Pneumatic tire

A pneumatic tire, tire circumferential technology, applied in tire parts, tire tread/tread pattern, transportation and packaging, etc. The effect of improving drainage performance and noise performance, reducing resonance noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Hereinafter, one embodiment of the present invention will be described with reference to the accompanying drawings.

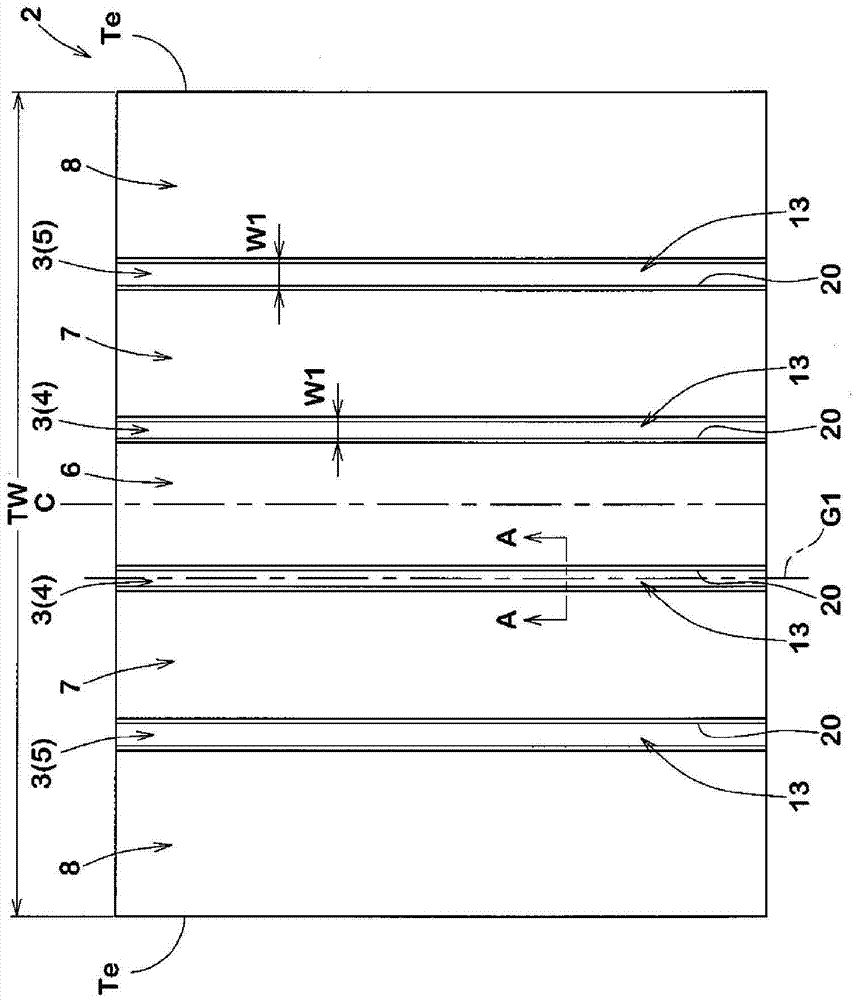

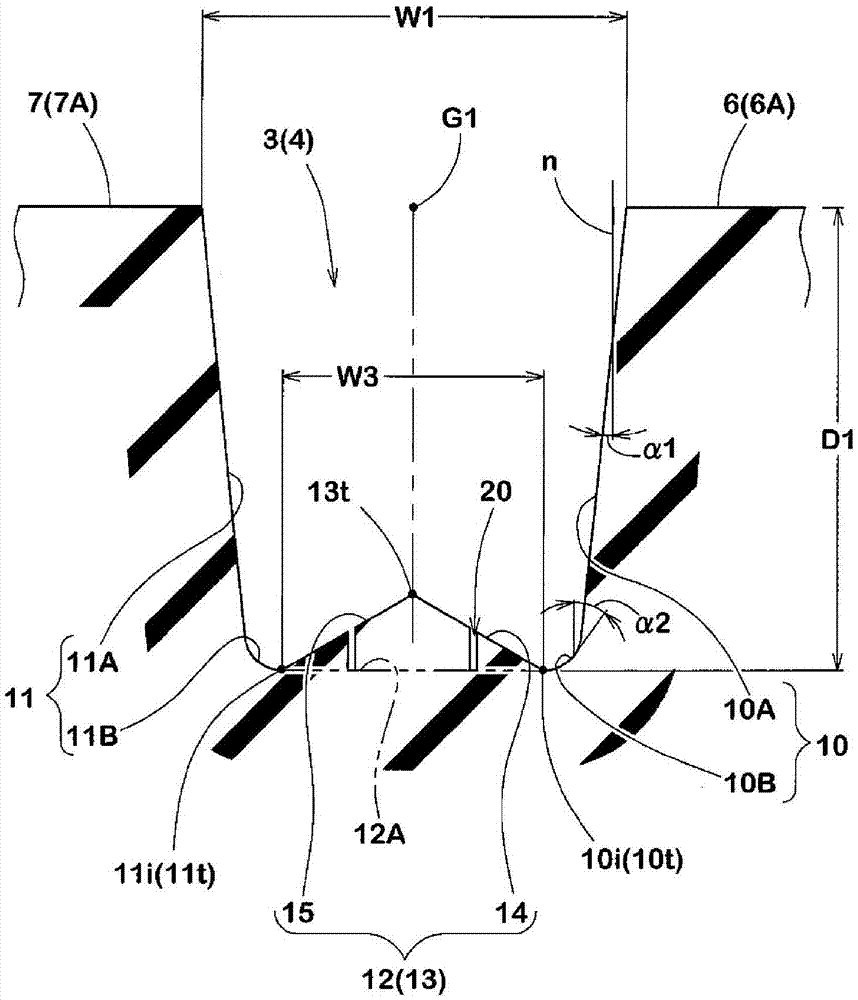

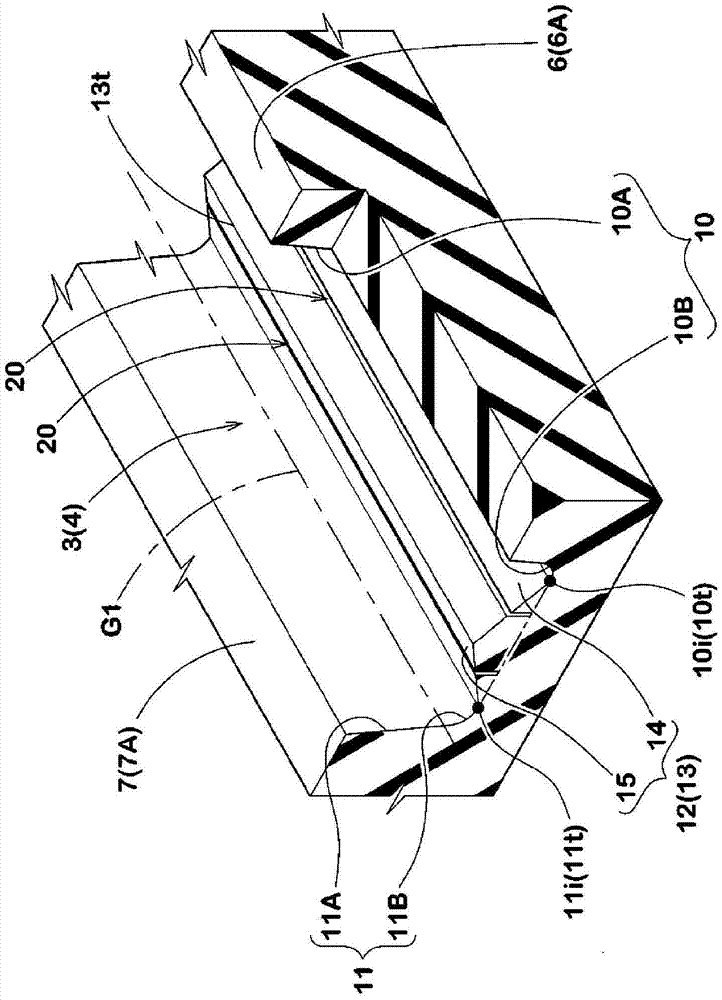

[0028] figure 1 is a developed view of the tread portion, showing an embodiment of the present invention. like figure 1 As shown in , the pneumatic tire (hereinafter, simply referred to as "tire") according to the present embodiment is suitable for use as, for example, a pneumatic tire for a passenger car. The tread portion 2 of the tire includes at least one main groove 3 extending continuously in the tire circumferential direction. The main groove 3 of the present embodiment includes a pair of central main grooves 4 extending on both sides of the tire equator line C and a pair of shoulder main grooves 5 . The shoulder main groove 5 extends axially outside the center main groove 4 .

[0029] The tread portion 2 of the present embodiment includes a central land portion 6 separated by a pair of central main grooves 4 , a pair of intermediate land port...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com