Design method for cutterheads of high-pressure water jet full-face rock tunnel boring machine

A technology of high-pressure water jet and design method, which is applied to mining equipment, earthwork drilling, tunnels, etc. It can solve the problems of high manufacturing cost, unsuitable for large-section continuous rock breaking, and huge cutter head structure, etc., and achieve high processing efficiency. , easy to achieve, and reduce the effect of resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

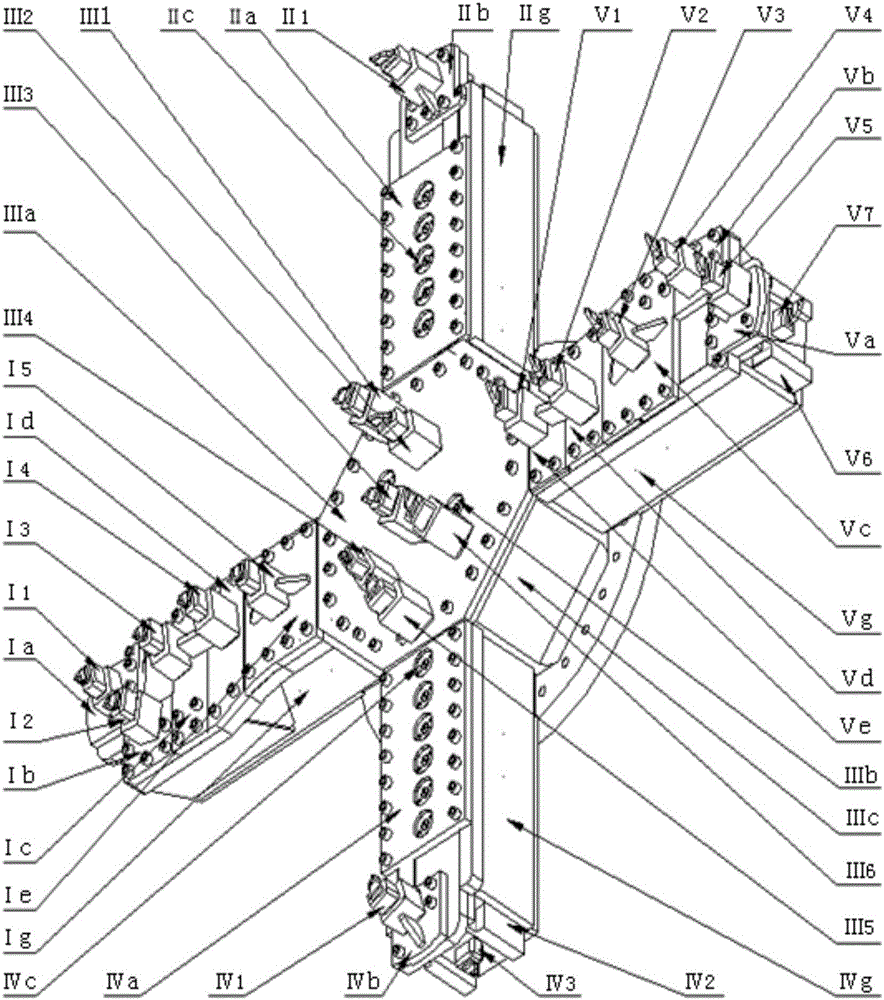

[0024] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings and technical solutions.

[0025] The cutter head of the existing traditional full-face tunnel boring machine, through the rotation of the overall cutter head, makes the hob on the cutter head continuously squeeze the rock. When the ultimate shear stress and tensile stress exceed the shear and tensile stress of the rock itself When the strength is high, shear and tensile cracks appear, and the rock is broken by further extrusion. Due to the direct contact with the rock, the wear of the cutter is serious, and the life of the cutter head is affected.

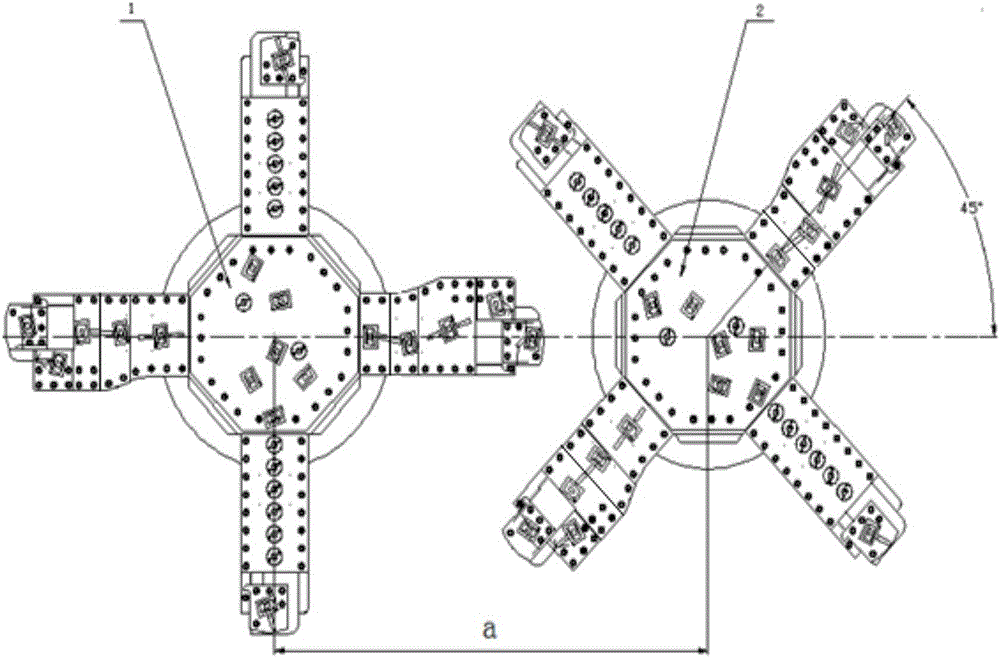

[0026] as attached figure 1 As shown, the cutterhead layout form adopted in the present invention is a cutterhead in the form of two synchronously rotating cross-shaped spokes with identical structures: the first cutterhead 1 and the second cutterhead 2, and the centers of the two cutt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com