Laminated adsorption type gas filtering tower for industrial waste gas treatment

An industrial waste gas and adsorption technology, which is applied in the direction of gas treatment, air quality improvement, combined devices, etc., can solve the problems of purification limitations, poor practicability, and difficult removal of impurities, etc., and achieve the effect of improving the effect of adsorption treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

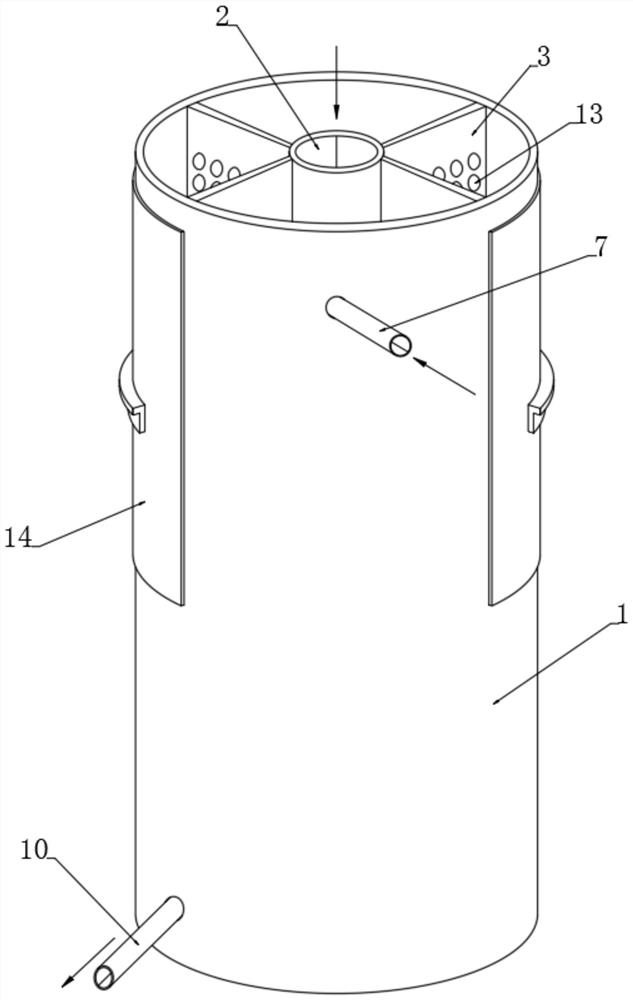

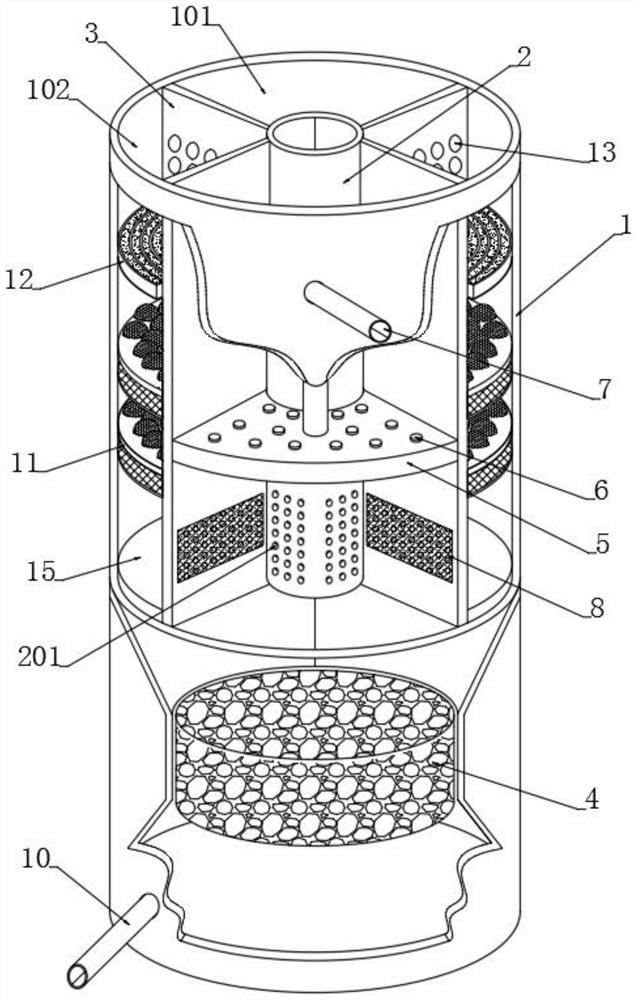

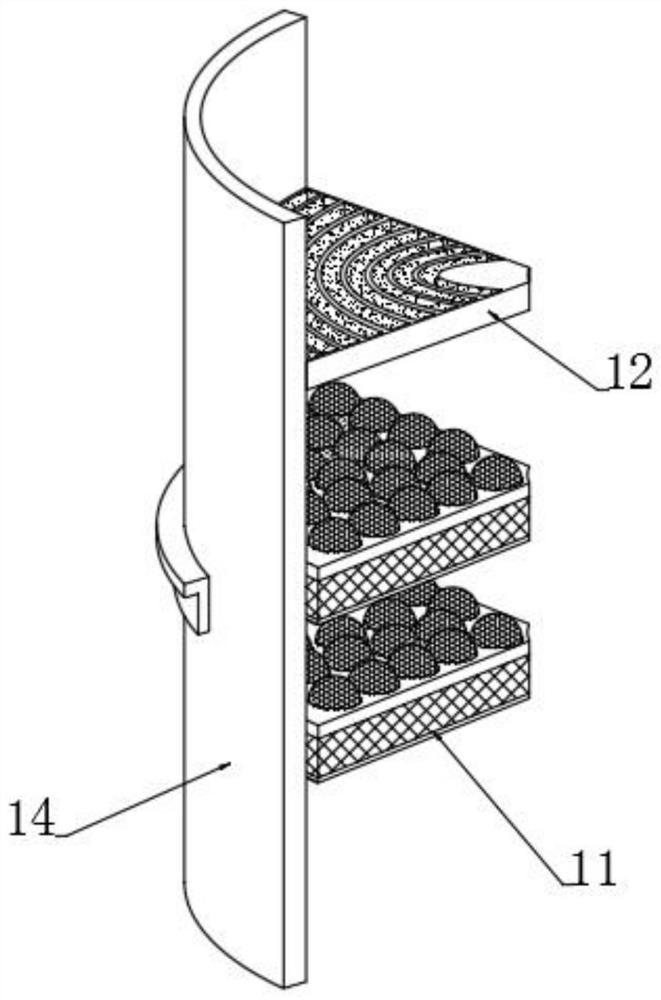

[0042] see Figure 1-2 , a stacked adsorption filter tower for industrial waste gas treatment, comprising a cylindrical tower body 1 and an air intake sleeve 2 embedded in the cylindrical tower body 1, and the surrounding side walls of the air intake sleeve 2 are distributed with A plurality of partitions 3 divide the interior of the cylindrical tower body 1 into a pair of spray chambers 101 and adsorption chambers 102 which are arranged oppositely, and the spray chambers 101 and adsorption chambers 102 which are arranged alternately effectively realize The exhaust gas after spraying treatment is exported to another cavity for adsorption treatment. The interior of a pair of spraying chambers 101 near the bottom is provided with a spraying mechanism connected to the outer wall of the intake sleeve 2. A plurality of air intake holes 201 located below the spray mechanism are opened on the side walls of the front and rear relative positions. The exhaust gas introduced by the intak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com