Sound suppressing device for tire tread

A technology for tires and treads, applied in the direction of tire tread/tread pattern, tire parts, transportation and packaging, etc., can solve problems such as interrupting the flow of liquid in grooves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to facilitate understanding of the drawings and the related description, the same reference numerals are used in the figures to refer to structural or functional elements that are the same regardless of the variation involved.

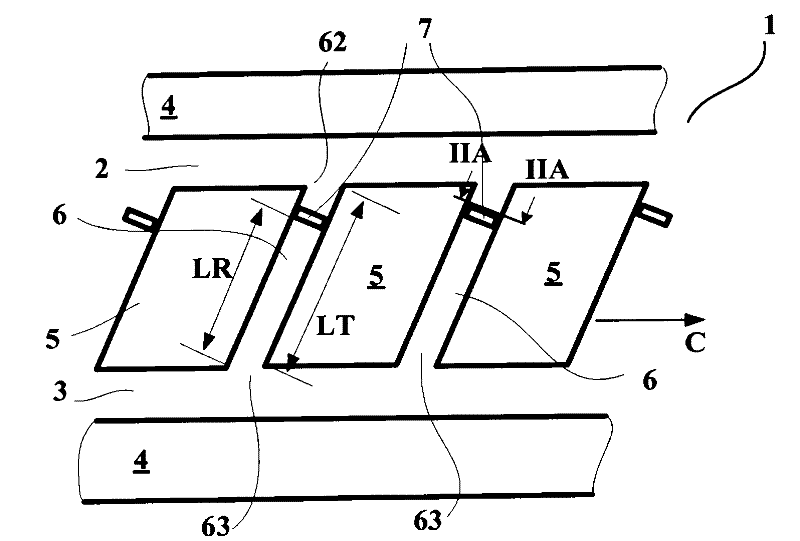

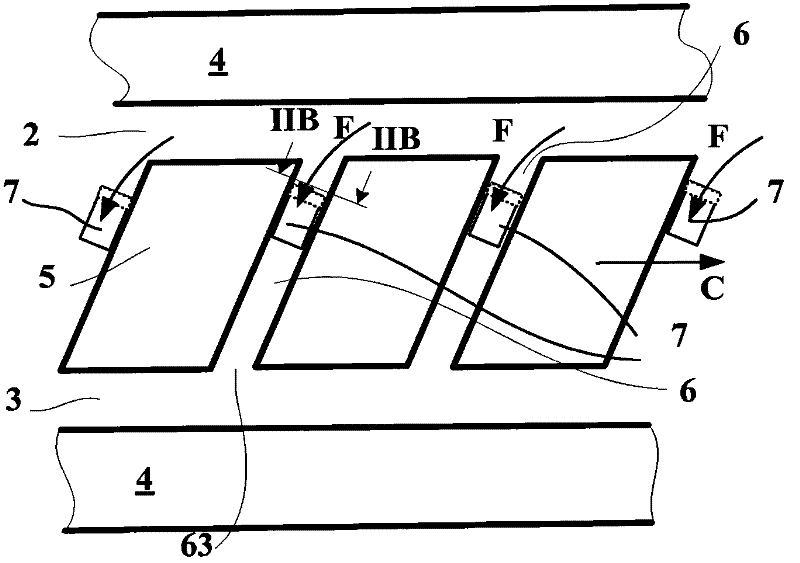

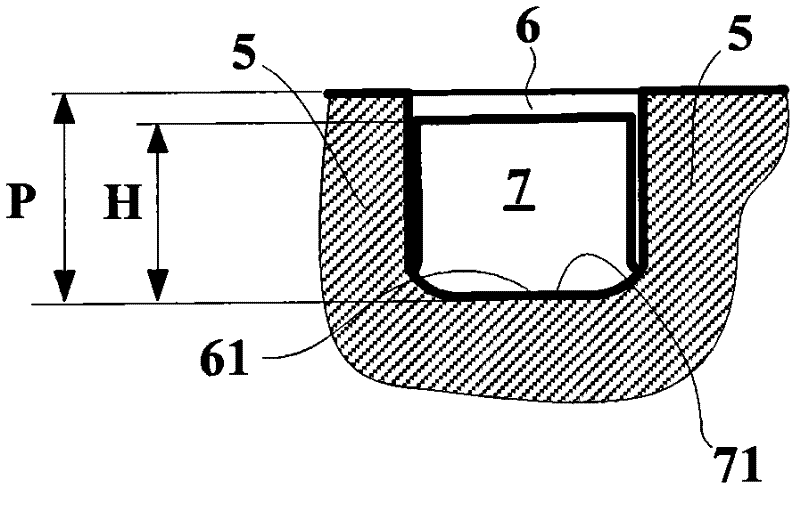

[0025] Figure 1A and 1B A view showing the running surface of a part of a tread 1 according to a first variant of the invention, which is designed to be fitted to a tire for passenger cars. The tire size is 255 / 40 R 19. These views show two circumferential grooves 2 , 3 each delimited by circumferentially continuous ribs 4 and a row of blocks 5 . The blocks 5 are separated from each other in the circumferential direction by inclined lug grooves 6, that is to say the lug grooves 6 form a non-zero angle with the circumferential direction indicated by the direction C in the drawing.

[0026] The circumferential grooves 2, 3 have an average width of 10 mm and a depth of 8 mm. The transverse grooves 6 have an average width of 3 mm and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com