Oxygenation barrel grate

A furnace grate and furnace tooth technology, which is used in household furnaces/stoves, lighting and heating equipment, solid fuel combustion, etc. The effect of warming and eliminating smoke, prolonging burning time and saving firewood consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

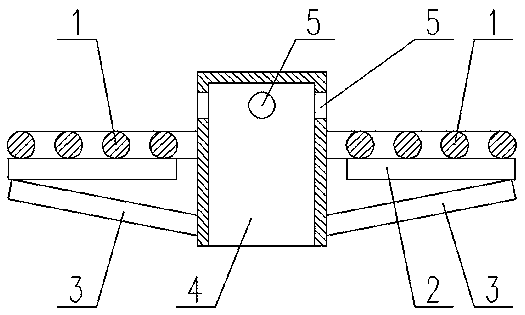

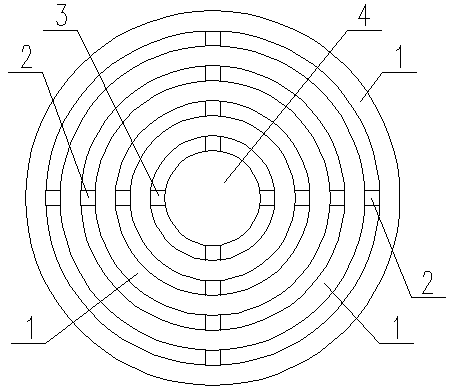

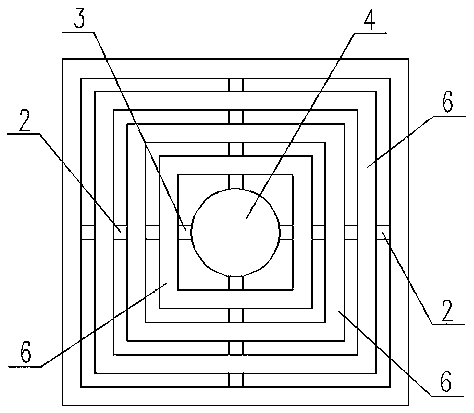

[0028] Depend on figure 1 and figure 2 As shown, the aeration cylinder grate includes a furnace tooth and an aeration cylinder 4, the aeration cylinder 4 is fixedly installed at the center of the furnace tooth, the top of the aeration cylinder 4 is closed, and the bottom is open. A horizontal through hole 5 is opened on the wall of the oxygen increasing cylinder 4 above the furnace teeth. The through holes are in 1 to 10 rows, and the number of holes in each row is 3 to 8. The bottom of the oxygen increasing cylinder 4 is lower than the furnace teeth. Make it have a certain height difference below the furnace teeth, and the height difference of the oxygen increasing cylinder 4 below the furnace teeth determines the strength of the oxygen supply. The specific structure of the furnace tooth and the specific connection relationship with the oxygen increasing cylinder 4 are as follows: the furnace tooth includes an annular furnace frame 1, the diameter of the annular furnace fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com