Method and installation for separating acid components, dust and tar from hot gases of gasification installations

A technology of hot gas and gasifier, which is applied in the field of separating acid, dust and tar from the hot gas discharged from the gasifier and the field of equipment, which can solve the problems of increased operation and efficiency loss, and achieve the effect of reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

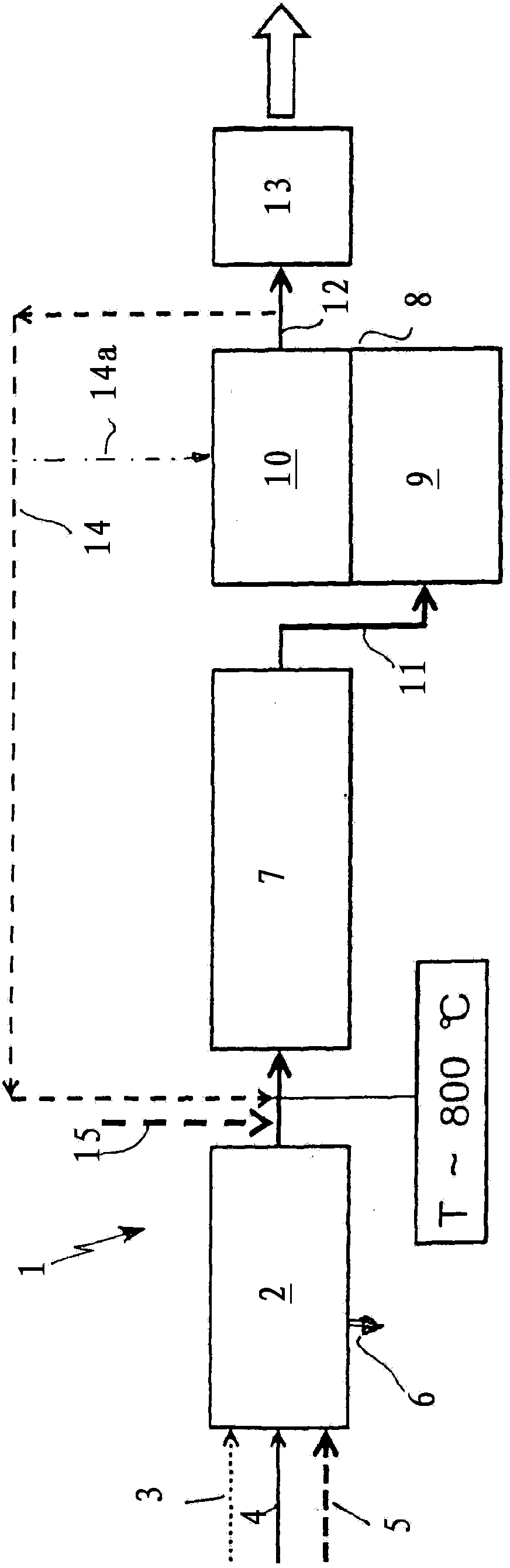

[0022] figure 1 The device generally designated 1 in is shown schematically in this figure. In this figure fuel (dotted arrow 3 ), oxygen (solid arrow 4 ) and possibly additives (dashed arrow 5 ) are fed into gasifier 2 . Reference numeral 6 denotes slag discharge. Connected after the gasifier 2 are a desulfurization device 7 and a device 8 with a cyclone separator 9 and a candle filter 10 inside.

[0023] Arrow 11 indicates that the gas flows into the cyclone separator 9 , and arrow 12 indicates that the useful gas flows out from behind the candle filter 10 . Then the useful gas 13 will flow to the next processing equipment.

[0024] The dotted arrow 14 marks a region where the quench gas is returned from the gas stream 12 to the desulfurization unit 7 . The dotted arrow 15 marks the area before the desulfurization unit 7 where additives can be added.

[0025] It can be seen from the figure that the separation of acid gas components, such as separation of H 2 S. The ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com