Ultrasonic self-cleaned extractor hood and method thereof

A range hood and self-cleaning technology, which is applied in the direction of oil fume removal, heating methods, household heating, etc., can solve the problems that the range hood is difficult to clean and the cleaning effect is not ideal, and achieves the same cleaning effect, fast cleaning speed, Effect of reducing resonance noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

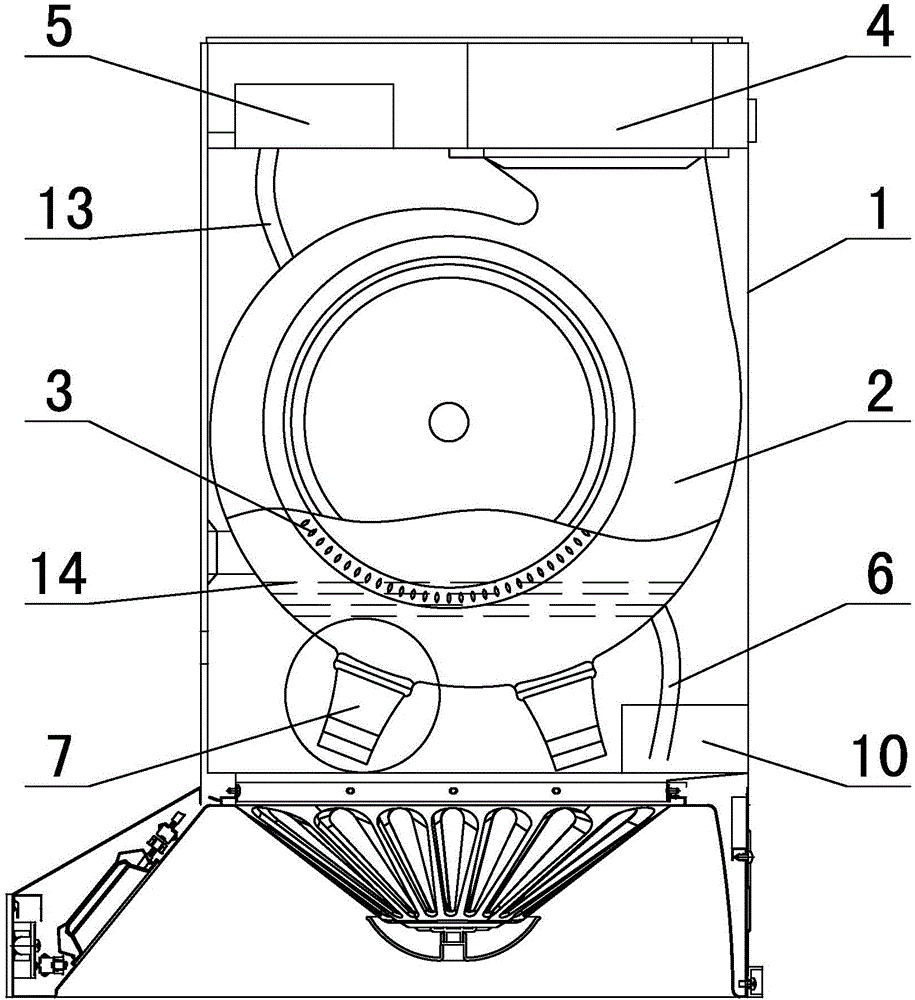

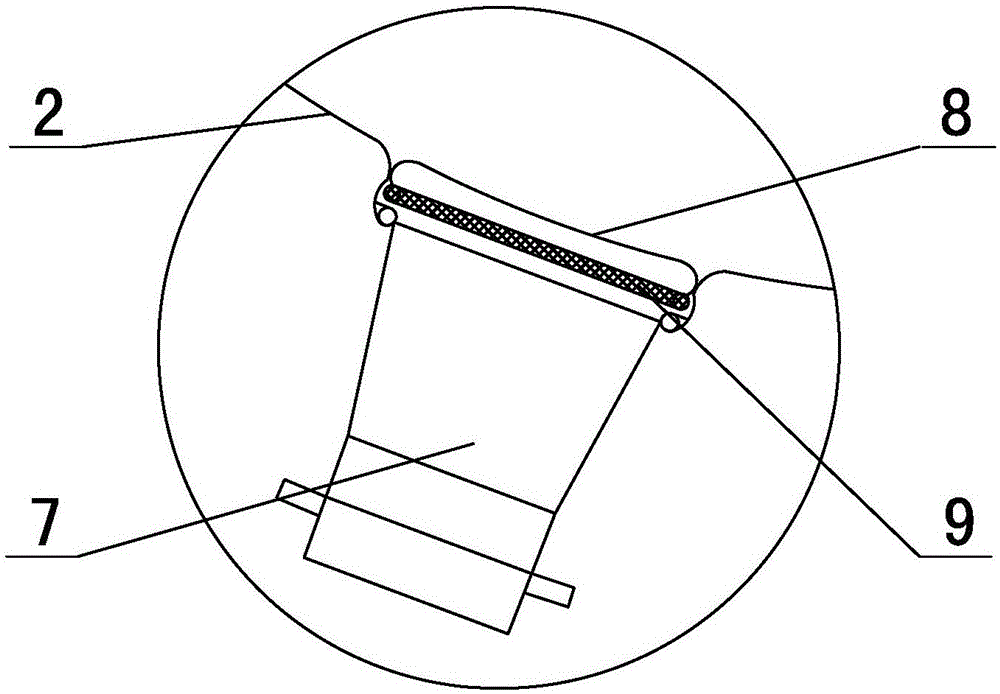

[0031] in such as figure 1In the shown embodiment 1, an ultrasonic self-cleaning range hood includes a controller, a casing 1 and a centrifugal fan arranged in the casing, and the fan includes a volute 2 and an impeller arranged in the volute 3. The rotating shaft of the impeller is set horizontally, the air outlet 4 of the fan is located on the top of the fan, the cleaning liquid suction and discharge pump 5 and the cleaning liquid suction and discharge port 6 are arranged in the casing, and one interface of the cleaning liquid suction and discharge pump is connected to the cleaning liquid through the pipeline 13 The liquid suction and discharge ports are connected, and the other interface of the cleaning liquid suction and discharge pump is directly connected to the bottom of the volute through the pipeline; the bottom of the volute is provided with at least two through holes, and the ultrasonic transducer 7 is fixed on the lower side of the through holes, and a cover is prov...

Embodiment 2

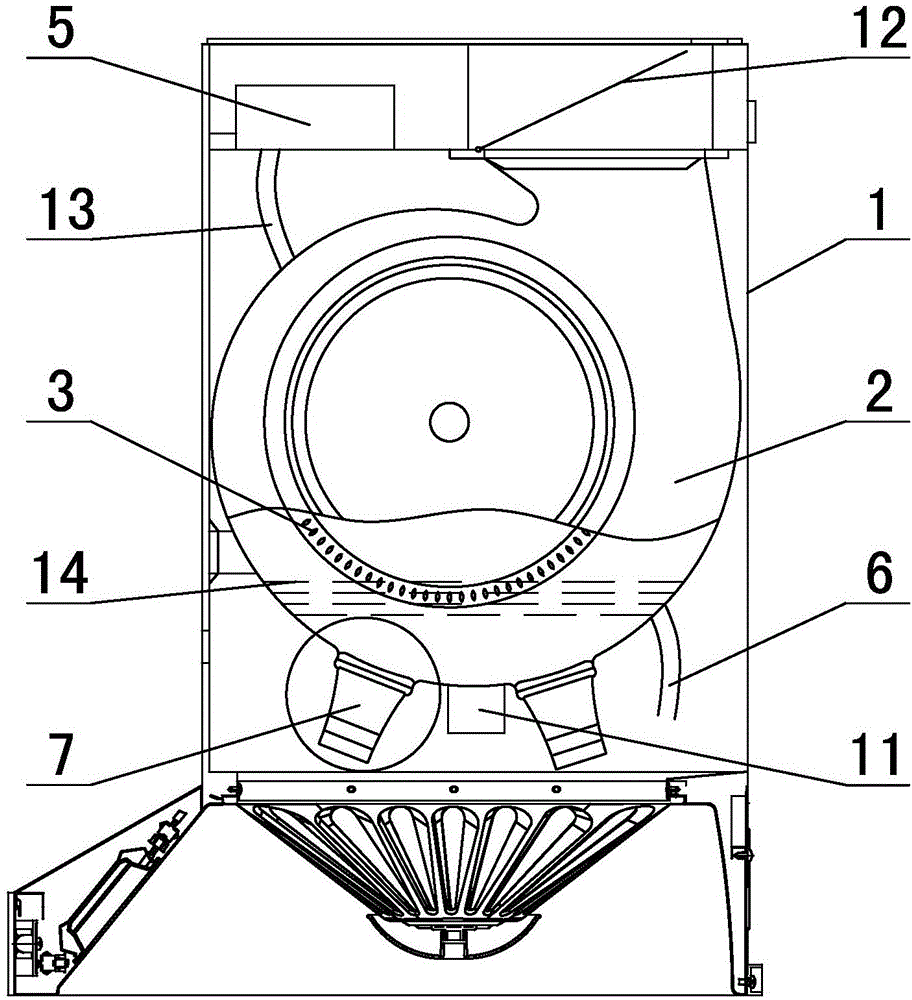

[0041] in such as figure 2 In the shown embodiment 2, the impeller of the fan and the inner wall of the volute are provided with a hydrophobic and oleophobic coating, the cleaning liquid suction and discharge pump is arranged above the fan in the casing, and the cleaning liquid suction and discharge port is equipped with a cleaning liquid suction and discharge pipe (Fig. not shown), the bottom of the volute is provided with a heating device 11, the air outlet of the fan is provided with a flap 12, the flap is driven by a flap motor, the heating device and the flap motor are connected to the control device, the rest and the implementation Example 1 is the same.

[0042] The cleaning method of the ultrasonic self-cleaning range hood of embodiment 2 comprises the following steps:

[0043] a. Put the lower end of the cleaning liquid suction and discharge pipe in a container filled with cleaning liquid, press the cleaning button to start the self-cleaning program of the range hoo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com