Sulfur content removing method and desulfurizer for fluidized bed device

A technology of fluidized bed and desulfurization agent, applied in the field of desulfurization agent, can solve the problems of low utilization rate and achieve good desulfurization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

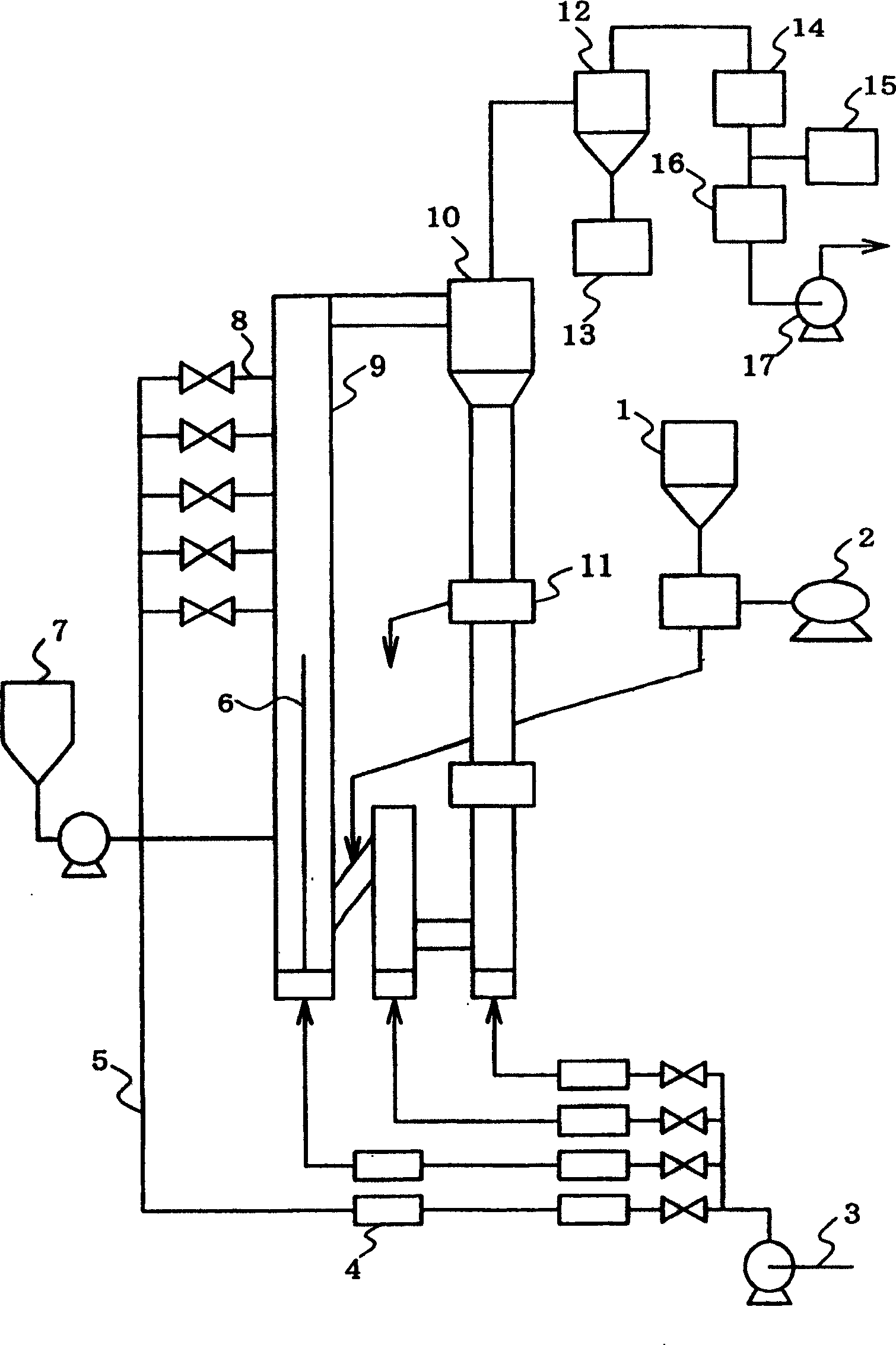

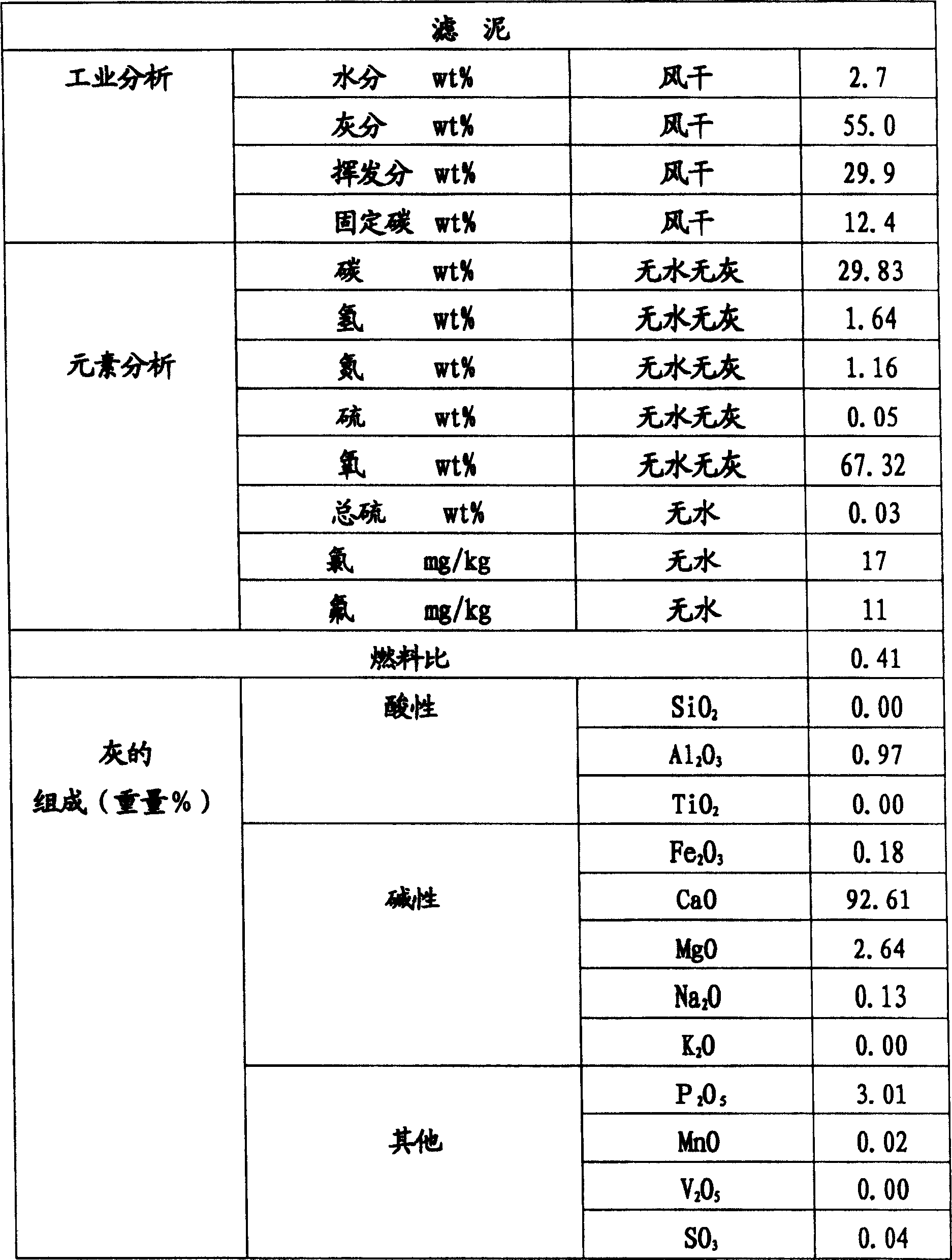

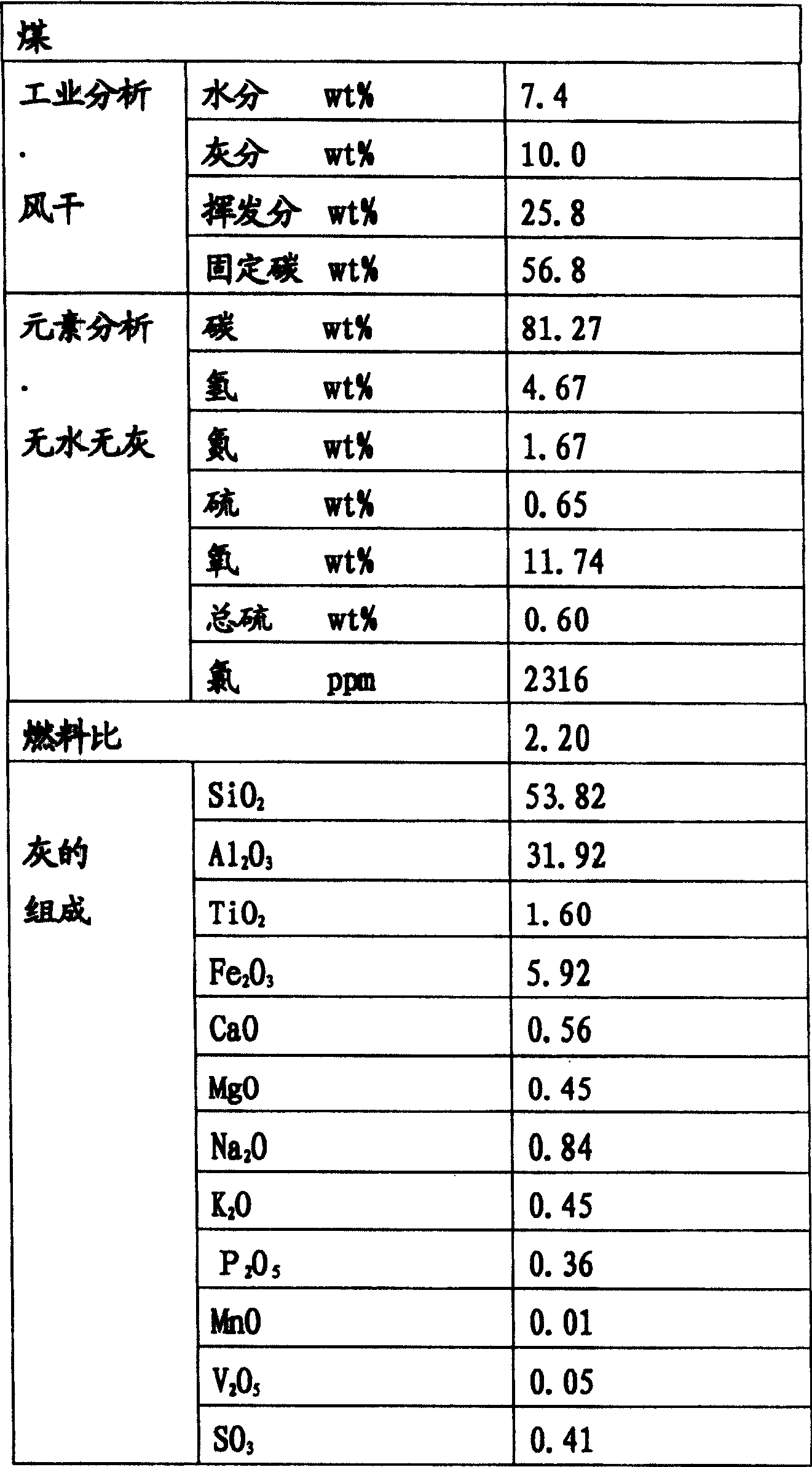

[0058] The lime filter cake manufactured by Nippon Sugar Co., Ltd. having the properties shown in Table 1 was dried, then adjusted to a maximum particle size of 2 mm or less, and the average particle size was 1.2 mm, and the fuel having the properties shown in Table 2 was pulverized into 2 mm or less. coal mix. Four types of mixtures were prepared in which the Ca content in the lime filter cake was 0, 1, 2, and 3 in molar ratio (Ca / S) relative to the sulfur content in the coal. The resulting mixture was burned in the circulating fluidized bed combustion furnace shown in Figure 1, the SOx concentration at the combustion outlet was analyzed, and the desulfurization rate was obtained by the following calculation method, and the results are shown in Table 3.

[0059] Desulfurization rate (%)=(a / b)×100

[0060] a=[SOx emission concentration when coal is burned alone (Ca / S=0)]-(SOx emission concentration)

[0061] b = SOx emission concentration when coal is burned alone (Ca / S=0) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com