Method and device for negative utilization of biomass carbon by utilizing molten salt

A molten salt and biomass technology, applied in the field of biomass energy utilization, can solve the problems that are not involved and difficult to achieve complete conversion of carbon-containing combustible gas, and achieve the effect of reducing CO2 and meeting energy demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

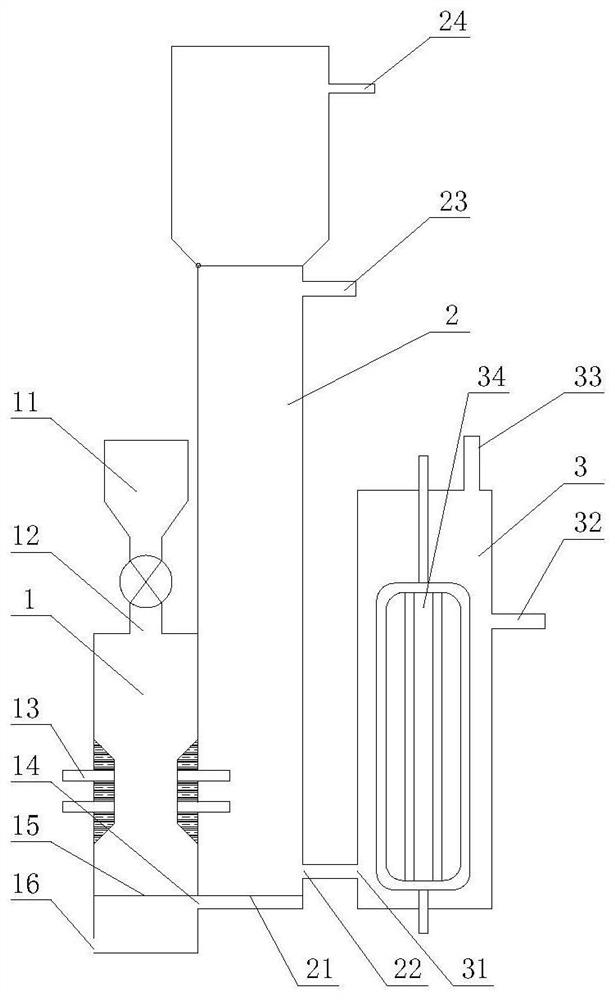

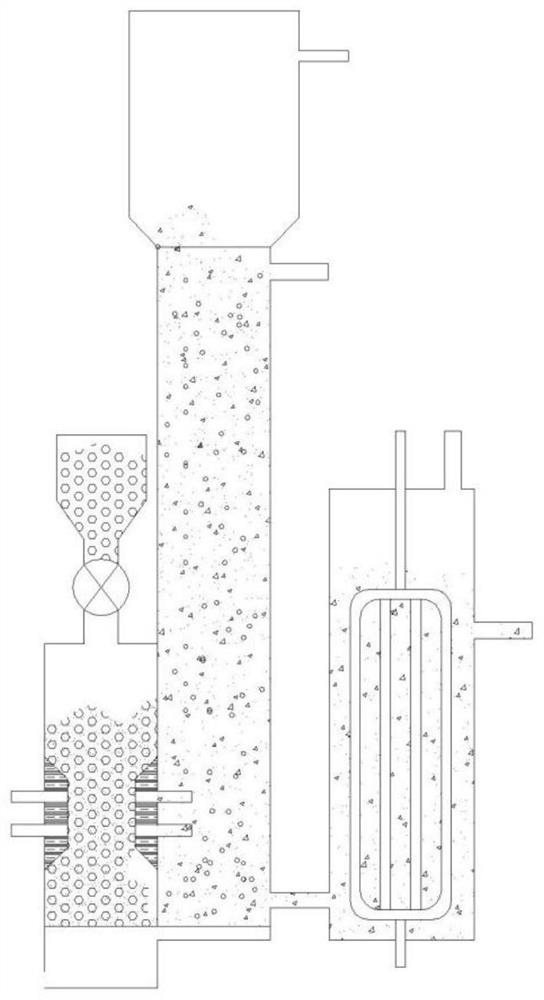

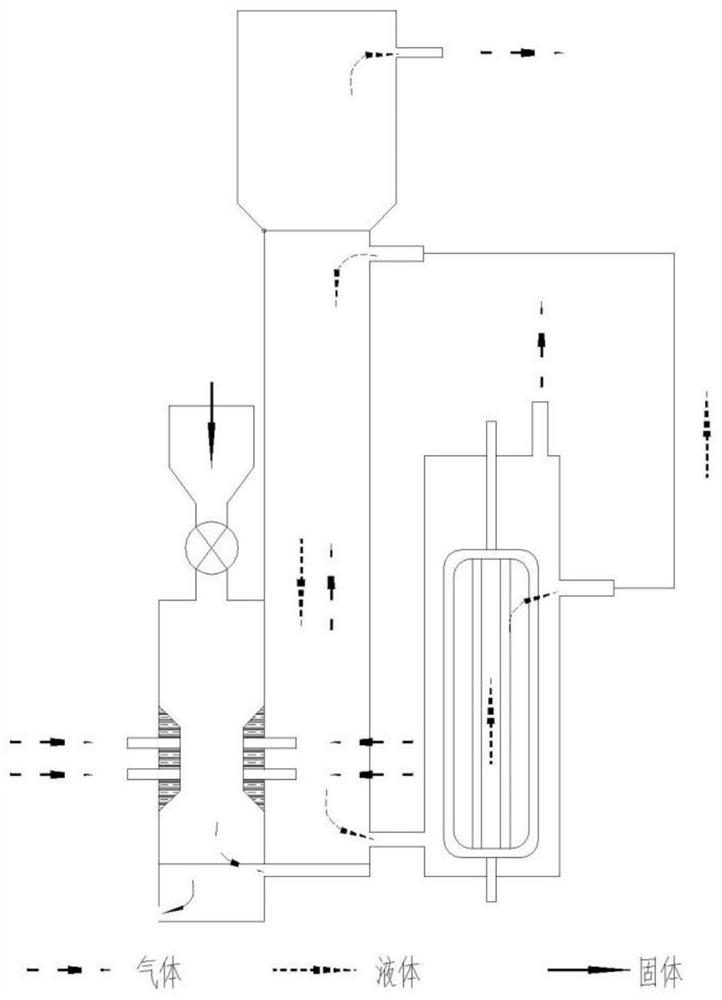

[0039] Such as Figure 1-5 Shown, a kind of method utilizing molten salt to carry out biomass carbon negative utilization, comprises the following steps:

[0040] (1) Biomass gasification: Biomass enters the downdraft fixed-bed gasifier 1 for gasification, and produces combustible gas containing tar and gasified solid products under the action of gasification agent. The gasification temperature is 800°C. The gasification agent is a mixture of water vapor and oxygen, the ratio of oxygen to water vapor is adjusted by controlling the gasification temperature to 800°C, and the gasification equivalent ratio is 0.28;

[0041] (2) Three-phase reforming: the combustible gas containing tar in step (1) enters the three-phase reforming reactor 2 for reforming, and the reforming reactor is filled with absorbent mixture, and the temperature of the reforming reaction is 500 ° C. The absorbent mixture includes liquid molten salt and solid calcium-based particles, the solid calcium-based par...

Embodiment 2

[0060] Referring to Example 1, the difference is that: the gasification temperature of the downdraft fixed-bed gasifier is 900°C, the gasification agent is air, and the gasification equivalent ratio is 0.29; the reforming temperature is 400°C, and the solid calcium-based particles are Ca(OH) 2 Granular, Ca(OH) 2 The particle diameter is 0.01mm, and the main component of the molten salt is KOH+K 2 CO 3 The mixture, the main component of molten salt is KOH+K 2 CO 3 The molar ratio of the mixture is KOH:K 2 CO 3 =30:70; regeneration temperature is 1200°C; molten salt regeneration heat source is electric heating. The gas composition at each position of the reaction system is shown in Table 2.

[0061] Table 2. Gas composition in different positions of the system (%)

[0062]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com