Membrane separation and hydrate combined gas desulfuration and deacidifying device and method

A hydrate and membrane separation technology, applied in gas fuel, petroleum industry, fuel and other directions, can solve the problems of regeneration and environmental pollution, high operating cost, high investment cost, and achieve the effect of simple equipment, convenient operation and improved purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

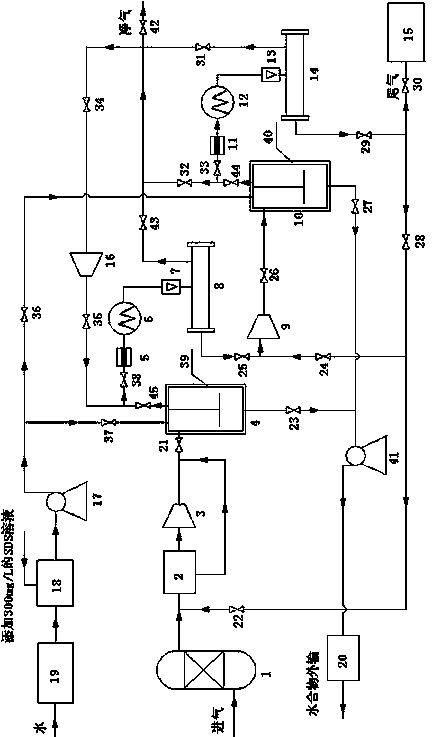

[0017] The implementation of the present invention will be further described below in conjunction with the accompanying drawings.

[0018] As shown in the drawings, the device of the present invention includes an activated carbon filter 1, a self-operated pressure valve 2, compressors 3, 9, 16, hydrate reactors 4, 10, coalescing filters 5, 11, and a heat exchanger 6 , 12, gas flow meter 7, 13, primary and secondary membrane separation units 8, 14, tail gas collection and processing unit 15, slurry pump 17, 41, grinder 18, ice maker 19, hydrate storage tank 20, One-way air valve 21, 22, 24, 25, 26, 28, 29, 30, 31, 33, 34, 35, 38, 42, 43, 44, 45, two-way air valve 32, stop valve 23, 27, 36 , 37, the specific processing method is as follows:

[0019] (1) The water passes through the ice maker 19 to make ice, and is crushed into an ice-water mixture by the grinder 18; the first slurry pump 17 passes through the third shut-off valve 36 and the fourth shut-off valve 37 to pump into...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com