Blast furnace gas deacidification device

A technology of blast furnace gas and blast furnace, which is applied in the field of blast furnace gas acid removal device, and can solve problems such as consumption, large water resources, and increased system operation and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

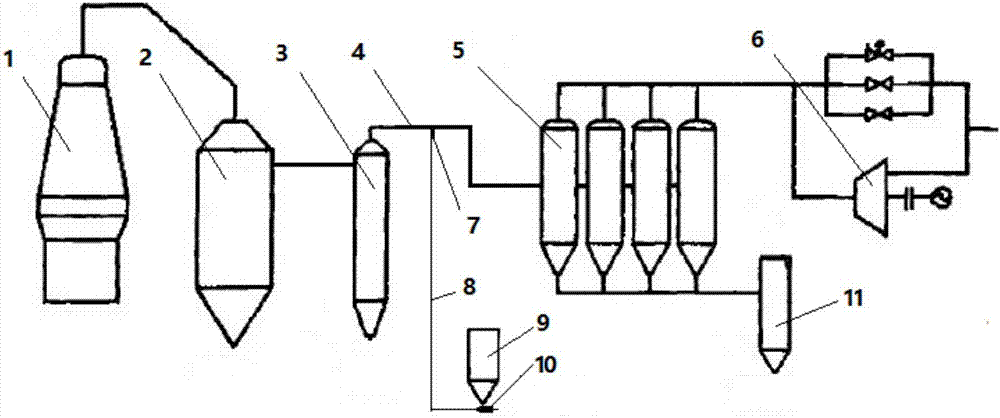

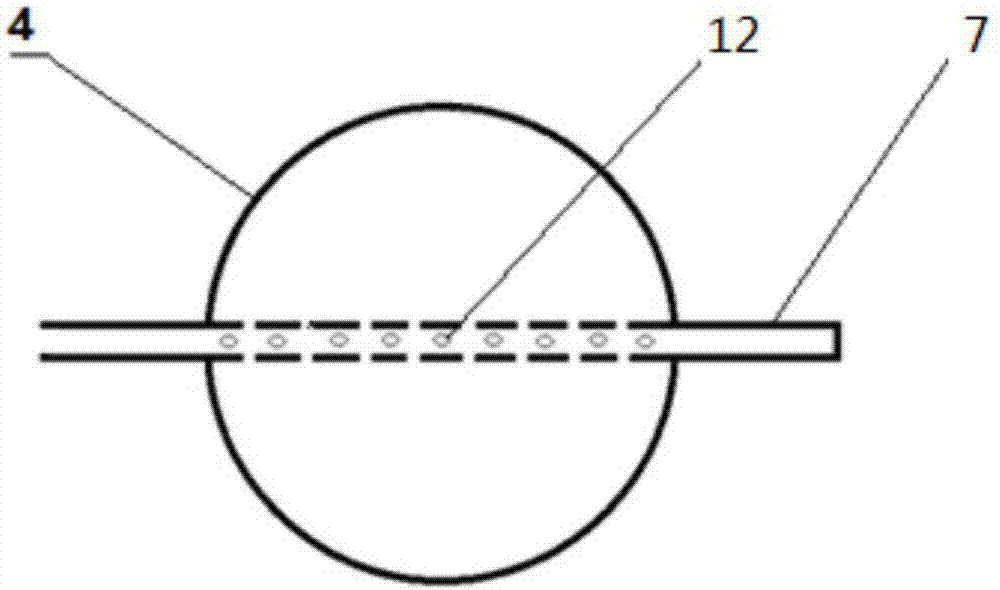

[0042] The blast furnace gas deacidification device includes: an injection tank 9 , a gas supply source and a powder spray gun 7 ; the powder spray gun 7 is arranged on the gas pipeline 4 between the cyclone dust collector 3 and the dry dust collector 5 . One end of the nozzle pipe of the powder spray gun 7 is closed, and the other end is connected with the powder spraying pipeline. Three groups of nozzles 12 are arranged on the nozzle pipe, and each group of nozzles 12 includes 8 nozzles arranged at equal intervals (20mm) along the axis of the nozzle pipe. ; 3 groups of nozzles 12 are evenly distributed on the circumference of the nozzle, and the diameter of the nozzles 12 is 5mm.

[0043] Lime powder is a by-product of steelmaking active ash produced by sleeve kiln; lime powder includes small-sized lime powder and large-sized lime powder; the mass ratio of small-sized lime powder to large-sized lime powder is 98:2; small-sized lime powder can pass 200 mesh sieve. The blowin...

Embodiment 2

[0049] The blast furnace gas deacidification device includes: a blowing tank 9, a gas supply source and three powder spray guns 7; the three powder spray guns 7 are respectively arranged on the gas pipeline 4 between the blast furnace 1 and the gravity dust collector 2, and the gravity dust collector 2 On the gas pipeline 4 between the cyclone dust collector 3 and on the gas pipeline 4 between the cyclone dust collector 3 and the dry dust collector 5 . One end of the nozzle pipe of the powder spray gun 7 is closed, and the other end is connected with the powder spraying pipeline 8. Three groups of nozzles 12 are arranged on the nozzle pipe, and each group of nozzles 12 includes 8 nozzles arranged at equal intervals (20mm) along the nozzle axis. Nozzle 12; 3 groups of nozzles 12 are evenly distributed on the circumference of the nozzle, and the diameter of the nozzle 12 is 5mm.

[0050] Lime powder is a by-product of steelmaking active ash produced by sleeve kiln; lime powder i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com