Electromagnetic control valve for variable displacement compressor

An electromagnetic control valve and compressor technology, applied in pump control, liquid variable capacity machinery, mechanical equipment, etc., can solve the problem of inability to control the rotation speed of the compressor, reduce the probability of resonance and abnormal noise, reduce the impact, and improve The effect of controlling precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

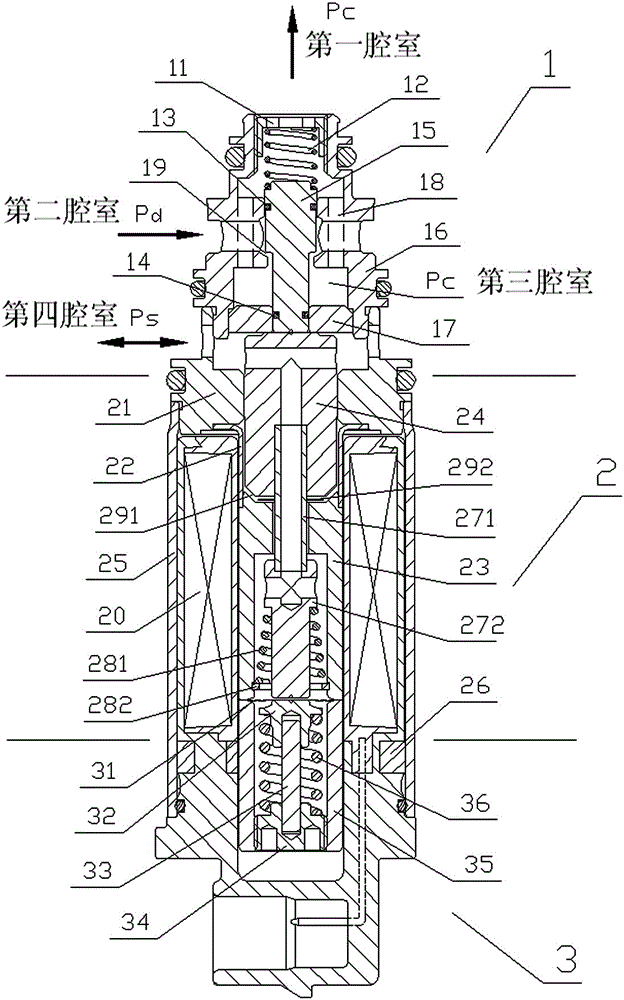

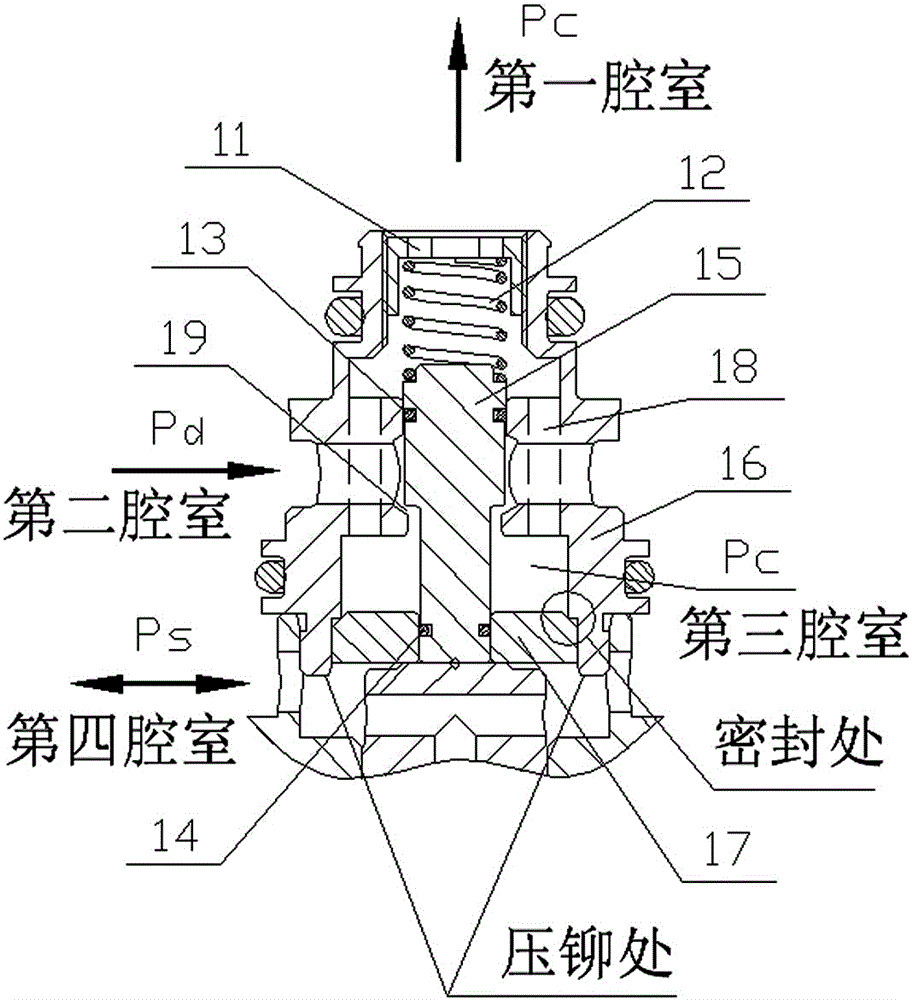

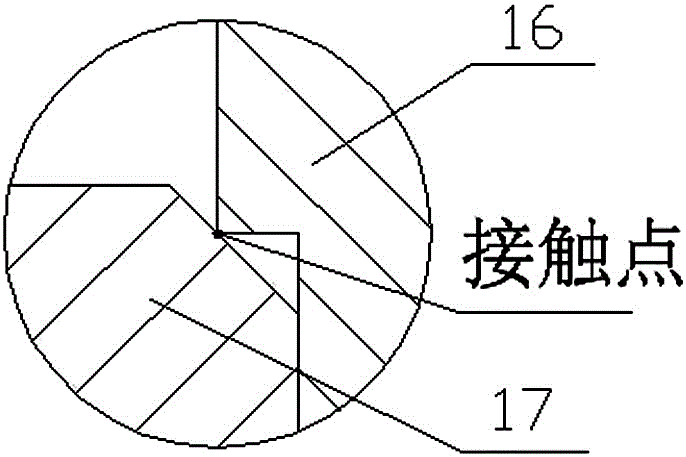

[0043] Example: figure 1 It is a schematic diagram of the structure of the electromagnetic control valve of the present invention. The electromagnetic control valve is mainly composed of three parts: valve part 1, electromagnet part 2 and pressure-sensing part 3, which are arranged on the same axis. The valve part 1 is usually provided with several gas passages for introducing the discharge pressure Pd, the suction pressure Ps and the swash plate chamber pressure Pc. The size 19 of the gas passage between the exhaust pressure Pd and the swash plate cavity pressure Pc is controlled by controlling the axial movement of the valve core 15 so as to realize the adjustment of the swash plate cavity pressure Pc. The electromagnet component 2 will generate an electromagnetic force that drives the valve core 15 to move after being energized. Similarly, the pressure-sensitive member 3 will also generate a force that drives the valve core 15 to move due to the change of the suction pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com