Grain drying device and use method thereof

A drying device and grain technology, applied in the direction of drying and preserving seeds, etc., can solve the problems of difficult feeding, poor drying effect, and no dust removal function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

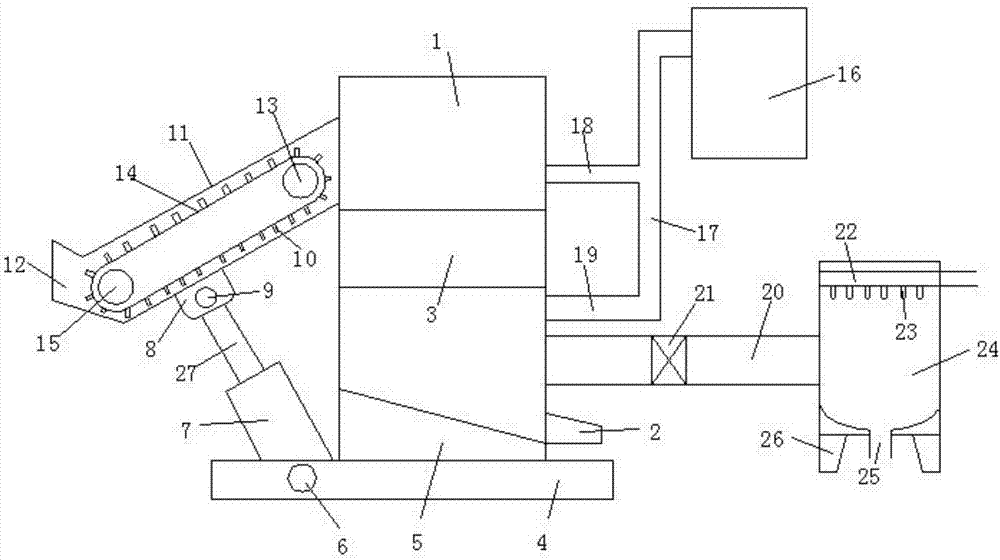

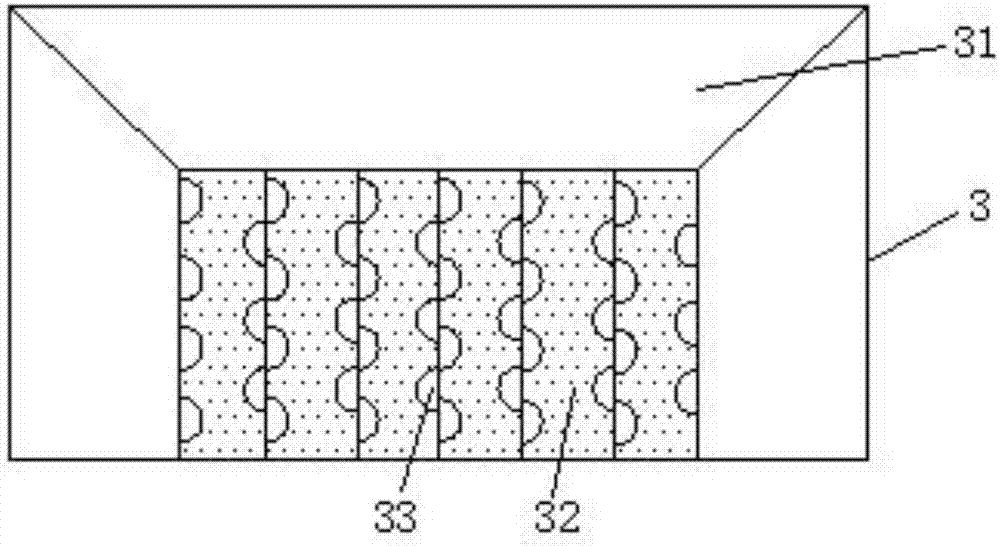

[0018] The present invention provides such Figure 1-2 A kind of grain drying device, comprises base 4, hot air stove 16 and dedusting tank 24, the left side of base 4 is connected with telescopic hydraulic cylinder 7 through first pin shaft 6, and the output end of telescopic hydraulic cylinder 7 is provided with piston Rod 27, the right side upper end of base 4 is provided with drying case 1, and the inner cavity middle part of drying case 1 is equipped with leaking grain box 3, and the inner cavity top of leaking grain box 3 is provided with funnel 31, and the lower end of funnel 31 is equidistant Be connected with pipeline 32, the side wall of pipeline 32 is provided with protrusion 33, the right side bottom of drying box 1 is provided with grain outlet trough 2, and the upper left side of drying box 1 is movably connected with grain inlet box 11, and grain inlet box The right end of 11 stretches into the inner cavity of drying box 1, and the right side inner cavity of gra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com