Device and method for treating heavy coal tar in coal gas

A treatment device and treatment method technology, which is applied in the direction of solid treatment gas purification, petroleum industry, combustible gas purification, etc., can solve the problems of difficult water treatment, poor quality, increased difficulty of discharge, etc., to solve the problem of difficult gas cooling operation, structural design Simple and reasonable, the effect of increasing productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings.

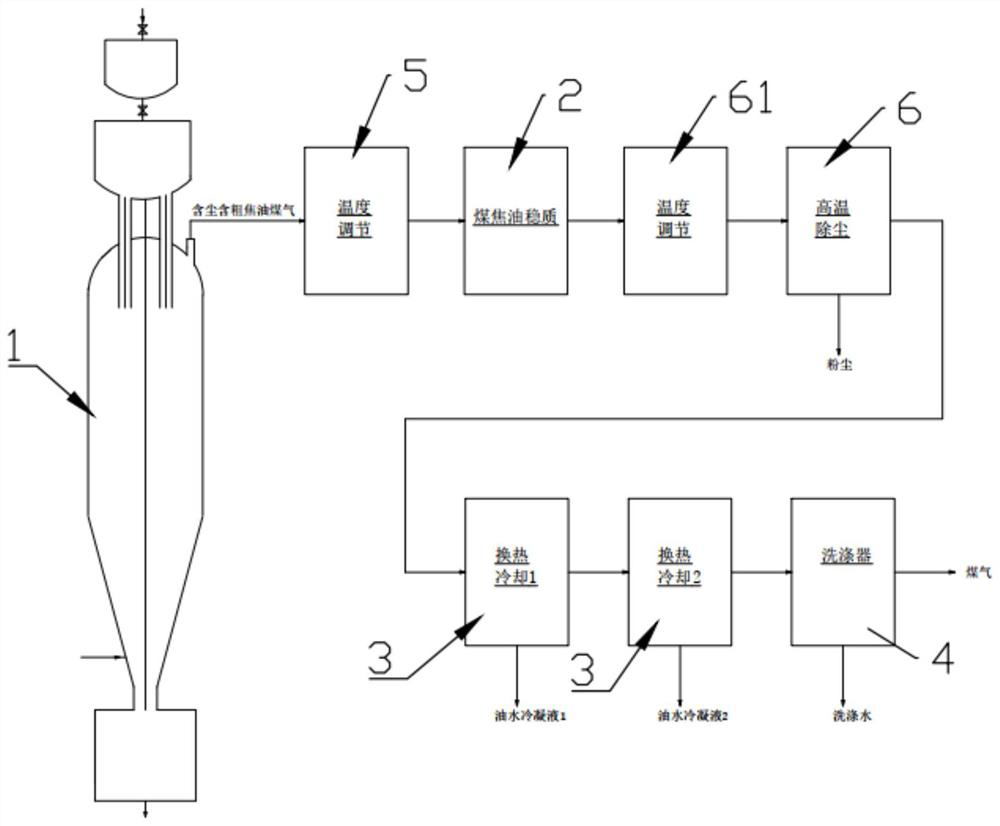

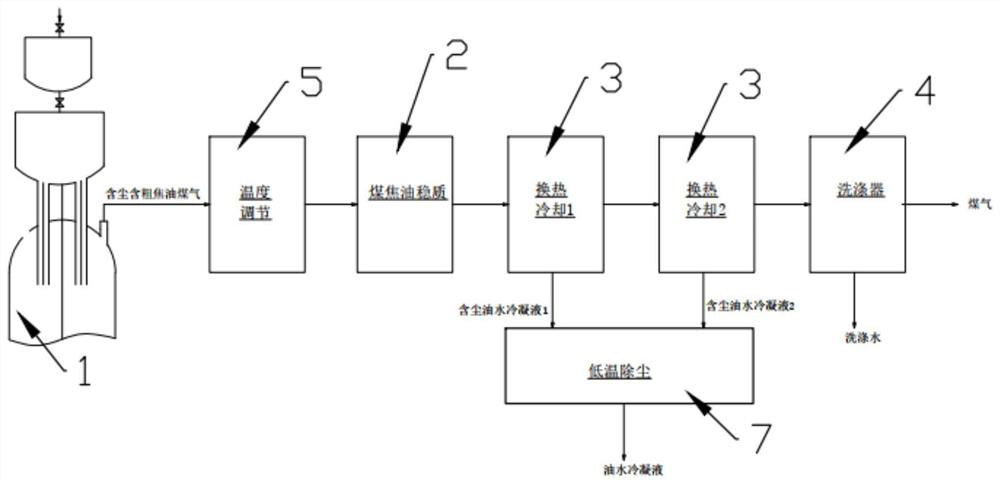

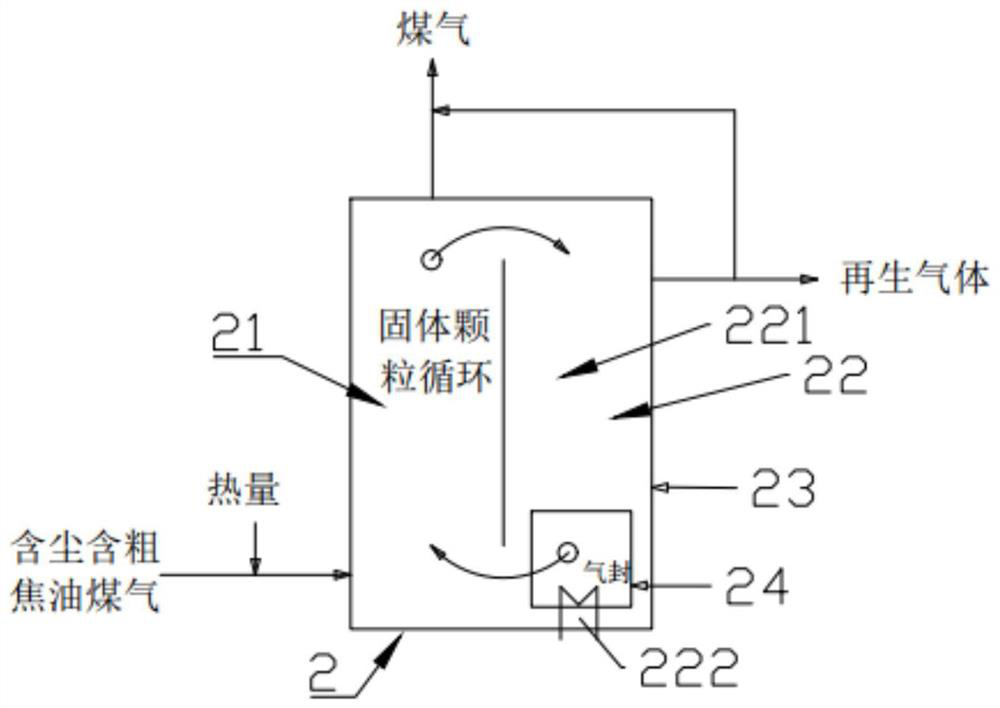

[0032] like figure 1 As shown, the heavy coal tar processing device in gas in this embodiment includes a furnace body 1, and also includes a coal tar stabilizing component 2, a graded cooling component 3 and a scrubber 4 arranged in sequence, and the coal tar stabilizing component 2 are respectively communicated with the furnace body 1 and the graded cooling assembly 3, the scrubber 4 is communicated with the graded cooling assembly 3, and the coal tar stabilizing assembly 2 is provided with a carbonization adsorption area 21 and a regeneration area 22, A fluidized bed 221 formed by solid particles is provided in the regeneration zone 22, and the solid particles circulate in the carbonization adsorption zone 21 and the regeneration zone 22, and the solid particles have a particle size of 50 to 2000 Micron coal slag particles and / or coke particles are provided with a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com