Complete-treatment process for waste gas generated during casting

A treatment process and exhaust gas technology, applied in the direction of gas treatment, separation method, dispersed particle separation, etc., can solve the problems of increasing the production cost of enterprises, unable to change the direction of smoke and dust, and unable to guide the treatment system, etc., to reduce power consumption and excellent exhaust gas transportation The effect of improving the efficiency of exhaust gas collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

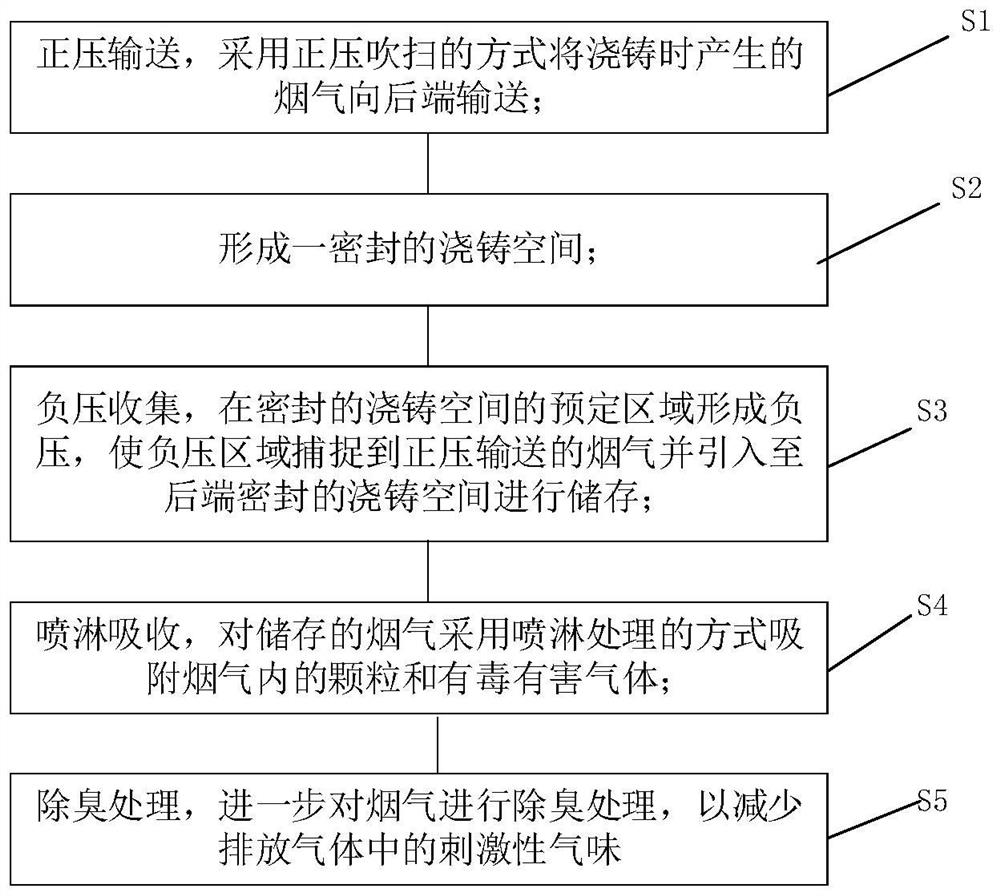

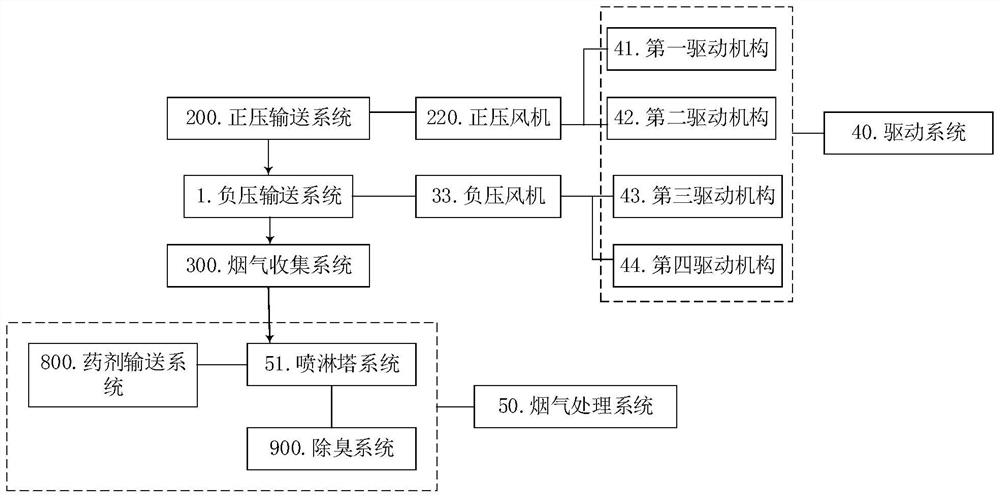

[0040] This embodiment provides a full treatment process for waste gas generated by casting, see figure 1 , is a flow chart of the treatment process of this embodiment, and the treatment process includes the steps: S1 positive pressure conveying, using positive pressure purge to transport the waste gas generated during casting to the rear end; S2 forming a sealed casting space; S3 Negative pressure collection, forming a negative pressure in the predetermined area of the sealed casting space, so that the negative pressure area captures the waste gas conveyed by positive pressure and introduces it into the sealed casting space at the rear end for storage; S4 Spray absorption, uses the stored waste gas The spray treatment method absorbs particles and toxic and harmful gases in the exhaust gas; S5 deodorization treatment further deodorizes the exhaust gas to reduce the pungent odor in the exhaust gas.

[0041] The treatment process of this embodiment adopts the combination of po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com