Permanent magnetic rotor for electromotor and method for making same

A permanent magnet rotor and motor technology, applied in the manufacture of stator/rotor body, electrical components, electromechanical devices, etc., can solve the problems of weakening the resonance of the motor and fan blades, not suitable for mass production, time-consuming and labor-intensive, etc., to reduce resonance noise , the production is convenient and fast, and the effect of reducing the quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

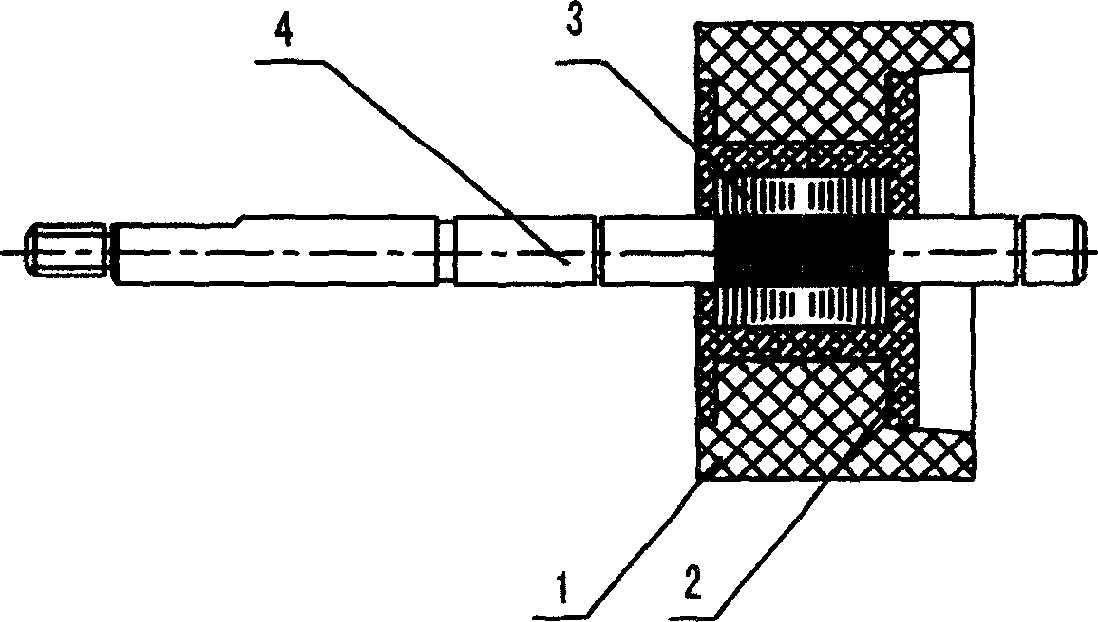

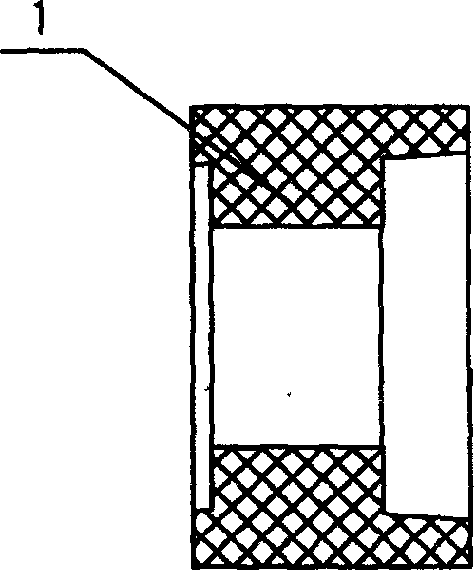

[0020] The structure diagram of the present invention is as figure 1 As shown, it includes a permanent magnetic ring (1), a rotor core (3), a rotor shaft (4), the rotor shaft (4) passes through the shaft hole of the rotor core (3), and is connected with the rotor core (3) ) are fastened together, the permanent magnetic ring (1) is set on the outside of the rotor core (3), and high temperature liquid rubber (2) is injected between the permanent magnetic ring (1) and the rotor core (3), And the rubber (2) is respectively consolidated with the permanent magnetic ring (1) and the rotor iron core (3) after cooling.

[0021] The rotor shaft (4) and the shaft hole of the rotor iron core (3) are fastened together by riveting.

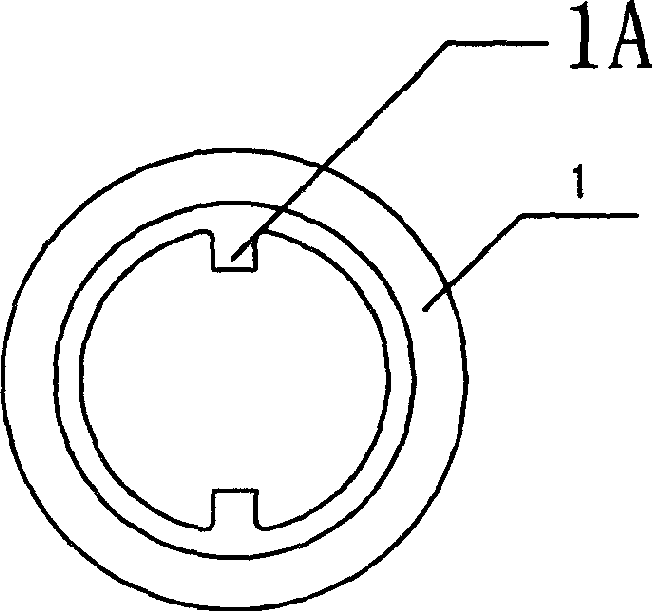

[0022] A protruding stop arm (1A) is provided on the inner wall of the permanent magnet ring (1), and a protruding stop arm (3A) is provided on the rotor core (3).

[0023] The method for manufacturing the permanent magnet rotor of the present invention compr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com