a filter valve

A filter valve and valve body technology, which is applied in the direction of filter separation, valve device, mechanical equipment, etc., can solve the problems of small filter area, filter deformation, waste of resources, etc., to improve the filter effect, increase the filter area, Wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

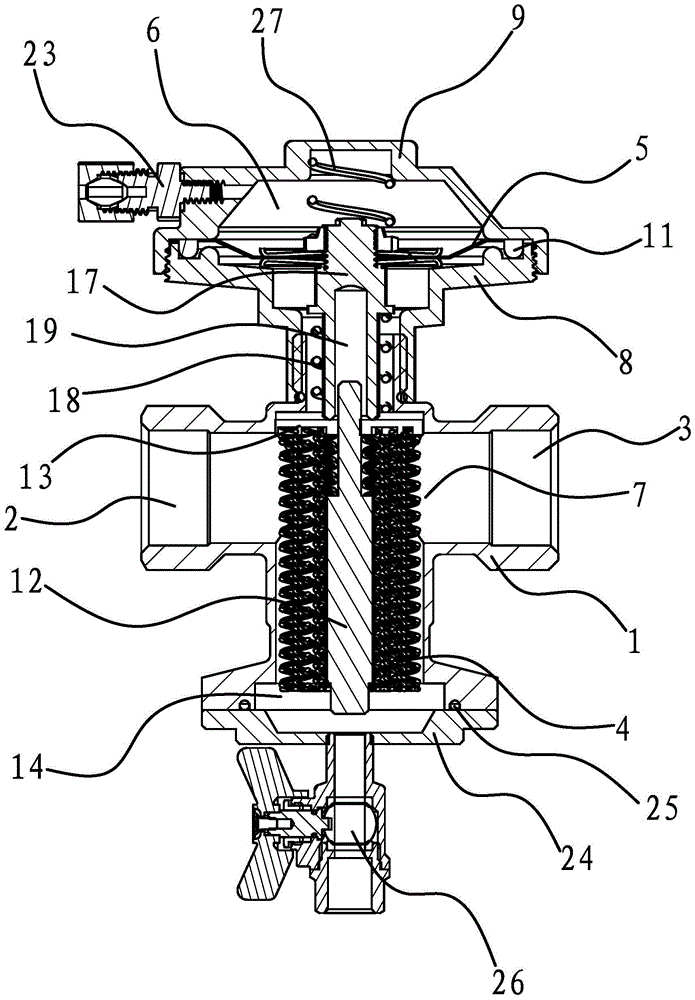

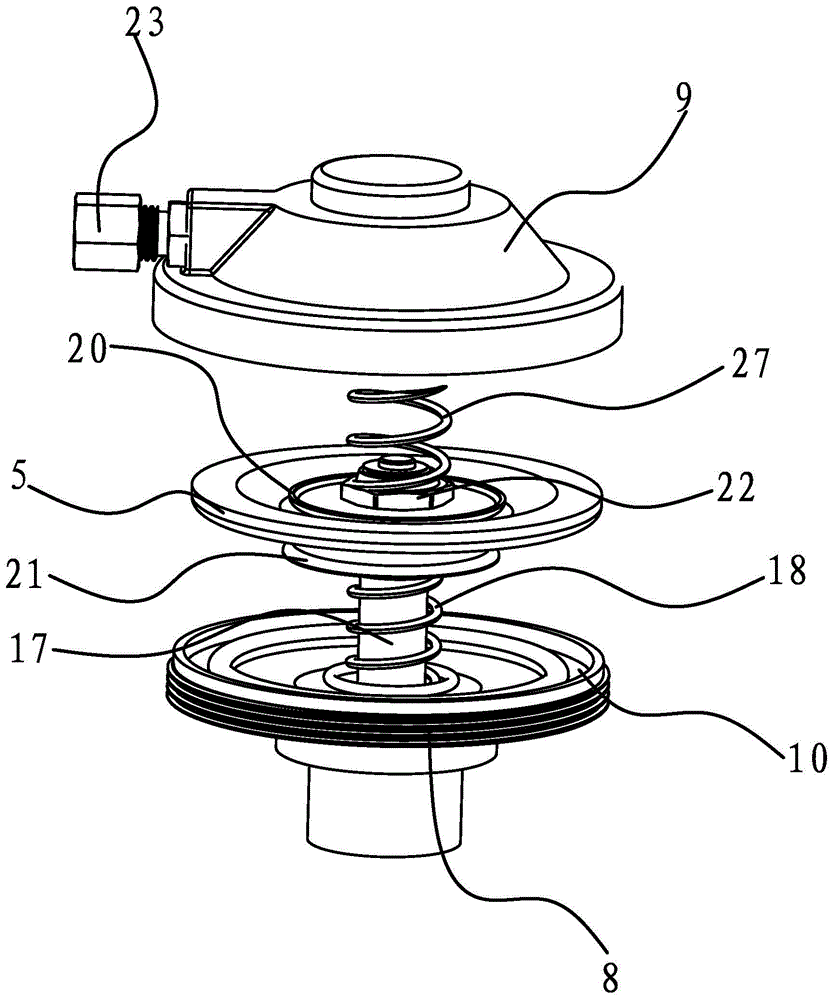

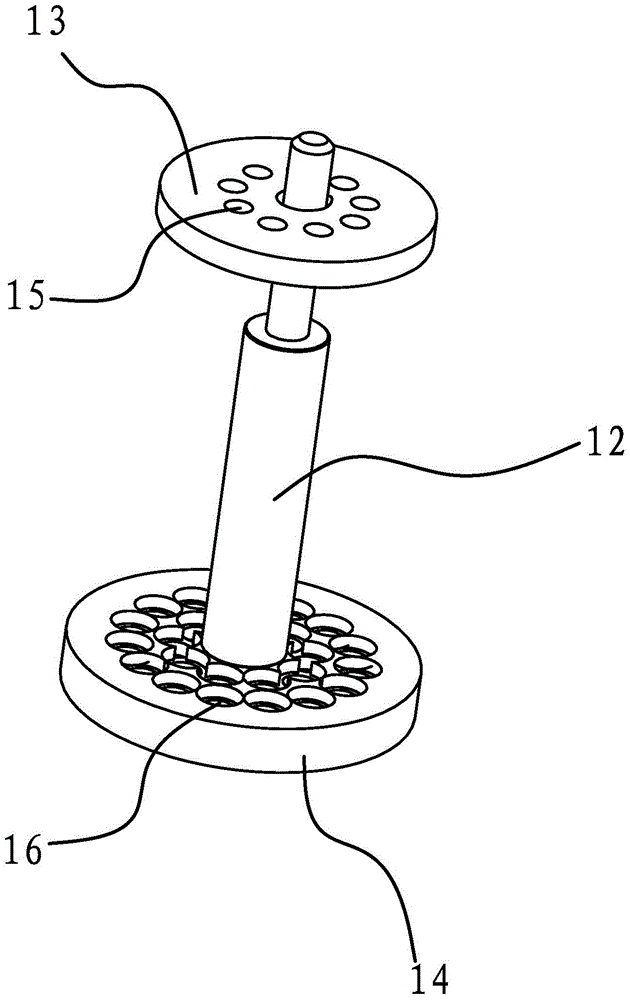

[0033] Such as figure 1 and image 3 As shown, a filter valve includes a valve body 1 with a cavity inside. The left and right ends of the valve body 1 are the water inlet 2 and the water outlet 3 respectively. A connecting rod perpendicular to the water flow direction is fixed in the valve body 1. 12. The upper end of the connecting rod 12 is covered with a baffle plate 13 and the lower end of the connecting rod 12 is fixed with a baffle plate 2 14. Several filter springs 4 are connected between the baffle plate 13 and the baffle plate 2 14, and the filter spring 4 The two ends lean against the first baffle plate 13 and the second baffle plate 14 respectively. The first baffle plate 13 and the second baffle plate 14 have a positioning hole 15 and a positioning hole 2 16 facing each other on the opposite surface respectively, and the two ends of the filter spring 4 are fixed in the positioning hole 1 15 and the positioning hole 2 16 respectively.

[0034] Such as figure 1 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com