Method for removing tar in fluidized layer furnace

A fluidized bed furnace and tar technology, applied in chemical instruments and methods, cracking, coking ovens, etc., can solve the problems of reduced cooling efficiency, lack of economy, and reduced cracking effect, and achieve high cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

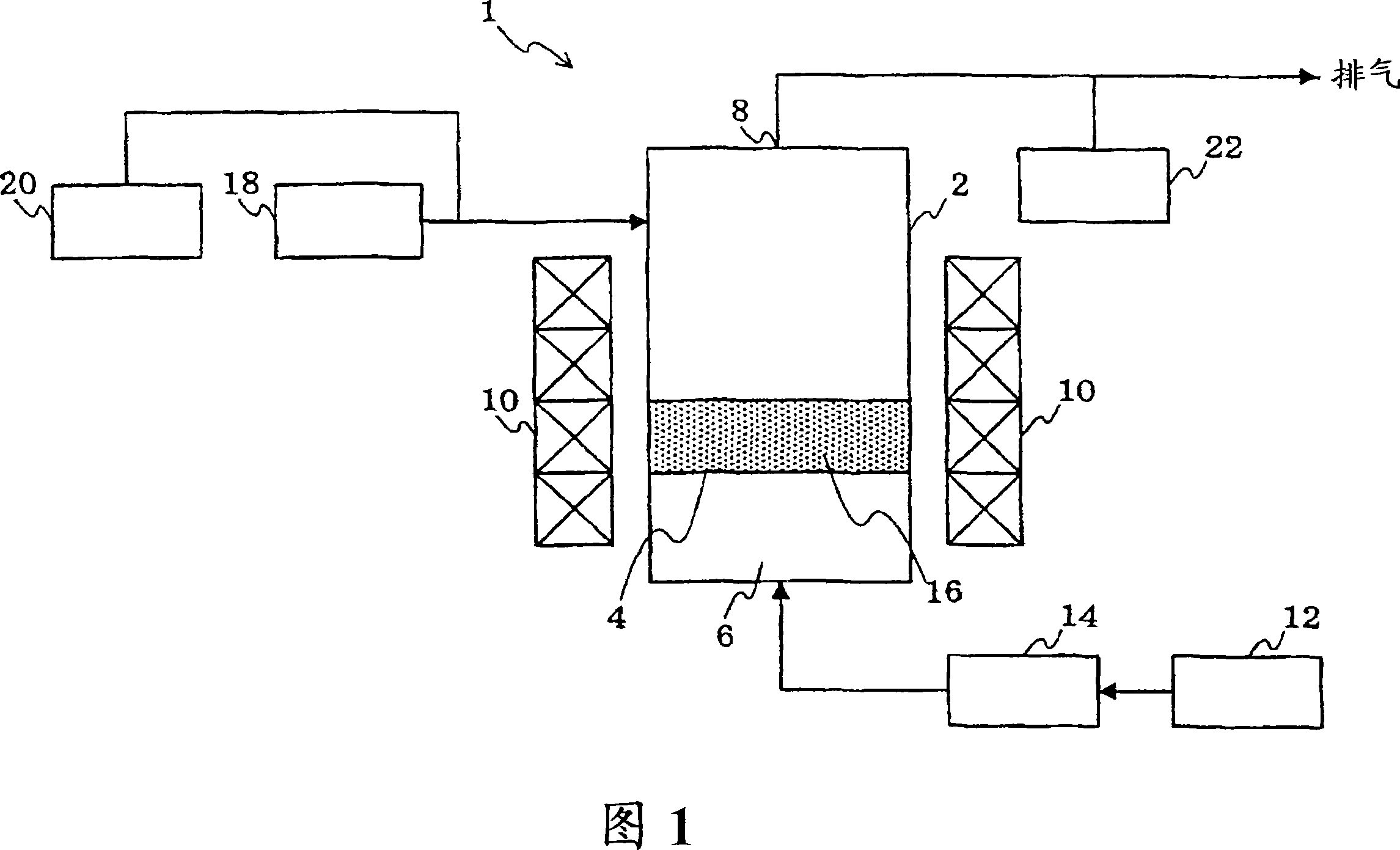

Image

Examples

Embodiment 1~9、 comparative example 1~6

[0060] The calculated tar removal rate per gasification temperature when the above pellets A to E were used. The results are shown in Table 1.

[0061] It should be noted that the tar removal rate was obtained from the following formula, where a represents the amount of tar generated when sand (JIS No. 7) having no tar removal effect is used as the pellets, and b represents the amount of tar generated when each pellet is used .

[0062] Tar removal rate=[1-(b / a)]×100(%)

[0063] particles

[0064] [Powdering rate]

Embodiment 10、11, comparative example 7、8

[0066] The pulverization rate when the above-mentioned Granules A, Granules B, Granules D, and Granules E were used as the granules was determined. The results are shown in Table 2.

[0067] It should be noted that the pulverization rate is obtained from the following formula, d represents the fluidized bed temperature is 800 ° C, the initial particle filling height is 150 mm, and only the raw material is put into the test under the conditions of the gasification time of 1 hour. The weight of residual particles, e represents the initial weight of particles filled.

[0068] Pulverization rate={1-[d / e]}×100(%)

[0069] particles

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com