Heat-phase separation solid residue discharged material cooling dust removal device and method

A solid residue and thermal phase separation technology, applied in packaging, transportation and packaging, loading/unloading, etc., can solve the problems of insufficient dust suppression, uneven mixing, large water consumption, etc., to reduce temperature, improve heat transfer efficiency, The effect of reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

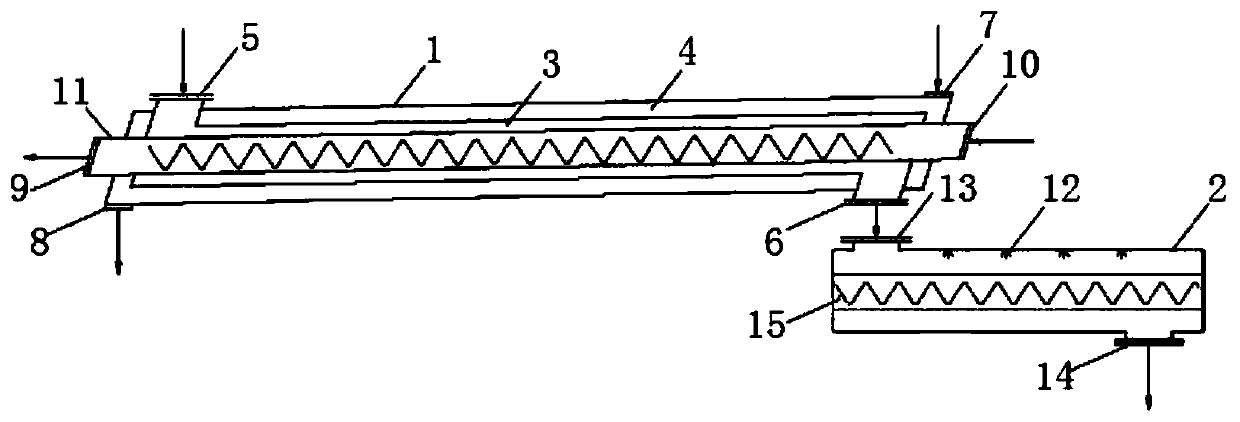

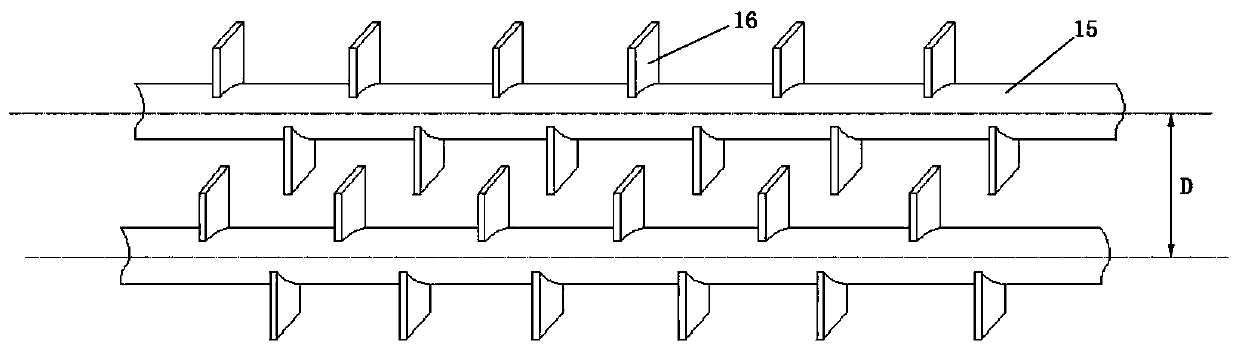

[0018] Such as Figures 1 to 2 As shown, a thermal phase separation solid residue discharge cooling and dedusting device includes a discharge screw device 1 and a discharge spray screw device 2, the discharge screw device 1 is connected to the discharge spray screw device 2, the The discharge screw device 1 is provided with a first screw shaft 11, a material cavity 3 and a jacket cavity 4, the first screw shaft 11 is covered with a material cavity 3, the jacket cavity 4 is set outside the material cavity 3, and the first screw The shaft 11 is used to transport the material in the material chamber 3. Further preferably, the first screw shaft 11 is provided with paddles, the paddles are in multiple groups, and the multiple groups of paddles are helically evenly distributed on the first screw shaft 11. On the screw shaft 11. One end of the material chamber 3 is provided with a first feed port 5, the first feed port 5 extends through the jacket chamber 4 to the outside of the jac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com