System and method for trapping power plant smoke carbon dioxide by rice husk gasified coupled sodium silicate

A technology of carbon dioxide and sodium silicate, applied in chemical instruments and methods, silicates, separation methods, etc., can solve environmental pollution and other problems, and achieve the effects of improving economy, saving decarbonization costs, and stabilizing fluidization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

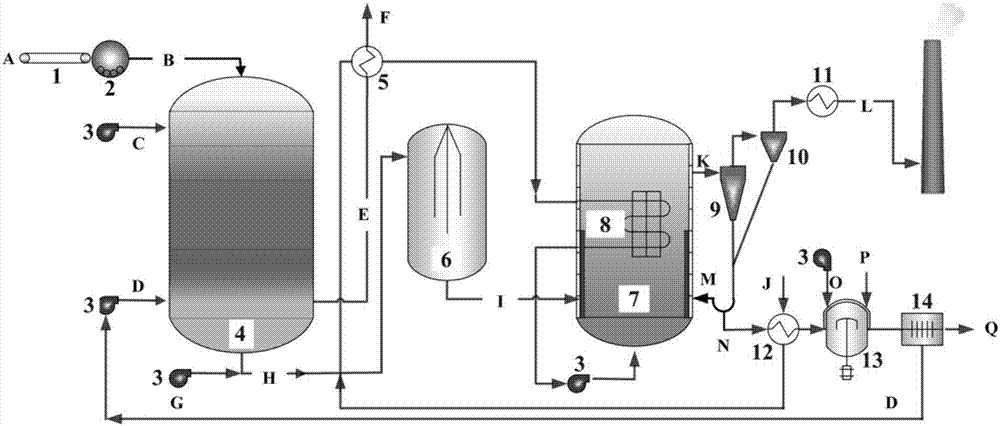

[0042] like figure 1 As shown, the present invention provides a system for rice husk gasification coupled with sodium silicate to capture power plant flue gas carbon dioxide, including:

[0043] Rice husk gasification coupled with Na 2 SiO 3 Preparation furnace 4, charger 6, electric field-assisted fluidized reactor 7, material separation device, dissolver 13, filter 14 and four sets of heat exchangers; wherein,

[0044] The rice husk gasification coupling Na 2 SiO 3 The input end of preparation furnace 4 is synthetic raw material, O 2 and Na 2 CO 3 The inlet of the solution is connected to the charger 6 and the first heat exchanger 5 at the output end;

[0045] The output end of the charger 6 is connected to the electric field-assisted fluidized reactor 7;

[0046] The electric field-assisted fluidized reactor 7 is provided with a second heat exchanger 8, and its output end is connected to a material separation device;

[0047] The material separation device is a two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com