Venturi cyclone dust extractor

The technology of a cyclone dust collector and a venturi is applied in the field of high-concentration flue gas dust removal and industrial dust dust removal. , good protective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

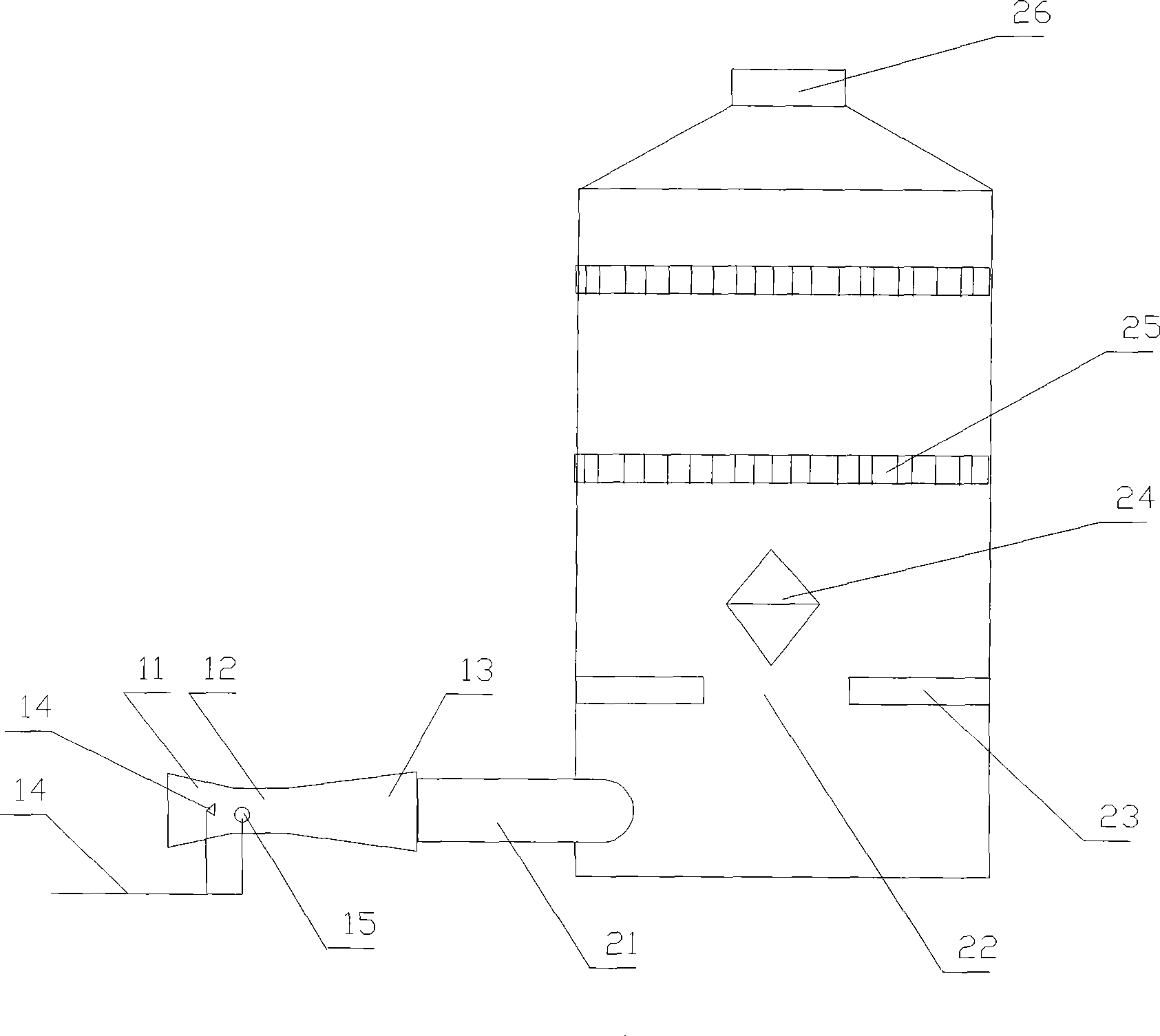

[0007] see figure 1 , a venturi cyclone dust collector, comprising a venturi tube and a cyclone settling tower, the outlet gas of the venturi tube enters the cyclone zone 22 at the bottom of the cyclone settling tower tangentially through the inlet pipe 21 of the cyclone settling tower, and the The Venturi tube is composed of a constriction section 11, a throat section 12 and a diffusion section 13. A number of through holes 14 are arranged on the side wall of the throat section, and the outside of the through holes is connected with a pressure water supply pipe 15. The air outlet of the venturi tube, the port of the contraction section constitutes the air inlet of the venturi tube, the lower part of the cyclone settling tower is a cyclone area, the upper part is a settlement and dehydration area, and an annular partition is arranged in the middle plate 23, several layers of gas-liquid separation layers 25 are arranged on the upper part of the settling and dehydration zone.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com