Patents

Literature

40results about "Gas purification by treating with solids" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

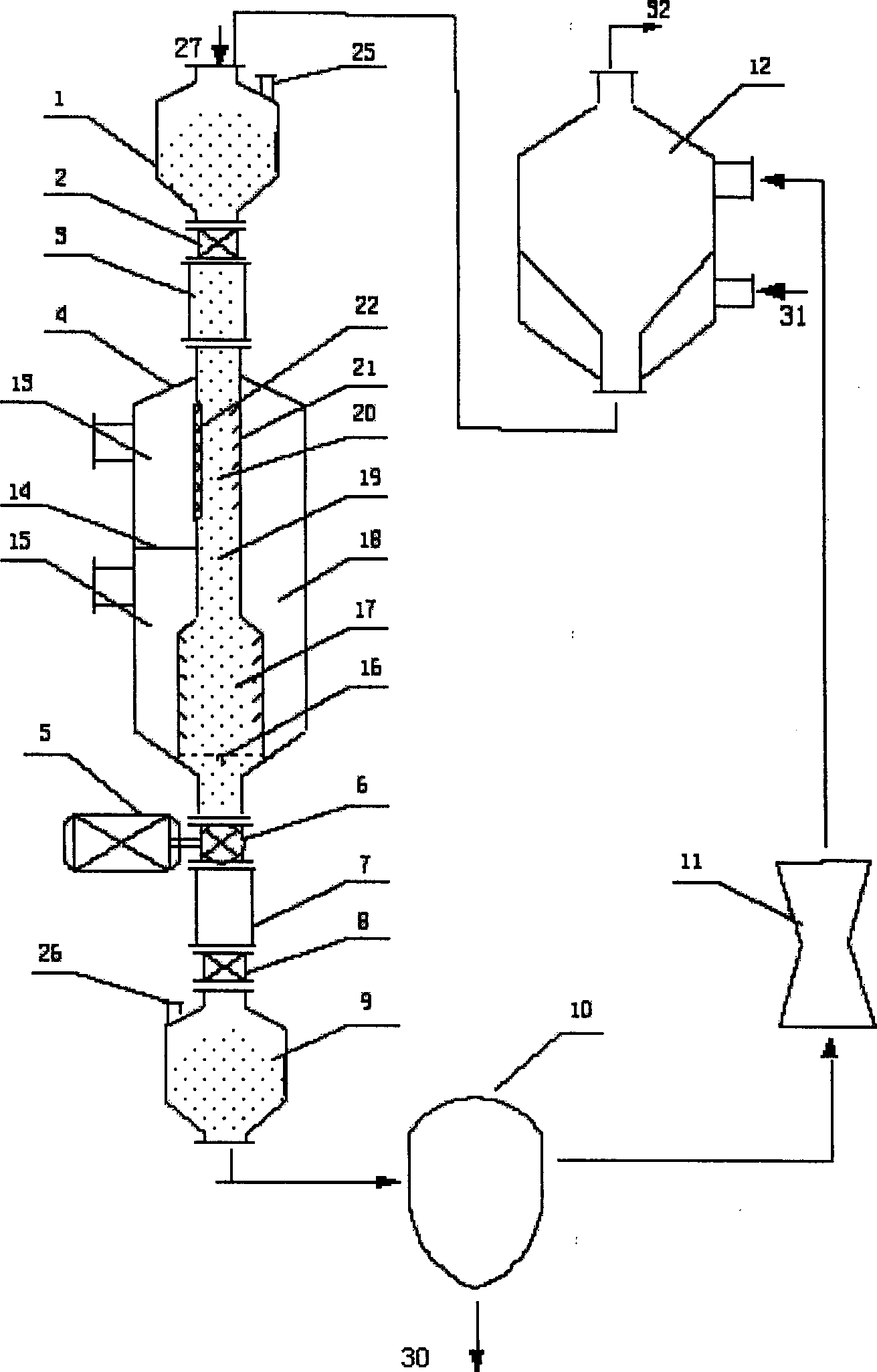

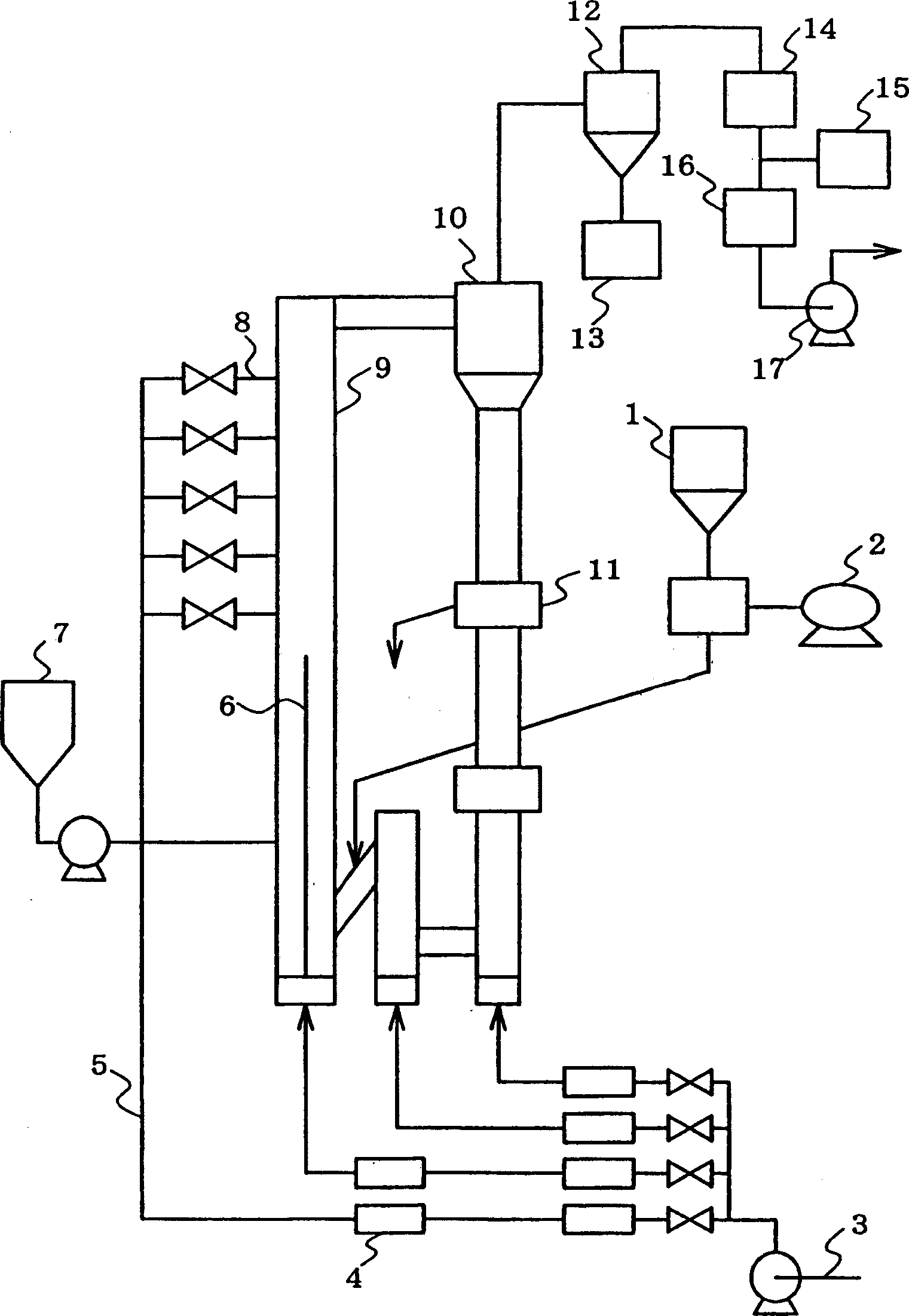

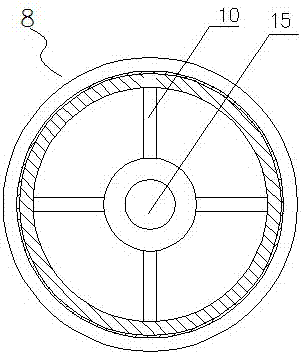

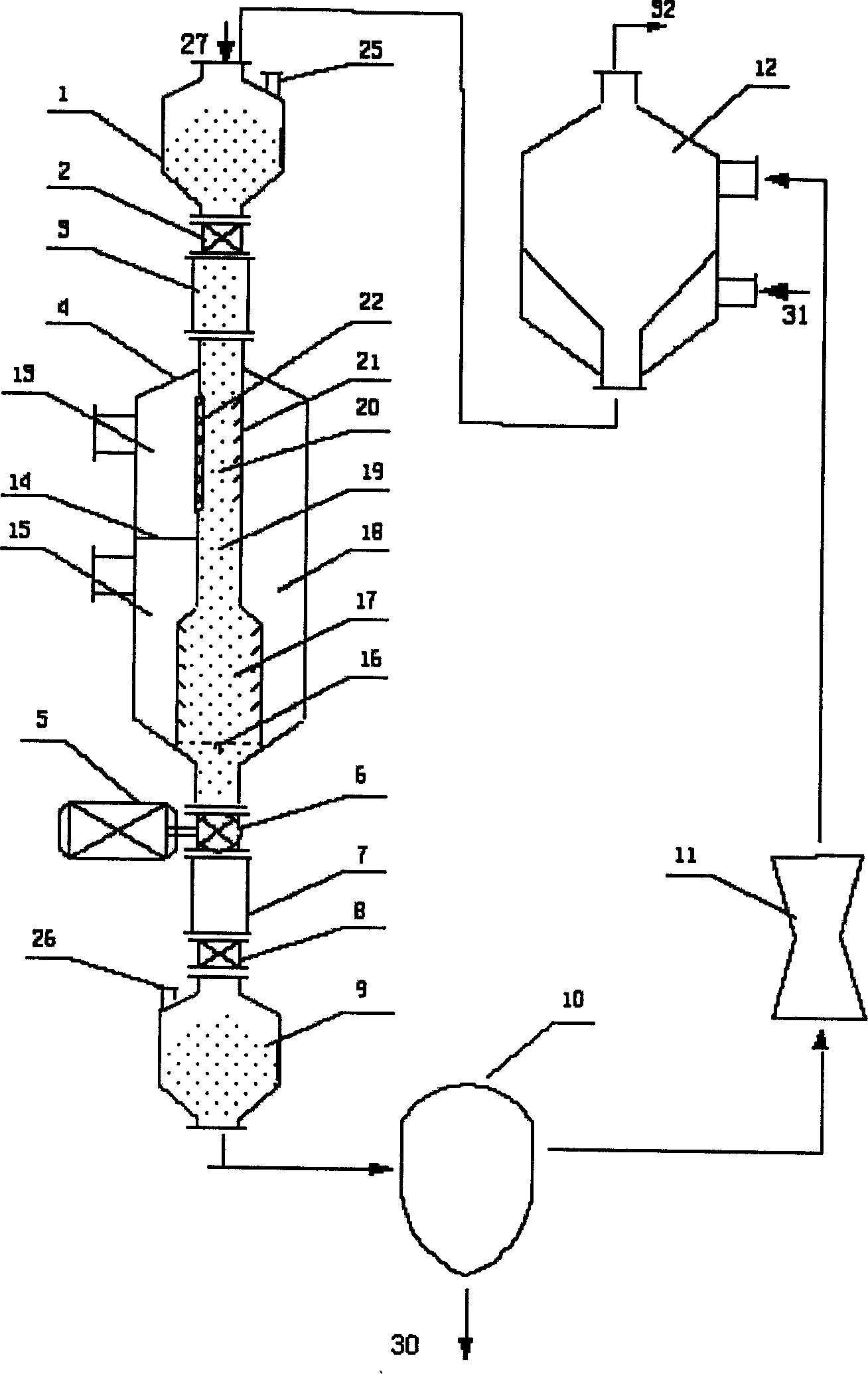

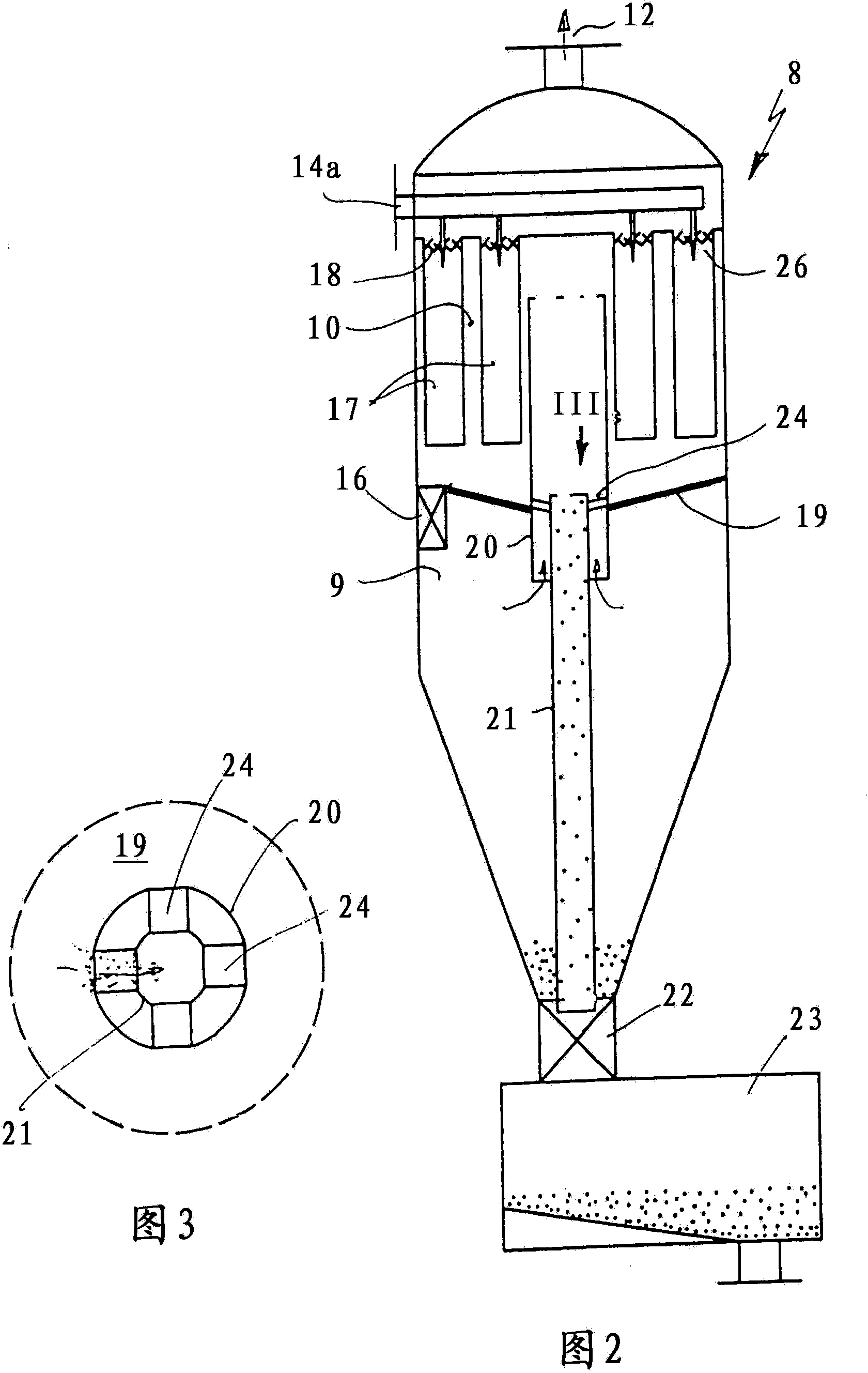

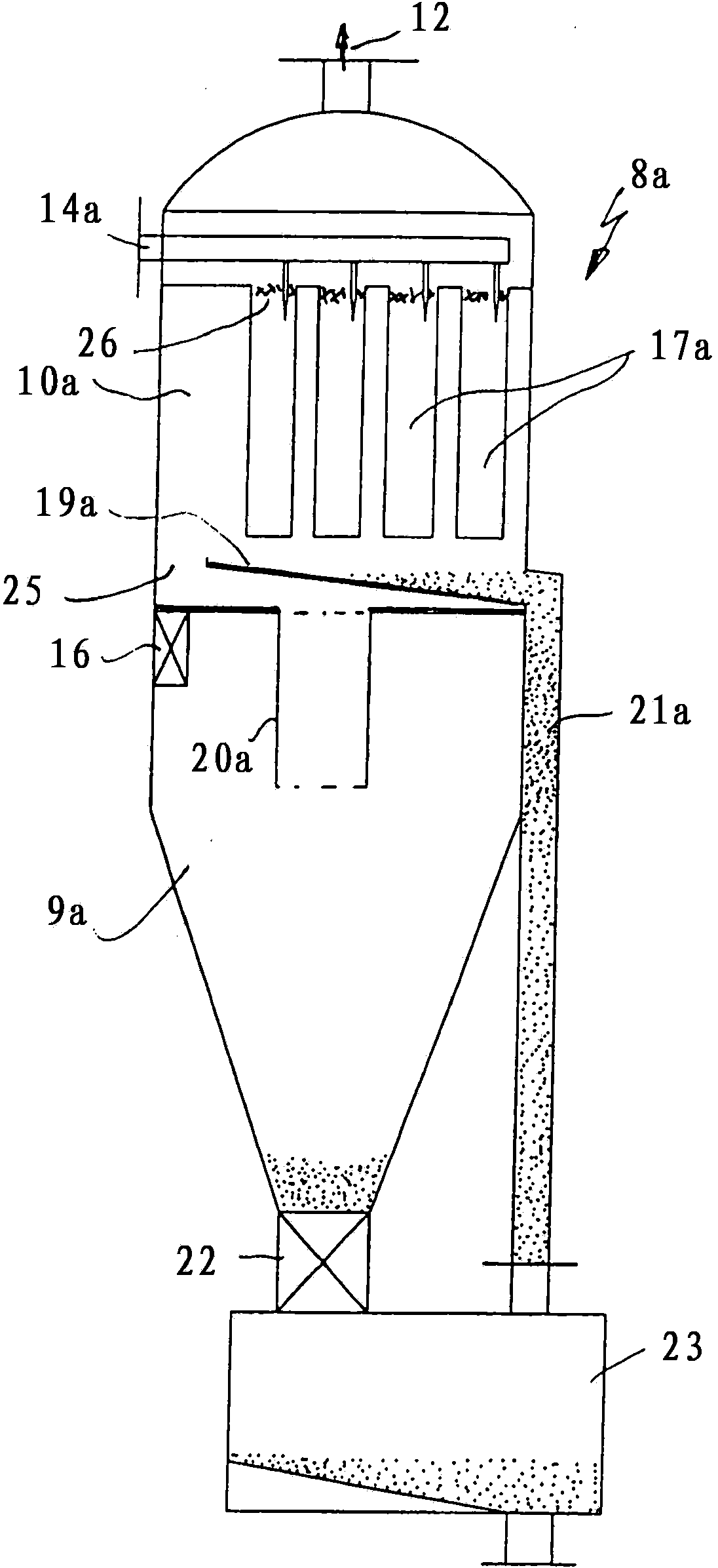

Integrated method and device of high temperature coal gas desulfur and dust removing

InactiveCN1478872ATake advantage ofOvercoming the disadvantage of low utilizationGas purification by treating with solidsFilter mediaSmall footprint

A process for desulfurizing and dusting high-temp gas features that the metallic oxide as desulfurizing agen is used as filter medium, the composite moving particles bed is used as filter, and the particles move downward and gas passes transversely through the particle layer to remove gas-state sulfide and dust. Said composite particles-moving bed has upper and lower layers and the gas passes through the particle layer upward.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Technology for producing cooled coal gas with no discharge of phenolic water

InactiveCN101613626ASolve the emission problemEasy to remove dustGas purification by treating with solidsGas dust removalTarProcess engineering

The invention relates to a technology for producing cooled coal gas with no discharging of phenolic water, belonging to the technical field of coal gas production and providing a technology for producing cooled coal gas with no discharging of phenolic water which has no contamination of the environment and can save energy and investment. The process flow of a single stage coal gas producer is as follows: the hot coal gas enters a ceramic filter deduster from the outlet of the coal gas producer; then enters an indirect cooling device to carry out heat exchange with phenolic water and the temperature drops to 40-50 DEG C; the cooled coal gas enters an electro detarrer to remove tar oil and small dust particles; the purified coal gas is supplied to users through a coal gas compresser; the phenolic water is heated into phenolic vapor and is used as gasification agent after being introduced into the bottom of the coal gas producer. The process flow of a two-stage coal gas producer is as follows: the lower-stage gas emerges out of the coal gas producer and passes through the ceramic filter deduster and the indirect cooling device; the upper-stage coal gas emerges, enters a rough electrical coke arrester and a refined electrical coke arrester, and is converged with the lower-stage coal gas to obtain purified coal gas, thus optimizing the dedusting and heat exchanging processes of hot coal gas, improving dedusting effect and hot exchange efficiency, being capable of saving investment of devices, protecting environmental and saving energy.

Owner:唐山雷浩能源技术装备有限公司

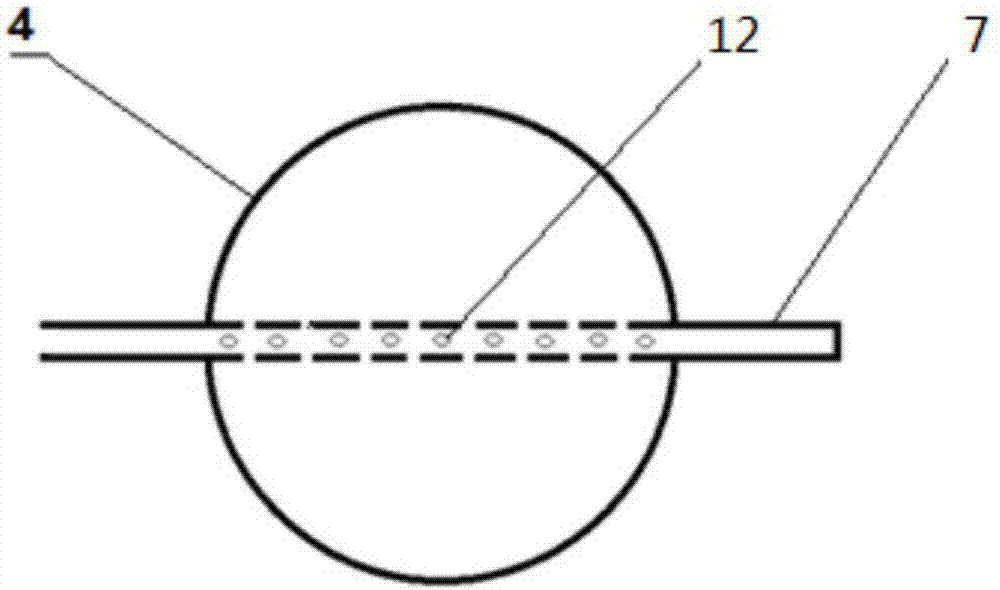

Blast furnace gas deacidification device

ActiveCN107034330AReduce generationHigh operating costsBlast furnace detailsIncreasing energy efficiencyEngineeringCorrosion

The invention relates to a blast furnace gas deacidification device which comprises a powder spray gun, an injection tank and a gas source, wherein the powder spray gun is connected with a gas pipeline and comprises a spray pipe penetrating the gas pipeline and spray nozzles arranged on the spray pipe; the spray nozzles are located in the gas pipeline; the injection tank is fixedly connected with the powder spray gun through a powder spray pipeline and is provided with a fluidization spray nozzle; and the gas source is connected with the fluidization spray nozzle through a gas pipe and used for conveying an injection carrier. The blast furnace gas deacidification device can absorb most acid gases such as chlorine and sulfur in blast furnace gas, save water and electricity, reduce the generation of high-salinity wastewater, alleviate the corrosion of the gas pipeline and downstream gas user facilities caused by blast furnace gas, and guarantee the calorific value of gas and the generating capacity of a blast furnace top gas recovery turbine unit.

Owner:SHOUGANG CORPORATION

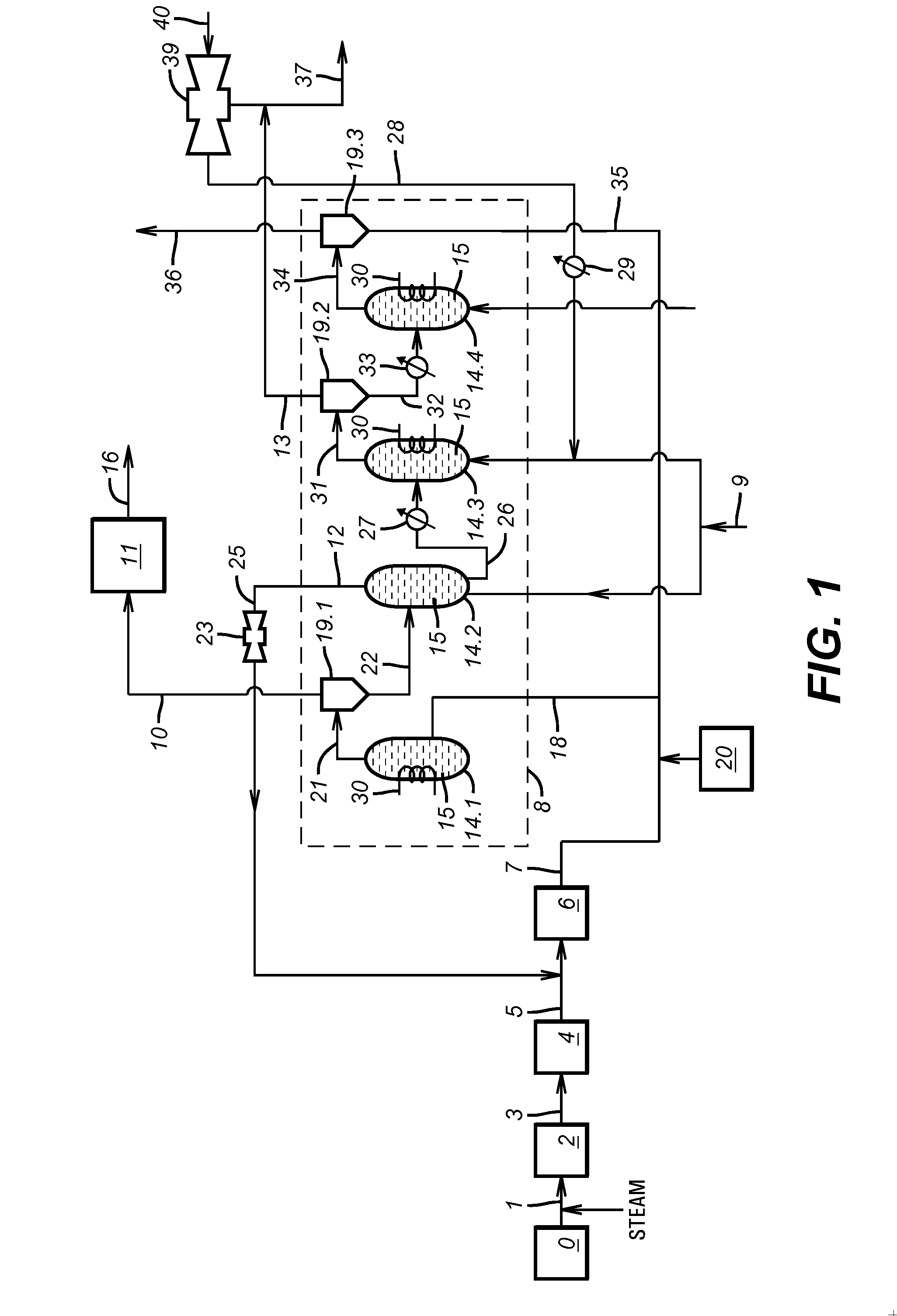

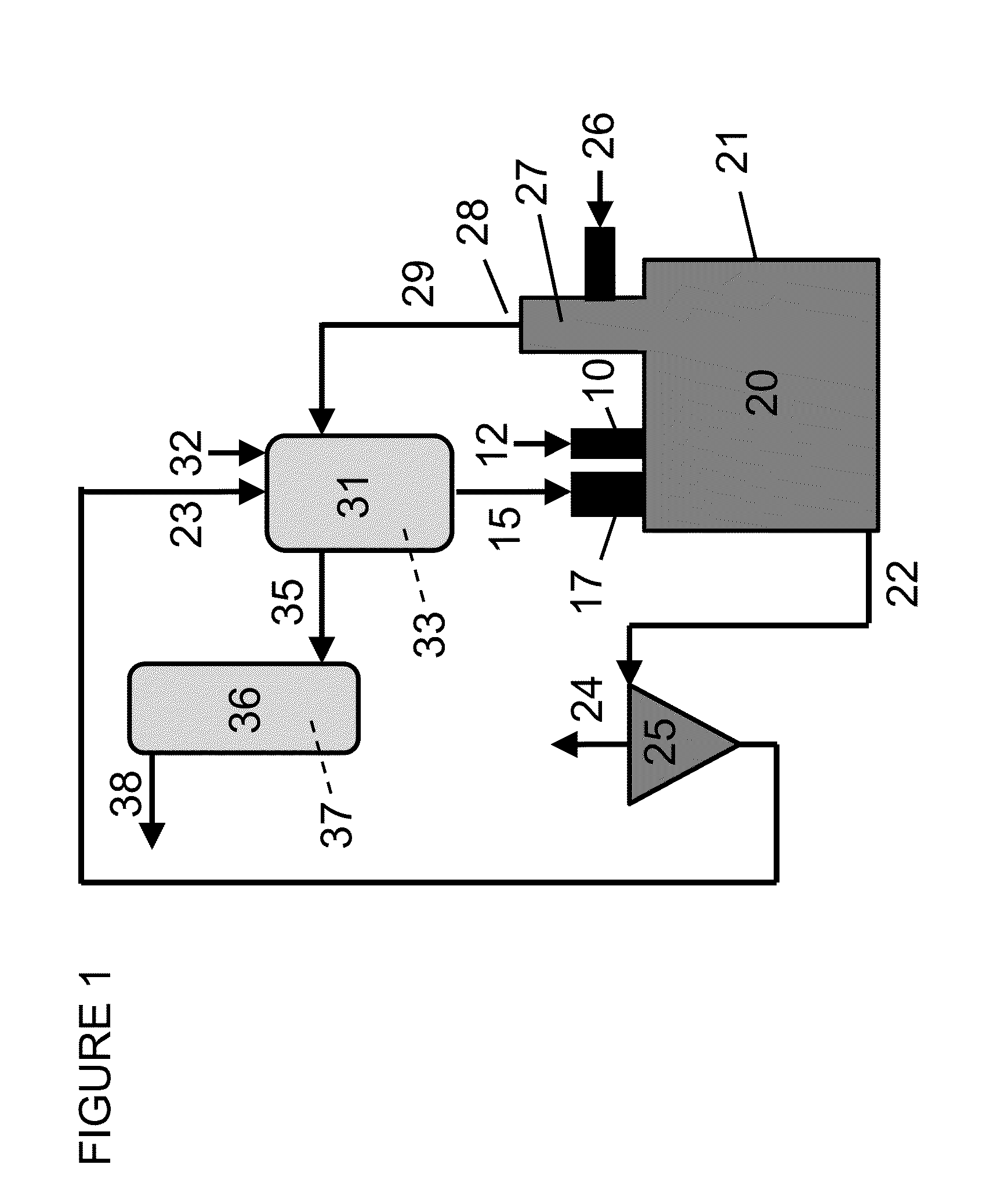

Process For The Production Of Hydrogen And Carbon Dioxide Utilizing Magnesium Based Sorbents

InactiveUS20130011326A1Economic recoveryImprove economyCarbon compoundsHydrogen separation using solid contactSorbentHydrogen pressure

The present invention relates to a process for recovering hydrogen along with high temperature high pressure carbon dioxide from one or more hydrocarbon gas streams by incorporating a carbon dioxide recovery unit which utilizes a fluidized magnesium based sorbent into a process that includes a gasification unit, an optional sulfur removal unit, a water gas shift reactor and a hydrogen pressure swing adsorption unit.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

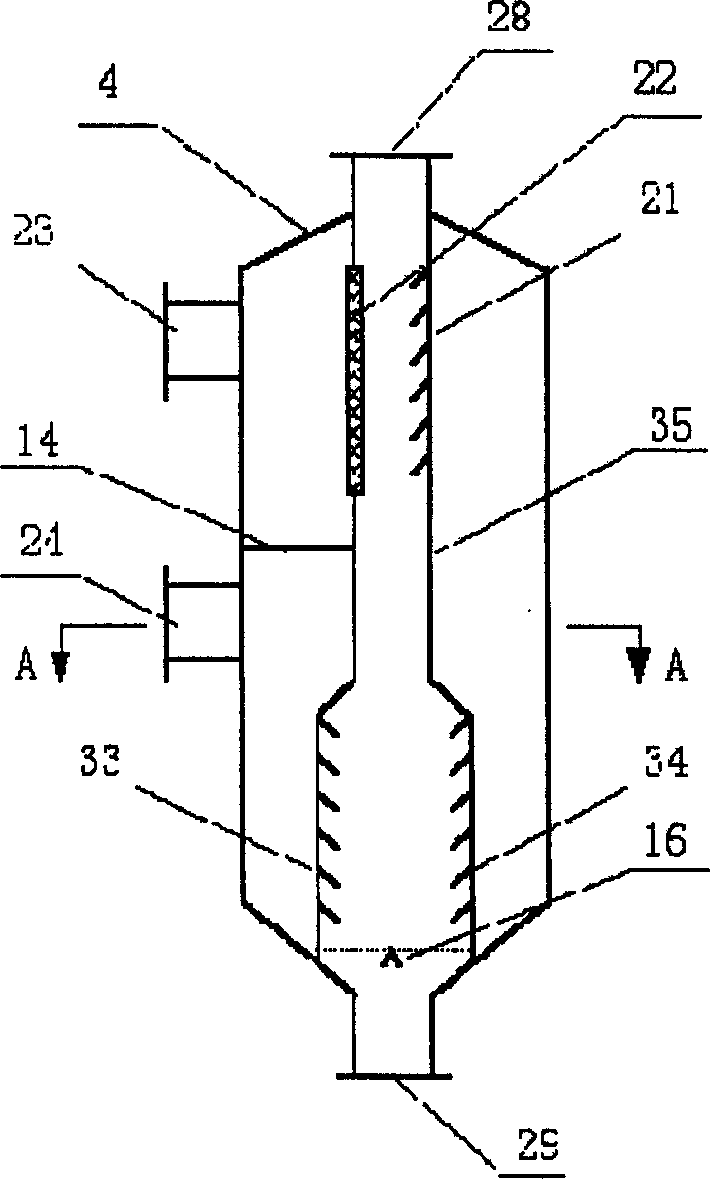

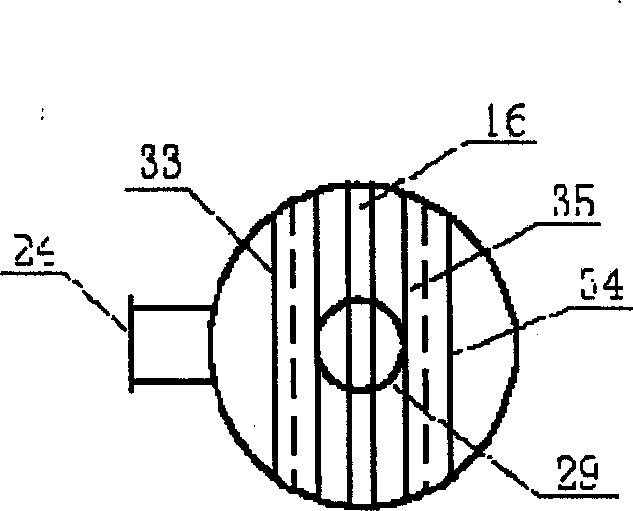

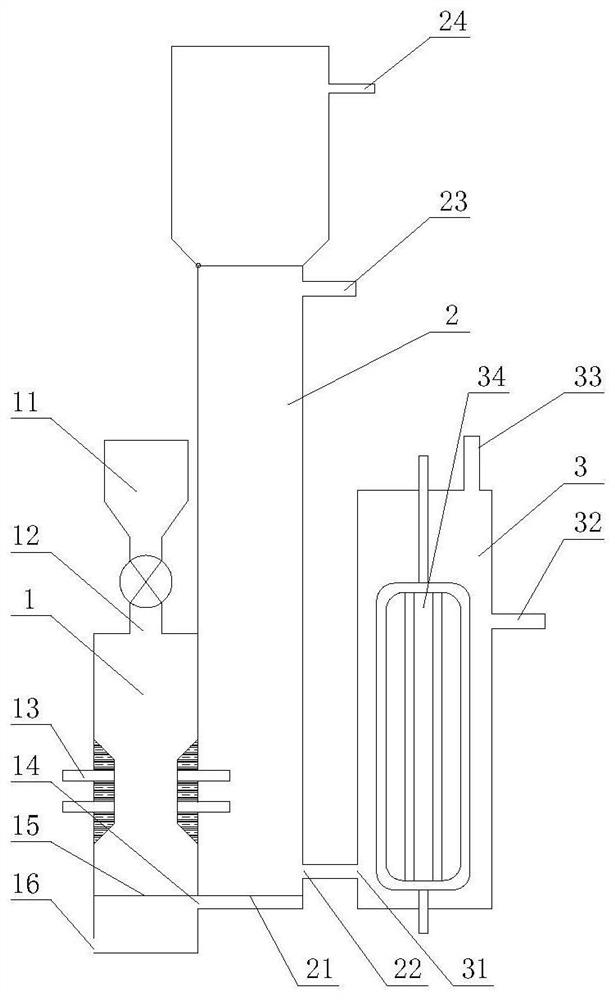

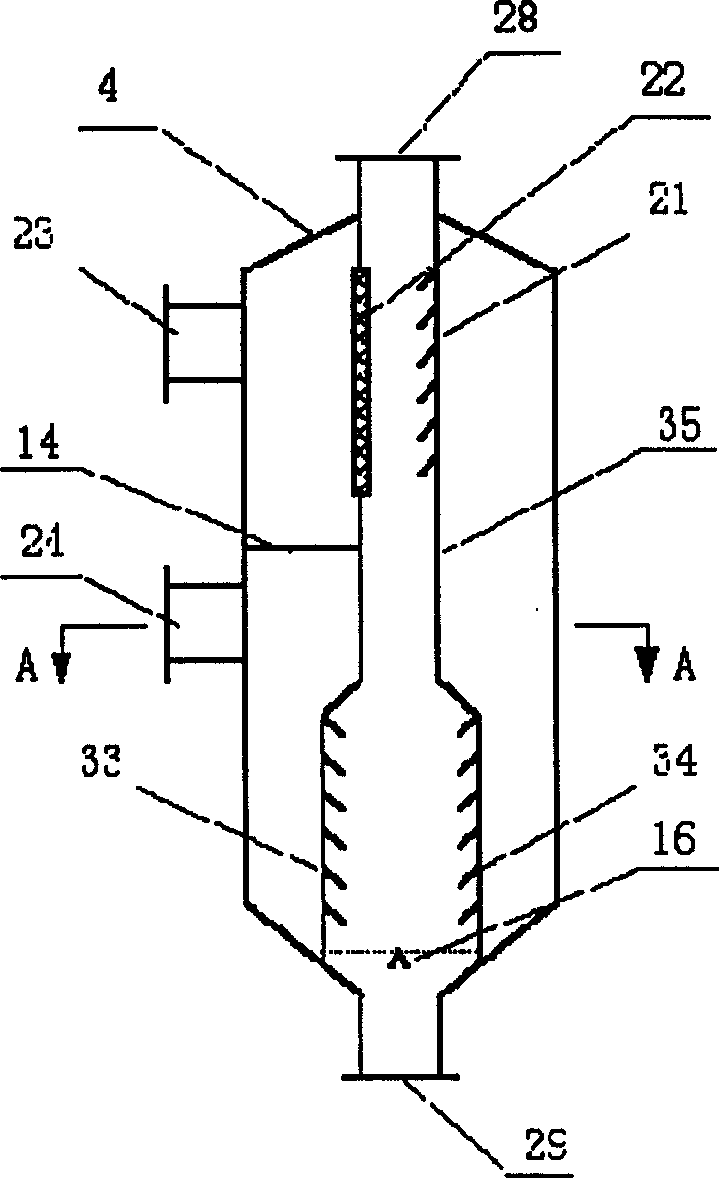

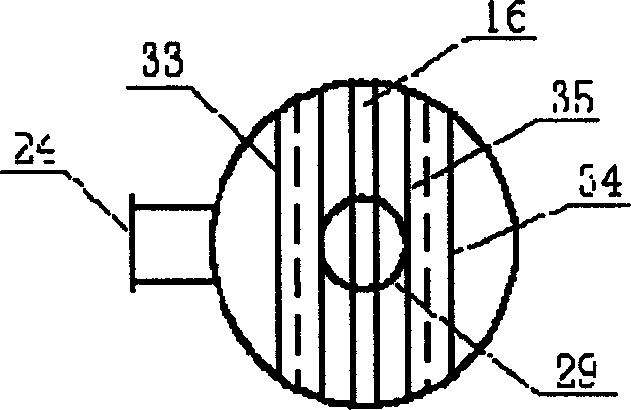

Integrated device and process for carrying out desulfurization, dust removal and modification on coal-pyrolyzed gas

ActiveCN104031693AWith recycling functionSignificantly environmentally friendlyGas purification by catalytic conversionGas purification by treating with solidsTarCoke oven

The invention discloses an integrated device and process for carrying out desulfurization, dust removal and modification on coal-pyrolyzed gas. Raw coke oven gas from a medium and low-temperature coal dry-distillation furnace or a coke oven directly enters an integrated moving bed purifier, and the desulfurization, dust removal and modification processes are implemented without reducing the temperature by utilizing the physical sensible heat taken by the gas so as to obtain clean and high-quality coal tar and gas. The integrated moving bed purifier is divided into three parts, including a desulfurization region, a primary catalytic region and a secondary catalytic region which are sequentially filled with a desulfurizing agent, a natural ore type tar cracking catalyst and an artificial tar cracking catalyst; when dust in the gas passes through a particle bed which is in a stacked state, the aim of dust purification can be reached by impact, sedimentation, interception and the like. All the desulfurizing agent and catalysts can be regenerated and recycled in place. The device and the process disclosed by the invention can be used for implementing the desulfurization, dust removal and modification in one step, are beneficial to simplification of the subsequent process of a coal thermal process, and have the advantages of increasing the added value of pyrolysis products and reducing the environmental pollution.

Owner:SHANDONG UNIV OF SCI & TECH

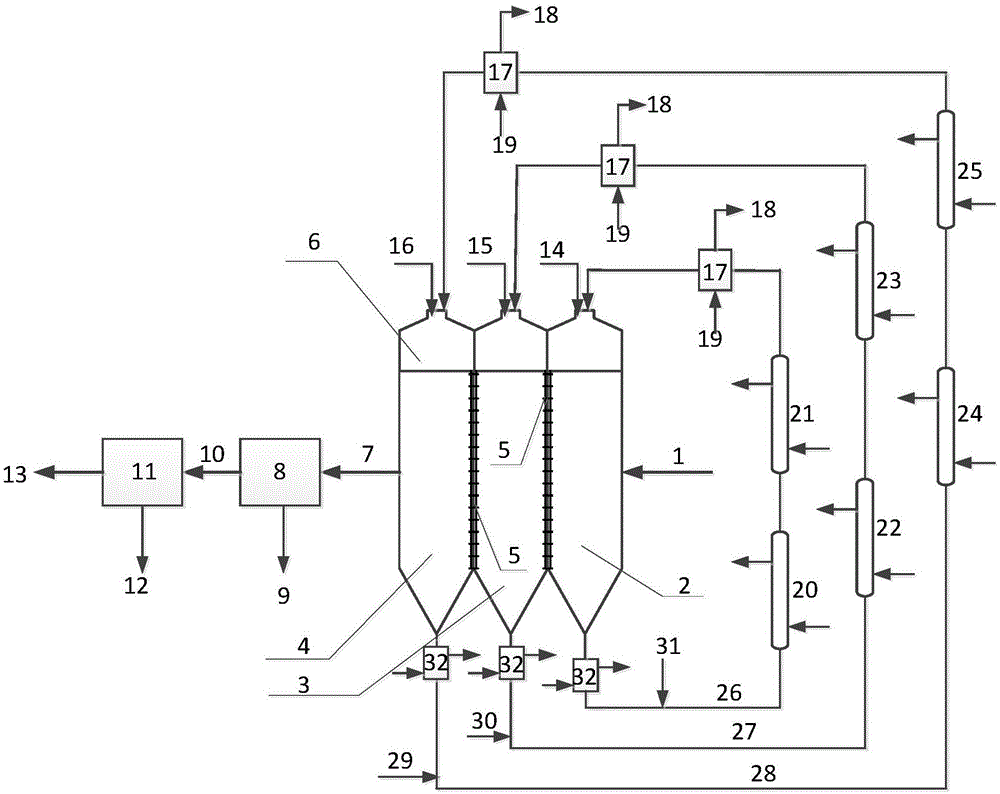

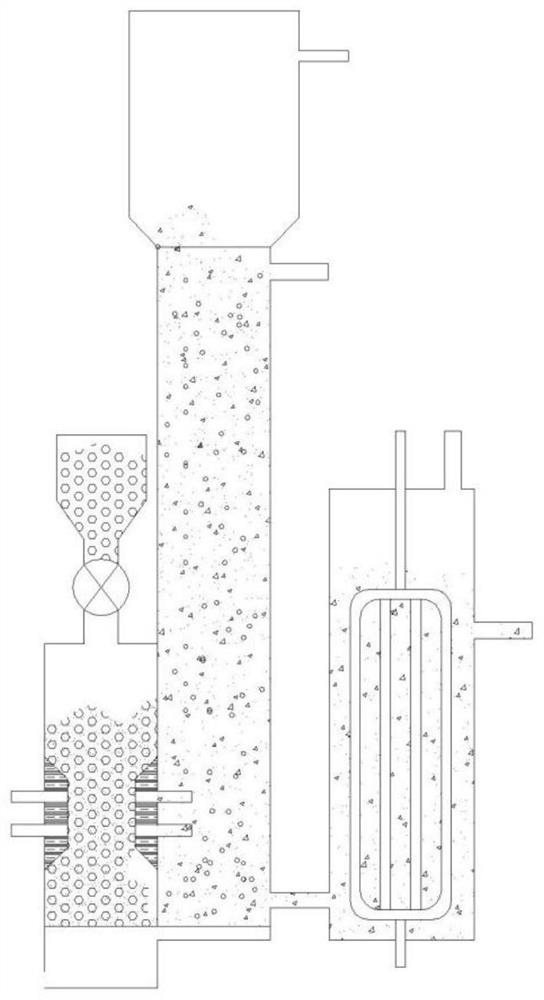

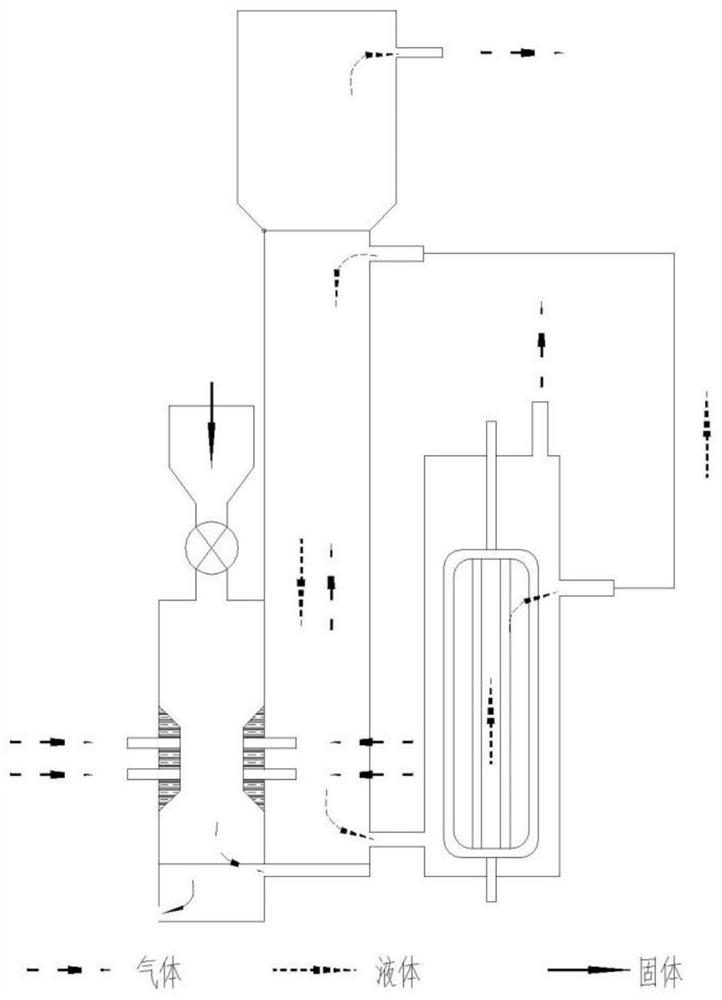

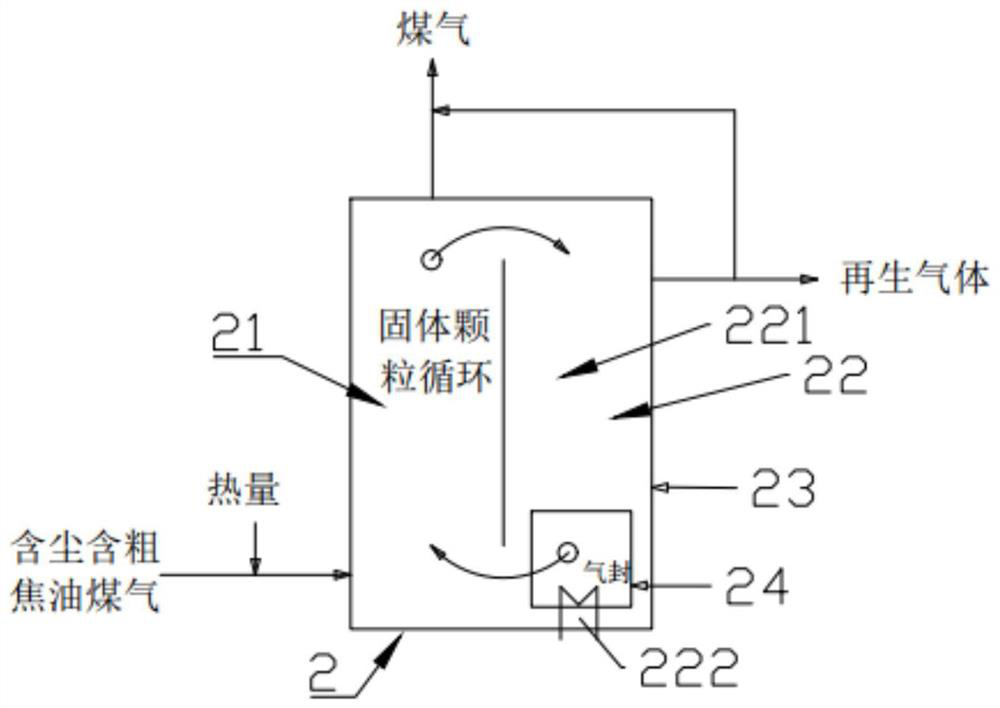

Combined process and device for dust removal for pyrolysis coal gas and delayed coking for heavy oil

ActiveCN104762109AAdvantages of dust removal processEasy to operateGas purification by treating with solidsGas dust removalProcess engineeringMoving bed

The invention provides a process and a device for dust removal for a pyrolysis coal gas, and a combined process and device for dust removal for a pyrolysis coal gas and delayed coking for heavy oil. The process for dust removal for the pyrolysis coal gas comprises the following steps: (1) enabling the pyrolysis coal gas to reversely pass through a moving bed particle layer formed by dry coal to obtain primary dust removal coal gas; and (2) carrying out a secondary dust removal treatment on the primary dust removal coal gas by the heavy oil with fractions with temperature of 350 DEG C or above to obtain dustless coal gas. Compared with the prior art, the process for dust removal disclosed by the invention is simple to operate and low in energy consumption and facilitates large-scale running; in addition, the process for dust removal for the pyrolysis coal gas is perfectly coupled together with delayed coking for heavy oil for the first time, thus greatly simplifying the process flow, reducing the operation difficulty, and reducing the cost investment and the energy consumption of a production device.

Owner:SHAANXI COAL & CHEM IND GRP SHENMU TIANYUAN CHEM IND +1

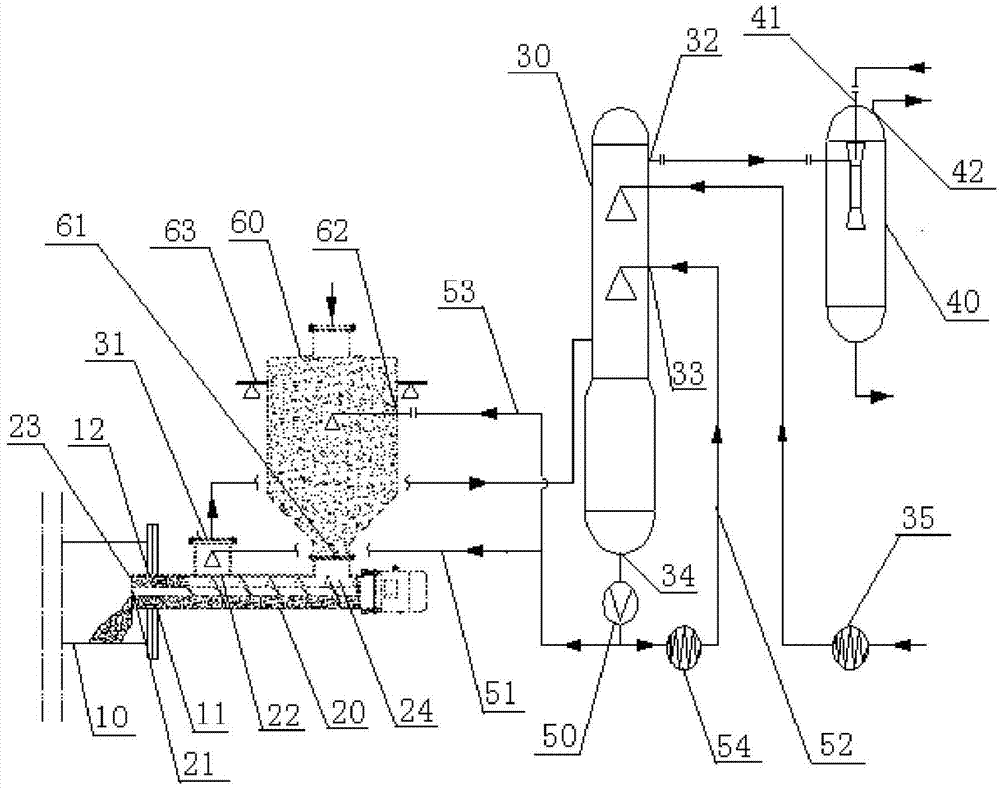

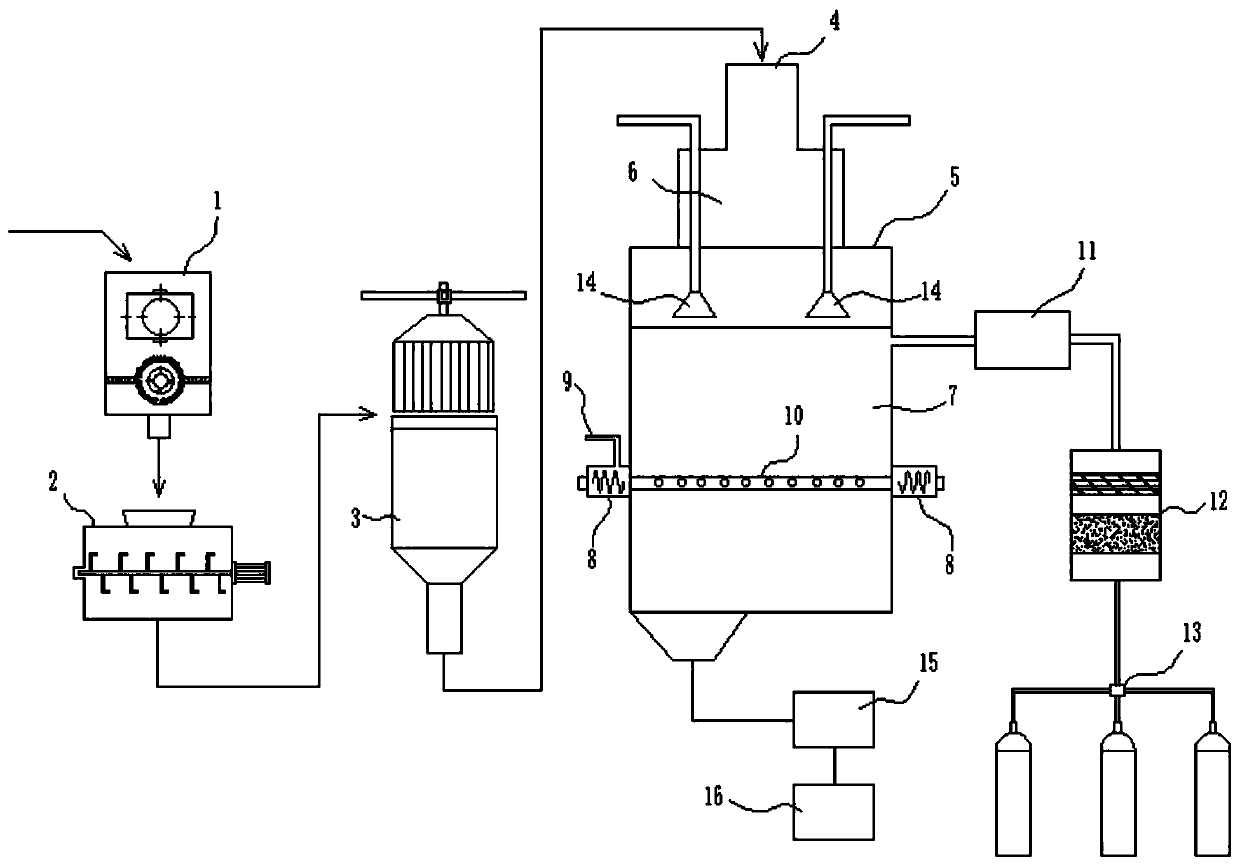

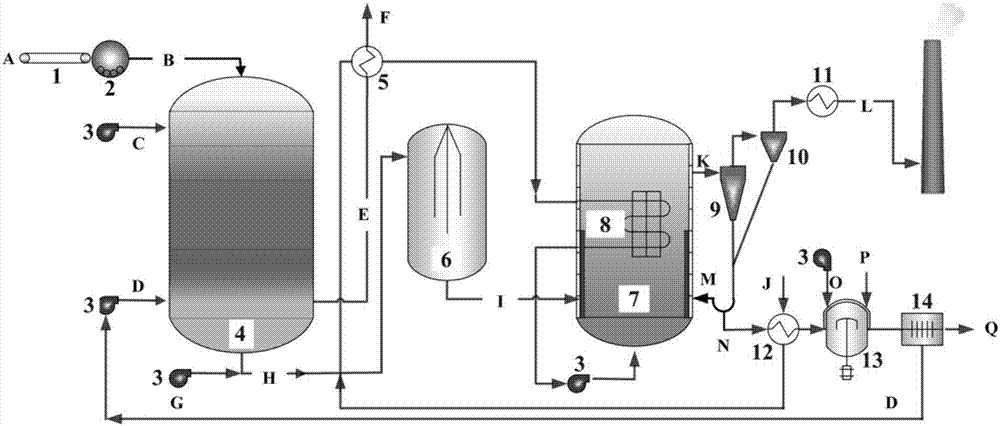

Solid waste plasma gasification pyrolysis recycle transformation method

ActiveCN107216916AIncrease the average comprehensive calorific valueEasy to fixGasification processes detailsGas purification by treating with solidsEnvironmental resistanceOperational costs

The invention discloses a solid waste plasma gasification pyrolysis recycle transformation method, which belongs to the technical field of garbage disposal, and mainly comprises the four steps of sorting and pretreating wastes, carrying out gasification pyrolysis on plasma, purifying gas and regenerating energy. Through adding a combustion-supporting mixture, an average comprehensive heat value and the fixed carbon content of the solid wastes are improved, so that the power consumption during a plasma gasification pyrolysis process is reduced; meanwhile, the method and a power station are linked to offset a part of and even all electric energy in the later period, so that the operation cost is reduced. A pulsed electromagnetic valve is utilized for spraying a dioxin inhibitor, dioxin is prevented from compounding at a low-temperature area, a later-period filtration and adsorption device is cooperated to thoroughly purify gas, and finally residues produced by gasification can be used for manufacturing microcellular foam glass used as an adsorbing medium, so that cyclic utilization of resources is realized. The solid waste plasma gasification pyrolysis recycle transformation method provided by the invention is high in recovery utilization rate, free of poisonous gas and matter discharge, green and environmentally-friendly, and favorable in economic benefit.

Owner:东莞中普环境科技有限公司

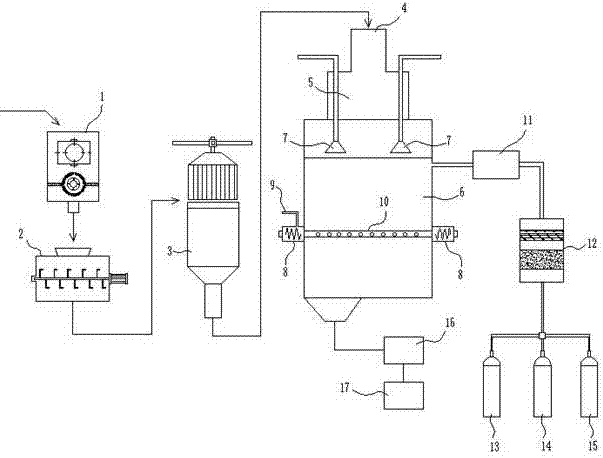

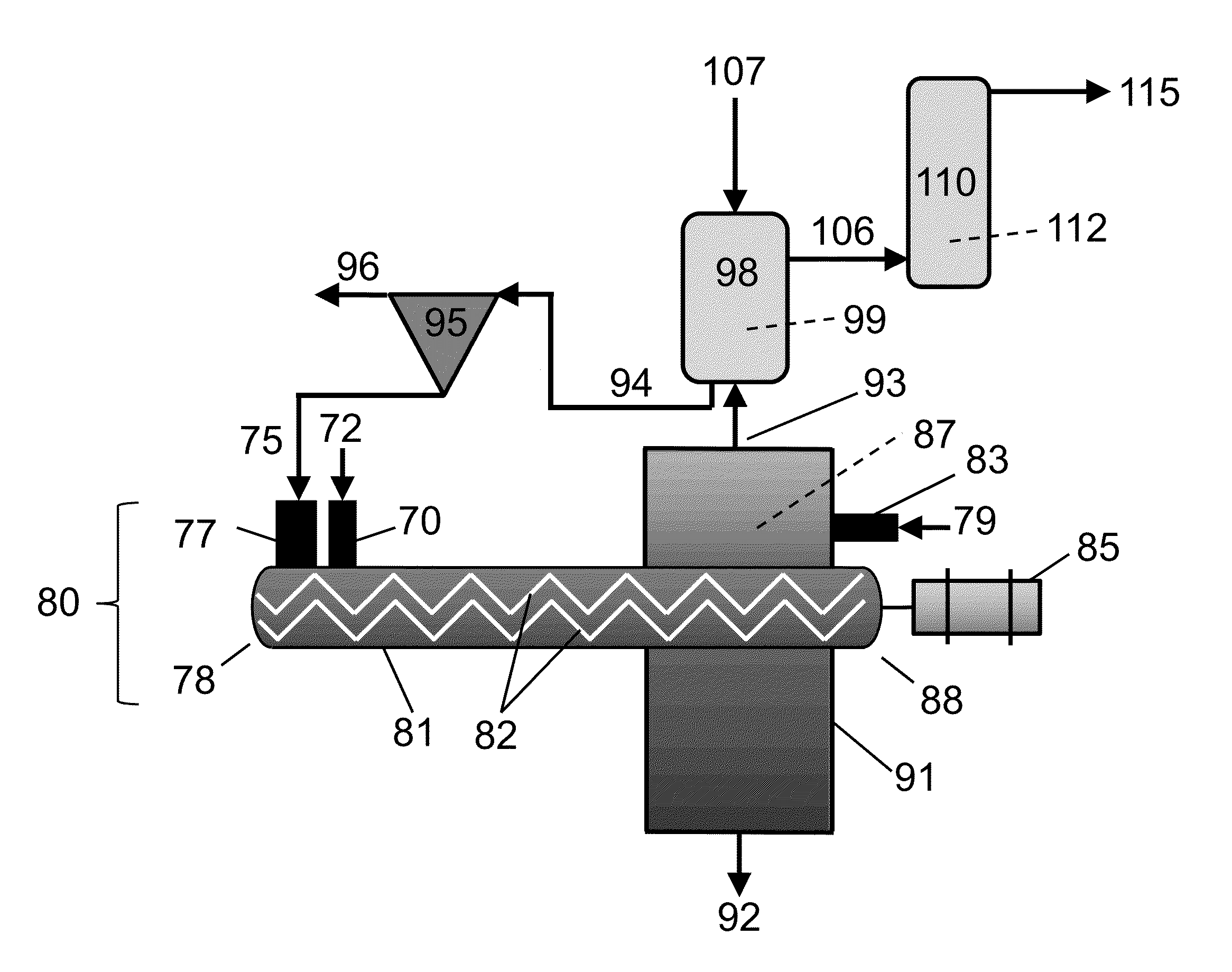

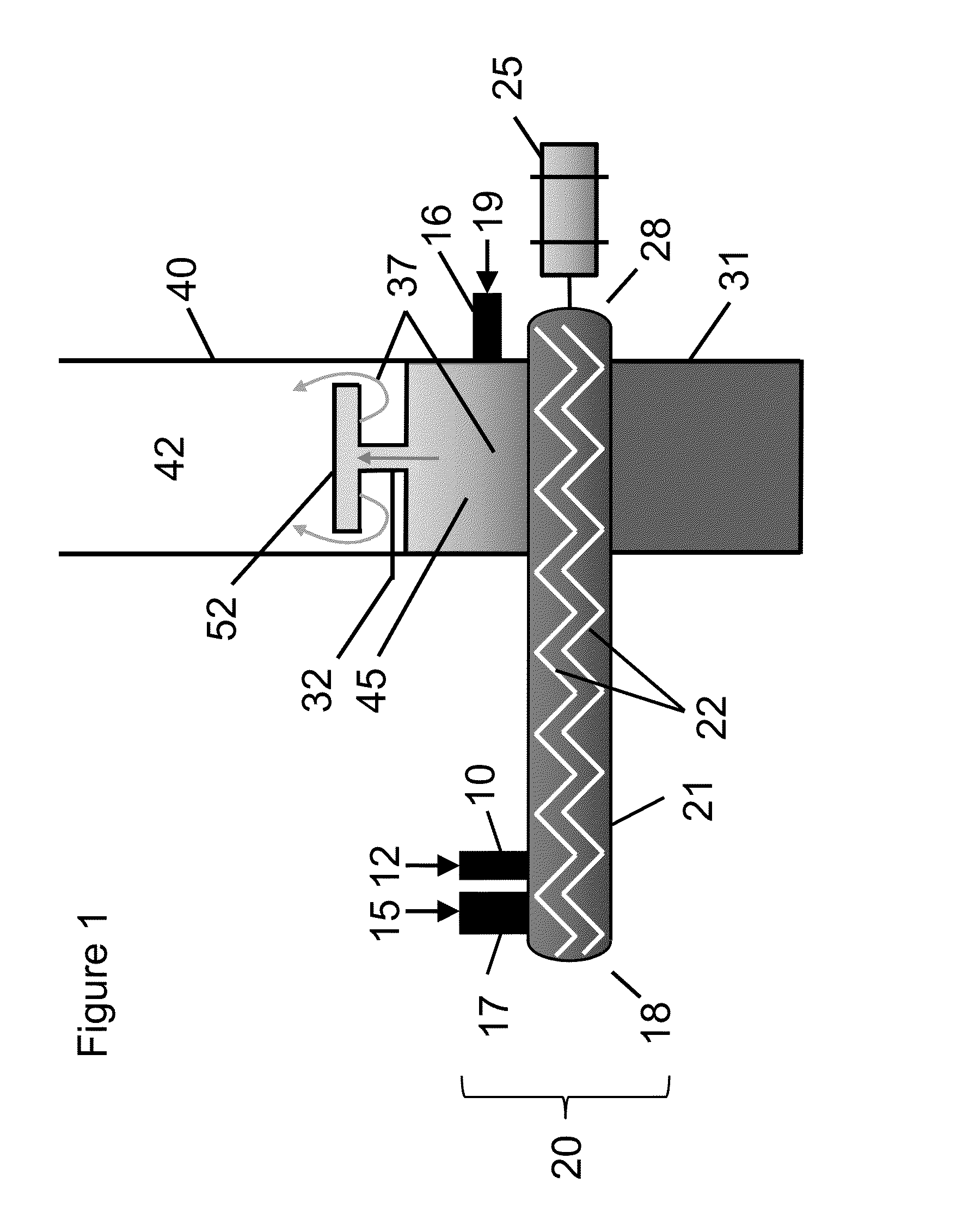

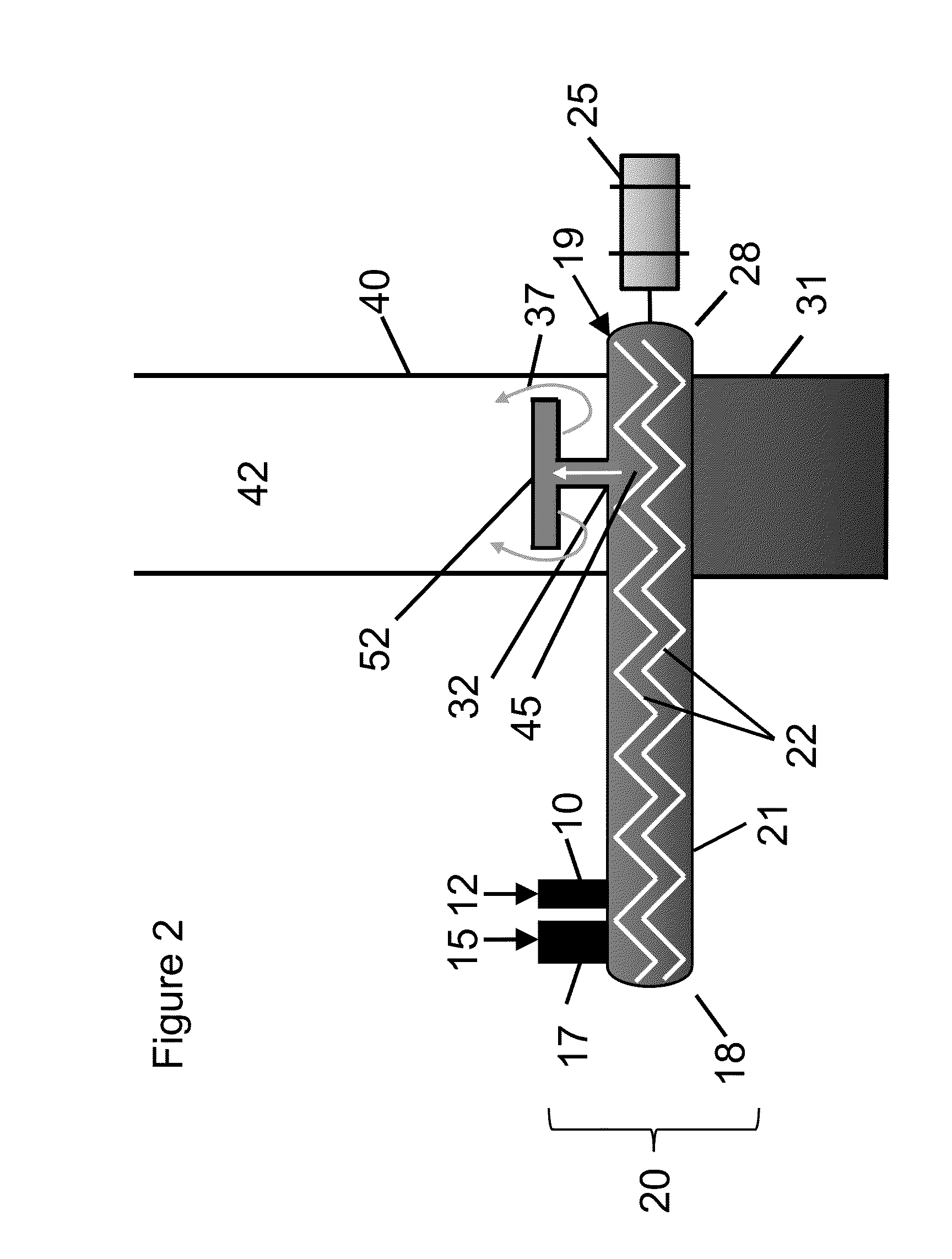

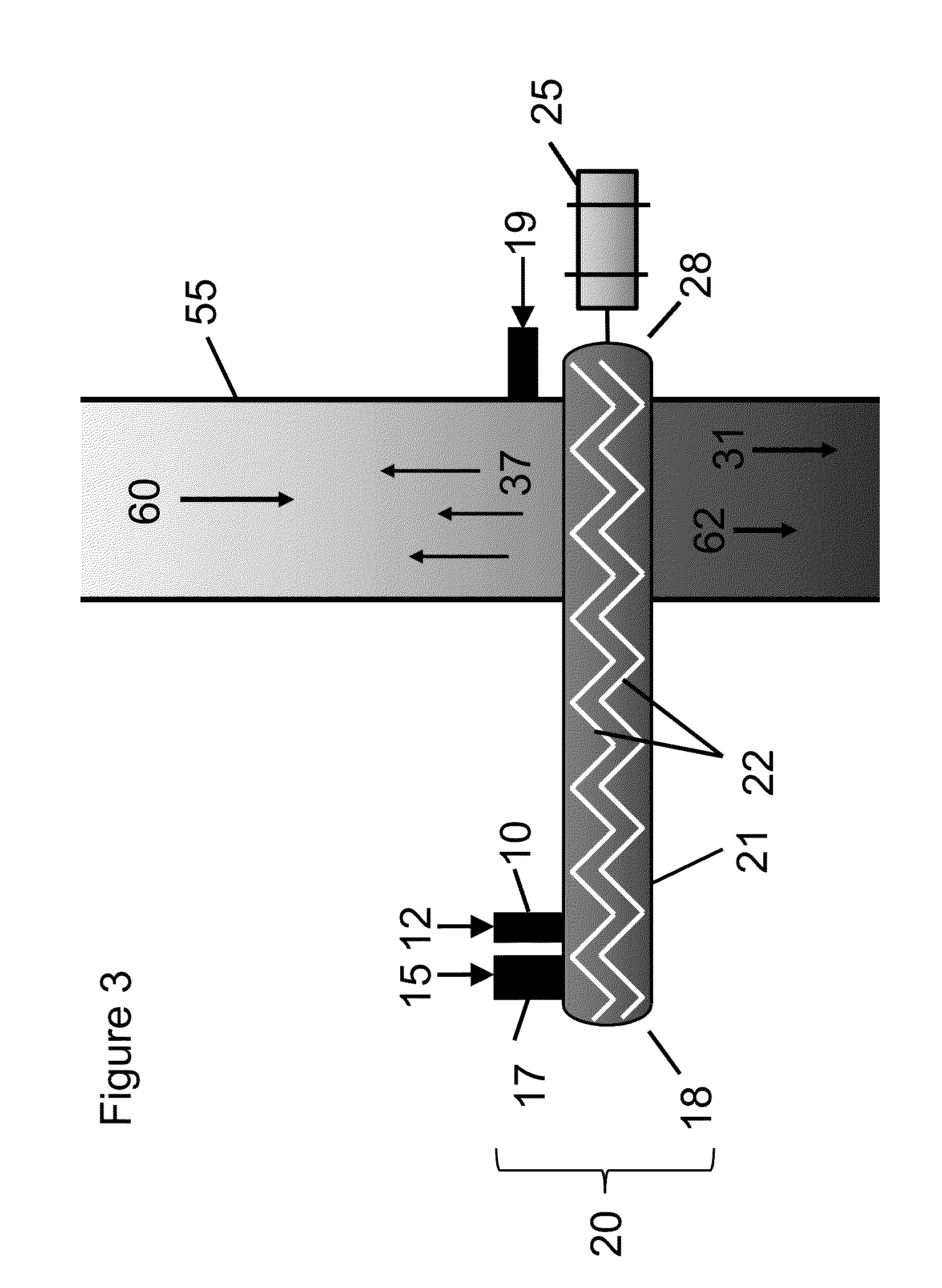

Pyrolysis vapor rapid filtration and conversion to fuel

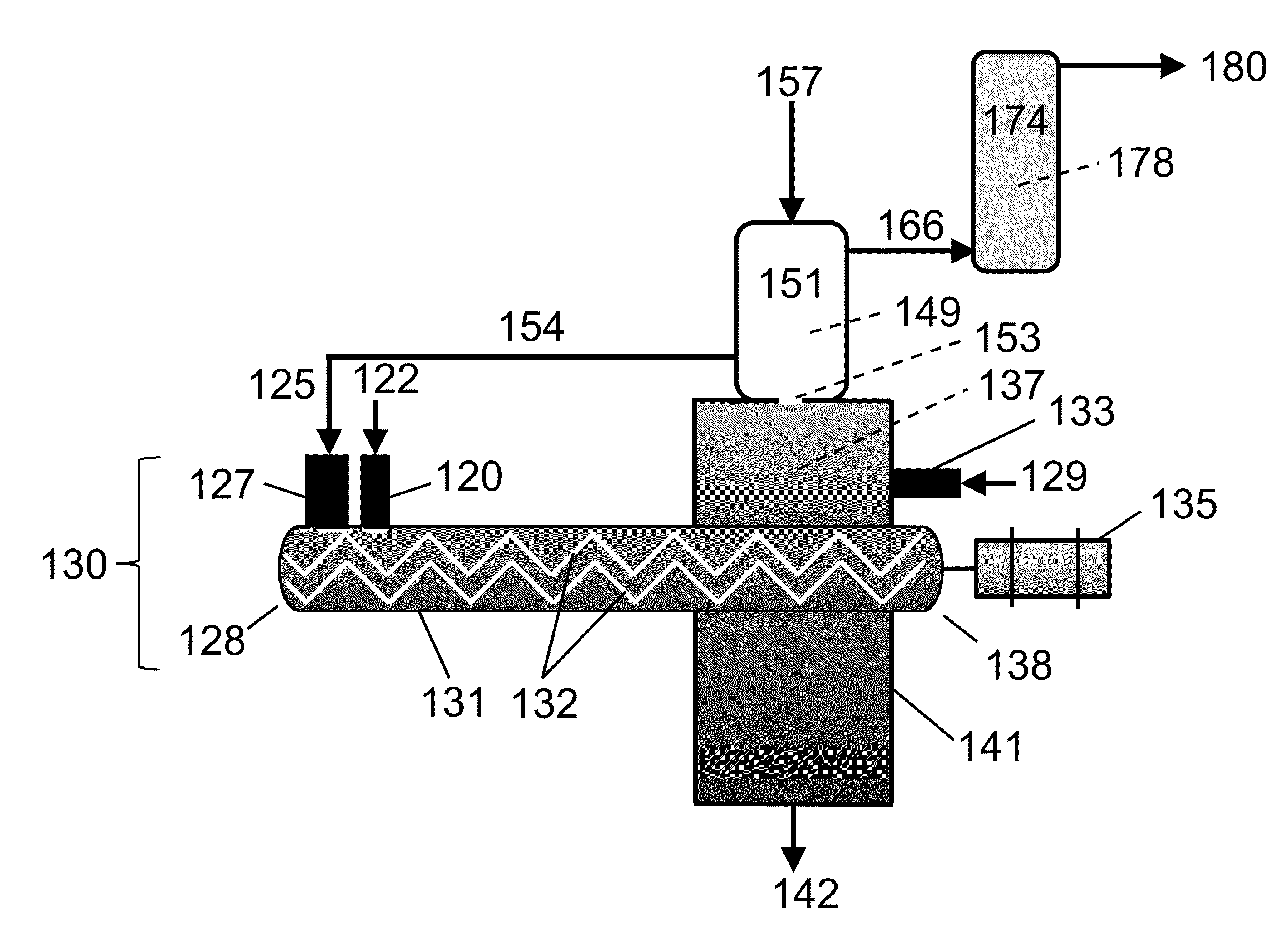

InactiveUS20140072480A1Delay minimizationDirect heating destructive distillationCombustible gas catalytic treatmentHeat carrierHydrocarbon mixtures

The present disclosure pertains to biomass pyrolysis processes and systems that decrease entrainment of char and other contaminants in the pyrolysis vapors by filtering the vapors in a heated container comprising a moving bed granular filter (MBGF), which in turn, comprises granular heat carrier. The granular heat carrier is heated within the MBGF and fed directly to the pyrolysis reactor, optionally along with filtered solids such as char. In certain embodiments, the MBGF additionally comprises at least one upgrading catalyst that contacts the vapors to produce a hydrocarbon mixture fungible with a petroleum-derived transportation fuel, a hydrocarbon transportation fuel component, or mixtures thereof.

Owner:PHILLIPS 66 CO

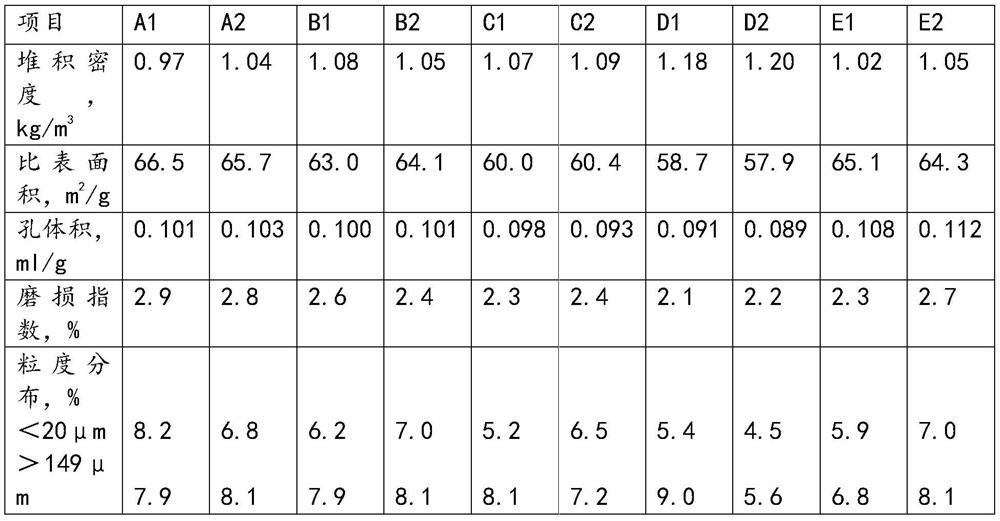

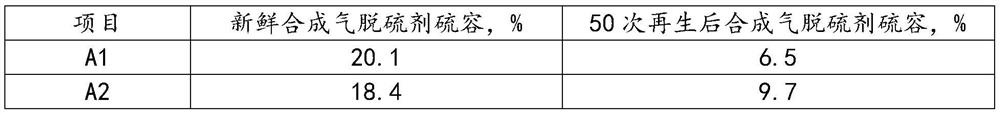

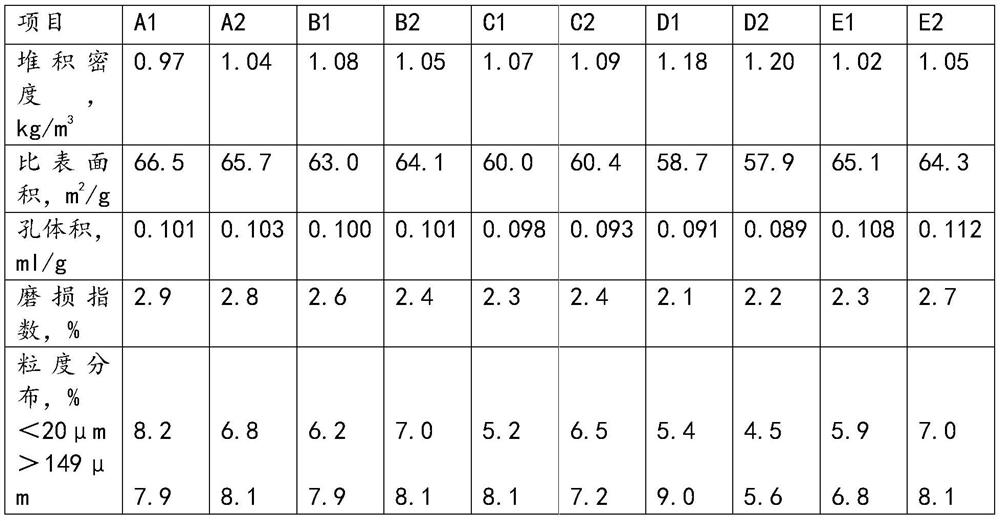

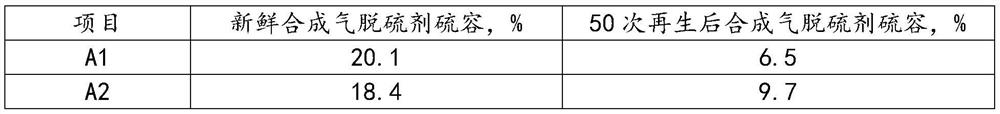

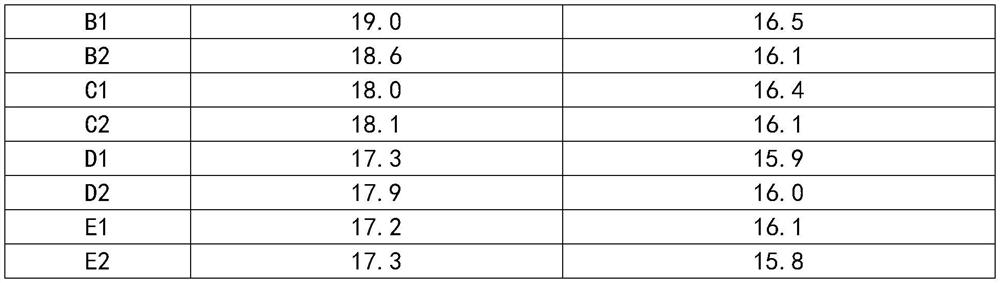

Synthetic gas desulfurizing agent as well as preparation method and application thereof

ActiveCN111701411AImprove structural stabilityHigh ability to remove sulfideGas treatmentDispersed particle separationFluidized bedProcess engineering

The invention discloses a synthetic gas desulfurizing agent as well as a preparation method and application thereof. The synthesis gas desulfurizing agent is prepared by modifying a conventional zincoxide desulfurizing agent through a metal oxide and a non-metal oxide. The prepared desulfurizing agent has very good structural stability, and still has high sulfide removal capacity under the conditions of high water vapor partial pressure and high-temperature oxidation. The synthetic gas desulfurizing agent is a renewable solid desulfurizer for removing hydrogen sulfide and organic sulfur fromsynthetic gas, is suitable for a fluidized bed high-temperature desulfurization process, can remove hydrogen sulfide and organic sulfur from the synthetic gas, and can save energy and reduce consumption.

Owner:CHINA PETROLEUM & CHEM CORP +1

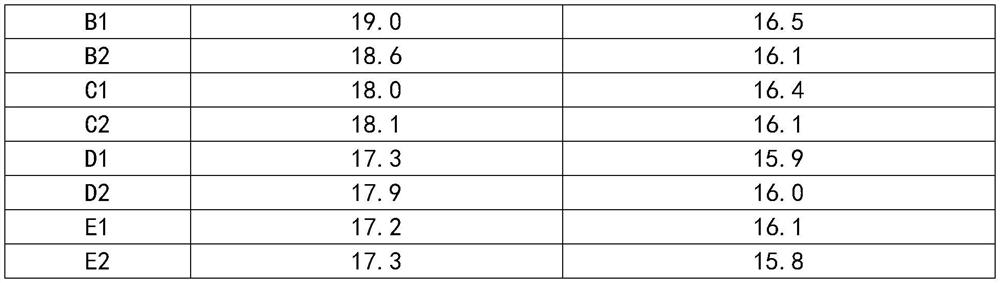

Dry desulfurization agent pretreatment system and pretreatment method

InactiveCN104324605ASimple structureLess investmentDispersed particle separationGas purification by treating with solidsSodium bicarbonatePretreatment method

The invention discloses a dry desulfurization agent pretreatment system, which is provided with a sodium hydrogen carbonate storage tank, an expansion device, a buffer tank, a sodium carbonate storage tank and a grinding device, which are communicated in sequence; a proportional valve is arranged in the communication pipeline of the sodium hydrogen carbonate storage tank and the expansion device, and a heating and roasting device is arranged in the expansion device; an instantaneous pressure relief valve is arranged in the communication pipeline of the expansion device and the buffer tank, and the buffer tank is communicated with the atmosphere. Sodium hydrogen carbonate is heated by a heating system to be decomposed to generate sodium carbonate; when the pressure reaches a certain value in the reaction, the pressure is instantaneously relieved to the buffer tank. The generated sodium carbonate is grinded by the grinding device and is sprayed into a desulfurizing tower by an ejection system after reaching a certain number to react with SO2 so as to desulfurize. The system has the advantages of simple structure, little investment, convenience in operation and the like.

Owner:ANHUI TONGXING ENVIRONMENTAL PROTECTION ENG

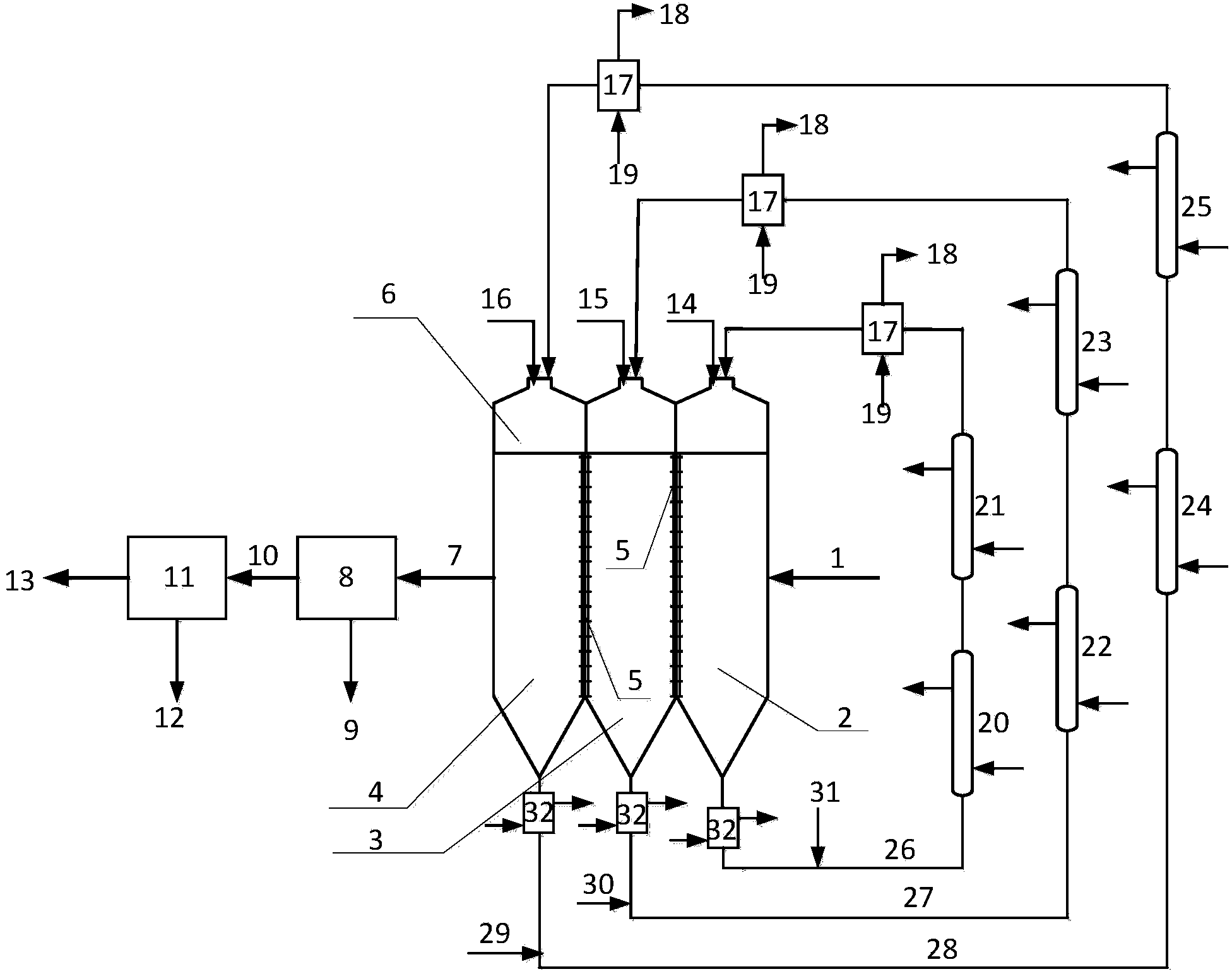

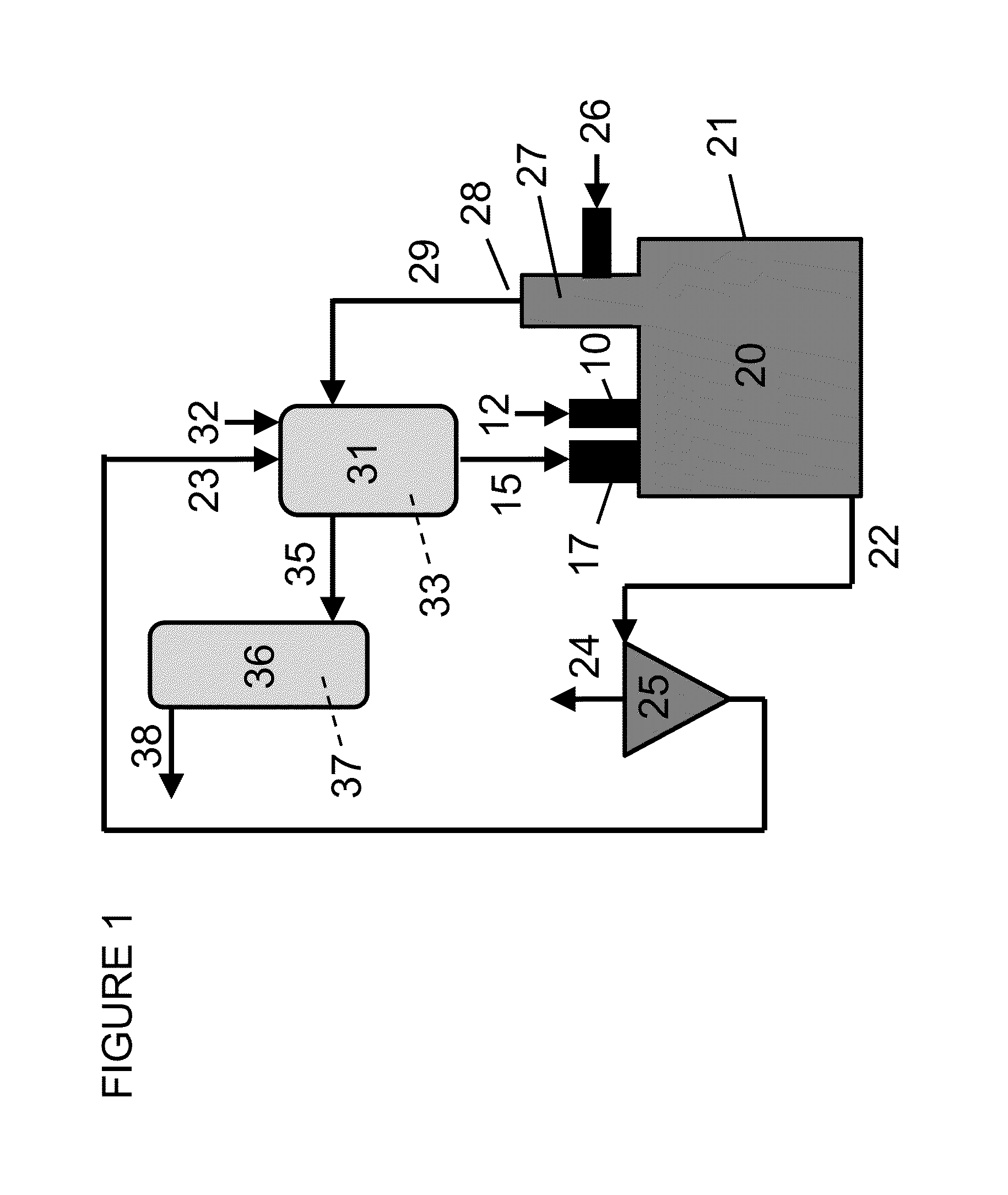

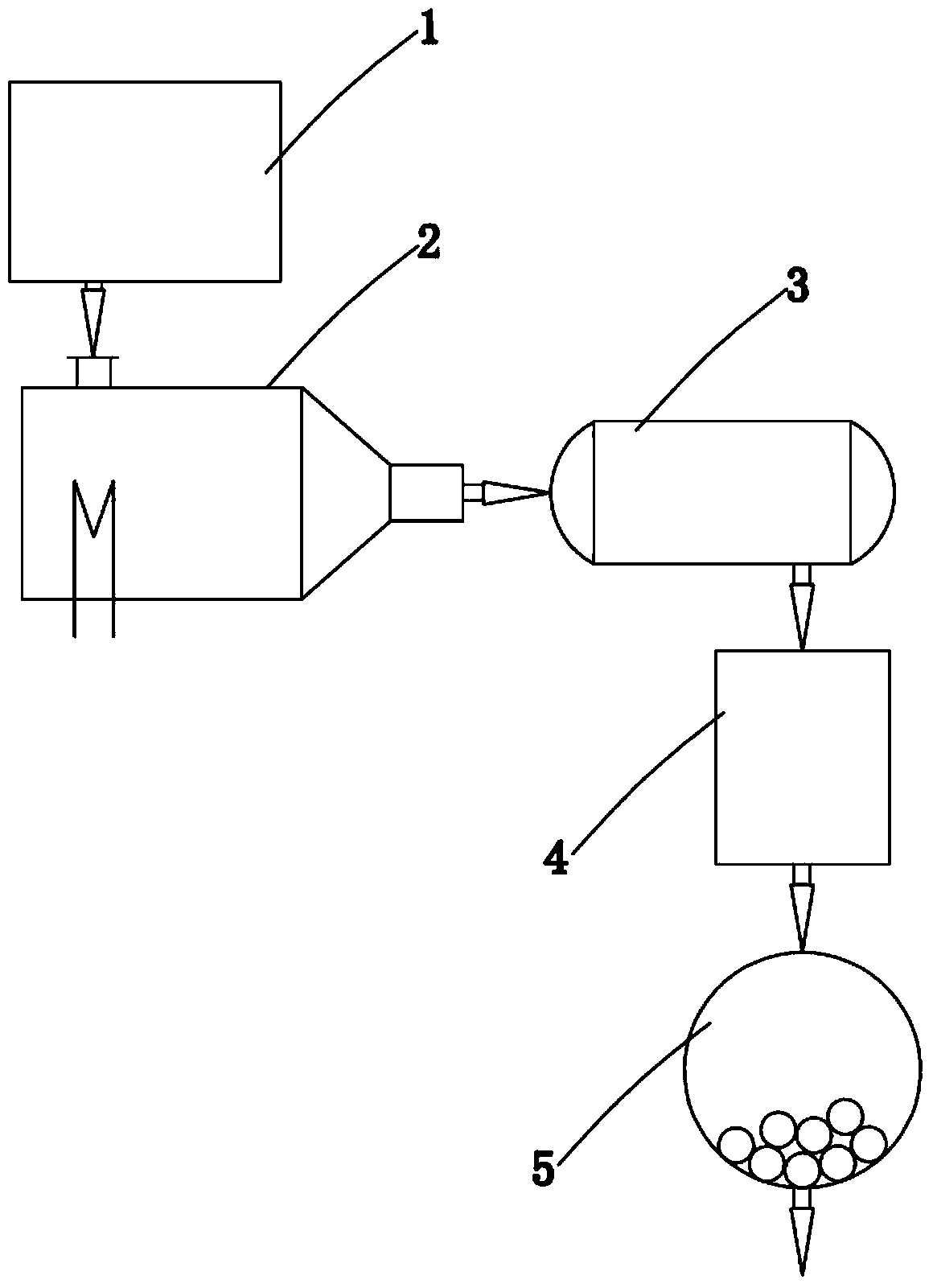

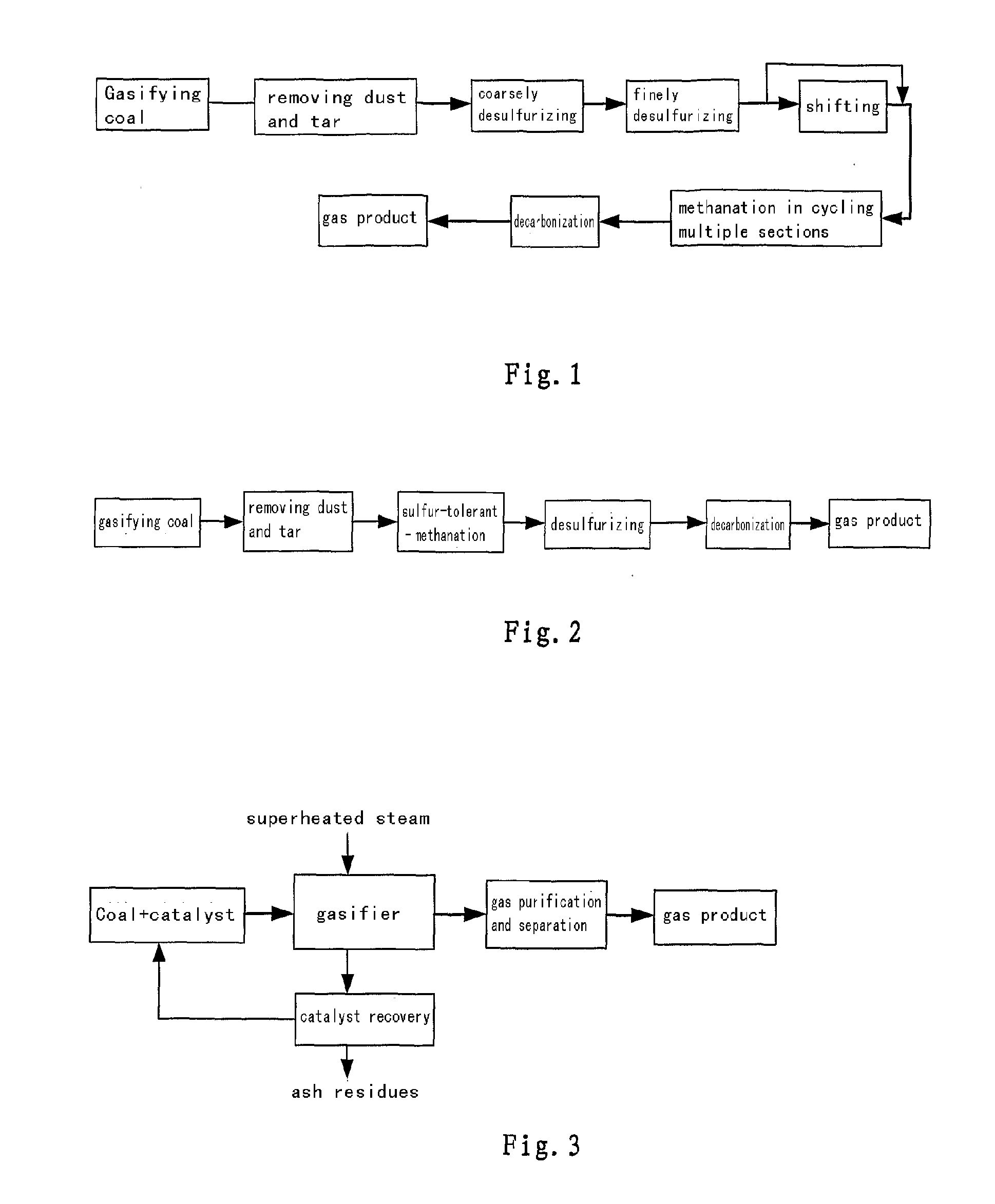

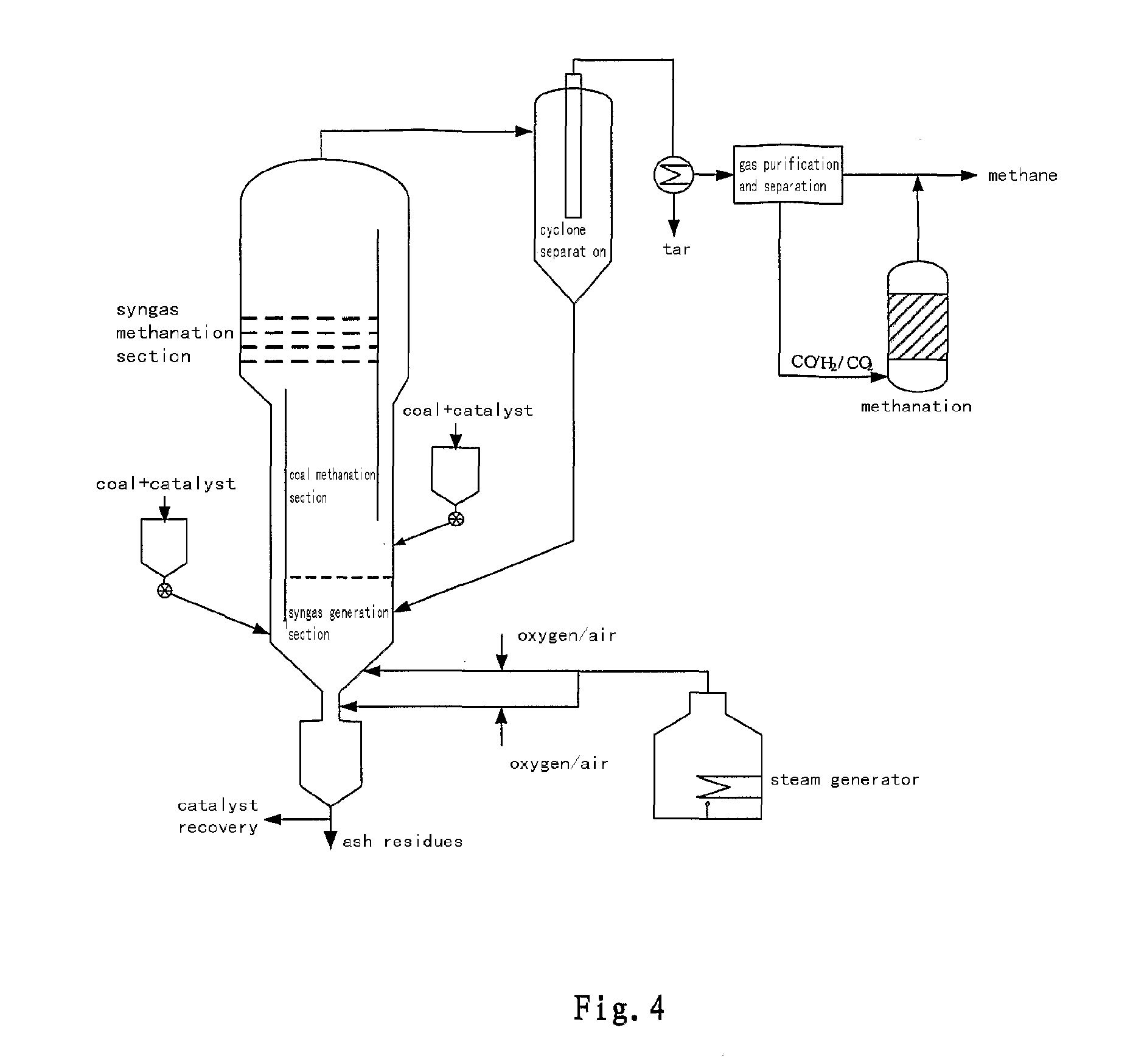

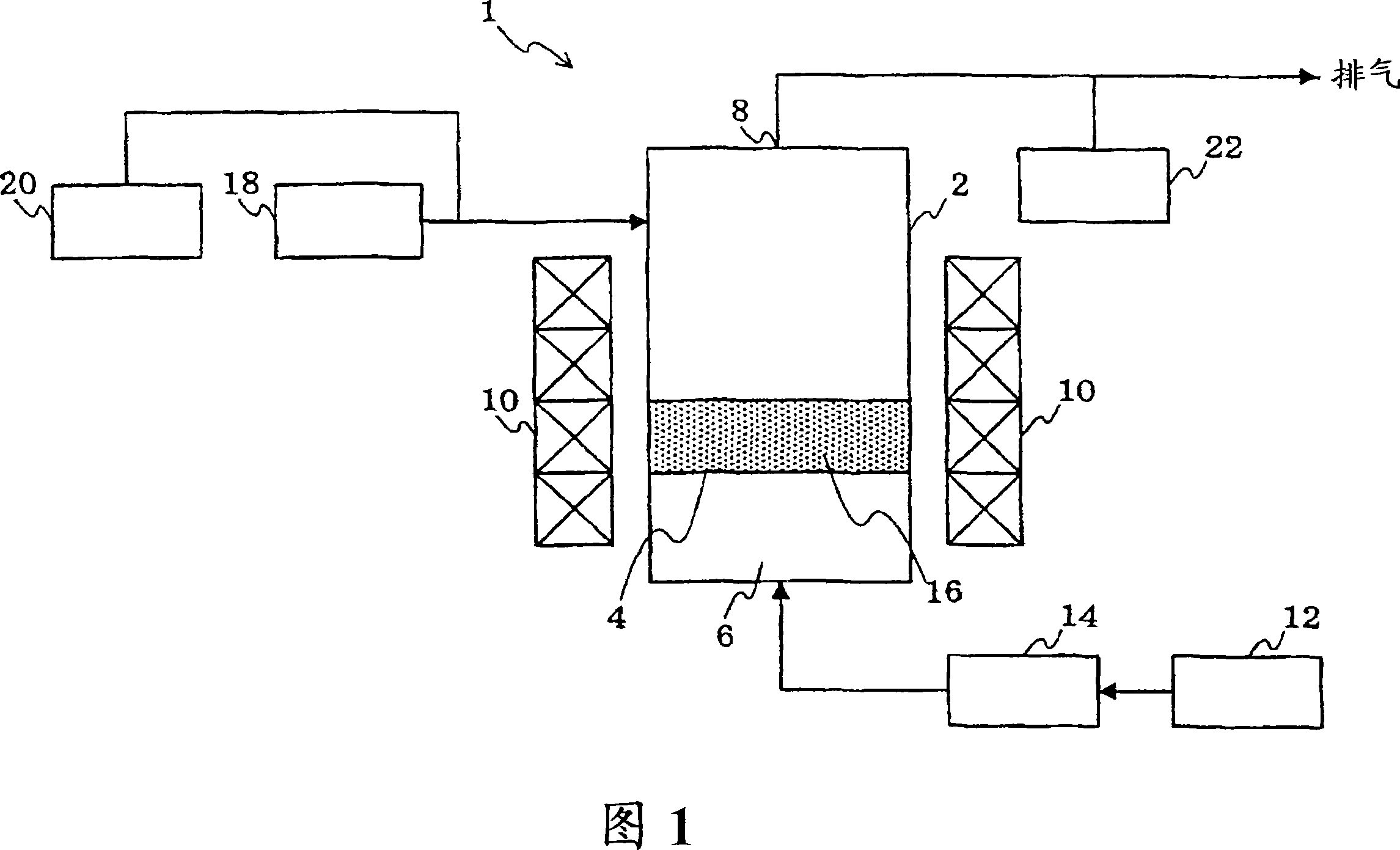

Method for Producing Methane by Catalytic Gasification of Coal and Device Thereof

ActiveUS20120238646A1Easy to controlFlowchart is simplifiedHydrocarbon from carbon oxidesOrganic compound preparationSyngasMethanation

The invention relates to a gasifier comprising a syngas generation section, a coal methanation section and a syngas methanation section in the order from bottom to top. The invention also relates to a process for preparing methane by catalytically gasifying coal using such a gasifier. Optionally, the gasifier is additionally provided with a coal pyrolysis section above the syngas methanation section.

Owner:ENN SCI & TECH DEV

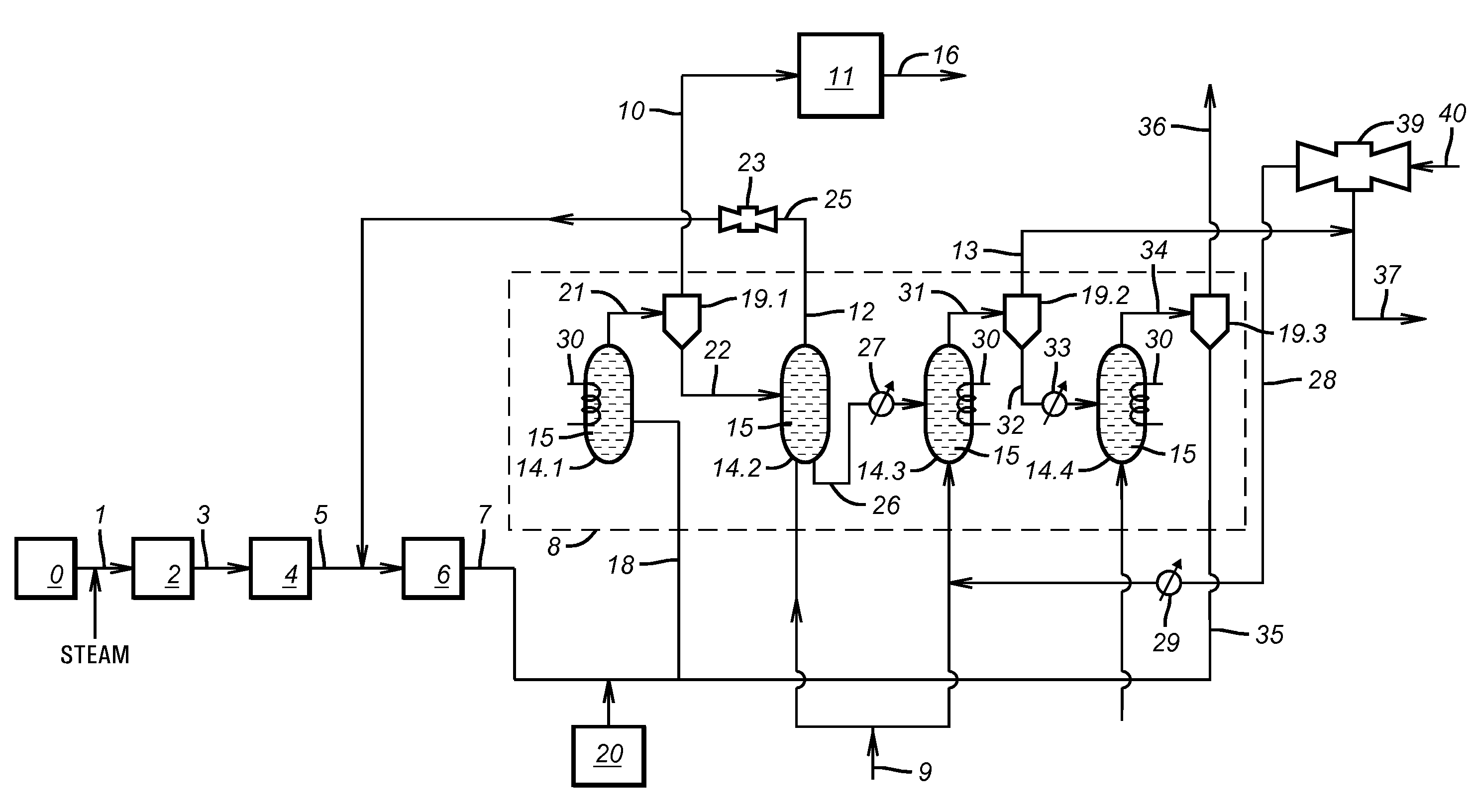

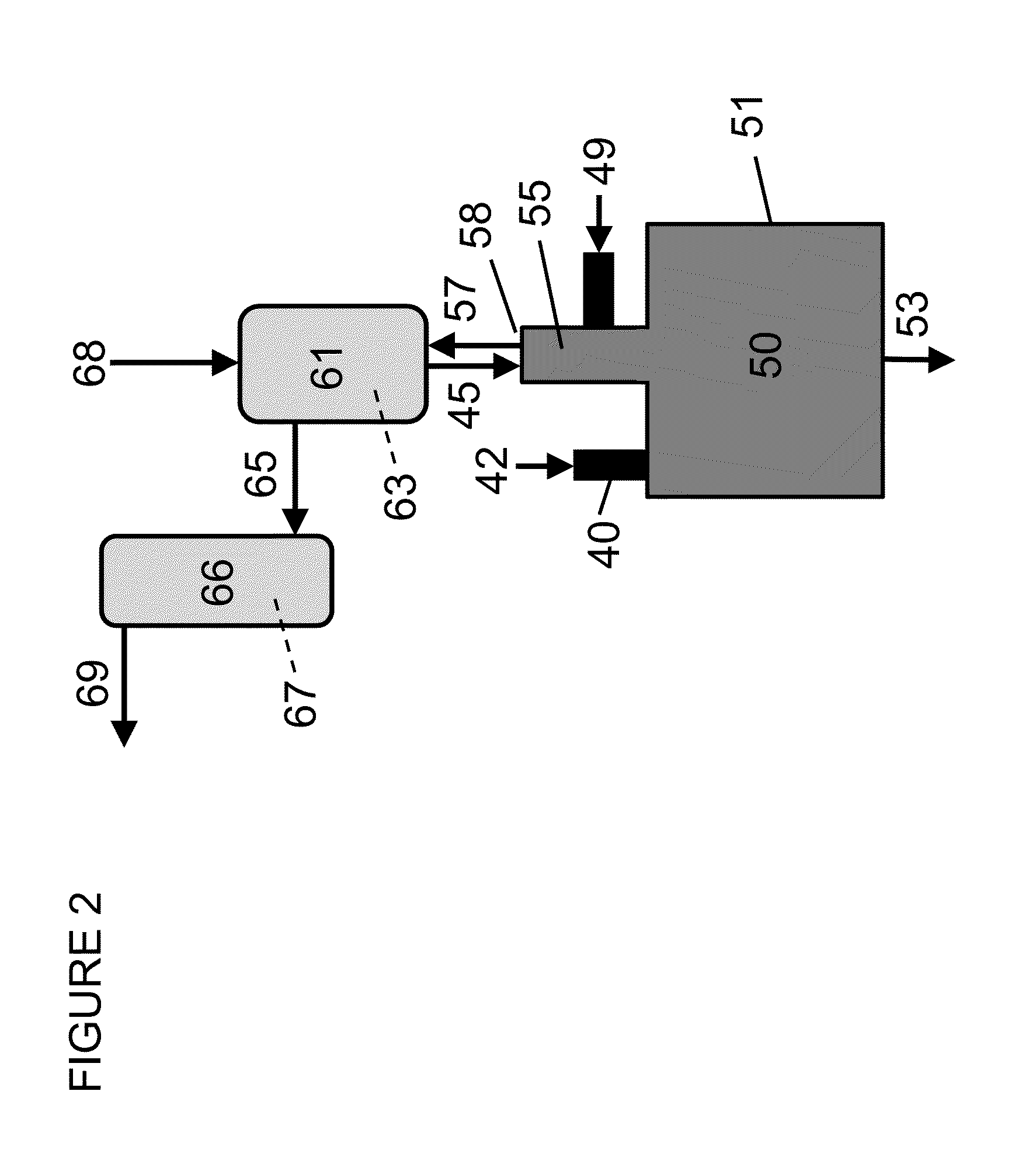

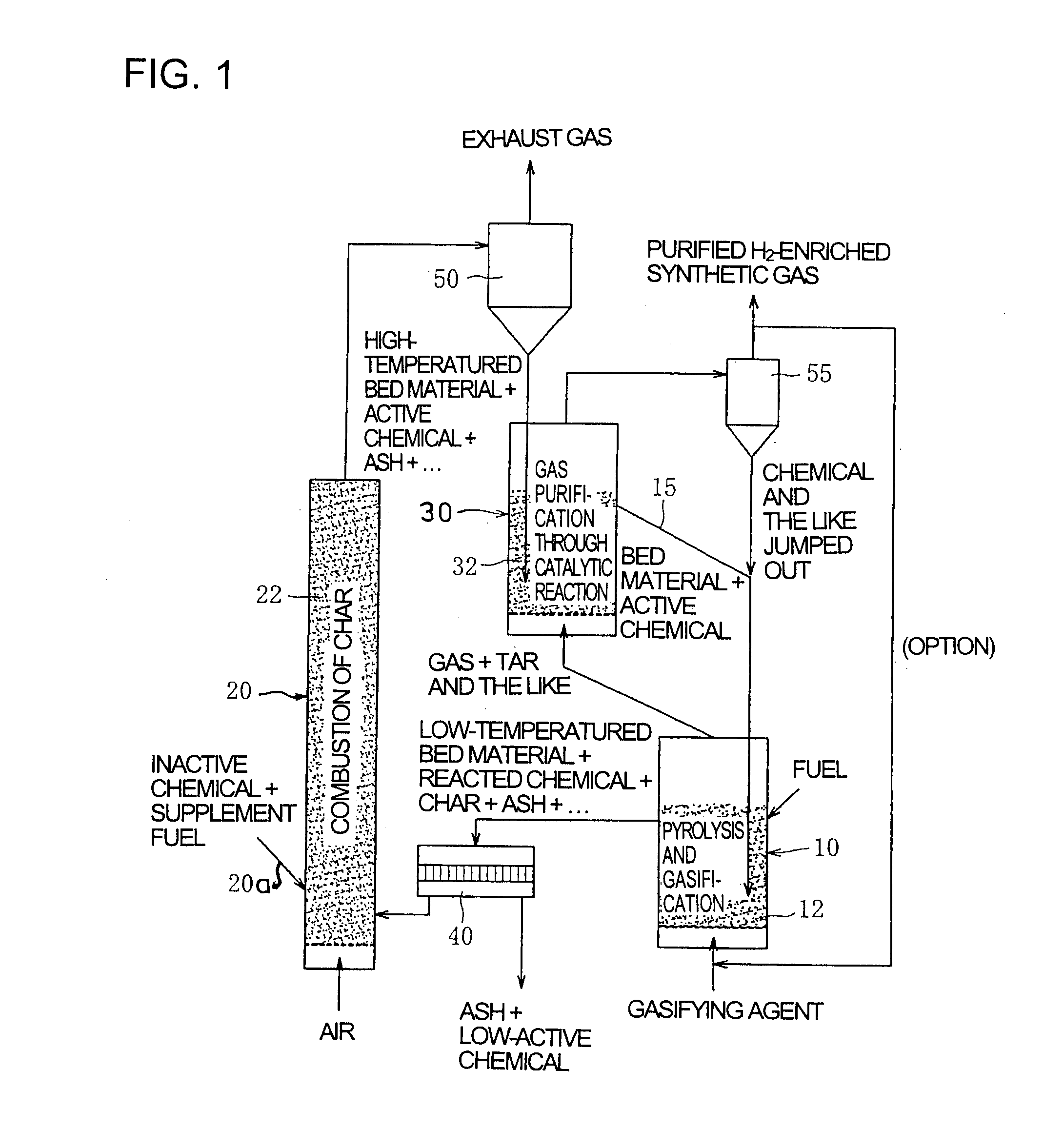

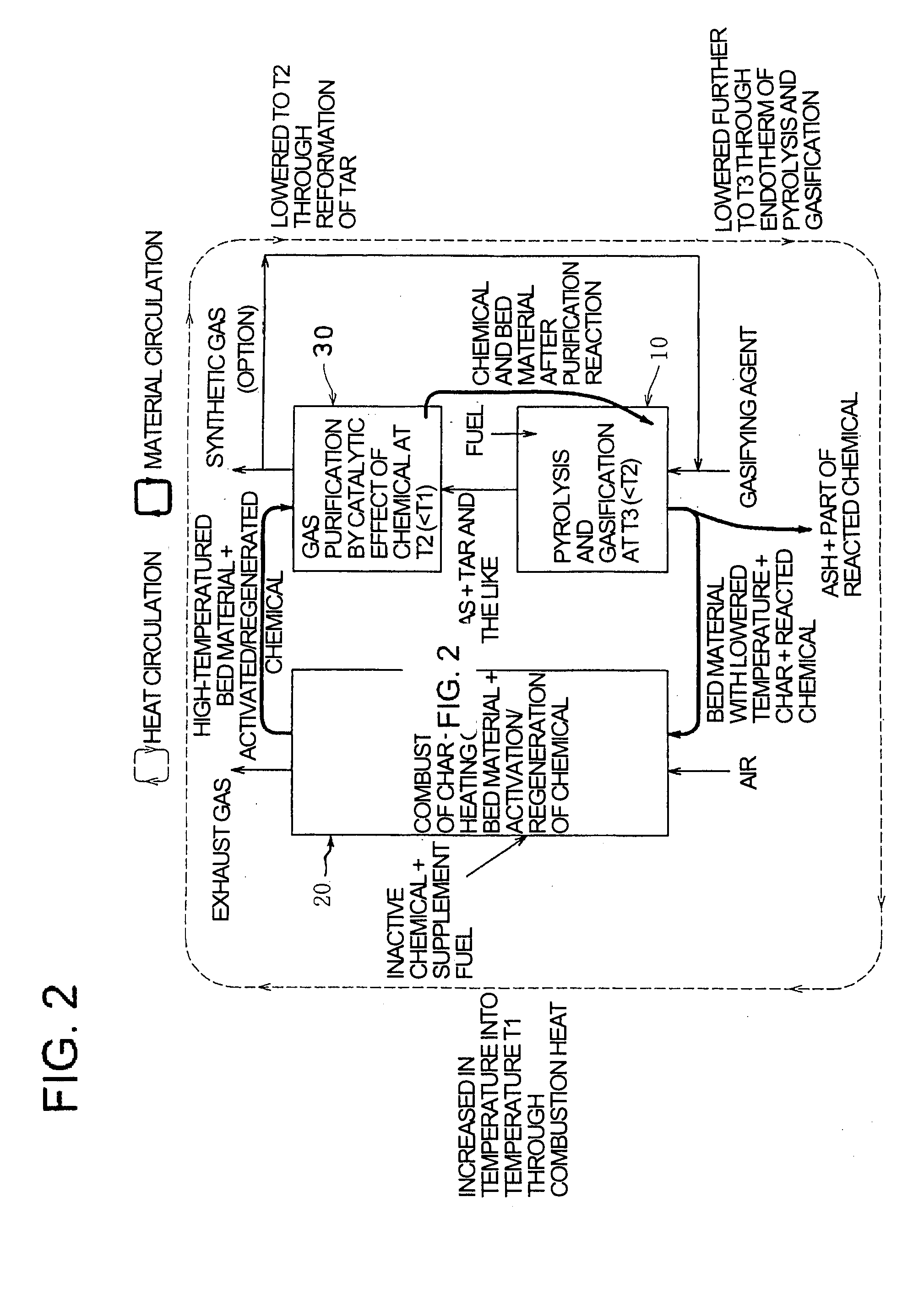

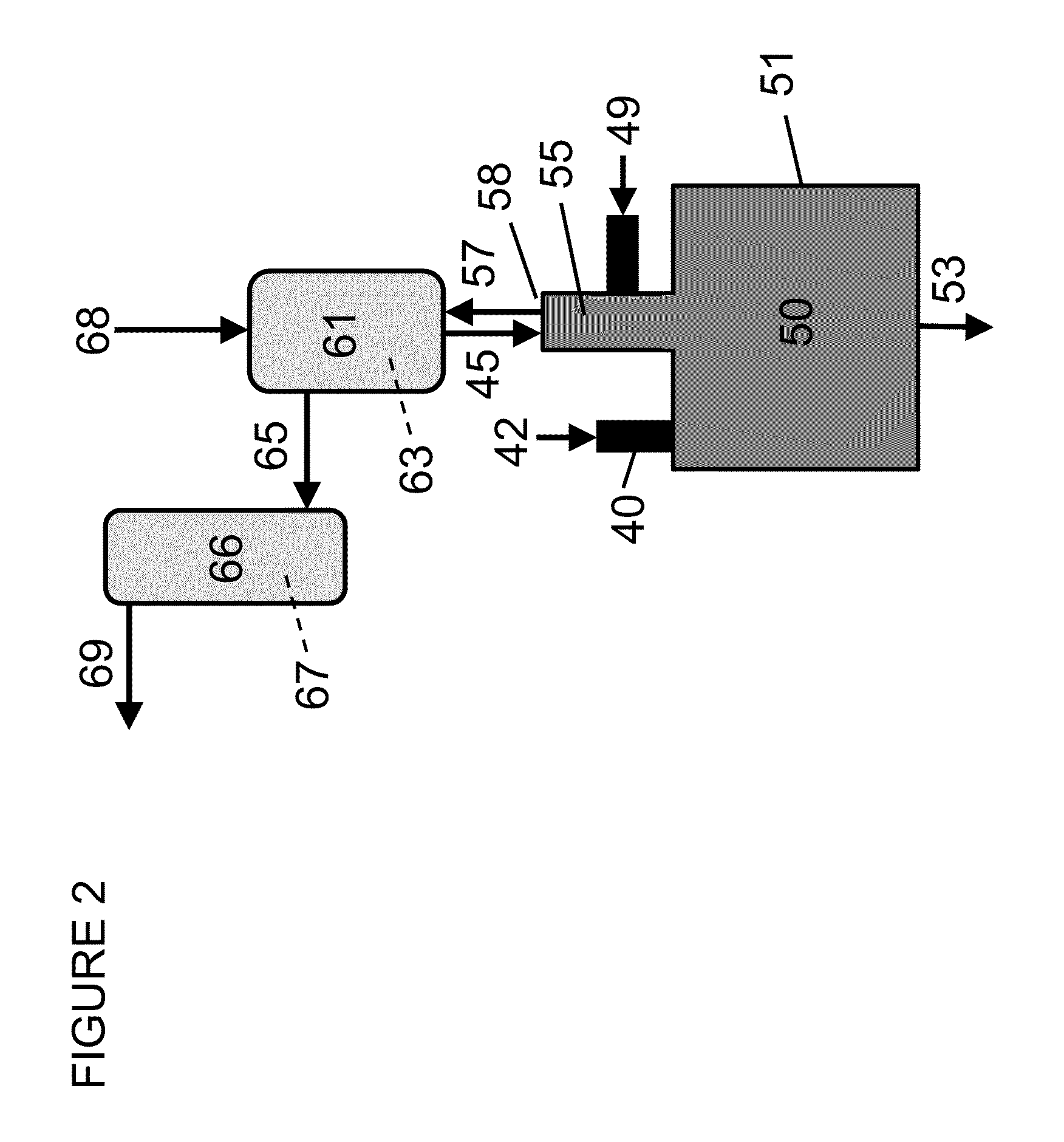

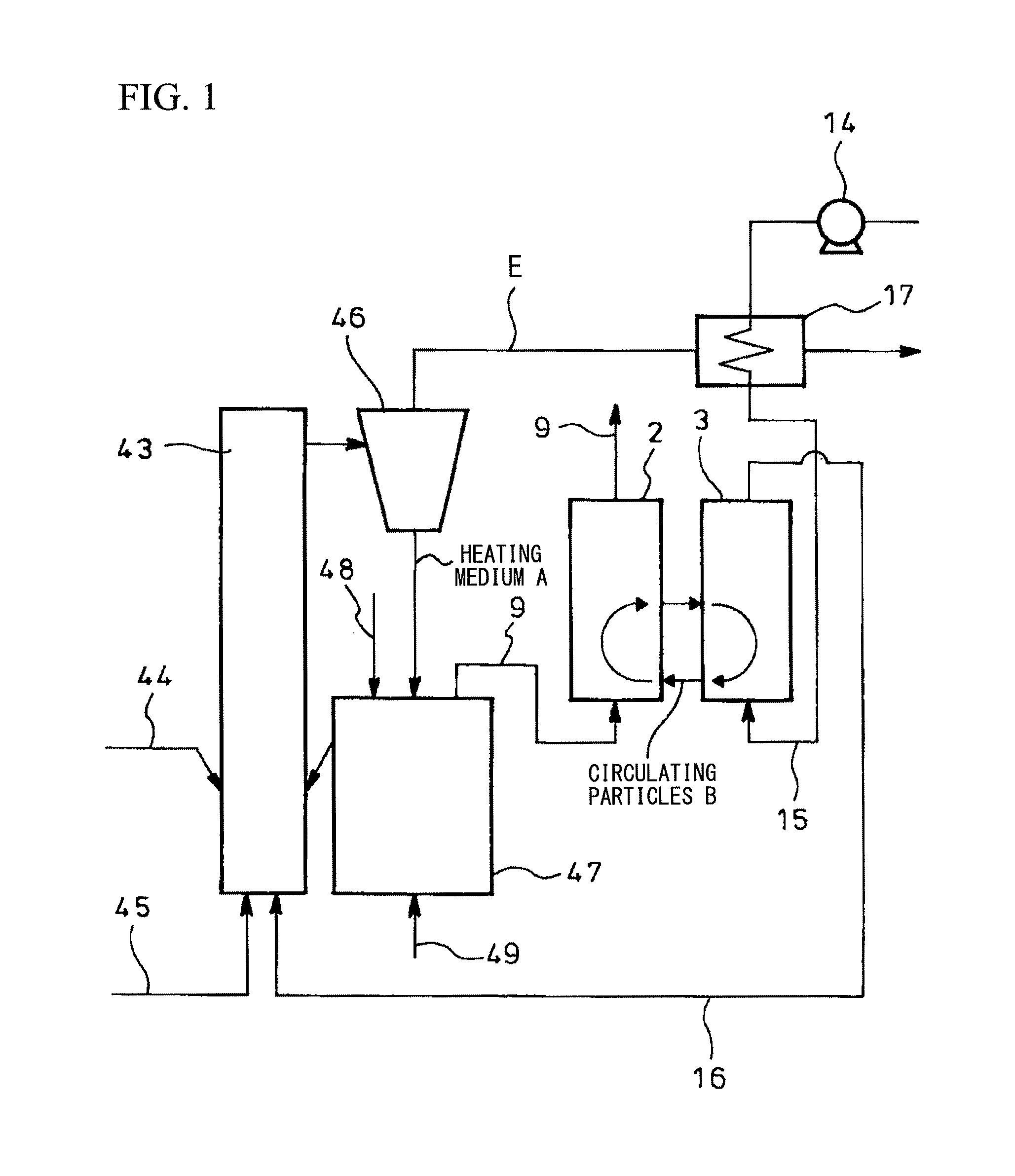

Method for gasifying solid fuel with unified gas purification and gasifier using said method

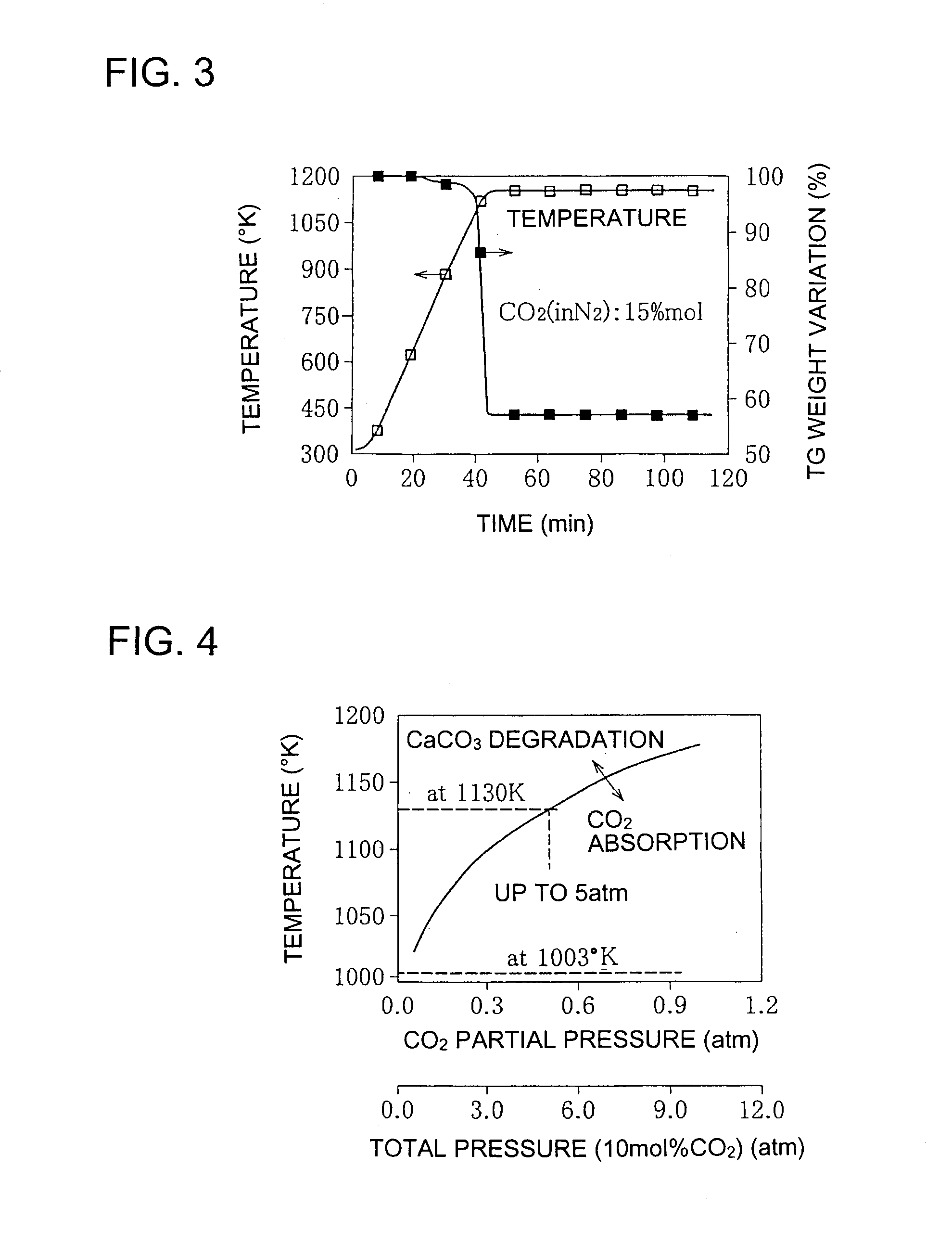

ActiveUS20120167467A1Quality improvementFully absorbedHydrogenCombustible gas catalytic treatmentChemical reactionHeat transmission

A gasification process is divided into three processes: a gasification furnace for carrying out gasification process by pyrolysis and gasification (pyrolysis gasification phase, first process), a combustion furnace for burning char to obtain calcined active chemical (char combustion phase, second process) and a gas purification furnace for purifying gasified gas (gasified gas purification phase, third process). Through heat transmission by the fluid heat medium and chemical reactions in respective phases by the chemical, the gasification furnace is independently controlled to a low or medium temperature (773-1073 K) which is required for gasification and which enables absorption of CO2; and the gas purification furnace is controlled to a high temperature (1073 K or more) required for gas purification.

Owner:IHI CORP

Pyrolysis vapor rapid filtration and conversion to fuel

InactiveUS20140073824A1Delay minimizationDirect heating destructive distillationCombustible gas catalytic treatmentHydrocarbon mixturesHeat carrier

The present disclosure pertains to biomass pyrolysis processes and systems that decrease entrainment of char and other contaminants in the pyrolysis vapors by filtering the vapors in a heated container comprising a moving bed granular filter (MBGF), which in turn, comprises granular heat carrier. The granular heat carrier is heated within the MBGF and fed directly to the pyrolysis reactor, optionally along with filtered solids such as char. In certain embodiments, the MBGF additionally comprises at least one upgrading catalyst that contacts the vapors to produce a hydrocarbon mixture fungible with a petroleum-derived transportation fuel, a hydrocarbon transportation fuel component, or mixtures thereof.

Owner:PHILLIPS 66 CO

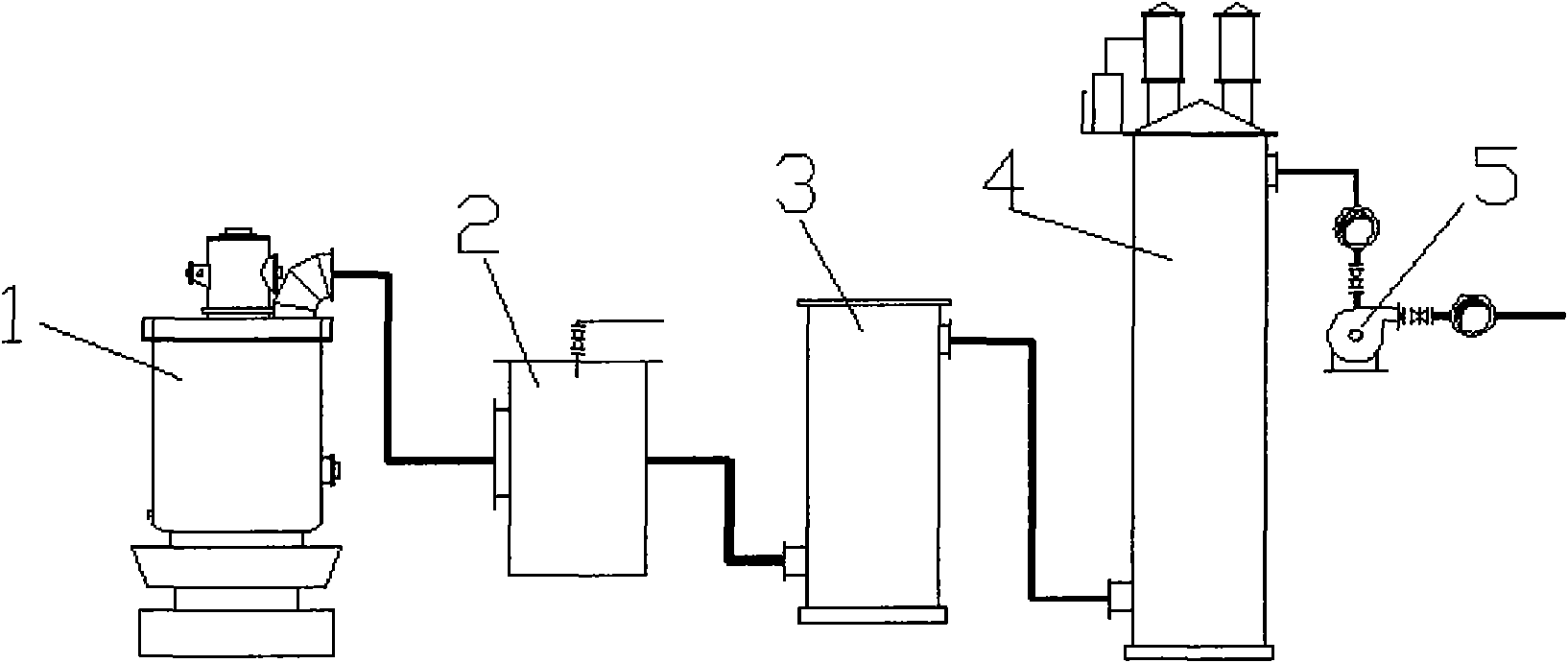

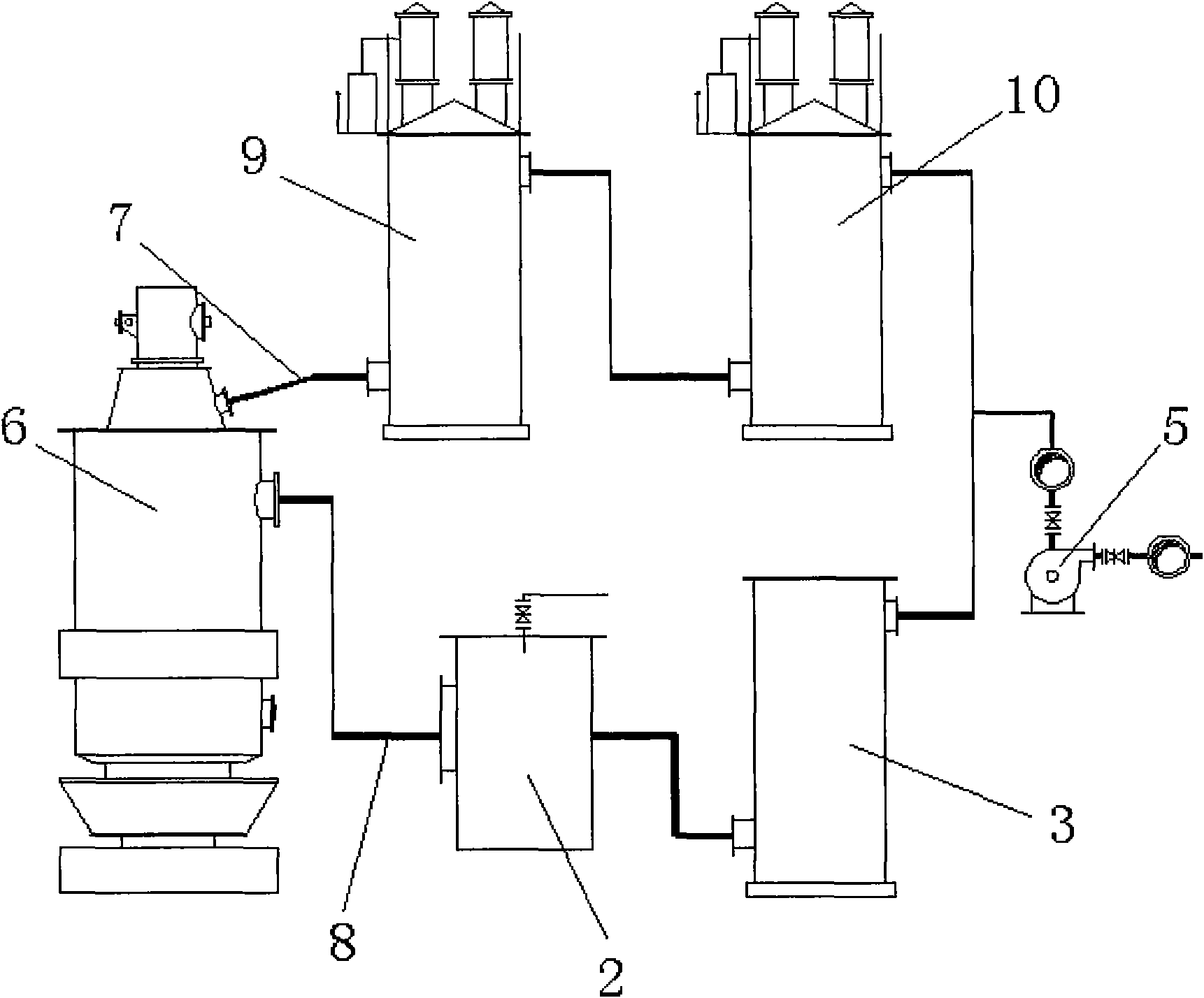

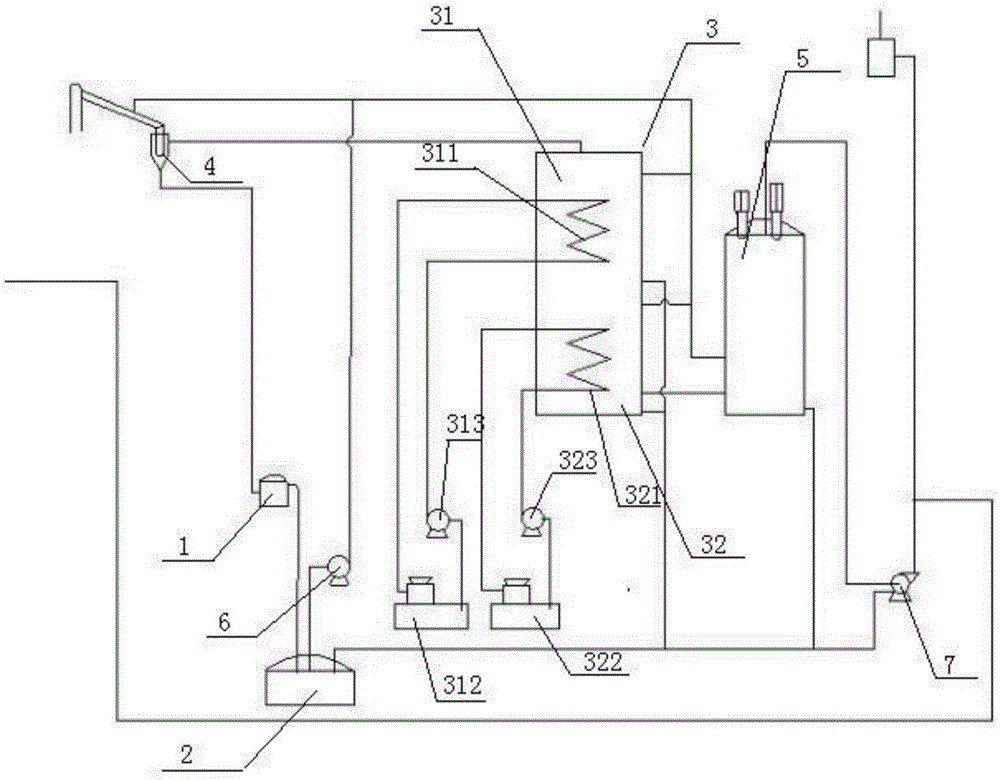

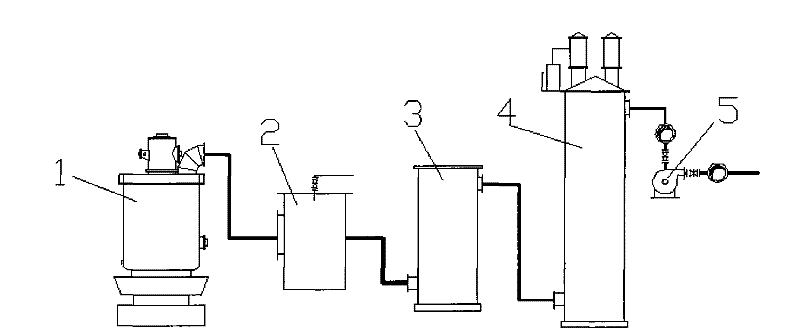

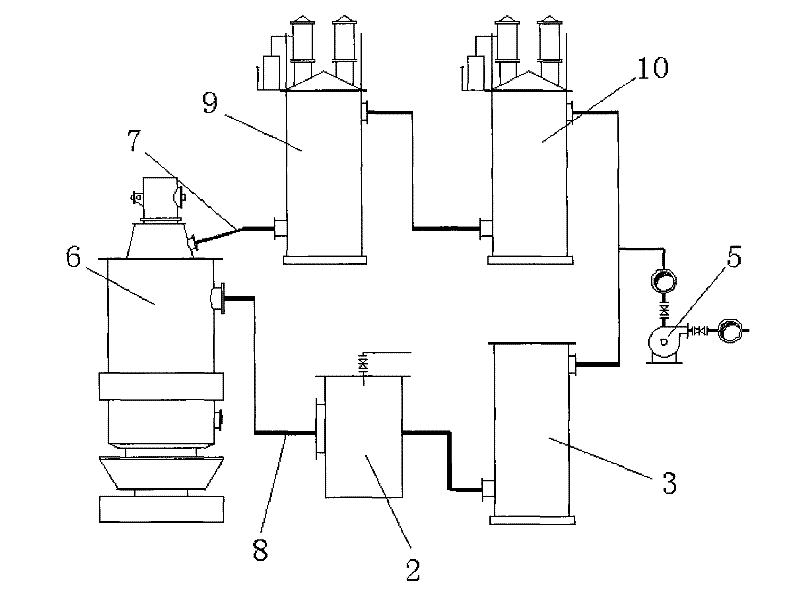

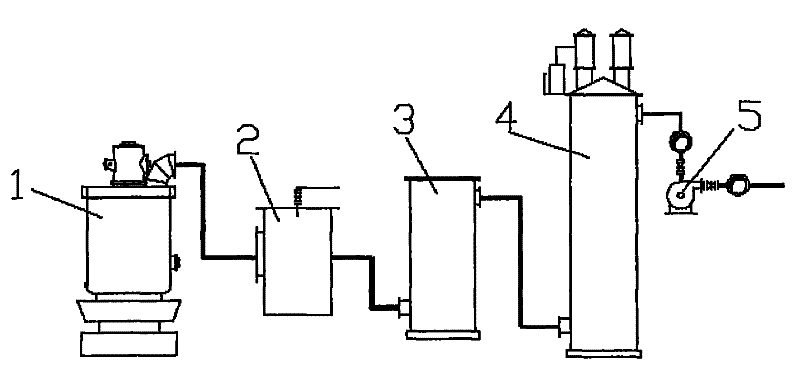

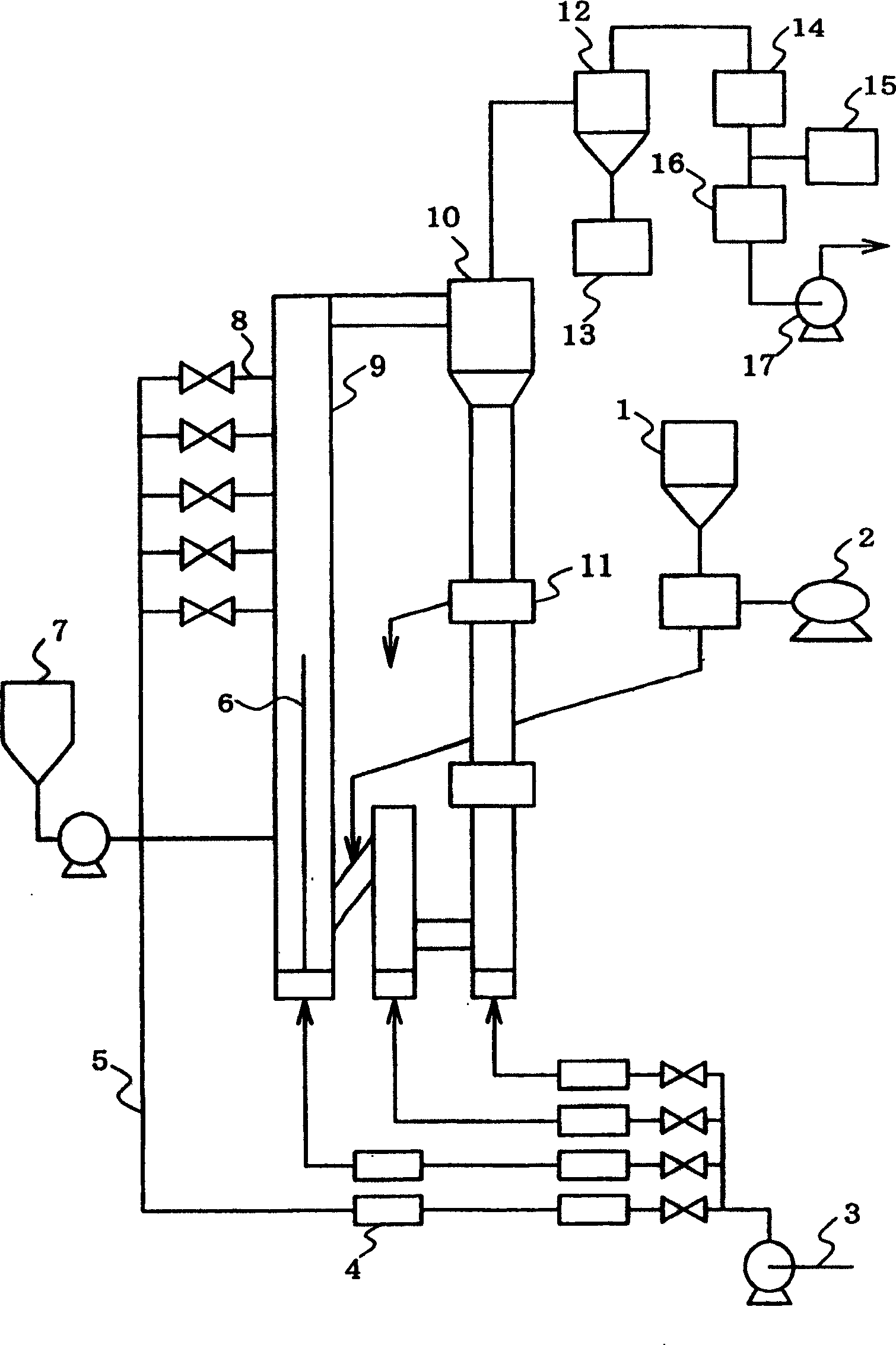

Raw coal gas purification circulating device and method

InactiveCN105623745AIncrease profitGas purification by treating with solidsGas purification by non-gaseous materials condensationTarCirculating pump

The invention discloses a raw coal gas purification circulating device and method. The raw coal gas purification circulating device comprises a sediment tank 1, a tar ammonia water collection tank 2, a horizontal water-tube cooler 3, a coal gas water seal tank 4, an electrostatic tar catcher 5, an ammonia water circulating pump 6 and a coal gas fan 7, wherein one end of the coal gas water seal tank 4 communicates with a low-temperature retort furnace through a pipeline, and the other end communicates with the horizontal water-tube cooler 3 through a pipeline; the coal gas water seal tank 4 also communicates with the sediment tank 1 through a pipeline; the sediment tank 1 communicates with the tar ammonia water collection tank 2 through a pipeline; the tar ammonia water collection tank 2 communicates with the ammonia water circulating pump 6 through a pipeline; and the ammonia water circulating pump 6 communicates with a pipeline between the low-temperature retort furnace and the coal gas water seal tank 4. The device can collect and reutilize tar and coal gas generated in the retort process. Compared with the traditional industries, the device disclosed by the invention is environment-friendly and enhances the raw material utilization ratio.

Owner:SHAANXI SHENMU SAN JIANG COAL CHEM

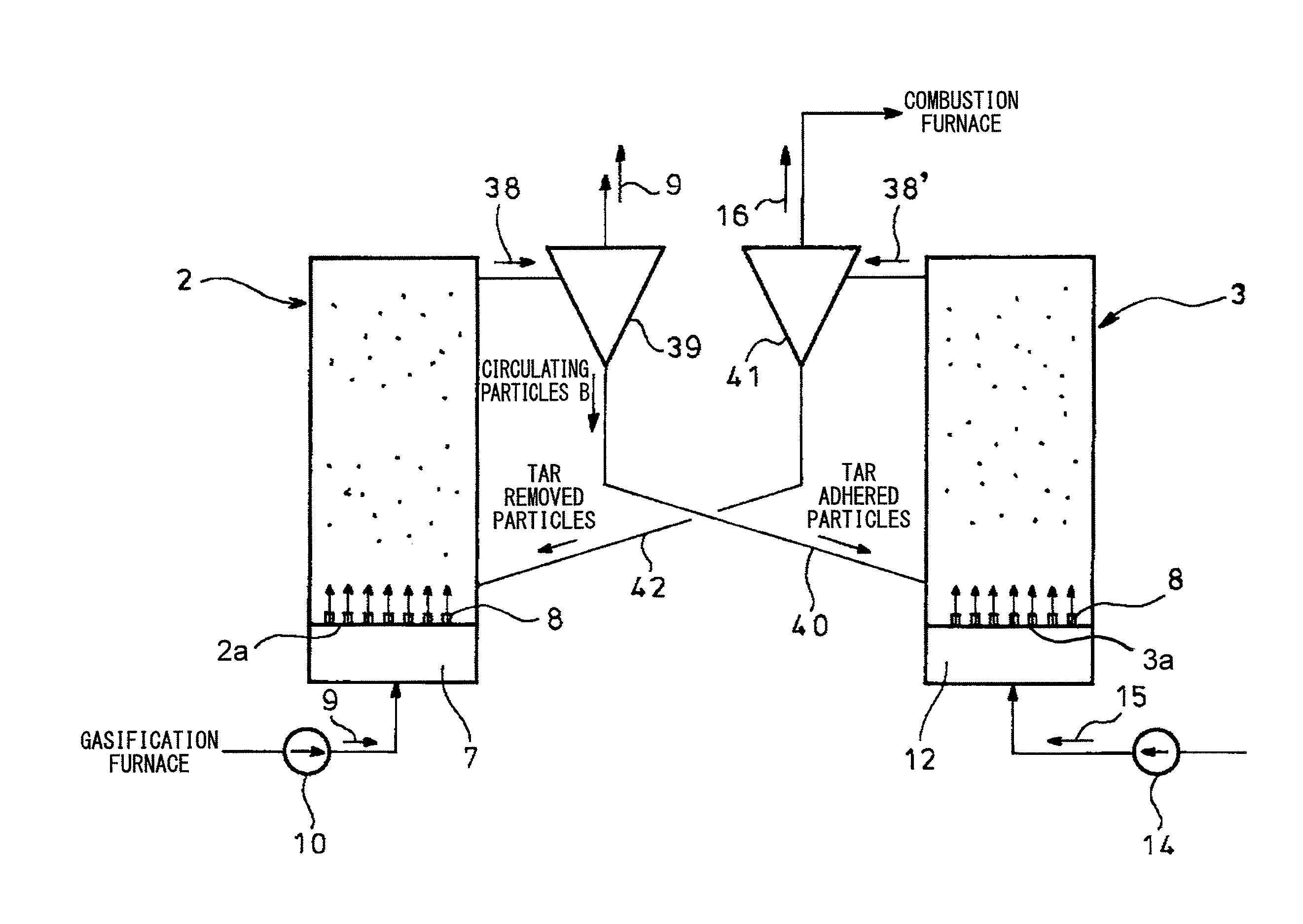

Method for removing tar in fluidized layer furnace

InactiveCN1934230AEasy to removeImprove cooling efficiencyThermal non-catalytic crackingCatalytic crackingDecompositionTar

A method for removing tar in a fluidized layer furnace which comprises subjecting, in a system wherein a raw material is gasified, pyrolyzed or partially oxidized to form an objective gas, a tar formed from the raw material to the adsorption and decomposition by the use of a fluidized cracking catalyst, a fluidized cracking equilibrium catalyst, silica-alumina based particles or alumina based particles prepared by the oil immersion granulation method, and / or to the attachment to a fluidized cracking catalyst, a fluidized cracking equilibrium catalyst, silica-alumina based particles or alumina based particles prepared by the oil immersion granulation method and to burning.

Owner:IDEMITSU KOSAN CO LTD

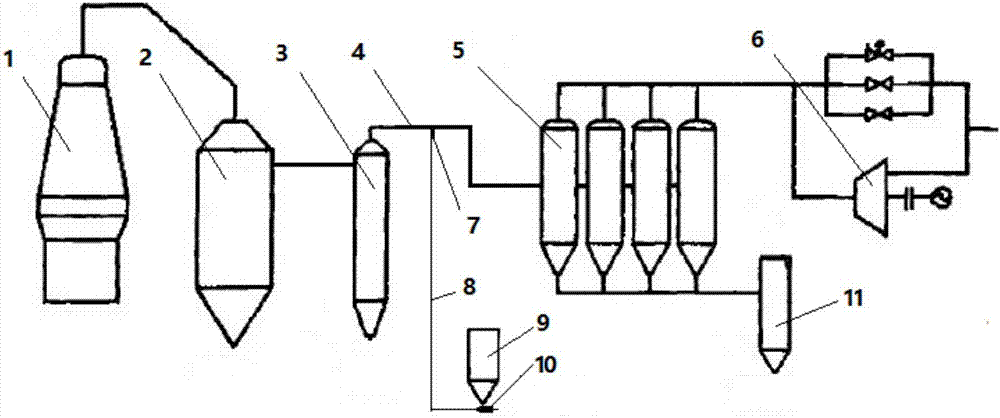

Coal pyrolysis gas desulfurization, dust removal, upgrading integrated device and process

ActiveCN104031693BWith recycling functionSignificant energy savingGas purification by catalytic conversionGas purification by treating with solidsProcess integrationEngineering

The invention discloses an integrated device and process for carrying out desulfurization, dust removal and modification on coal-pyrolyzed gas. Raw coke oven gas from a medium and low-temperature coal dry-distillation furnace or a coke oven directly enters an integrated moving bed purifier, and the desulfurization, dust removal and modification processes are implemented without reducing the temperature by utilizing the physical sensible heat taken by the gas so as to obtain clean and high-quality coal tar and gas. The integrated moving bed purifier is divided into three parts, including a desulfurization region, a primary catalytic region and a secondary catalytic region which are sequentially filled with a desulfurizing agent, a natural ore type tar cracking catalyst and an artificial tar cracking catalyst; when dust in the gas passes through a particle bed which is in a stacked state, the aim of dust purification can be reached by impact, sedimentation, interception and the like. All the desulfurizing agent and catalysts can be regenerated and recycled in place. The device and the process disclosed by the invention can be used for implementing the desulfurization, dust removal and modification in one step, are beneficial to simplification of the subsequent process of a coal thermal process, and have the advantages of increasing the added value of pyrolysis products and reducing the environmental pollution.

Owner:SHANDONG UNIV OF SCI & TECH

A method for regeneration and conversion of solid waste by plasma gasification cracking

ActiveCN107216916BEasy to fixAchieve recyclingGasification processes detailsGas purification by treating with solidsEnvironmental resistanceFiltration

The invention discloses a solid waste plasma gasification pyrolysis recycle transformation method, which belongs to the technical field of garbage disposal, and mainly comprises the four steps of sorting and pretreating wastes, carrying out gasification pyrolysis on plasma, purifying gas and regenerating energy. Through adding a combustion-supporting mixture, an average comprehensive heat value and the fixed carbon content of the solid wastes are improved, so that the power consumption during a plasma gasification pyrolysis process is reduced; meanwhile, the method and a power station are linked to offset a part of and even all electric energy in the later period, so that the operation cost is reduced. A pulsed electromagnetic valve is utilized for spraying a dioxin inhibitor, dioxin is prevented from compounding at a low-temperature area, a later-period filtration and adsorption device is cooperated to thoroughly purify gas, and finally residues produced by gasification can be used for manufacturing microcellular foam glass used as an adsorbing medium, so that cyclic utilization of resources is realized. The solid waste plasma gasification pyrolysis recycle transformation method provided by the invention is high in recovery utilization rate, free of poisonous gas and matter discharge, green and environmentally-friendly, and favorable in economic benefit.

Owner:东莞中普环境科技有限公司

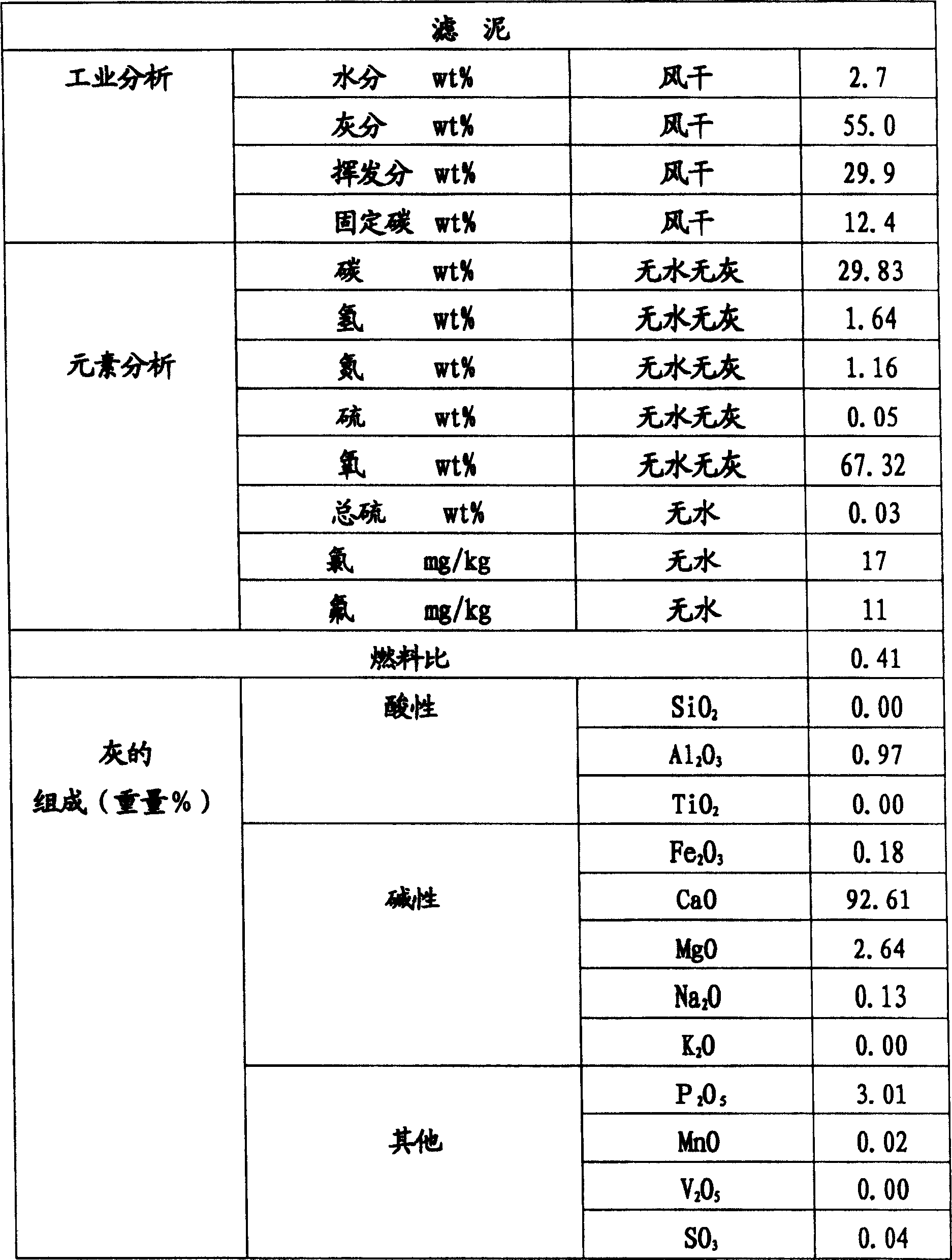

Sulfur content removing method and desulfurizer for fluidized bed device

ActiveCN1607354AImprove desulfurization effectFluidized bed combustionOther chemical processesProduct gasEngineering

The invention provides a method for removing sulfur in a fluidized bed device and a desulfurizing agent. The method of the present invention is a method for removing sulfur in gas generated in a fluidized bed furnace that burns fuel and / or raw materials using fluidized bed combustion, and is characterized in that a desulfurizer containing a lime filter cake is put into In the fluidized bed furnace. Preferably, the particle size of the lime filter cake is above 0.08mm, and the calcium content in the desulfurizer is 0.5-7 (molar ratio) relative to the sulfur content in the fuel and / or raw materials.

Owner:IDEMITSU KOSAN CO LTD

Generating deoxygenated pyrolysis vapors

InactiveUS20140073823A1High activityDirect heating destructive distillationCombustible gas catalytic treatmentBiomassChar

Owner:PHILLIPS 66 CO

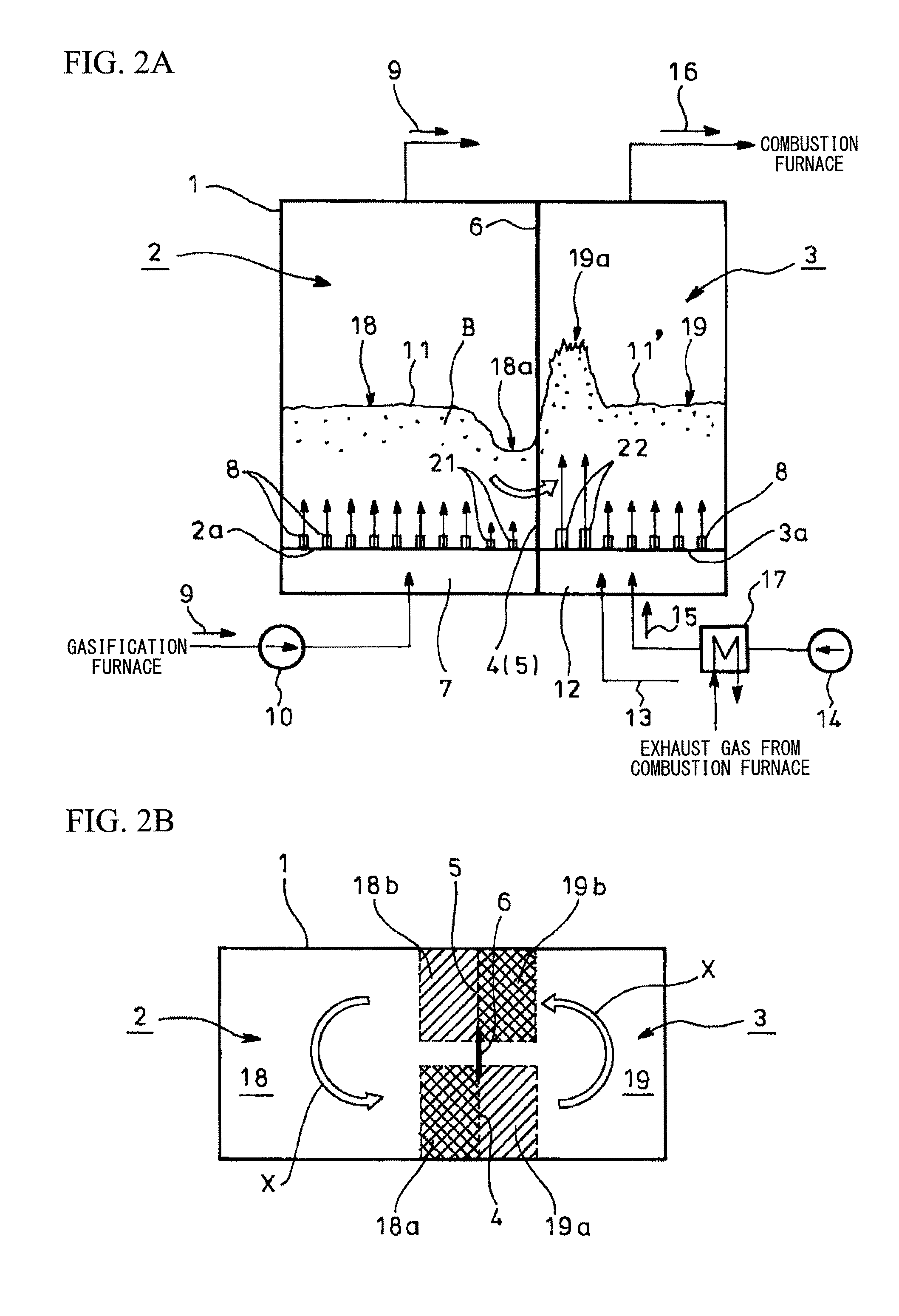

Tar removal device

ActiveUS9393514B2Efficient removalImprove thermal efficiencyFluidized bed combustionGasification processes detailsCombustionTar

A tar removal device removes tar contained in a gasification gas (9) generated in a gasification furnace of a two-towered gasifier having a combustion furnace (43) heating a heating medium (A) and the gasification furnace (47) introducing the heating medium (A) heated in the combustion furnace to perform gasification of a starting material (48). The tar removal device includes a tar separation unit (2) that introduces the gasification gas from the gasification furnace to fluidize the circulating particles (B) so as to adhere the tar in the gasification gas to the circulating particles, and a tar combustion unit (3) that introduces the circulating particles to which the tar is adhered at the tar separation unit, fluidizes the circulating particles using air (15) so as to burn the tar adhered to the circulating particles, supplies the combustion gas (16) in which the tar is burnt to the combustion furnace as a gas for combustion, and returns the circulating particles from which the tar is burnt and removed to the combustion furnace.

Owner:IHI CORP

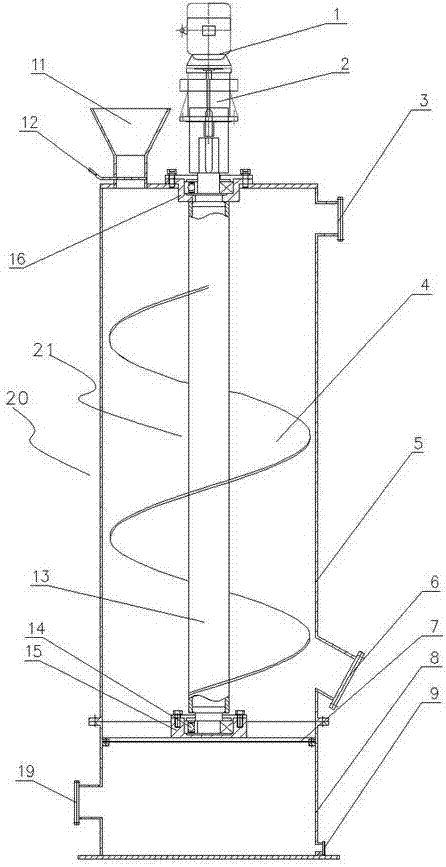

Vertical type gas filtering and purifying device

PendingCN107057775APollution is notSimple and fast operationGas purification by treating with solidsGas contaminants removalStructural engineeringSewage treatment

The invention discloses a vertical type gas filtering and purifying device which comprises a barrel body, wherein a spiral shaft is mounted in an inner cavity of the barrel body along the axial line of the barrel body; the vertical type filter gas purifying device further comprises a gas inlet formed on the upper part of the side wall of the barrel body, an exhaust opening formed on the lower part of the side wall of the barrel body, a material inlet formed on the top of the barrel body, a waste outlet formed on a position, which corresponds to the lower end of the spiral shaft, on the side wall of the barrel body and a filter net fixedly arranged along a direction perpendicular to the axial line of the barrel body; the filter net is located below the spiral shaft; a cavity in the upper part of the filter net is filled with granular biomasses; the granular biomasses are carried by the filter net and cannot leak; the exhaust opening is arranged below the filter net. According to the vertical type filter gas purifying device, no harmful gas is discharged into air, no sewage treatment process is needed, and the problem of sewage discharging outer is successfully solved. Therefore, the environment is protected, a lot of engineering construction investment is saved, and the vertical type filter gas purifying device has the advantages of simplicity and convenience in operation and low cost.

Owner:HUNAN YUANYANG COAL MACHINE MFG

A kind of syngas desulfurizer and its preparation method and application

ActiveCN111701411BImprove structural stabilityHigh ability to remove sulfideGas treatmentDispersed particle separationSyngasZincum oxydatum

Owner:CHINA PETROLEUM & CHEM CORP +1

Technology for producing cooled coal gas with no discharge of phenolic water

InactiveCN101613626BSolve the emission problemEasy to remove dustGas purification by treating with solidsGas dust removalElectricitySingle stage

The invention relates to a technology for producing cooled coal gas with no discharging of phenolic water, belonging to the technical field of coal gas production and providing a technology for producing cooled coal gas with no discharging of phenolic water which has no contamination of the environment and can save energy and investment. The process flow of a single stage coal gas producer is as follows: the hot coal gas enters a ceramic filter deduster from the outlet of the coal gas producer; then enters an indirect cooling device to carry out heat exchange with phenolic water and the temperature drops to 40-50 DEG C; the cooled coal gas enters an electro detarrer to remove tar oil and small dust particles; the purified coal gas is supplied to users through a coal gas compresser; the phenolic water is heated into phenolic vapor and is used as gasification agent after being introduced into the bottom of the coal gas producer. The process flow of a two-stage coal gas producer is as follows: the lower-stage gas emerges out of the coal gas producer and passes through the ceramic filter deduster and the indirect cooling device; the upper-stage coal gas emerges, enters a rough electrical coke arrester and a refined electrical coke arrester, and is converged with the lower-stage coal gas to obtain purified coal gas, thus optimizing the dedusting and heat exchanging processes of hotcoal gas, improving dedusting effect and hot exchange efficiency, being capable of saving investment of devices, protecting environmental and saving energy.

Owner:唐山雷浩能源技术装备有限公司

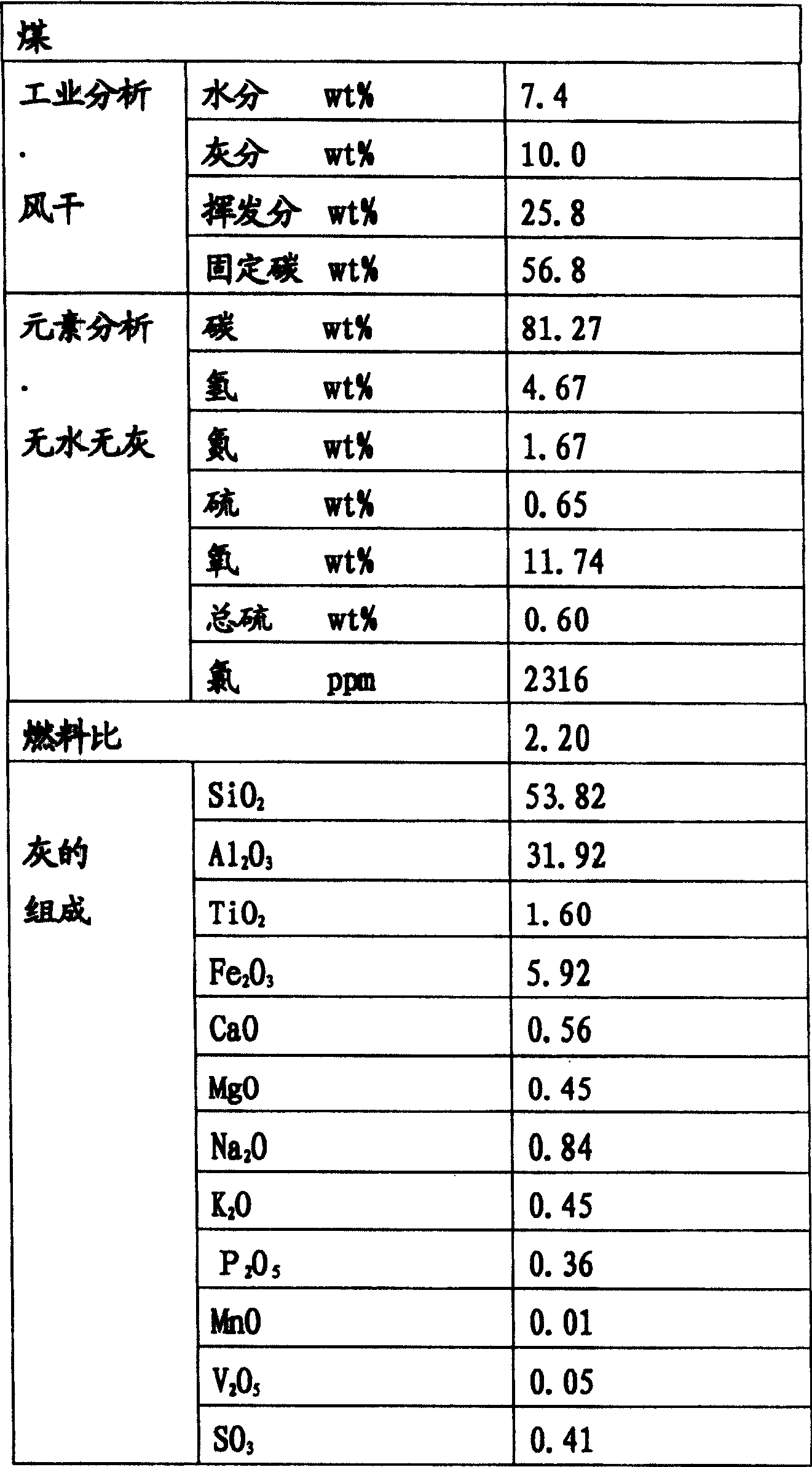

Low-cost and high-efficiency blast furnace gas desulfurization method

PendingCN113088341AReduce usageImprove desulfurization effectSolid fuelsGas purification by treating with solidsThermodynamicsCombustion

The invention relates to the technical field of blast furnace gas desulfurization, and in particular, relates to a low-cost and high-efficiency blast furnace gas desulfurization method. The low-cost and high-efficiency blast furnace gas desulfurization method provided by the invention comprises the following steps: a, conveying raw coal to powder making equipment through conveying equipment to be ground and dried to form pulverized coal; b, conveying the pulverized coal to coal injection equipment, injecting the pulverized coal into a blast furnace for combustion, adding a desulfurizing agent before the pulverized coal is injected into the blast furnace, mixing the pulverized coal and the desulfurizing agent to form mixed powder, and injecting the mixed powder into the blast furnace for combustion through the coal injection equipment, or injecting the desulfurizing agent into the blast furnace through another set of coal injection equipment before the pulverized coal is combusted, mixing and combusting the pulverized coal and the desulfurizing agent, and injecting the desulfurizing agent and the pulverized coal into the blast furnace together for desulfurization. Therefore, the use of subsequent desulfurization equipment is reduced, and the desulfurization cost is greatly reduced.

Owner:刘森

Method and device for negative utilization of biomass carbon by utilizing molten salt

The invention discloses a method and a device for negative utilization of biomass carbon by utilizing molten salt. The method comprises the following steps: (1) gasifying biomass in a downdraft fixedbed gasifier to generate tar-containing combustible gas and a gasified solid product under the action of a gasifying agent; (2) performing three-phase reforming: the combustible gas containing tar enters a three-phase reforming reactor to be reformed, the reforming reactor is filled with a mixed absorbent, and the temperature of the reforming reaction is 400-700 DEG C; and (3)performing absorbentregeneration: feeding the mixed absorbent after the reforming reaction into an absorbent regeneration reactor for regeneration, recovering the mixed absorbent to a state before use after regeneration,and releasing CO2. According to the invention, the gasification process of the carbon neutral fuel biomass is combined with the carbon capture and carbon sequestration technology, the carbon negativeutilization of the biomass is realized by reducing the carbon discharged into the atmosphere in the conversion process of the biomass energy, and an approach for reducing the CO2 in the atmosphere while meeting the energy demand is provided.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

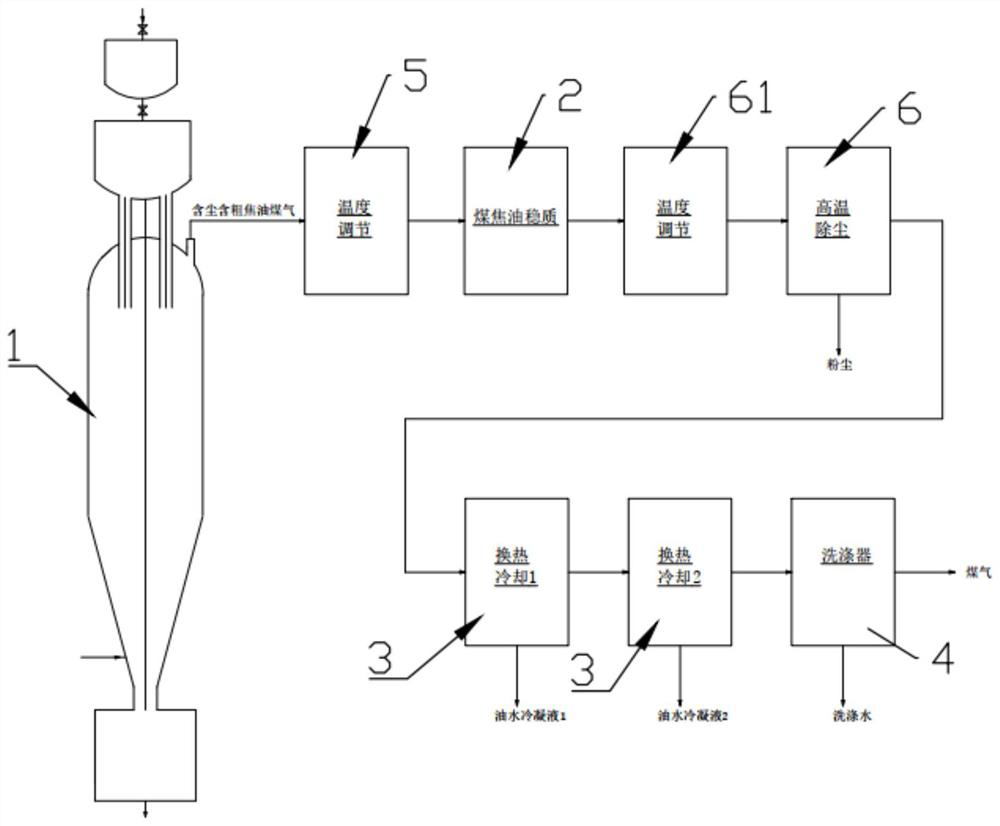

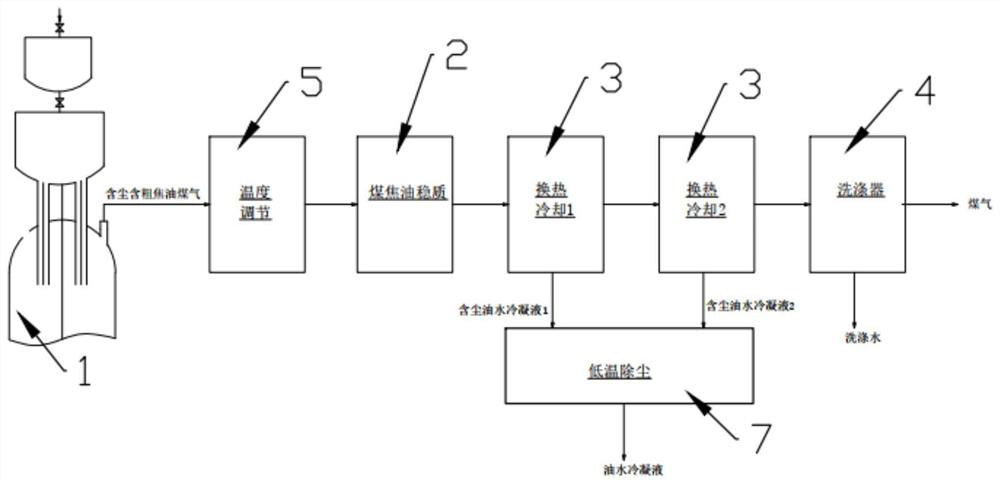

Device and method for treating heavy coal tar in coal gas

PendingCN113150841AHigh yieldSolve the problem of difficult cooling operationGas purification by treating with solidsGas purification with selectively adsorptive solidsCarbonizationProcess engineering

The invention relates to the technical field of coal tar treatment, in particular to a device and method for treating heavy coal tar in coal gas. The treatment device comprises a furnace body and further comprises a coal tar stabilizing assembly, a graded cooling assembly and a washer which are sequentially arranged, and the coal tar stabilizing assembly is provided with a carbonization adsorption area and a regeneration area; according to the invention, hot coal gas output by the gasification furnace is directly fed into the coal tar stabilizing assembly for reaction, and the heavy part of coal tar contained in the coal gas is subjected to organic matter molecule reforming, so that the problem of difficult coal gas cooling operation caused by high-viscosity organic matters in the coal tar is effectively solved; and according to the treatment method disclosed by the invention, the temperature of the fractions of the coal tar in the coal gas is reduced through carbonization adsorption, and the components with higher fractions are condensed in advance and separated from the gas by adopting graded cooling treatment, so that the treatment method is simple in process and wide in application range, and has a good application prospect.

Owner:李冶

Sulfur content removing method and desulfurizer for fluidized bed device

ActiveCN100483026CImprove desulfurization effectFluidized bed combustionOther chemical processesSulfur contentRaw material

The invention is aimed to provide a method of removing sulfur in a fluid bed furnace, and a desulfurizing agent. In this method of removing the sulfur in a gas generated in the furnace in the fluid bed furnace for burning the fuel and / or raw material by fluidized combustion, the desulfurizing agent including a lime cake is charged into the furnace. Preferably, a particle diameter of the lime cake is 0.08 mm or more, and a mol ratio of Ca in the desulfurizing agent to the sulfur in the fuel and / or raw material is 0.5-7.

Owner:IDEMITSU KOSAN CO LTD

Integrated method and device of high temperature coal gas desulfur and dust removing

InactiveCN1213131CTake advantage ofOvercoming the disadvantage of low utilizationGas purification by treating with solidsFilter mediaSmall footprint

A process for desulfurizing and dusting high-temp gas features that the metallic oxide as desulfurizing agen is used as filter medium, the composite moving particles bed is used as filter, and the particles move downward and gas passes transversely through the particle layer to remove gas-state sulfide and dust. Said composite particles-moving bed has upper and lower layers and the gas passes through the particle layer upward.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

System and method for trapping power plant smoke carbon dioxide by rice husk gasified coupled sodium silicate

ActiveCN107983111AEfficient use ofSavings on decarbonization costsProductsGas treatmentElectric fieldRaw material

Owner:NANJING NORMAL UNIVERSITY

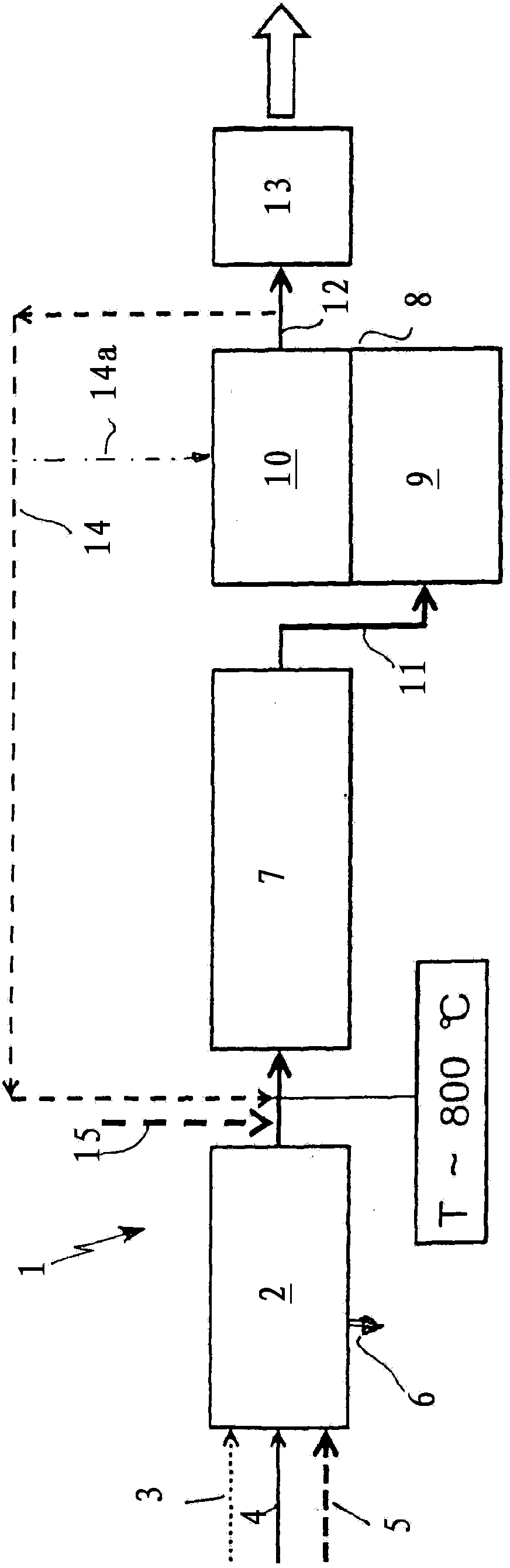

Method and installation for separating acid components, dust and tar from hot gases of gasification installations

#CMT# # / CMT# The method involves supplying a combined cyclone (9) with assigned filter cartridges in a common vessel over 700 degree Celsius hot medium flow with additives (5) of a sulfur removal (7). The gas for further use is removed behind the filter cartridges. A separation of acid gas components, for example, hydrogen sulfide separation is conducted by the dust removal by additional additives. #CMT# : # / CMT# An independent claim is also included for a system for executing a deposition method. #CMT#USE : # / CMT# Method for the deposition of acidic components, dust and coal tar from hot gases of gasification plants. #CMT#ADVANTAGE : # / CMT# The method involves supplying a combined cyclone with assigned filter cartridges in a common vessel over 700 degree Celsius hot medium flow with additives of a sulfur removal, and thus ensures improved deposition method. #CMT#DESCRIPTION OF DRAWINGS : # / CMT# The drawing shows a schematic view of a system for executing a deposition method. 2 : Carburetor 3 : Fuel 5 : Additives 7 : Sulfur removal 9 : Cyclone.

Owner:ТІССЕНКРУПП УДЕ ҐМБГ

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com