-cured glue, the viscosity of the semi-cured glue is 10-80 Pa.s (Pa per second), and the first isolation film 5 will carry the glue The platform is isolated from the packaging glue 2, and the packaging gl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com