Chemical experiment waste liquid treatment device for teaching

A technology for waste liquid treatment and chemical experiments, applied in the field of chemical experiments, can solve problems such as hidden safety hazards, no anti-volatile measures in the treatment pool, and incomplete treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

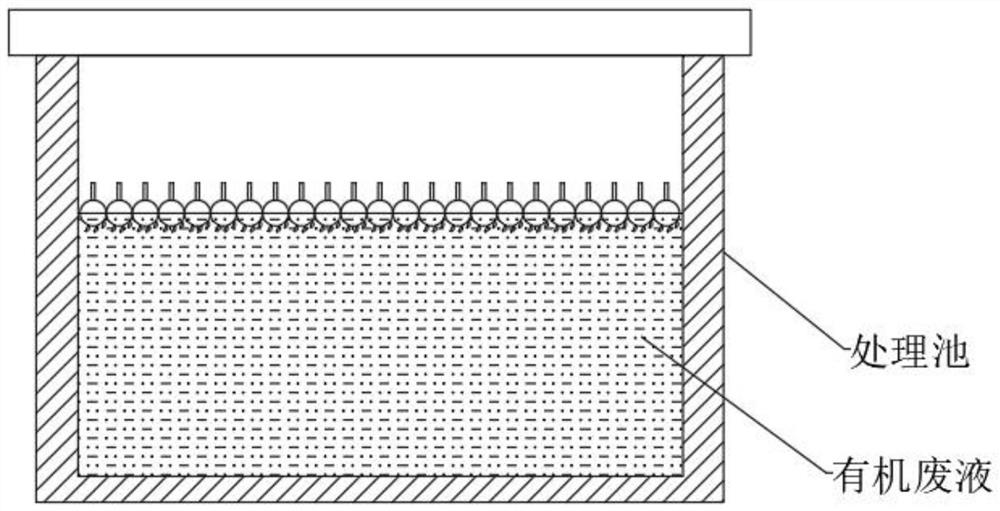

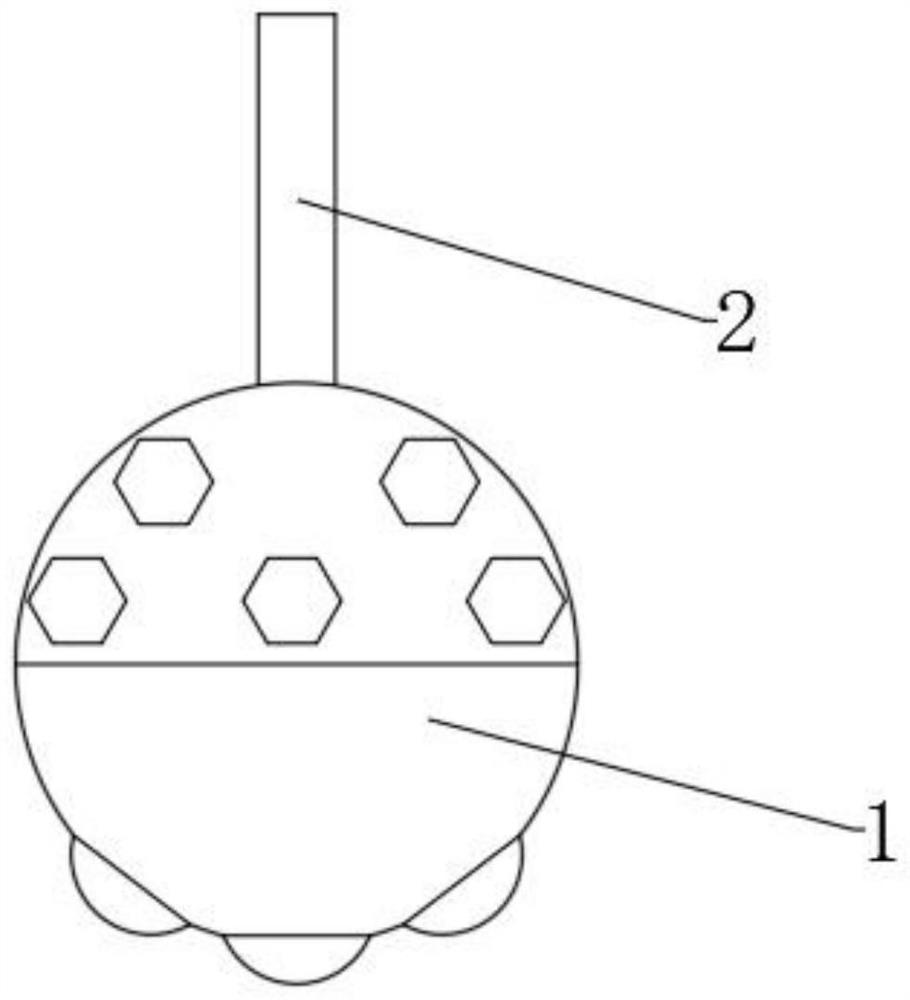

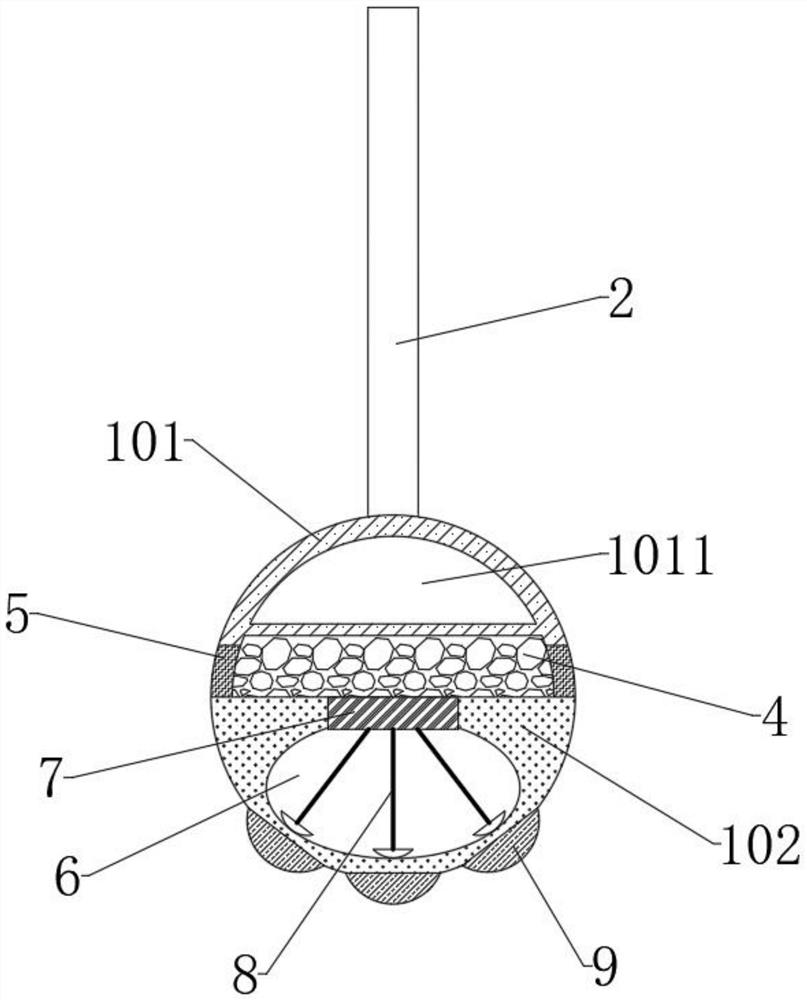

[0046] see Figure 1-9 , a chemical experiment waste liquid treatment device for teaching, including a treatment tank, please refer to Figure 1-2 , the treatment tank is injected with organic waste liquid, the organic waste liquid is diluted with water, and an appropriate amount of throwing balls are put into the organic waste liquid. Connected, the floating rod 2 is a hollow structure made of lightweight materials, and the density of the light material is lower than that of the organic waste liquid. This is to keep the floating rod 2 in a vertical neutral state, thereby facilitating recycling. The floating rod 2 It is divided into upper and lower parts. The upper part of the floating rod 2 is made of light material, and the lower part of the floating rod 2 is made of magnetic material. When the floating rod 2 is recovered, a large amount of floating rod 2 can be absorbed at one time by using a magnet on the top , which is convenient for recycling and saves time compared wit...

no. 2 example

[0051] see Figure 5-9 The throwing ball also includes a cover umbrella 3 fixedly connected to the upper end of the floating rod 2. The cover umbrella 3 includes a plurality of umbrella-shaped umbrella wings 301 connected to each other, and elastic embedded rods 303 are inlaid inside the opposite two umbrella wings 301, which are equivalent to The span of an elastic embedded rod 303 is the span of two umbrella wings 301 combined, so that the elastic embedded rod 303 can recover to its original shape after the water-soluble connecting band 302 is dissolved by water to open the umbrella 3, which includes the 301 is fixedly connected to the umbrella skirt 304, and there are multiple water-soluble connecting belts 302 fixedly connected between the umbrella skirt 304 and the outer surface of the floating rod 2. After the water in the waste liquid dissolves the water-soluble connecting belts 302, the elastic embedded rod 303 loses its The original shape is restored by the binding fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com